Special material for high-toughness and high-water pressure resistance polypropylene randon copolymer (PPR) pipe material and preparation process thereof

A special material for pipes and random copolymerization technology, which is applied in the field of plastic modified materials, can solve the problems of heat resistance and water pressure resistance of PPR pipes, poor low temperature toughness of PPR pipes, and reduced high temperature pressure bearing capacity of pipes, etc. Smooth surface and improved low temperature impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

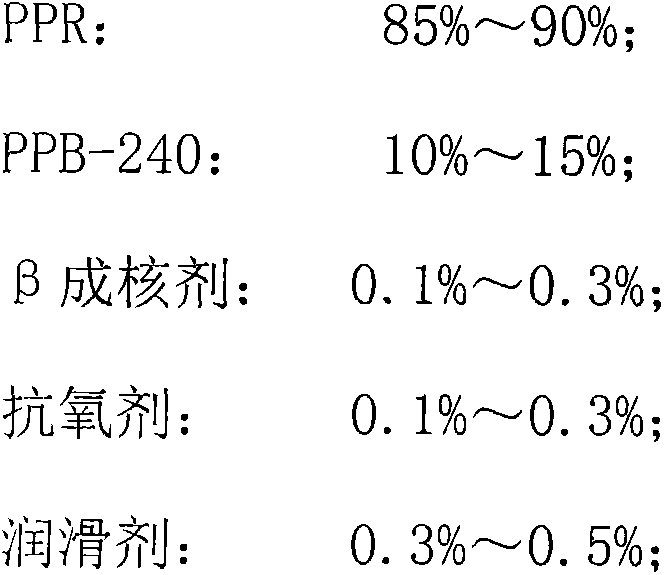

[0040] High toughness, high water pressure resistance random copolymer polypropylene (PPR) pipe material, the following raw materials are used in mass percentage:

[0041]

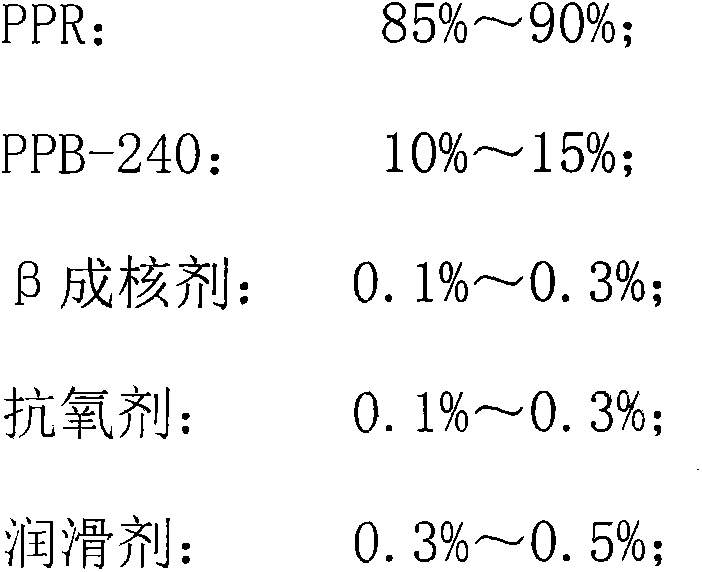

[0042] For areas where the ambient temperature is higher than 0°C all year round, the following raw materials are used in mass percentages:

[0043]

[0044]

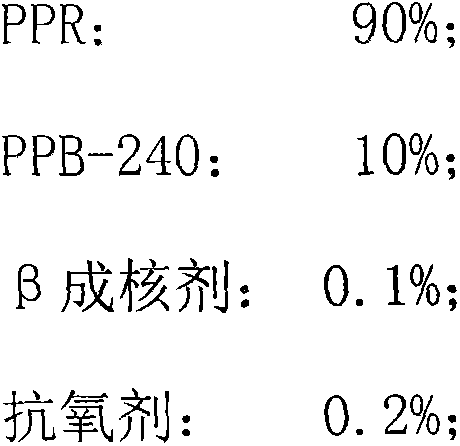

[0045] For areas where the ambient temperature is lower than 0°C most of the time, use the following raw materials in mass percentage:

[0046]

[0047] By further optimizing the above-mentioned components and their proportions, the mechanical properties of the special material for high toughness and high water pressure resistant random polypropylene (PPR) pipes of the present invention can meet the performance requirements of products in different regions, making the products optimal.

[0048] The preparation process of the present invention comprises the steps of:

[0049] Step 1. Use a low-speed mixer, weigh appropriate amounts of PP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com