Weather-resistant high impact polystyrene material and preparation method thereof

A polystyrene and polystyrene resin technology, applied in the field of modification and preparation of high-impact polystyrene materials, can solve the problem of affecting the service life of high-impact polystyrene materials and the gloss of high-impact polystyrene materials Reduced strength, toughness, hardness, rigid mechanical properties and other problems, to achieve the effect of maintaining color, strengthening mechanical properties, and avoiding yellowing of color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] And the preparation method of this weather-resistant high-impact polystyrene material consists of the following steps:

[0021] a: Weigh the raw materials according to the above ratio for later use;

[0022] b: Add anti-ultraviolet radiation agent, toughening agent, antioxidant and processing aid to high-impact polystyrene resin, and dry at 60-70°C for 1.5-3 hours;

[0023] c: dry mix the mixture obtained in step b in a high-speed mixer at room temperature for 20-30 minutes;

[0024] d: Put the mixture obtained in step c into an extruder, extrude and granulate at a temperature of 170-230°C.

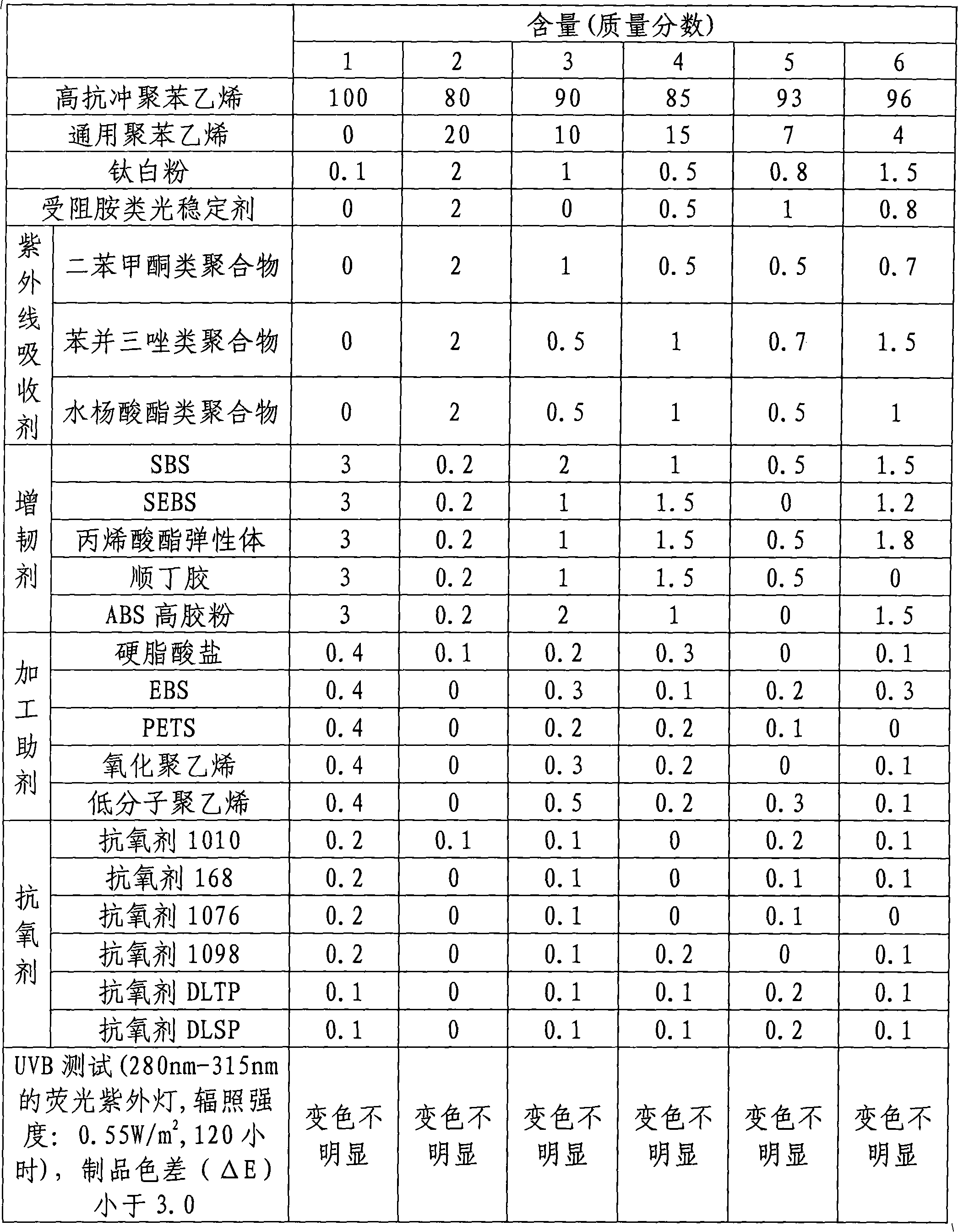

[0025] Through the modification of high-impact polystyrene resin, its weather resistance is improved, tested in UVB (280nm-315nm fluorescent ultraviolet lamp, irradiation intensity: 0.55W / m 2 , 120 hours), the high-impact polystyrene resin product of the present invention does not change color significantly, and the product color difference (ΔE) is less than 3.0.

Embodiment 1

[0028] The weather-resistant high-impact polystyrene material of the present invention includes high-impact polystyrene resin, titanium dioxide, SBS, SEBS, ABS high rubber powder, butadiene rubber, acrylate elastomer, antioxidant 1010, antioxidant 168 , Antioxidant 1076, Antioxidant 1098, Antioxidant DLTP, Antioxidant DLSP, Stearate, EBS, PETS, Low Molecular Polyethylene and Oxidized Polyethylene. The above ingredients are calculated according to the mass fraction: 100 parts of high impact polystyrene resin; 0.1 part of titanium dioxide; 3 parts of SBS; 3 parts of SEBS; 3 parts of ABS high rubber powder; 3 parts of butadiene rubber; 0.2 part of antioxidant 1010; 0.2 part of antioxidant 168; 0.2 part of antioxidant 1076; 0.2 part of antioxidant 1098; 0.1 part of antioxidant DLTP; 0.1 part of antioxidant DLSP; stearate 0.4 parts; EBS 0.4 parts; PETS 0.4 parts; low molecular weight polyethylene 0.4 parts; oxidized polyethylene 0.4 parts. The preparation method of the weather-res...

Embodiment 2

[0035] The weather-resistant high-impact polystyrene material of the present invention includes high-impact polystyrene resin, general-purpose polystyrene, titanium dioxide, hindered amine light stabilizers, benzophenone polymers, and benzotriazole polymers , Salicylate polymer, SBS, SEBS, ABS high rubber powder, butadiene rubber, acrylic elastomer, antioxidant 1010 and stearate. The above ingredients are calculated by mass fraction: 80 parts of high-impact polystyrene resin; 20 parts of general-purpose polystyrene; 2 parts of titanium dioxide; 2 parts of hindered amine light stabilizer; 2 parts of benzophenone polymer; 2 parts of benzotriazole polymer; 2 parts of salicylate polymer; 0.2 part of SBS; 0.2 part of SEBS; 0.2 part of ABS high rubber powder; 0.2 part of butadiene rubber; 0.2 part of acrylate elastomer; Agent 1010 0.1 part; stearate 0.1 part. The preparation method of the weather-resistant high-impact polystyrene material consists of the following steps:

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com