Co-extruded one-time formed backplate with three-layer structure for solar cell module

一种太阳能电池、三层结构的技术,应用在电气元件、电路、电子器材等方向,能够解决导热效率差、耐热性差、耐UV性能低等问题,达到提高尺寸稳定性、提高机械强度、提高耐摩擦的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

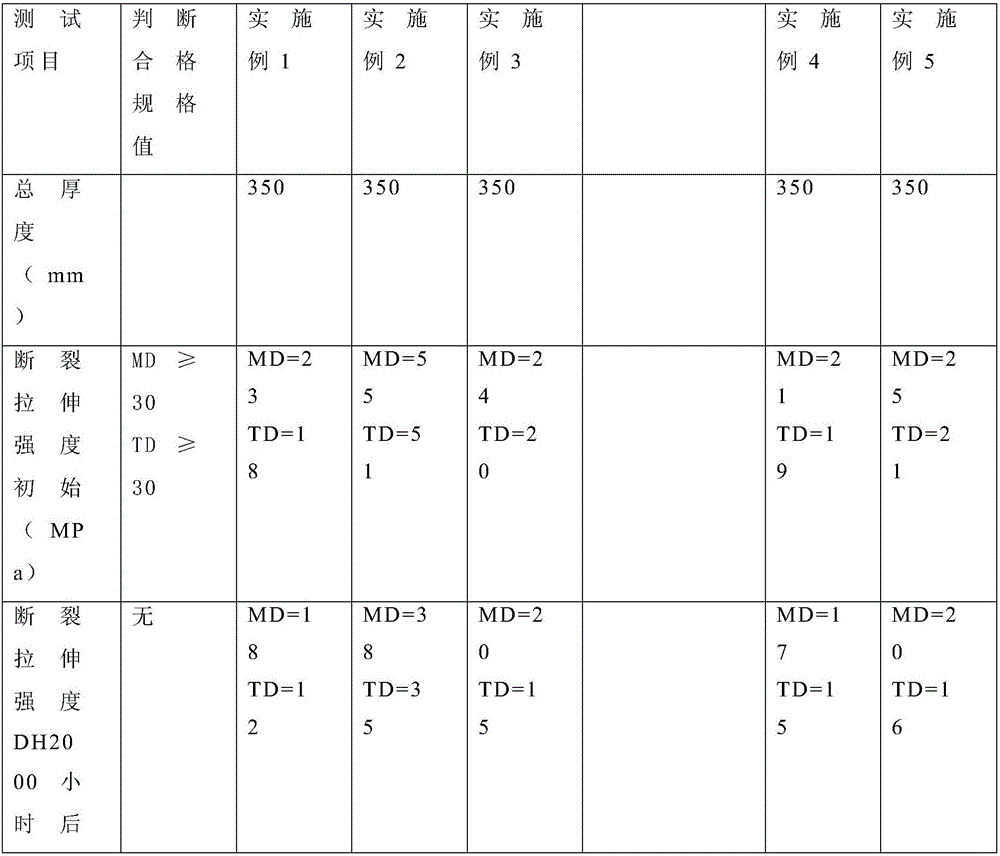

Embodiment 1

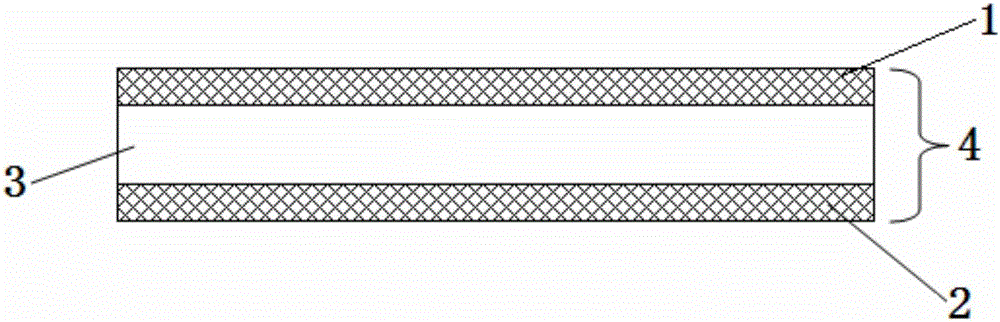

[0035] like figure 1 Shown is a schematic structural diagram of a solar cell module backsheet 4 with a three-layer structure, including an intermediate layer 3 located in the middle and an outer layer 1 and an inner layer 2 located on both sides of the intermediate layer, which are produced by three-layer co-extrusion one-time continuous production; That is, through high temperature co-extrusion (Co-extrusion) film processing, a polymer mixture film is formed.

[0036] Among them: the raw material of outer layer 1 is PA12 content 88% + TiO 2 The content is 12% (all are mass content, the same below), and the thickness is 0.050mm;

[0037] The chemical formula is [NH-(CH 2 ) 11 -CO] n ; The raw material of inner layer 2 is EVA19%+LLDPE69%+TiO 2 The content is 12%, and the thickness is 0.050mm;

[0038] Chemical formula of inner layer 2: (C 2 H 4 ) x (C 4 H 6 O 2 )+(C 2 H 4 ) n ;

[0039] Among them, EVA chemical formula: (C 2 H 4 ) x (C 4 H 6 O 2 ) y , LLD...

Embodiment 2

[0044] like figure 1 The schematic structural diagram of the solar cell module back sheet 4 of the three-layer structure shown, including the middle layer 3 located in the middle and the outer layer 1 and the inner layer 2 located on both sides of the middle layer,

[0045] Among them, the raw material of outer layer 1 is PA12 content of 88% + TiO 2 The content is 12%, and the thickness is 0.050mm;

[0046] Chemical formula of PA12: [NH-(CH 2 )11 -CO] n ;

[0047] The raw material of inner layer 2 is PA12 content 88%+TiO 2 The content is 12%, and the thickness is 0.050mm;

[0048] The raw material of the intermediate layer 3 has a PA12 content of 98% + TiO 2 The content is 2%, and the thickness is 0.250mm.

[0049] After high temperature co-extrusion (Co-extrusion) film processing, a polymer mixture film is formed.

Embodiment 3

[0051] like figure 1 Shown is a schematic structural diagram of a solar cell module back sheet 4 with a three-layer structure, including an intermediate layer 3 located in the middle and an outer layer 1 and an inner layer 2 located on both sides of the intermediate layer. production.

[0052] Among them, the raw material of outer layer 1 is HDPE-g-GMA content of 65% + PA12 content of 23% + TiO 2 The content is 12%, and the thickness is 0.050mm; among them: HDPE Chemical formula: [-CH 2 -CH 2 -] n ;

[0053] The inner layer 2 selects HDPE-g-GMA content of 65% + PA12 content of 23% + TiO2 content of 12%, with a thickness of 0.050mm;

[0054] Intermediate layer 3 is homopolymer PP content 58% + PP-g-GMA content 20% + PA12 content 20% + TiO 2 2%, the thickness is 0.250mm. After high-temperature co-extrusion (Co-extrusion) film processing, a part of the cross-linking reaction occurs to form a mixed polymer alloy film.

[0055] In the actual manufacturing process, the thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectivity | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| glossiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com