Orientation electro-spinning nanometer fiber spinning method and device thereof

A technology for electrospinning nanofibers and nanofibers, which is applied in spinning machines, fiber processing, and continuously wound spinning machines, etc., can solve the problems of multi-yarn mechanical properties and evenness, low nanofiber orientation, and fiber waste. and other problems, to achieve the effect of convenient operation, inhibition of spinning instability, and good yarn continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

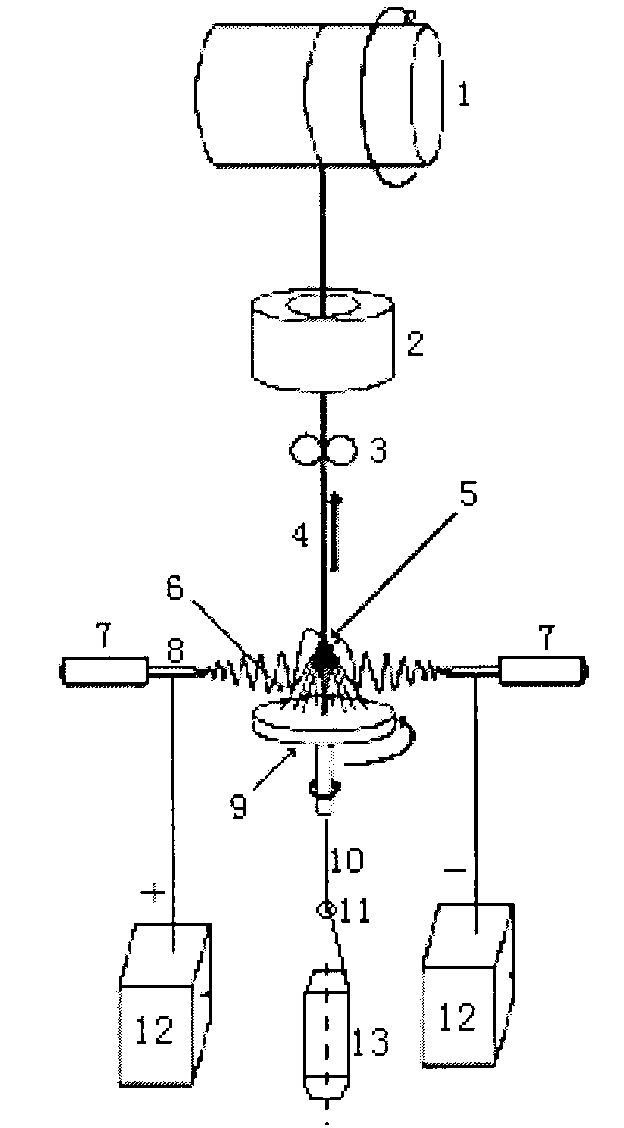

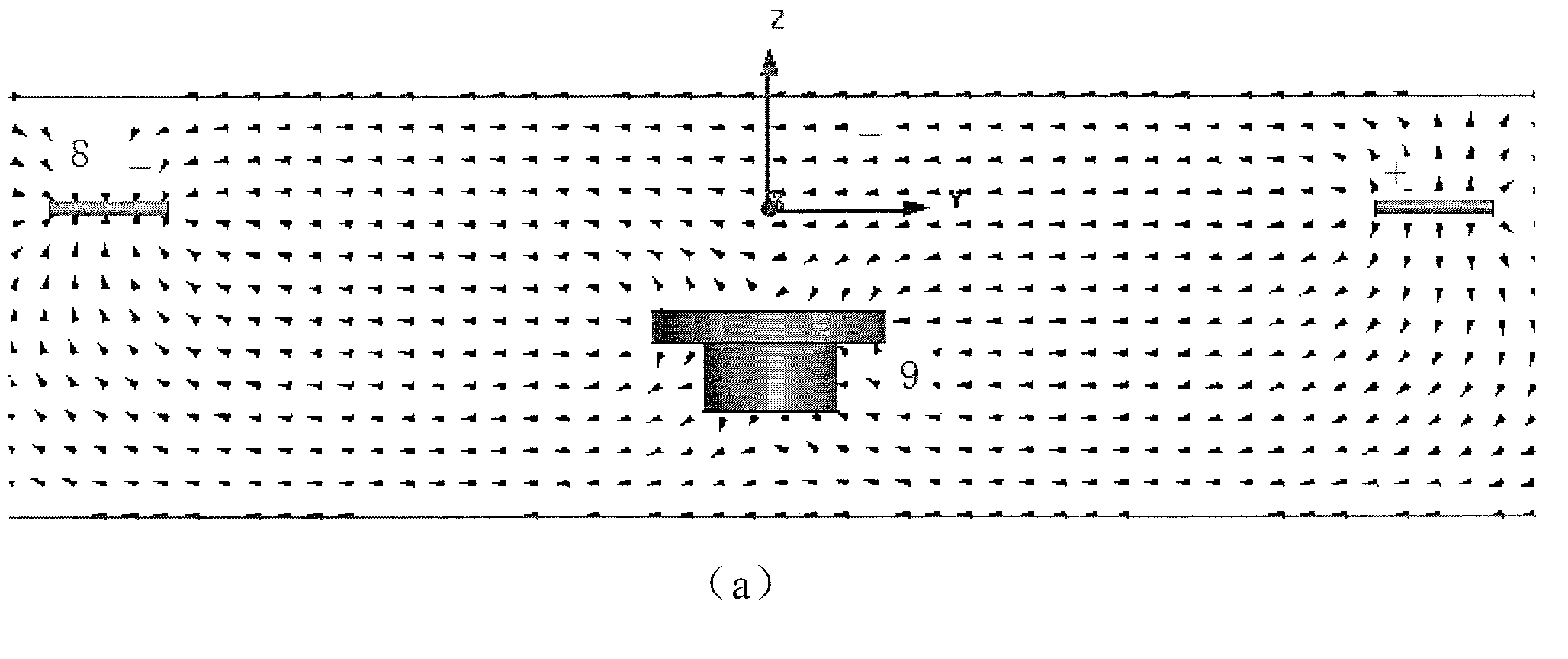

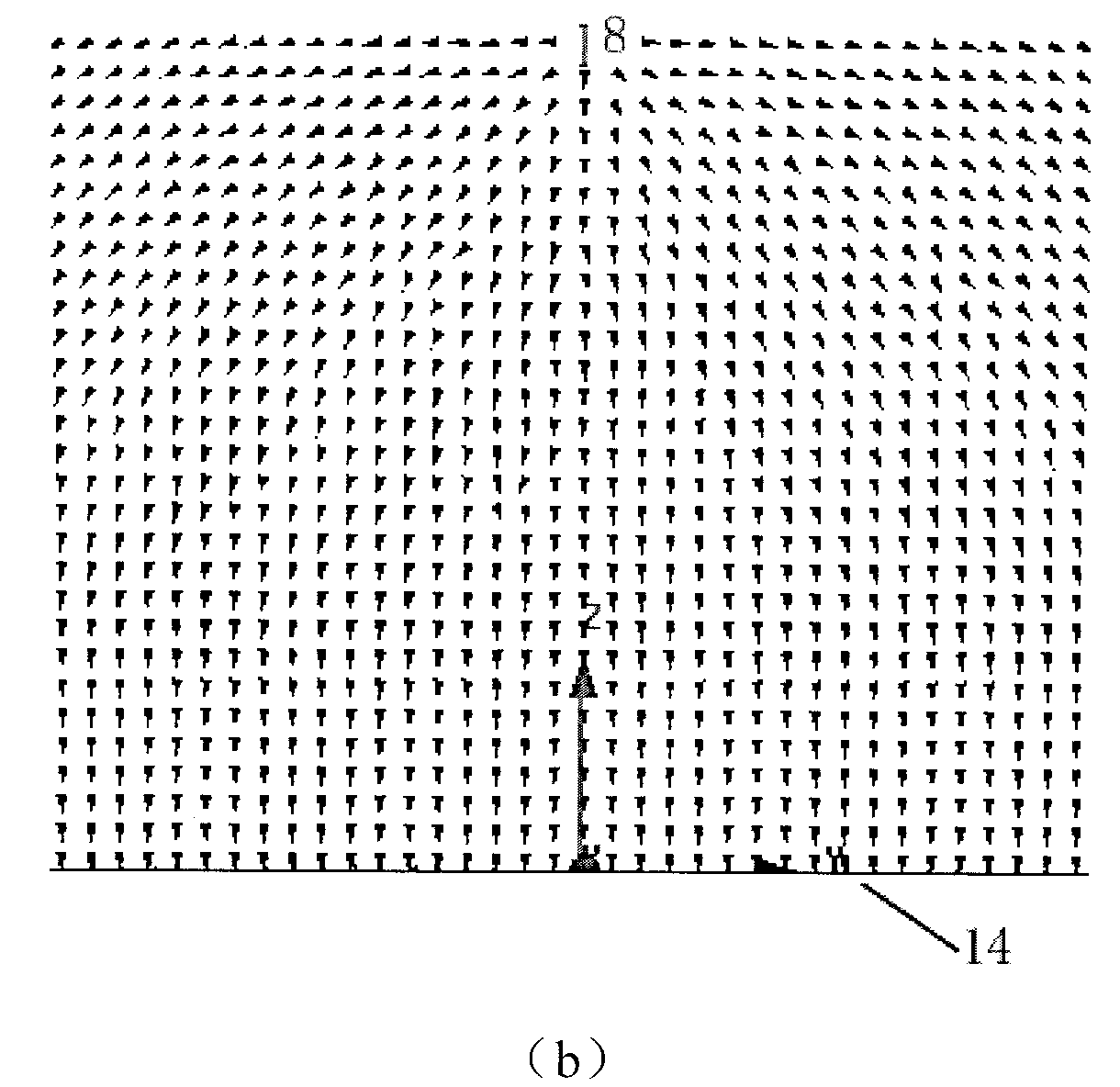

[0022] The polyvinyl alcohol (PVA) aqueous solution that adopts mass percent concentration to be 10% is spinning solution, extrudes from metal shower nozzle 8 by raw material delivery pump 7 with the speed of 1ml / h, on two metal shower nozzles 8 of opposite configuration respectively by The high-voltage generator 12 applies 8kV positive and negative high-voltage electricity, and the metal nozzles are 30mm long, 0.5mm in diameter, and 150mm apart. Under the action of a high-voltage electrostatic field, the spinning solution is drawn and thinned through stable and unstable stages to form nanofibers 6, and is collected toward the side of the metal twister 9 close to the nozzle 8. The core filament 10 is a 100dtex polylactic acid (PLA) filament, which is unwound from the filament bobbin 13, passes through the center of the metal twister 9 through the yarn guide hook 11. Metal twister 9 rotating speed 20rpm, filament 10 line speed 5m / h. Two strands of nanofibers 6 with positive an...

Embodiment 2

[0024] Polyester (PET) chips are used as the spinning raw material, melted at a temperature of 340°C, and the melt is extruded from the metal nozzle 8 through the raw material delivery pump 7 at a speed of 5ml / h, and is respectively placed on the eight metal nozzles 8 that are oppositely arranged. 18kV positive and negative high-voltage electricity is applied by the high-voltage generator 12. The length of the metal nozzle is 35mm, the diameter is 0.7mm, and the distance is 180mm. Under the action of a high-voltage electrostatic field, the polymer melt is drawn and thinned through stable and unstable stages to form nanofibers 6, which are collected toward the side of the metal twister 9 close to the nozzle 8. The core yarn 10 is a 92dtex polyester (PET) filament, which is unwound from the filament bobbin 13, passes through the center of the metal twister 9 through the yarn guide hook 11. Metal twister 9 rotating speed 80rpm, core wire 10 line speed 20m / h. Two strands of nanof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com