Preparation method of high heat conductivity carbon fiber

A high thermal conductivity and fiber technology, applied in the fields of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of difficult preparation of bulk samples and batch production, harsh preparation conditions, application restrictions, etc., to achieve continuous production and easy Industrial continuous production, the effect of realizing industrial continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

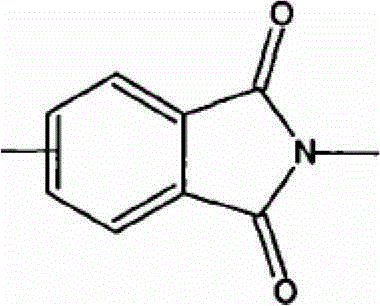

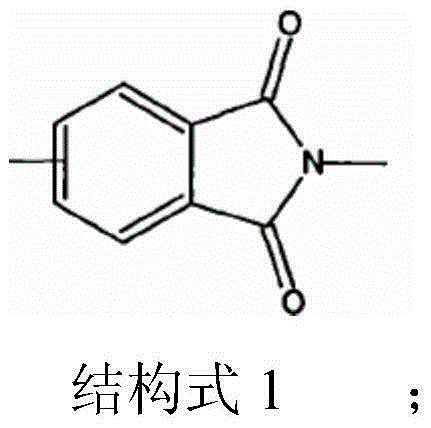

[0038] Use polyimide fibers composed of polymer chains whose imide groups are structural formula 1, the elongation at break is greater than 4% (such as 7-8%), and the strength is greater than 100Mpa (such as 150-200Mpa), and at the same time The axial preferred orientation degree of the polymer chain is greater than 60% (such as 70-80%). The two ends of these fibers are fixed (that is, the draft is 0), and they are placed in a heat treatment furnace for gas phase thermal stabilization. , from room temperature to 350°C at a rate of 5°C / min, then from 350°C to 500°C at a rate of 1°C / min, and stay for 30 minutes; Low-temperature carbonization treatment under high-purity nitrogen atmosphere, pressure 0.1005MPa, rising to 500°C at a rate of 10°C / min, then rising to 800°C at a rate of 2°C / min, and holding for 30 minutes. After cooling, both ends of the fiber were fixed, placed in a graphitization furnace, and graphitized under a high-purity argon atmosphere (2600°C, constant tempera...

Embodiment 2

[0040] Get the polyimide fiber that meets the requirements in Example 1, and the other conditions are the same as in Example 1, except that the graphitization temperature is increased to 3200 ° C, and the thermal conductivity of the resulting material reaches 391W m -1 ·K -1 , with a density of 1.96g / cm 3 .

Embodiment 3

[0042] Get the polyimide fiber that meets the requirements in Example 1, other conditions are the same as in Example 1, but apply 10% stretching in the stabilization process, and the graphitization temperature increases to 3000 ° C simultaneously, the thermal conductivity of the gained material 405W·m -1 ·K -1 , with a density of 2.05g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com