Crimped yarn, method for manufacture thereof, and fiber structure

A manufacturing method and elastic yarn technology, applied in the field of crimped elastic yarn, can solve the problems of appearance change, easy change of product appearance, insufficient peeling resistance, etc., and achieve the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

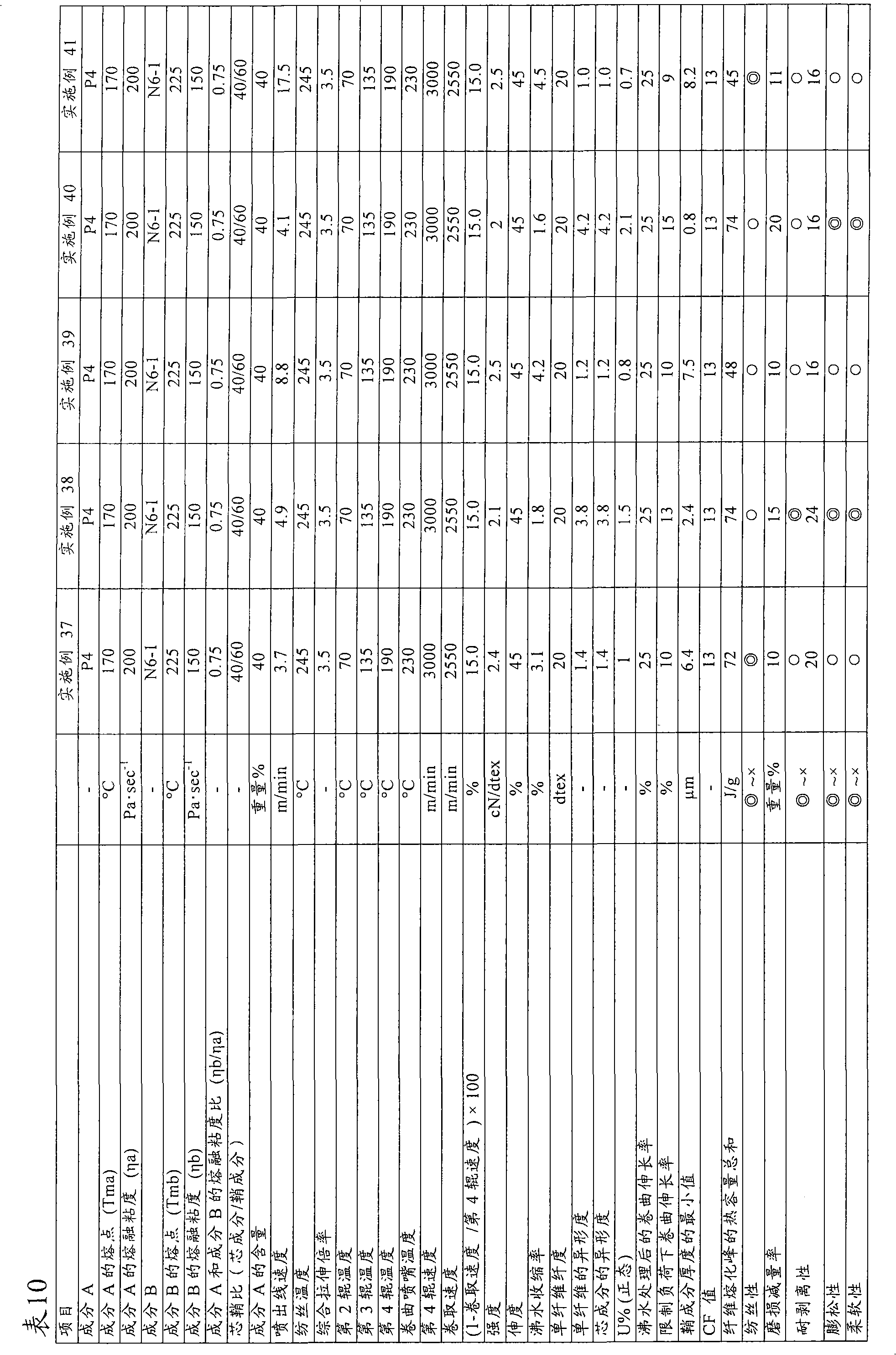

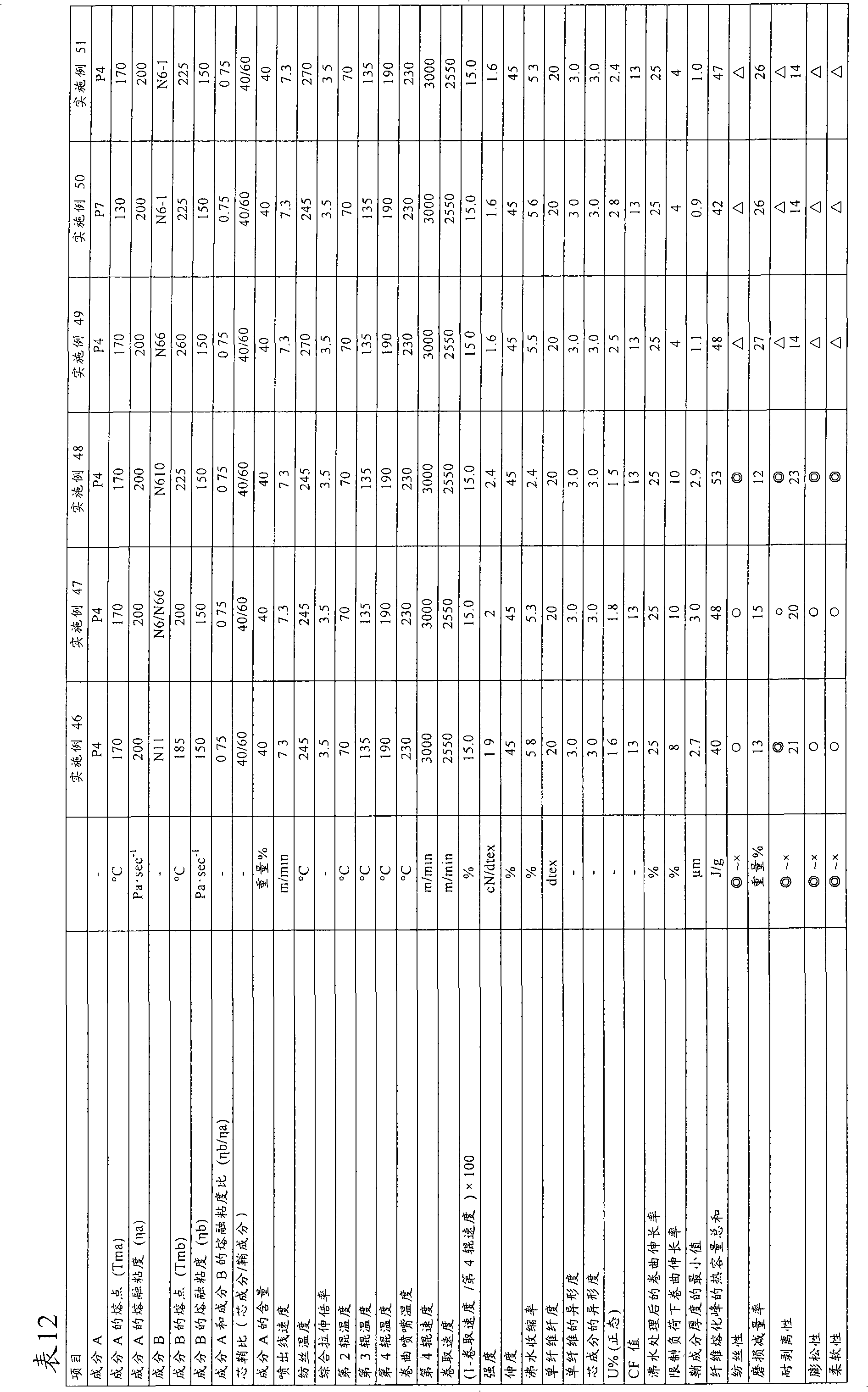

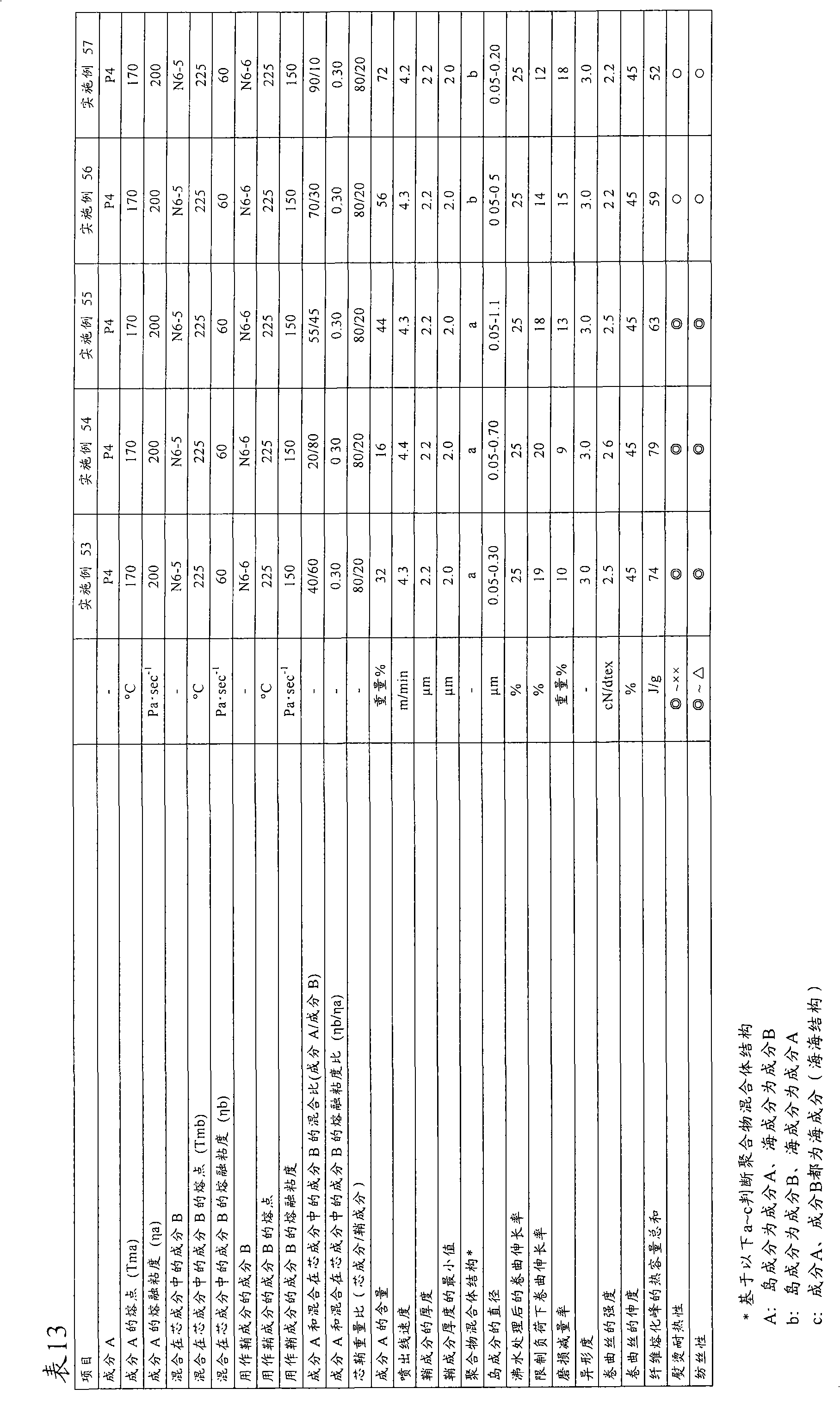

Examples

Embodiment Construction

[0097] The aliphatic polyester resin (A) (hereinafter also referred to as "component A") in the present invention means a polymer in which aliphatic alkyl chains are linked by ester bonds. The aliphatic polyester resin (A) used in the present invention preferably has crystallinity, and more preferably has a melting point of 150 to 230°C. Examples of the aliphatic polyester resin (A) used in the present invention include polylactic acid, polyhydroxybutyrate, polybutylene succinate, polyglycolic acid, and polycaprolactone. Among the above-mentioned aliphatic polyesters, polylactic acid is most preferable because it has a high melting point and excellent thermal stability.

[0098] The above-mentioned polylactic acid is -(O-CHCH 3 -CO) n - The polymer as a repeating unit is obtained by polymerizing an oligomer of lactic acid such as lactic acid or lactide. Lactic acid has two optical isomers of D-lactic acid and L-lactic acid, so the above-mentioned polymers have poly(D-lactic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com