Light jute fiber reinforced polypropylene alloy composite plate and machining process thereof

A processing technology, hemp fiber technology, applied in the field of processing technology of automotive decorative materials, can solve the problems of high product density, non-renewable utilization, unsatisfactory product rigidity, etc., and achieve the effect of improving performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of " lightweight hemp fiber reinforced polypropylene alloy composite board " production process of the present invention is specifically described as follows:

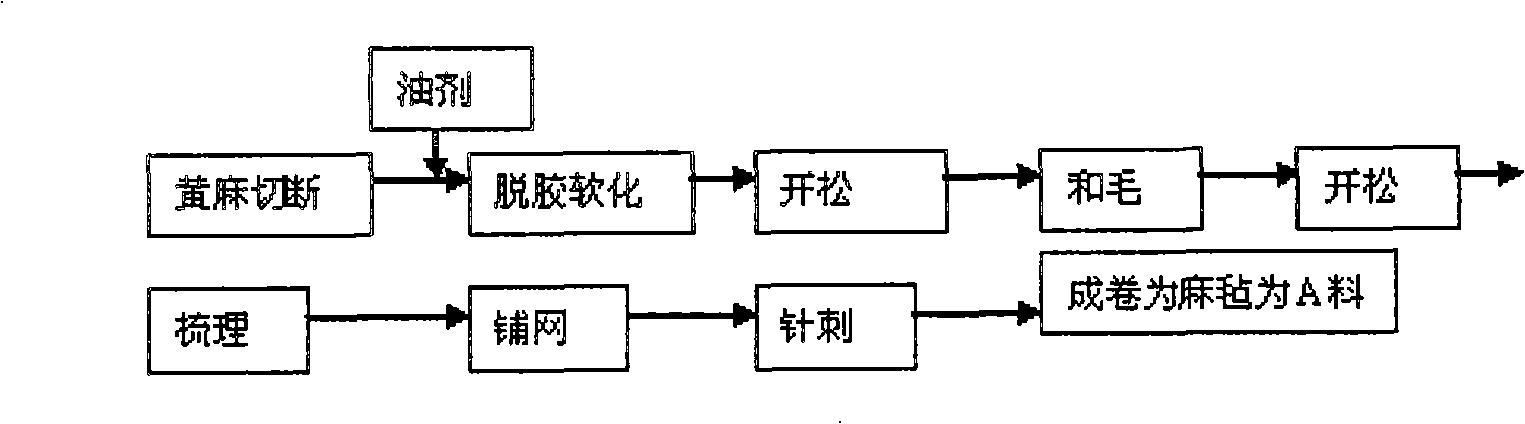

[0037] 1. The preparation process of material A hemp felt (the process flow is as follows: figure 1 shown)

[0038] 1. Cutting: Cut off the jute with a guillotine, and the length of the cut hemp is 10CM;

[0039] ②, Degumming and softening: Lay the cut jute on the ground with a thickness of 10-15CM, the surface should be smooth, add oil (equivalent to 2% of the weight of the hemp), and keep turning the jute when oiling to ensure uniform degumming , the hemp after degumming is stored for 24 hours before it can be used in the next process;

[0040] ③. Opening: Feed the degummed hemp into the opening machine to open the hemp into fibers;

[0041] ④, Wool: Feed the hemp fiber and a small amount of polyester (about 10%) into the wool machine, mix evenly, and send it to the next process;

[0042] ⑤. Carding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com