Functional co-extrusion composite alloy material floor-heating floor and manufacturing method thereof

A technology of co-extrusion composite and alloy materials, which is applied in the field of building decoration materials, can solve the problems of complicated preparation process, lack of fireproof and flame-retardant properties of geothermal floor, easy to catch fire and other problems, and achieve simple preparation process, good floor heating conductivity, heat dissipation The effect of high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

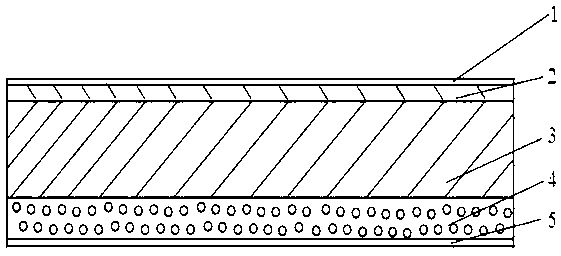

[0046] A functional co-extruded composite alloy floor heating floor, including a vacuum coating layer 5, a conductive heating plastic layer 4, a PVC-based polymer alloy composite material layer 3, a co-extruded composite decorative layer 2 and a UV surface layered sequentially from bottom to top processing layer 1;

[0047] Among them, the coating evaporation material selected for the vacuum coating layer is aluminum wire.

[0048] Wherein, the conductive and heating plastic layer is a nylon-based heat-conducting material.

[0049] Wherein, the PVC-based polymer alloy composite material layer 3 includes the following components by weight:

[0050] PVC resin 100 parts

[0051] ABS resin (747S) 30 parts

[0052] Active fine calcium carbonate (1250 mesh) 80 parts

[0053] Calcium zinc composite stabilizer 5.0 parts

[0054] Flame retardant 7 parts

[0055] Processing aid ACR401 2 parts

[0056] 8 copies of CPE

[0057] Semi-refined paraffin wax 0...

Embodiment 2

[0069] A functional co-extruded composite alloy floor heating floor, comprising a vacuum coating layer 5, a conductive heating plastic layer 4, a PVC-based polymer alloy composite material layer 3, a co-extruded co-extruded composite decorative layer 2 and UV surface treatment layer 1;

[0070] Among them, the coating evaporation material selected for the vacuum coating layer is aluminum wire.

[0071] Wherein, the conductive and heating plastic layer is a nylon-based heat-conducting material.

[0072] Wherein, the PVC-based polymer alloy composite material layer 3 includes the following components by weight:

[0073] PVC resin 100 parts

[0074] Glutarimide copolymer 20 parts

[0075] Active fine calcium carbonate (1250 mesh) 100 parts

[0076] Calcium zinc composite stabilizer 5.0 parts

[0077] Flame retardant 7 parts

[0078] Processing aid ACR401 2 parts

[0079] 12 copies of MBS

[0080] Semi-refined paraffin wax 0.6 parts

[0081] 0.5 ...

Embodiment 3

[0092] A functional co-extruded composite alloy floor heating floor, comprising a vacuum coating layer 5, a conductive heating plastic layer 4, a PVC-based polymer alloy composite material layer 3, a co-extruded co-extruded composite decorative layer 2 and UV surface treatment layer 1;

[0093] Among them, the coating evaporation material selected for the vacuum coating layer is aluminum wire.

[0094] Wherein, the conductive and heating plastic layer is nylon 6-based thermally conductive material.

[0095] Wherein, the PVC-based polymer alloy composite material layer 1 includes the following components by weight:

[0096] PVC resin 100 parts

[0097] Heat-resistant α-methylstyrene-acrylonitrile copolymer 15 parts

[0098] Active fine calcium carbonate (1250 mesh) 100 parts

[0099] Calcium zinc composite stabilizer 5.0 parts

[0100] Flame retardant 7 parts

[0101] Processing aid ACR401 2 parts

[0102] 9 copies of MBS

[0103] Semi-refined par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com