Flexible hanging system of all-hydraulic forging manipulator

A forging manipulator and full hydraulic technology, applied in forging/pressing/hammering machinery, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problem of large impact force, high forging frequency of electro-hydraulic hammer, large vibration, etc. problem, to achieve the effect of strong buffer function and good follow-up performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further explained below in conjunction with accompanying drawing:

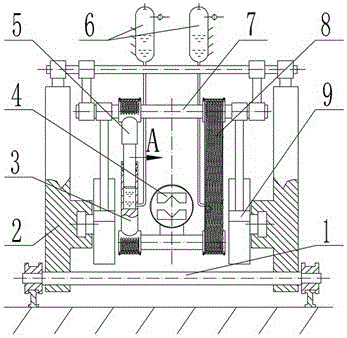

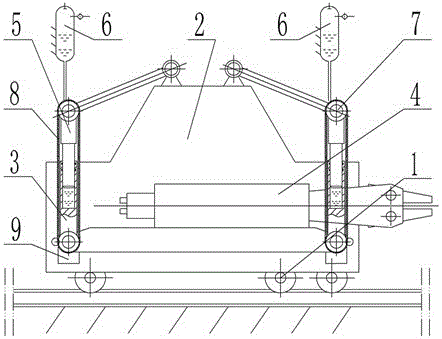

[0016] as attached figure 1 , 2 As shown, the cart 1 is provided with a frame 2, and the frame 2 is divided into two sides; four hydraulic cylinders 9 are symmetrically arranged on the two sides along the central plane of the frame 2, and are connected with the two sides. The four points above form a fixed hinge; the two hinge shafts 7 respectively swing in parallel around the two axes on the frame 2, and the two ends respectively form the movable hinges of four rotary pairs with the single output rods in the four hydraulic cylinders 9; The upper ends of the four suspenders also form the fixed hinges of the four rotary pairs with the two ends of the two hinge shafts 7 respectively, and the four points on the lower end and the pincer bar 4 constitute the movable hinges of the four rotary pairs; The support rod and the steel wire rope 8 for bearing and suspension are compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com