A kind of polishing liquid and its preparation method and the processing method of silicon carbide crystal

A processing method and technology of silicon carbide, which is applied in the fields of polishing compositions containing abrasives, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of low polishing efficiency, reduce the time of fine polishing, increase hardness, and avoid surface scratch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

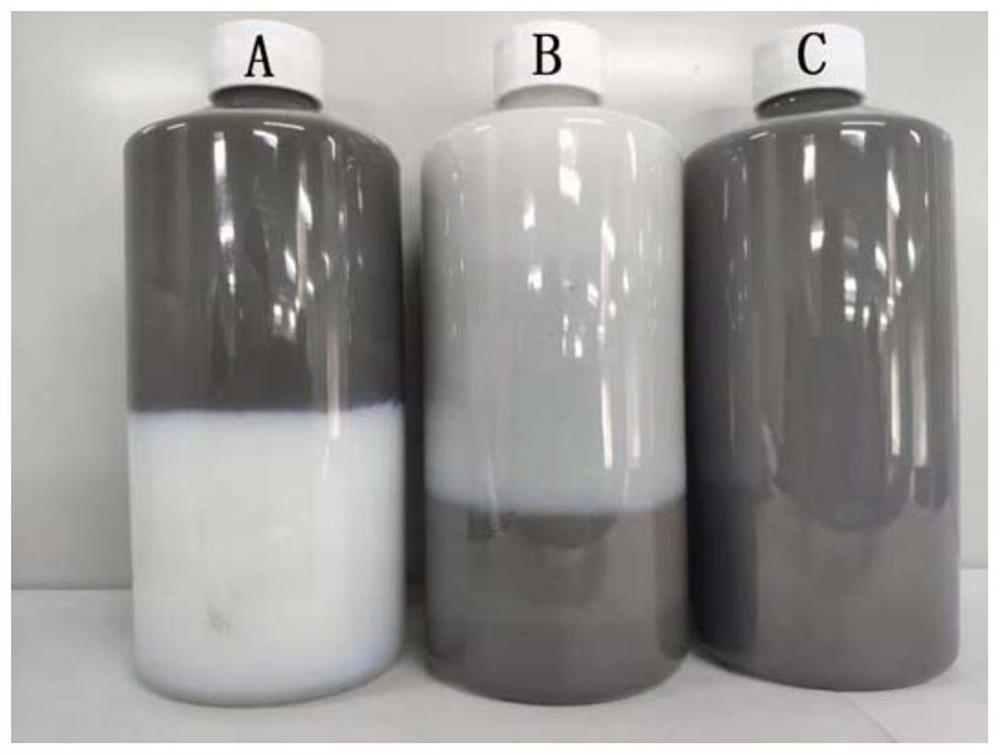

Embodiment 1

[0076] The preparation method of the polishing liquid of the present embodiment comprises the steps:

[0077] (1) Take 50g of polycrystalline diamond powder with D50=0.125μm, 100g of inorganic bentonite, 35g of BYK-345, 50g of AFE-3168, and 10g of borax, add 5kg of pure water, and stir ultrasonically for 0.5h;

[0078] (2) Add 5 kg of silica sol with a solid content of 40% and a particle size of 70 nm to the material in step (1), and then ultrasonically stir for 0.5 h to obtain a polishing solution.

Embodiment 2

[0080] The preparation method of the polishing liquid of the present embodiment comprises the steps:

[0081] (1) Take 25g of polycrystalline diamond powder with D50=0.5μm, 45g of Silok7370W, 60g of BYK-W 9010, 20g of BYK-024, 10g of BYK-094 and 50g of methyl monoethanolamine, add 5kg of pure water, and ultrasonically stir for 0.5h ;

[0082] (2) Add 5 kg of silica sol with a solid content of 45% and a particle size of 80 nm to the material in step (1), and then ultrasonically stir for 0.5 h to obtain a polishing solution.

Embodiment 3

[0084] The preparation method of the polishing liquid of the present embodiment comprises the steps:

[0085] (1) Take 100g D50=0.25μm polycrystalline diamond powder, 30g BYK-431, 30g TRITON CF-10, 45g FOAMEX 825, and 20g of potassium hydroxide, add 5kg of pure water, after ultrasonic stirring for 0.5h;

[0086] (2) Add 5 kg of silica sol with a solid content of 50% and a particle size of 60 nm to the material in step (1), and then ultrasonically stir for 0.5 h to obtain a polishing solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com