Hydraulic system hose withhold machine

A technology of hydraulic system and crimping machine, which is applied in the field of hydraulic system hose crimping machine, can solve the problems that it is difficult to ensure the radial force of the extrusion block, reduce the accuracy and efficiency of crimping, extrusion deformation and extrusion sealing, etc., and achieve improvement Withholding accuracy and efficiency, good shock absorption effect, and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following is attached Figure 1-9 The application is described in further detail.

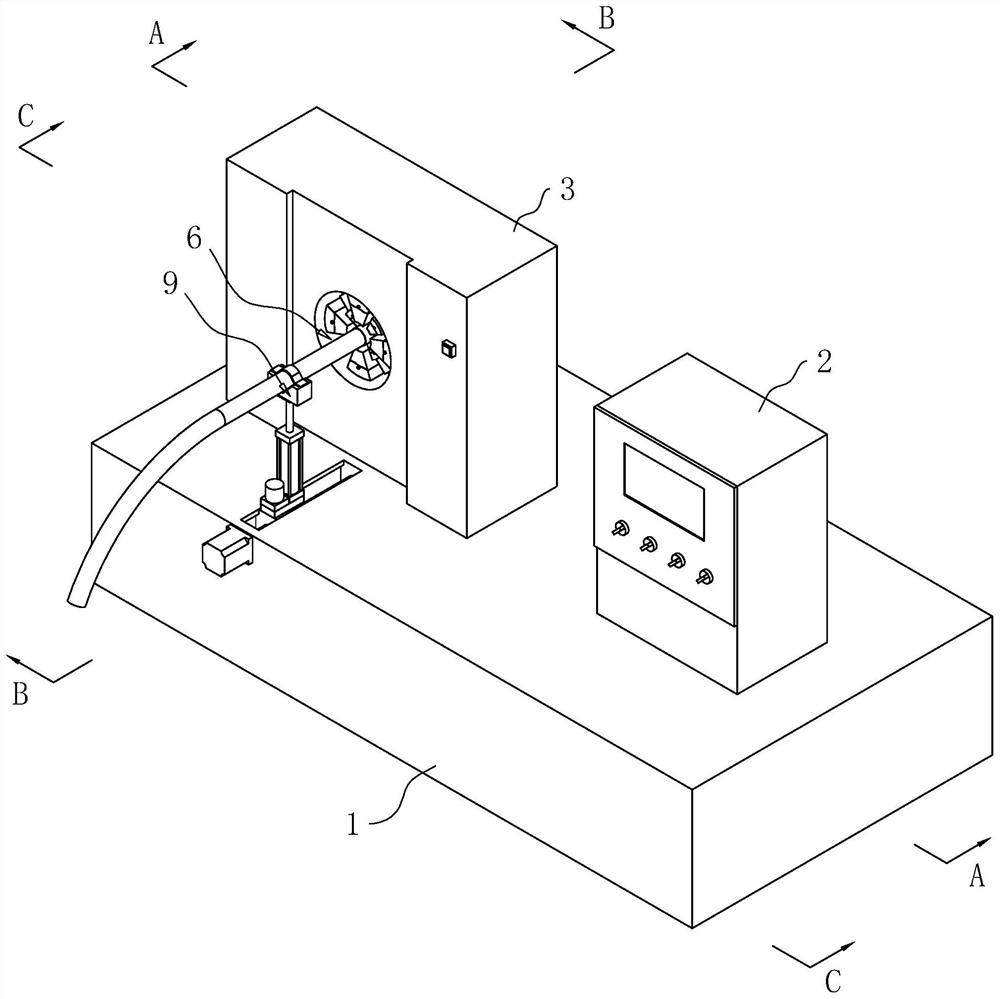

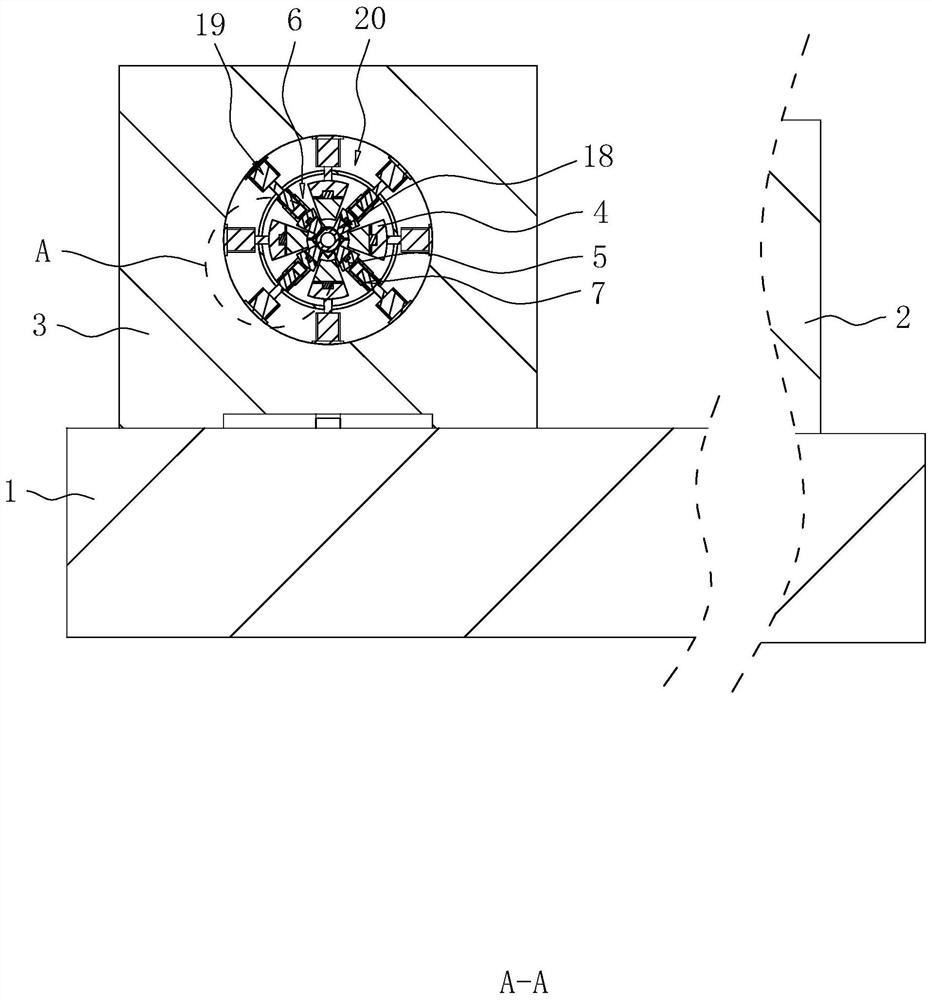

[0047] The embodiment of the present application discloses a hydraulic system hose crimping machine. refer to figure 1 The crimping machine includes a workbench 1, a control box 2 installed on the workbench 1, and a clamping seat 3 located on one side of the control box 2. The middle part of the side wall of the clamping seat 3 is provided with a clamping groove 6. In this embodiment, The longitudinal section of the clamping groove 6 is circular, and the clamping groove 6 is a through groove, and the clamping groove 6 runs through the two side walls of the clamping pipe seat 3 respectively, so that the hose provided with the connector can be inserted into the clamping groove 6 .

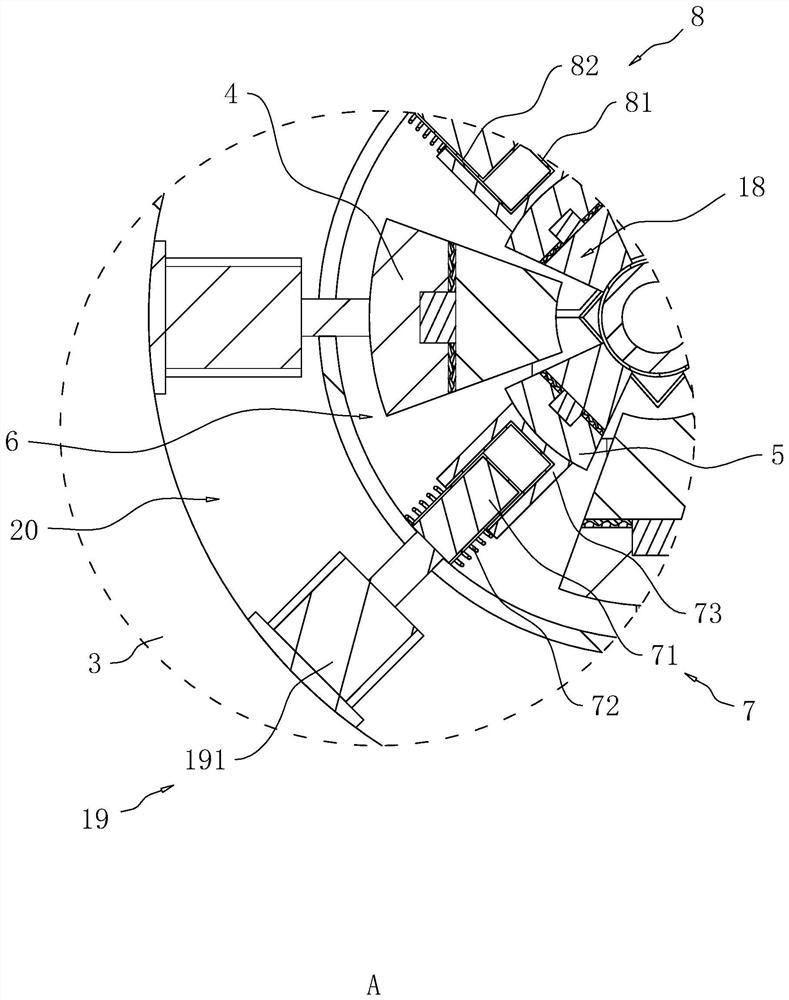

[0048] refer to figure 1 and figure 2 , a number of first arc blocks 4 are arranged in the clamping groove 6 and along its own circumferential array, a second arc block 5 is arranged between two adjace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com