Crushing machine

A pulverizer and vibrator technology, applied in grain processing, etc., can solve problems such as leakage, electric shock, inability to observe and check, and inability to ensure the safe use of electrical equipment, so as to achieve uniform feeding, prevent machine doors from loosening, and solve damage phenomena. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

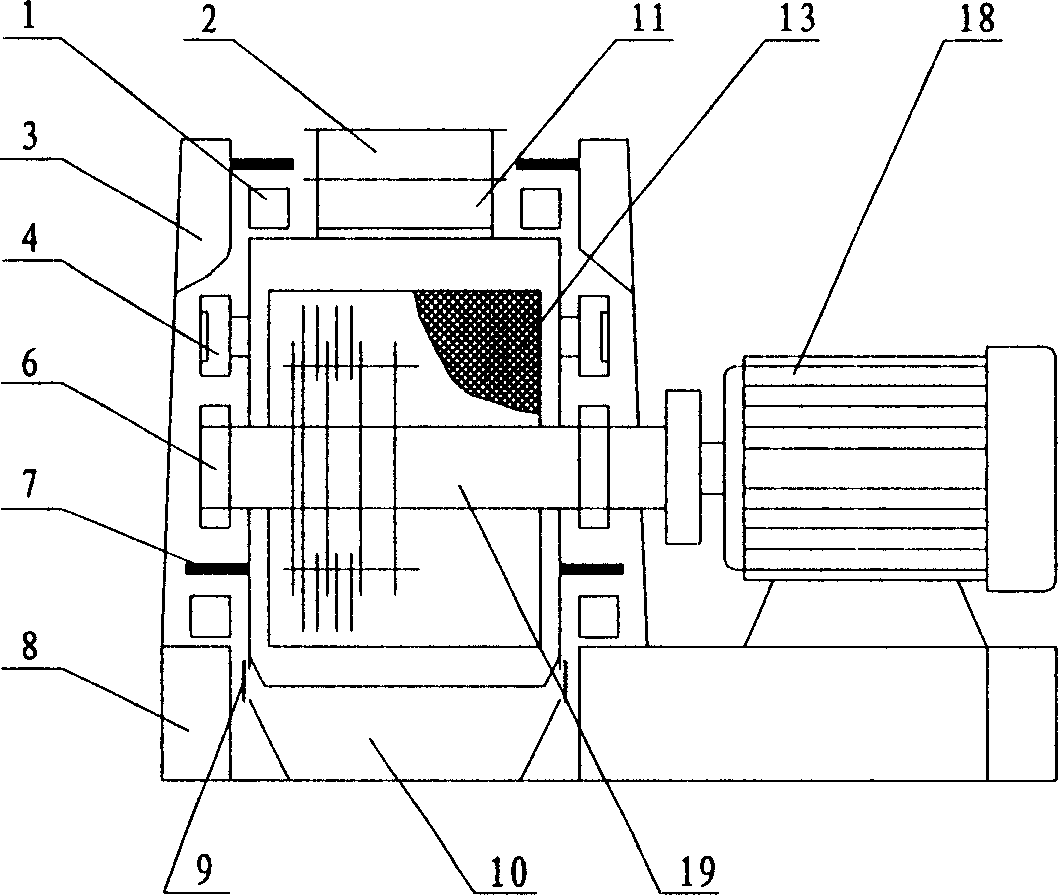

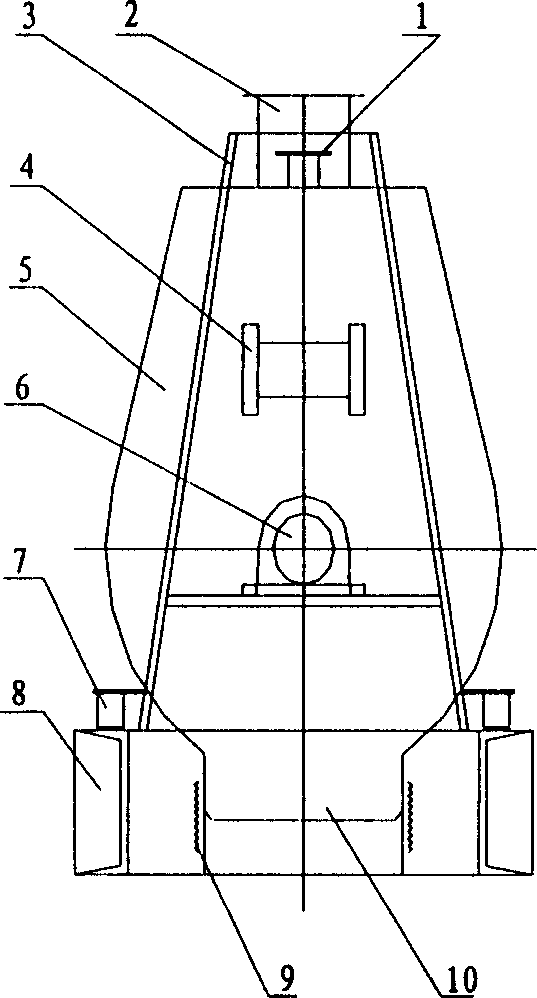

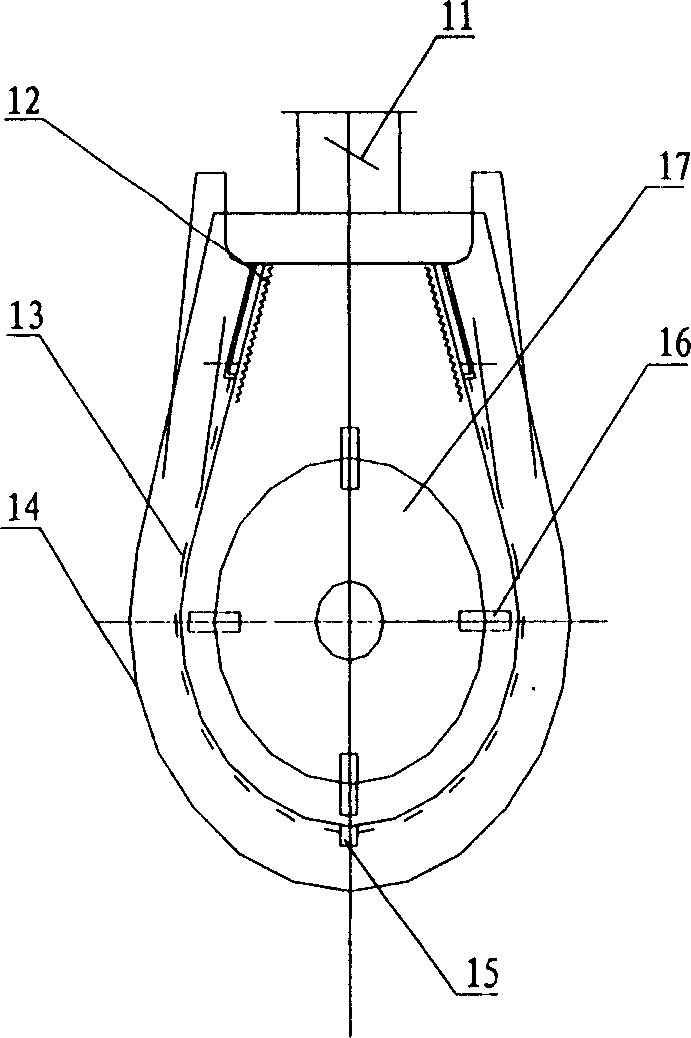

[0013] like figure 1 , 2 , shown in 3: the pulverizer of the present invention comprises: main shaft 19, rotor 17, hammer blade 16, drive main shaft 19 by motor 18, make hammer blade 16 rotate at high speed and generate centrifugal force, material enters through channel direction plate 11, feed port 2 Outside the crushing chamber, through hammer 16 impact and sieve screening, qualified products are discharged, and unqualified materials are left in the machine to continue crushing through the discharge port 10.

[0014] Tooth plate 12, sieve piece 13, machine door 14, sieve piece bar 15, feed port 2, discharge port 10, and seal 9 are combined to form an assembly 5, and the sieve piece 13 and machine door 14 pass through the chain circumference Fasten the combination. combine Figure 4 As shown: the combination 5 is rotatably connected with an upper joint plate joint buckle 20, and the other end of the upper joint plate joint joint buckle is provided with a connecting piece 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com