Patents

Literature

42results about How to "Uniform amplitude" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

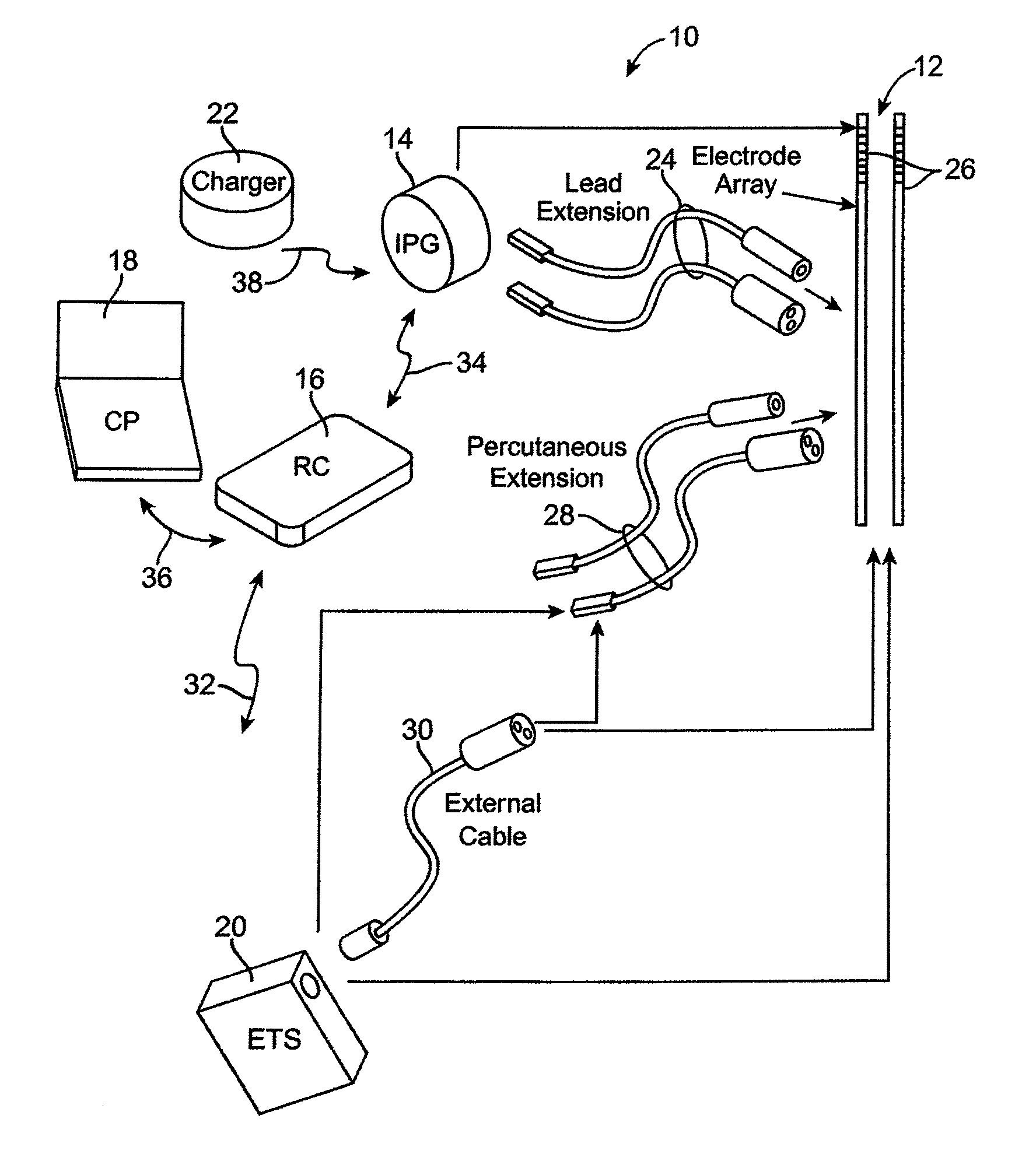

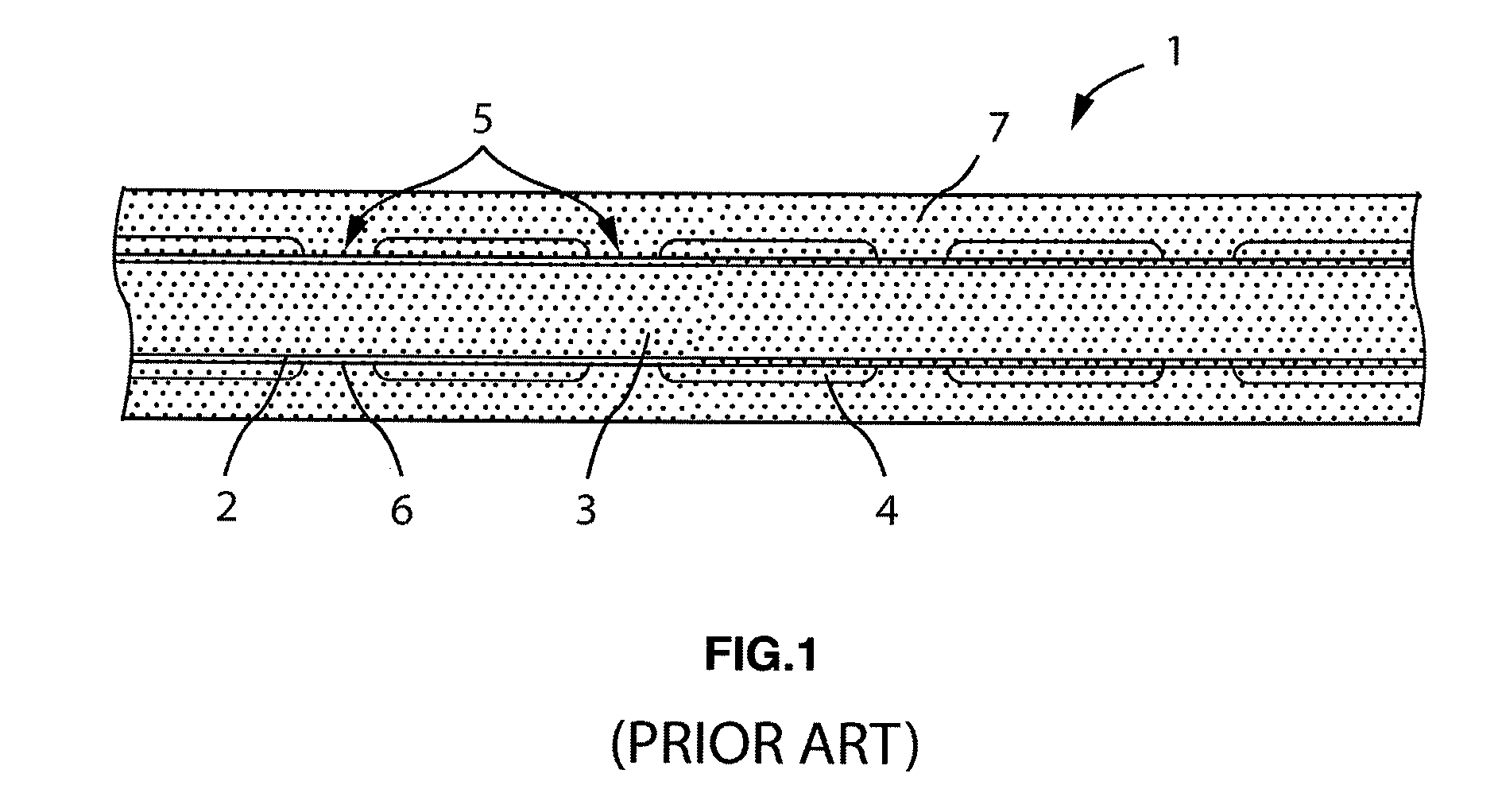

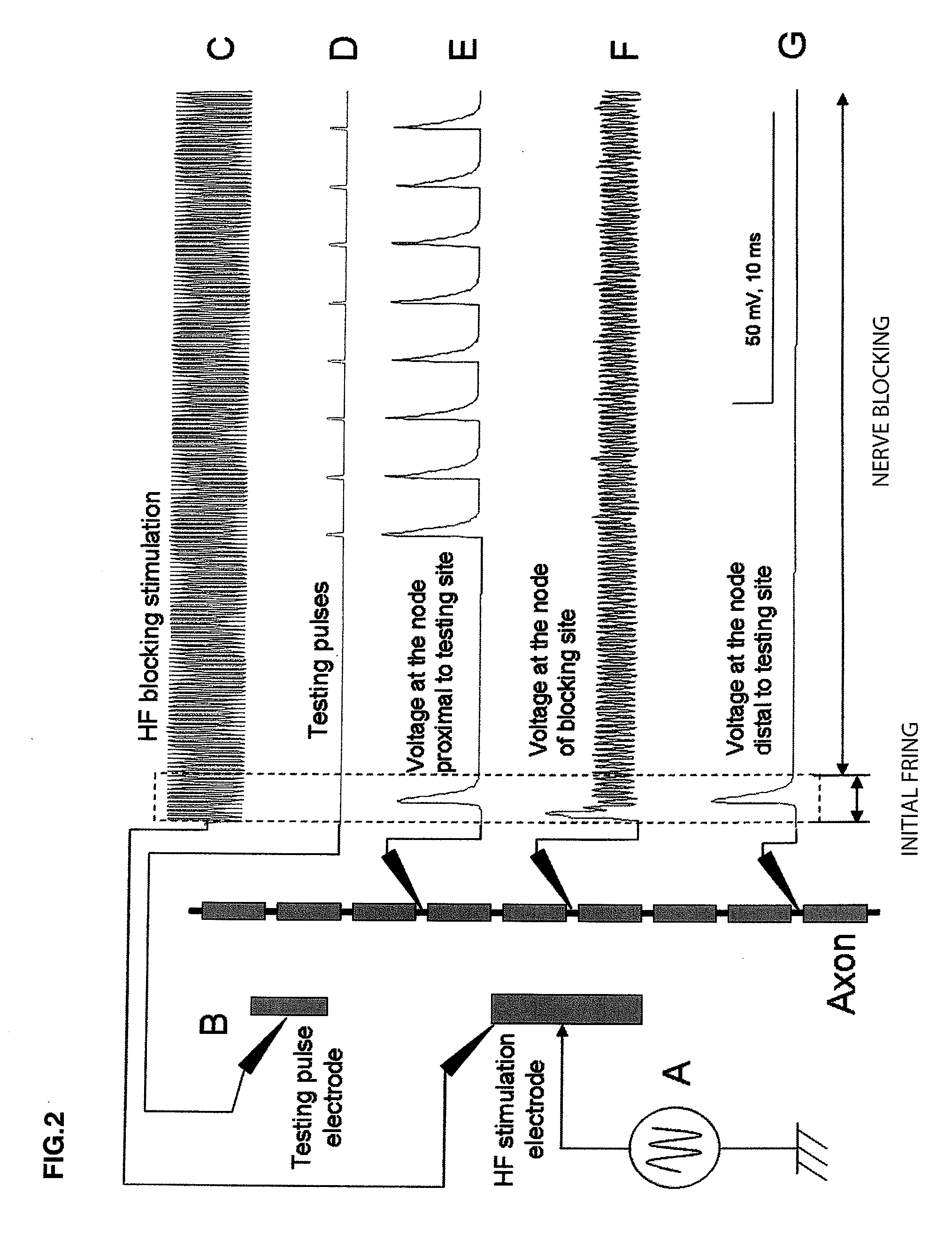

Energy efficient high frequency nerve blocking technique

InactiveUS20120016448A1Uniform amplitudeReduce frequencySpinal electrodesImplantable neurostimulatorsEngineeringNeurostimulation

A neurostimulation system and method of blocking a neural axon. Time-varying electrical energy is conveyed to a blocking site on the neural axon for an initial phase. The conveyed electrical energy has an amplitude and frequency during the initial phase sufficient to block action potentials from propagating along the neural axon from a location proximal to the blocking site to a location distal to the blocking site. The time-varying electrical energy is conveyed to the blocking site on the neural axon for a subsequent phase contiguous with the initial phase. The conveyed electrical energy has a decreased amplitude and a frequency during the subsequent phase sufficient to maintain blocking of the action potentials along the neural axon from the location proximal to the blocking site to the location distal to the blocking site.

Owner:BOSTON SCI NEUROMODULATION CORP

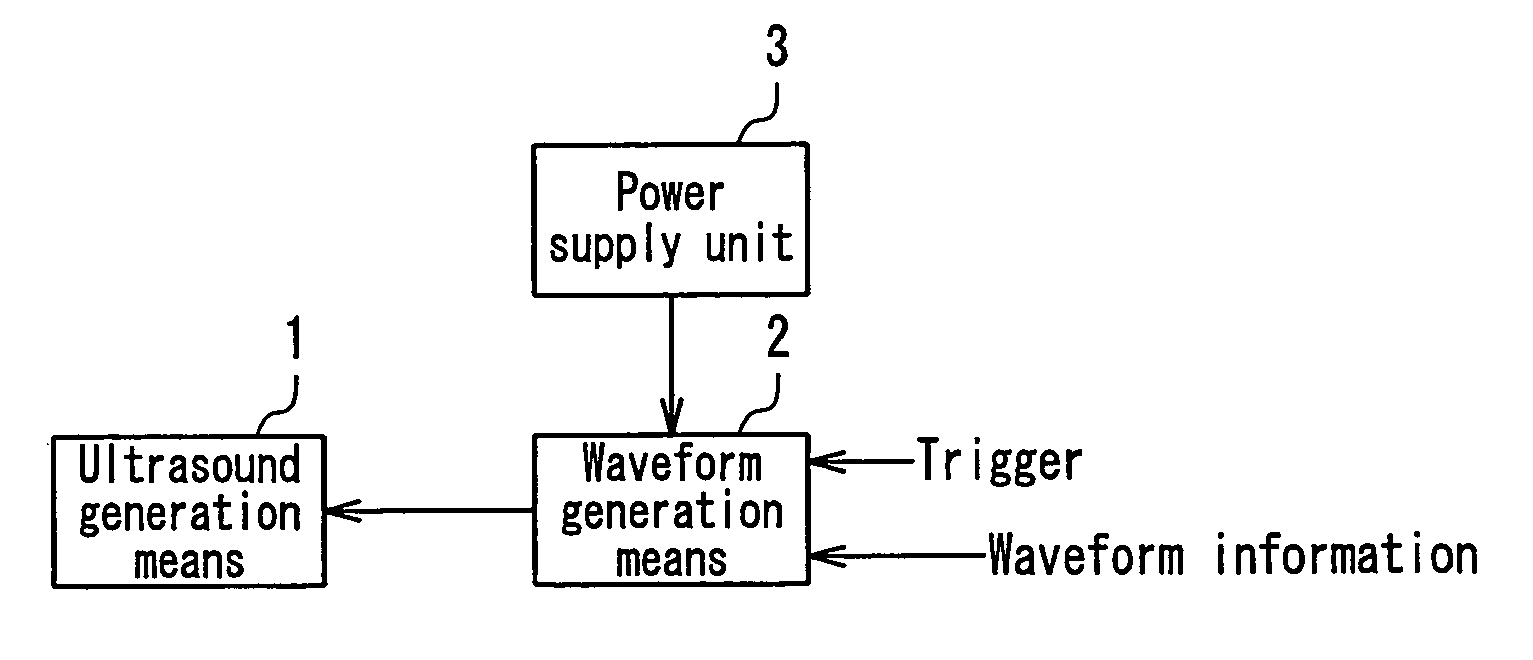

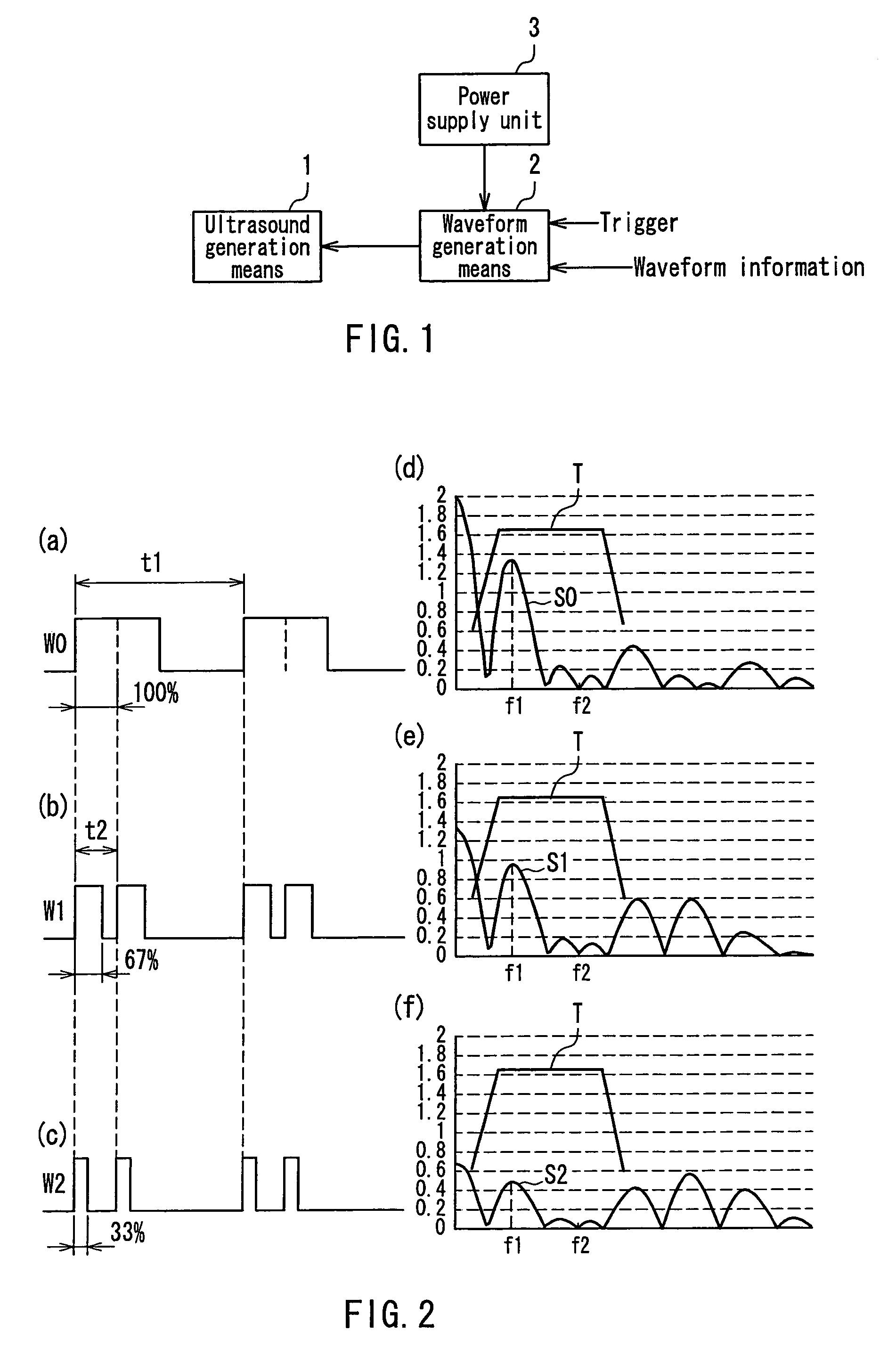

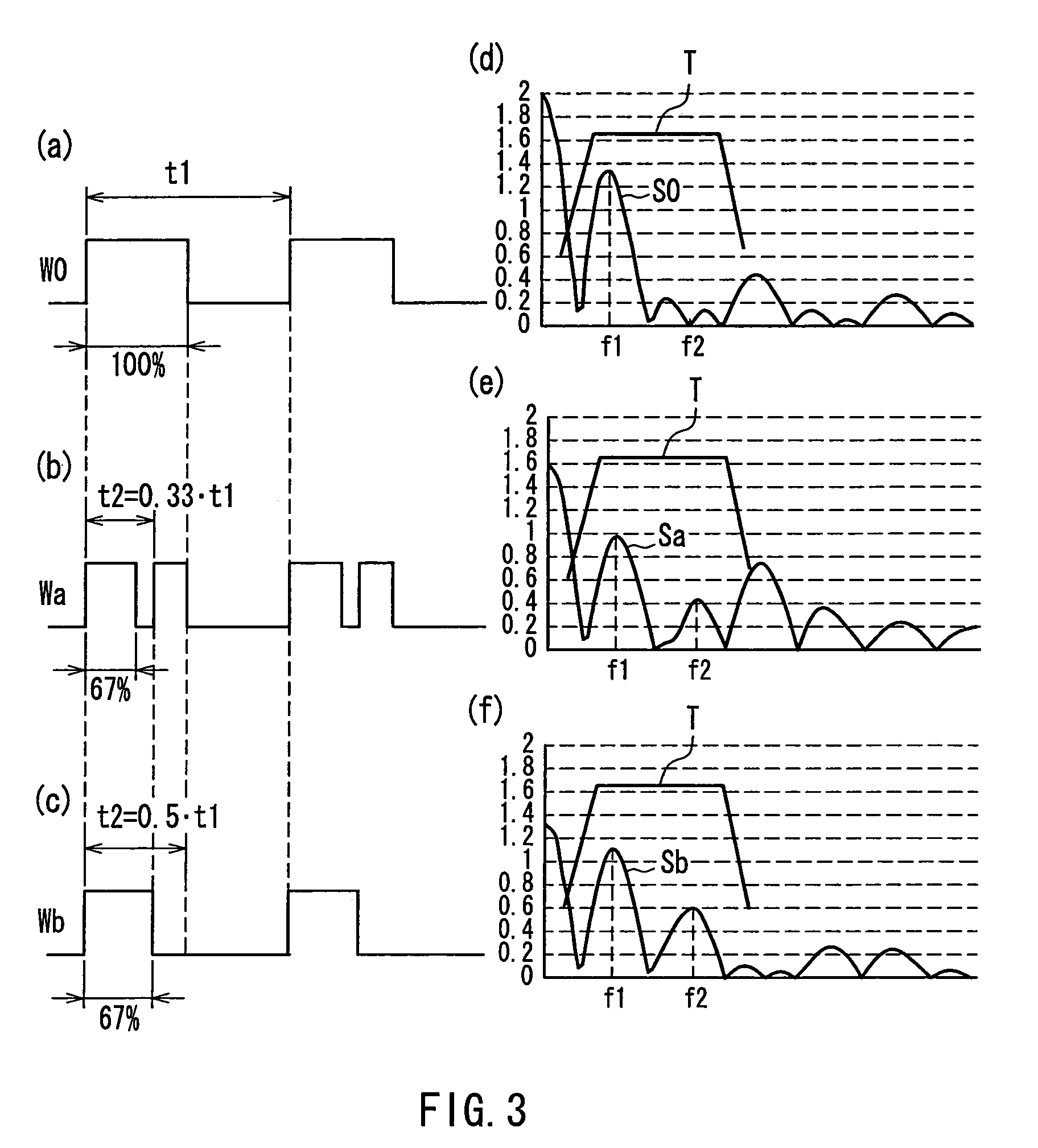

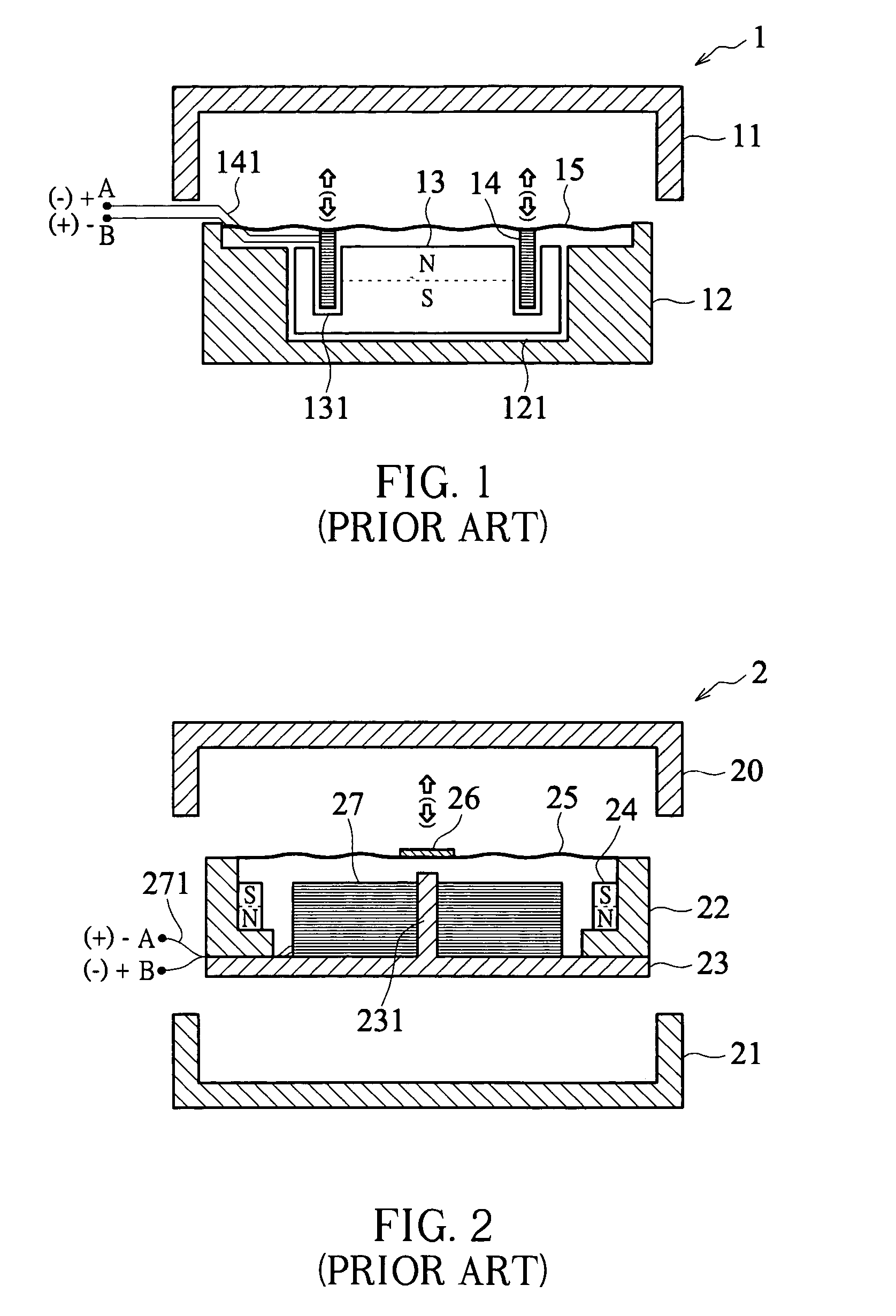

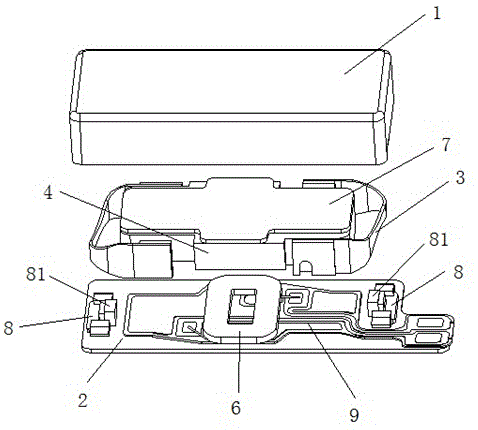

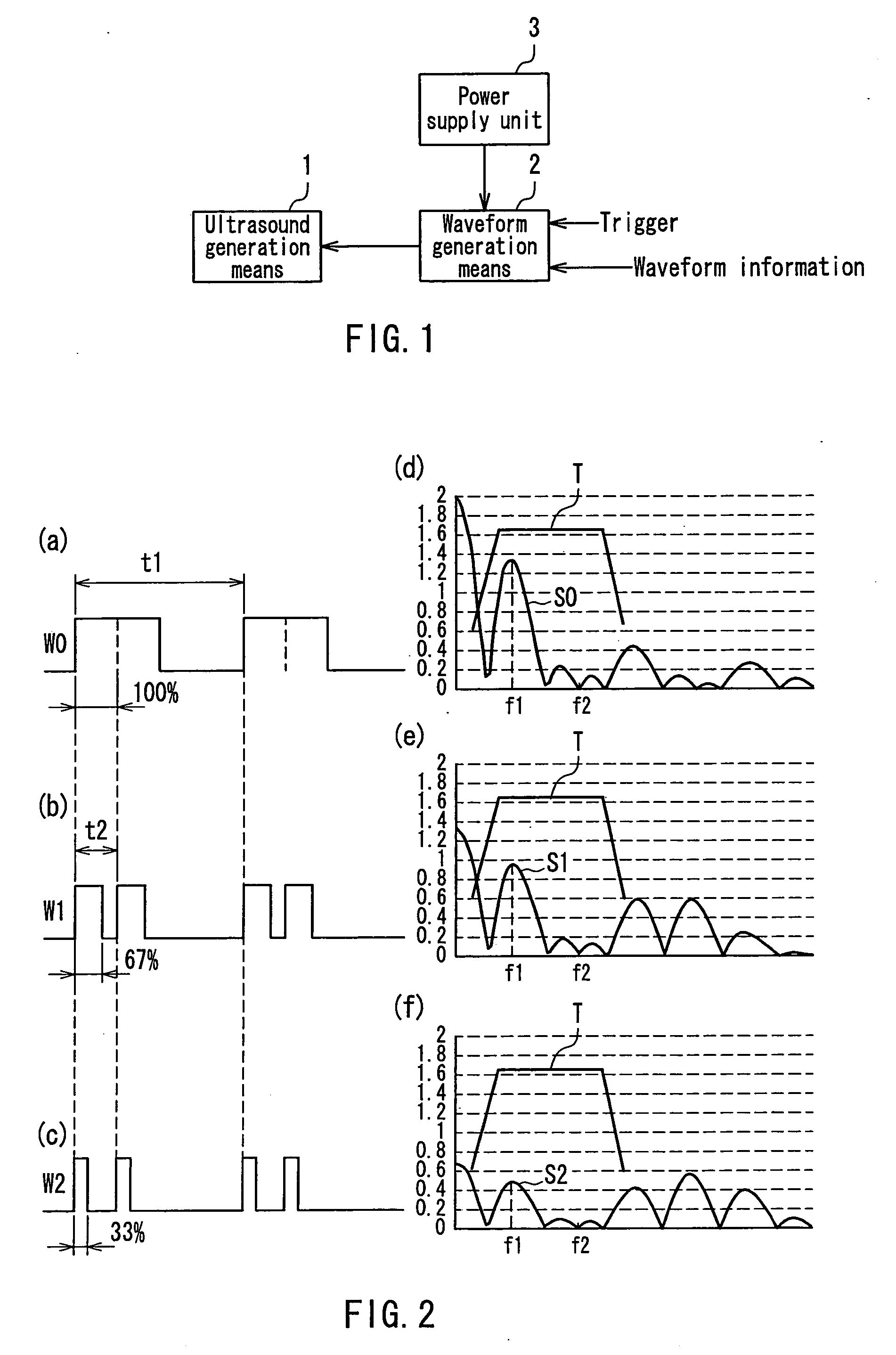

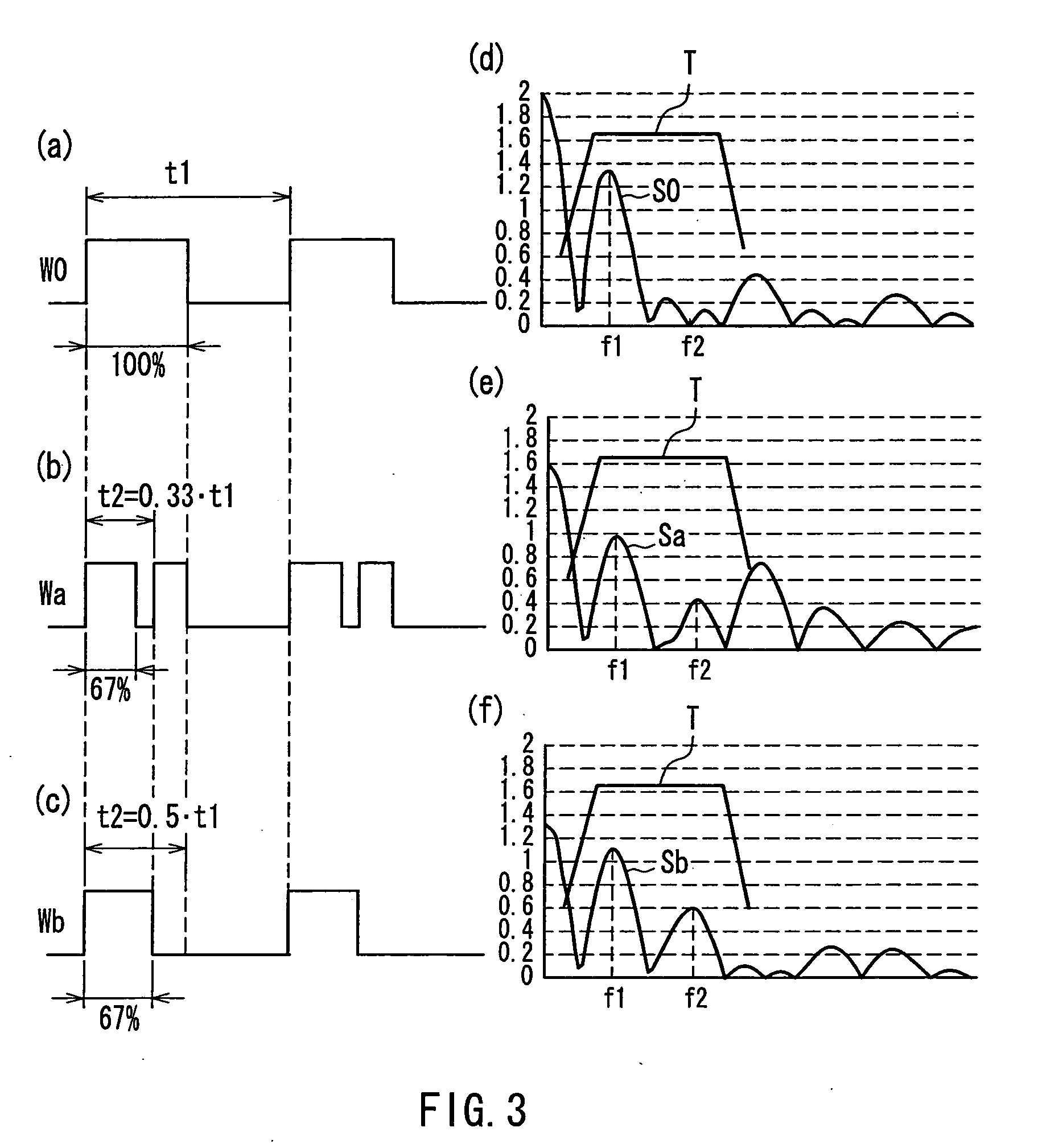

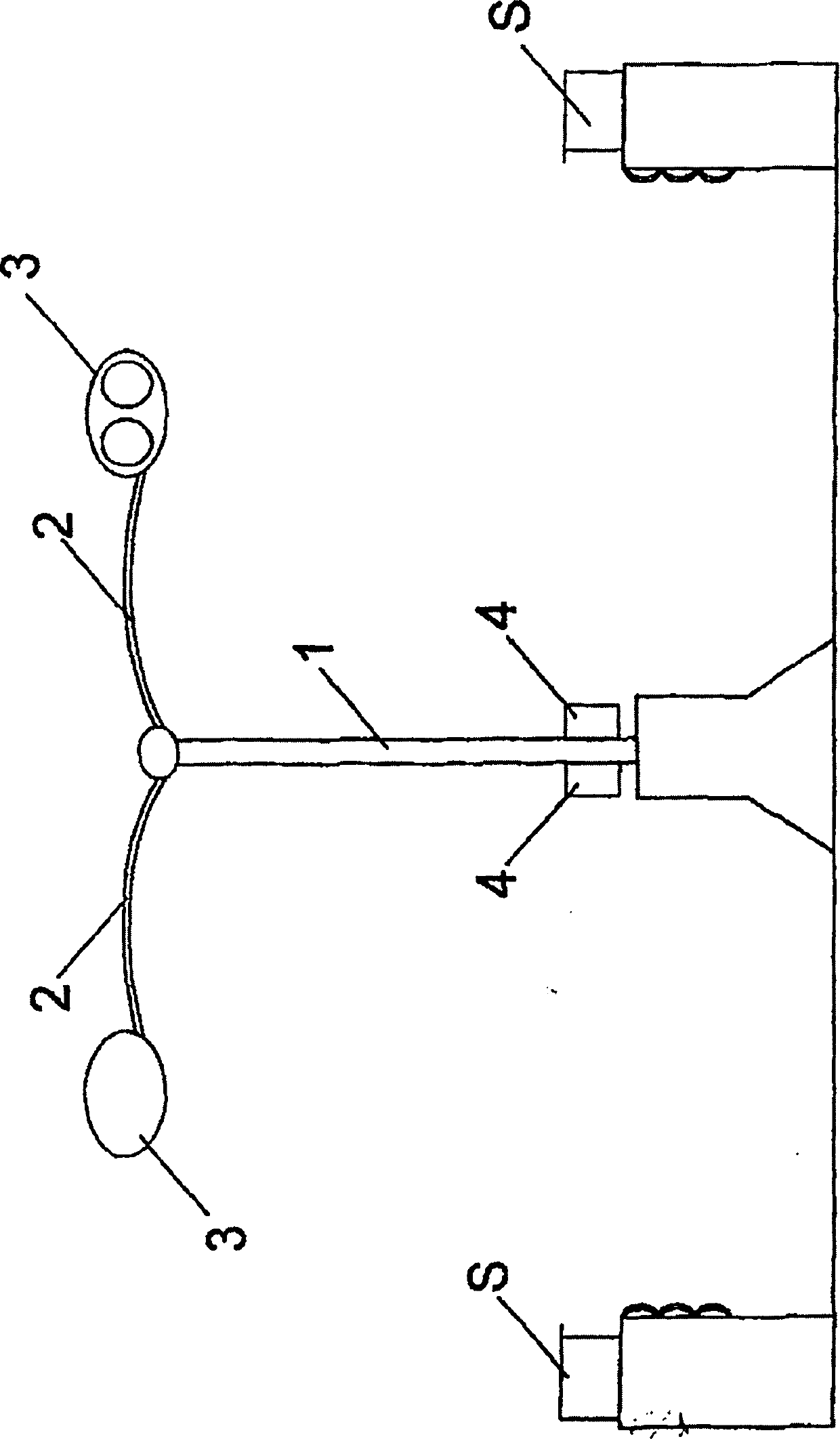

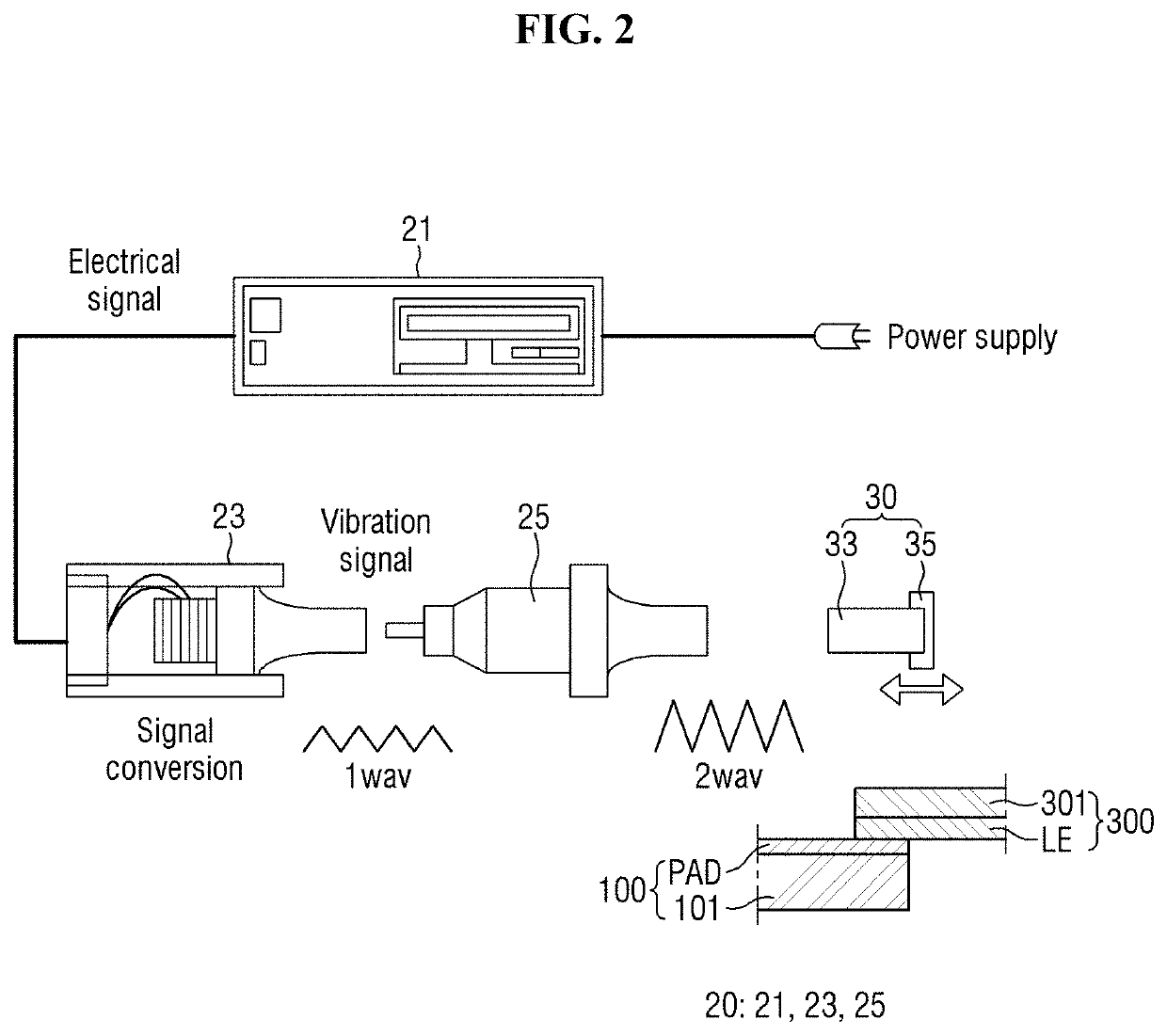

Ultrasound diagnostic device

InactiveUS7566304B2Low costEasy to controlUltrasonic/sonic/infrasonic diagnosticsMechanical vibrations separationTransmission amplitudeSonification

A small ultrasound diagnostic device is provided at a low cost that enables the appropriate control by a single power supply unit so as to give a predetermined transmission power to a driving waveform different for each mode without excess or deficiency and without affecting properties of the driving waveform. The ultrasound diagnostic device includes: an ultrasound generation unit (1) that transmits ultrasound; a waveform generation unit (2) that generates a single pulse or a burst pulse whose duty factor is variable in units of a time that is a period corresponding to a frequency outside a frequency band of the ultrasound generation unit (1) so as to drive the ultrasound generation unit (1); and a single power supply unit (3) that determines an amplitude of a driving waveform generated by the waveform generation unit (2). Thereby, an acoustic power of the transmitted ultrasound can be controlled without making the transmission amplitude variable.

Owner:KONICA MINOLTA INC

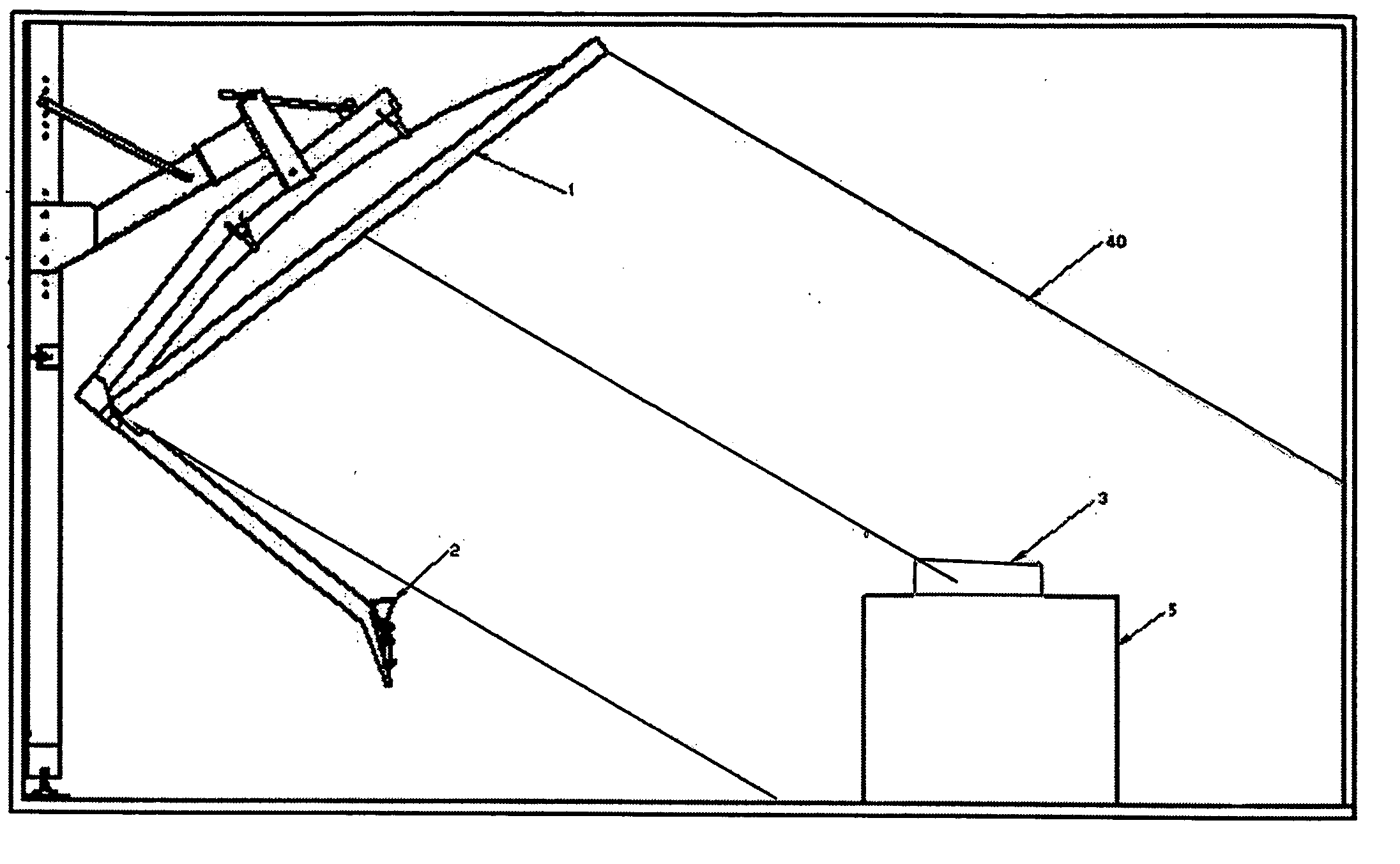

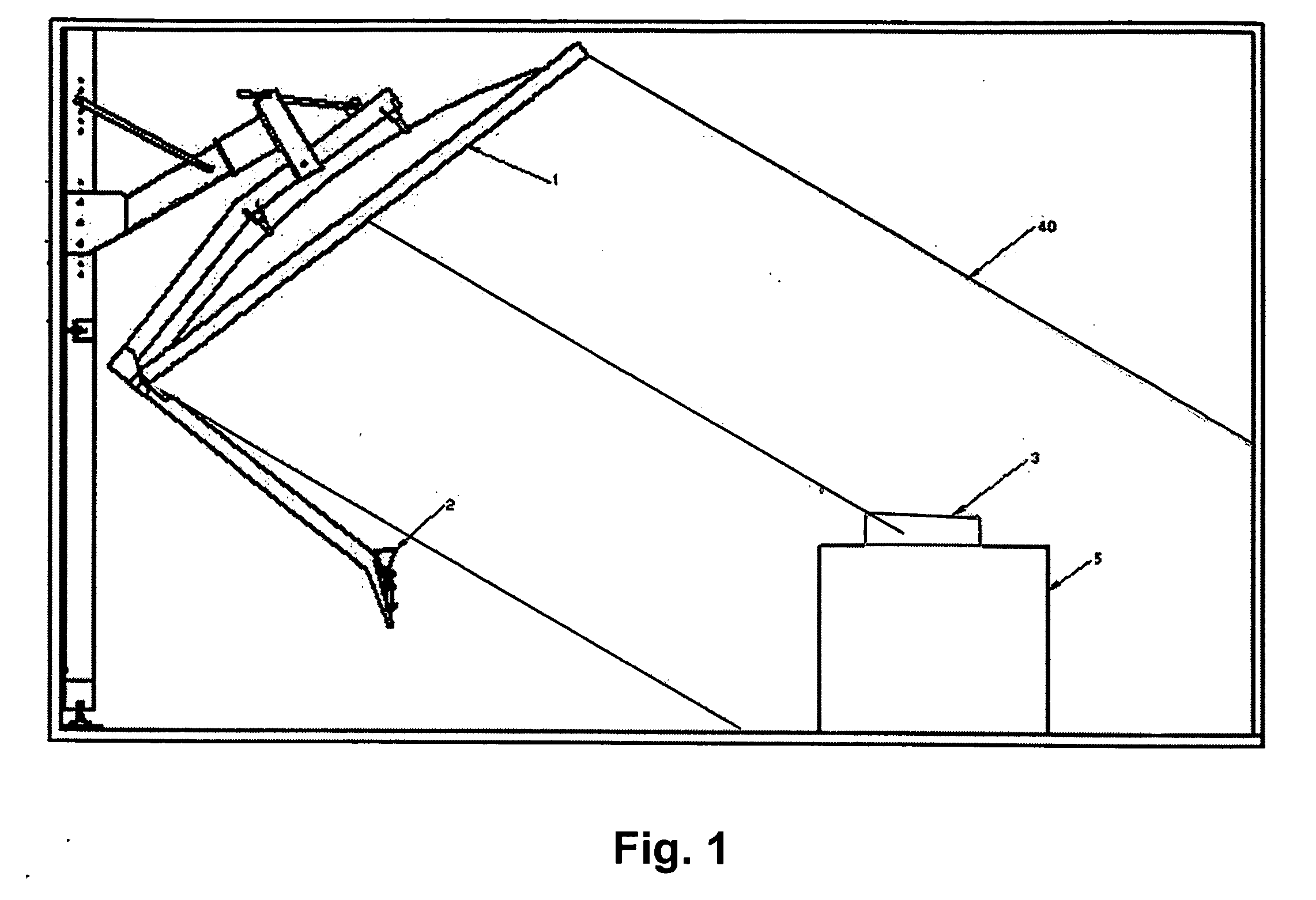

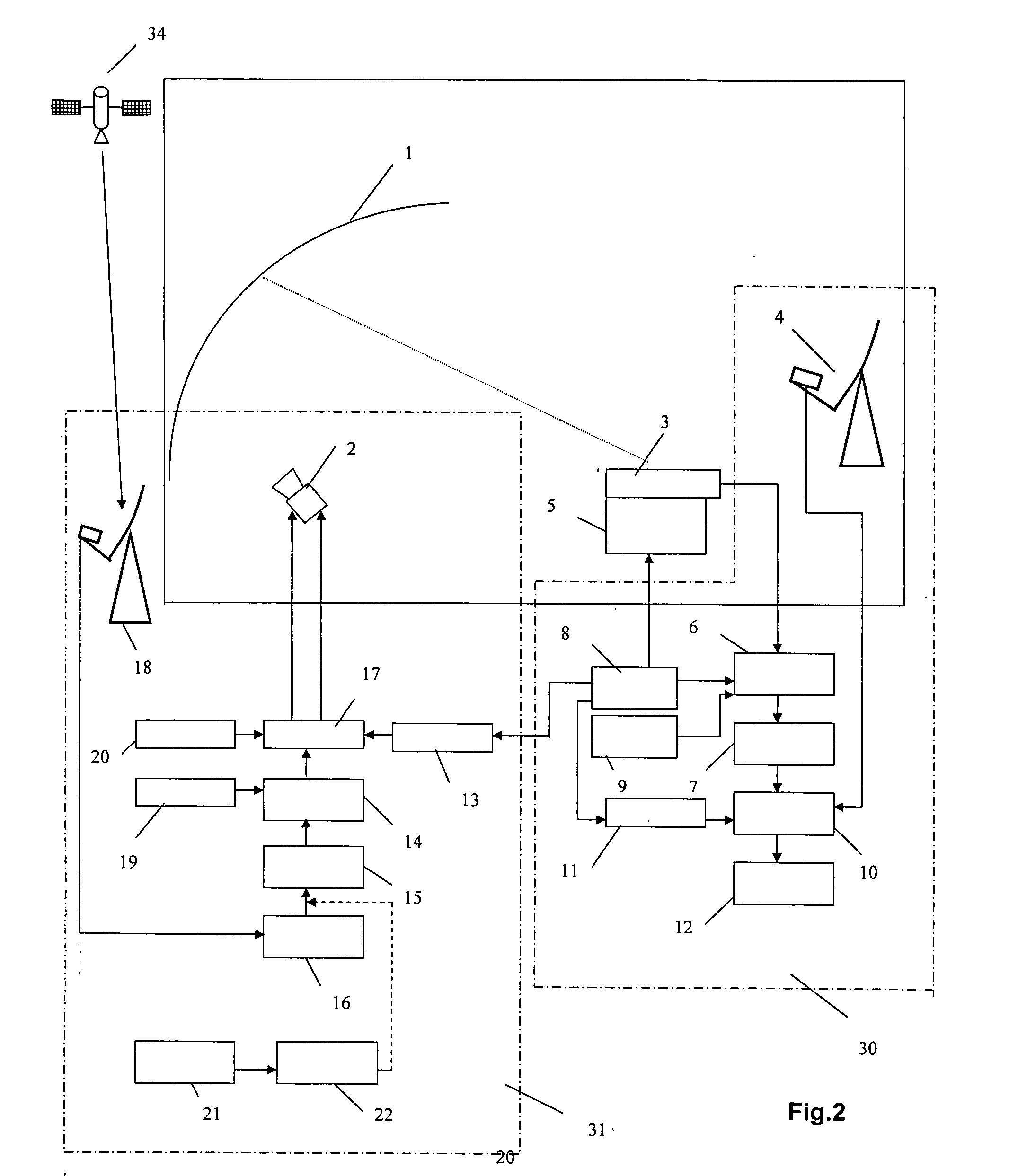

Low cost indoor test facility and method for mobile satellite antennas

InactiveUS20060199543A1Minimize shadowsImprove flatnessReceivers monitoringAntenna radiation diagramsSatellite antennasMobile antennas

A test system and method for indoor testing of a mobile antenna terminal having a first antenna with a first aperture of a first size and, preferably, operable in a receive-only mode and / or a transmit and receive mode. The system uses a second antenna having a dual port feed and a reflector, the second antenna having a second aperture of a second size, which is two or more times the first size, and being operative to form a plane wave. The first antenna is mounted to a test platform that is positioned within the second aperture and is operative for rotating and tilting movement of the antenna to simulate movement on a vehicle. The test system uses a source of RF test signals and communications test equipment coupled to at least the first antenna, as well as a processor for determining a performance of the mobile antenna terminal.

Owner:RAYSAT ANTENNA SYST L L C

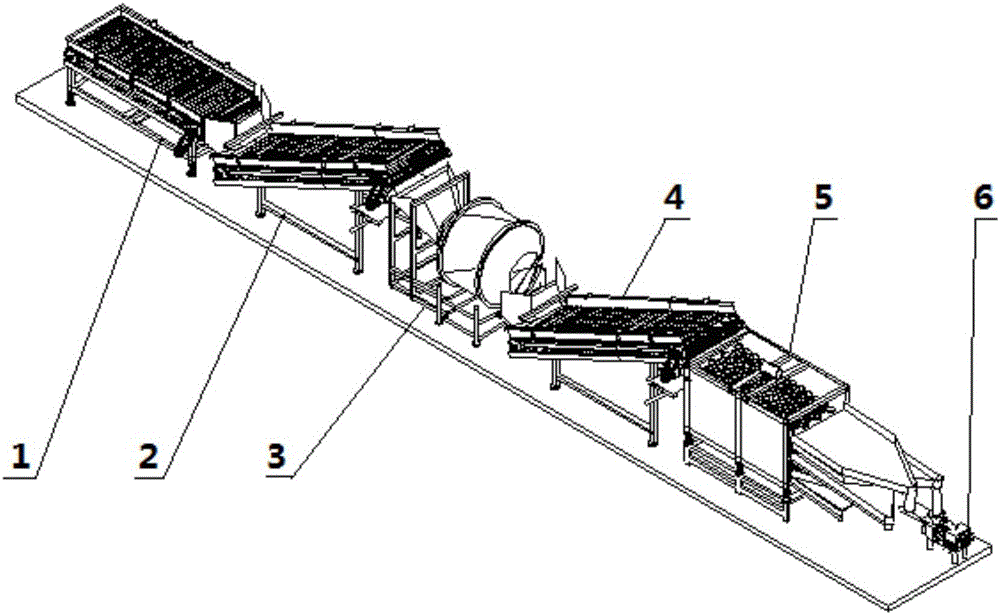

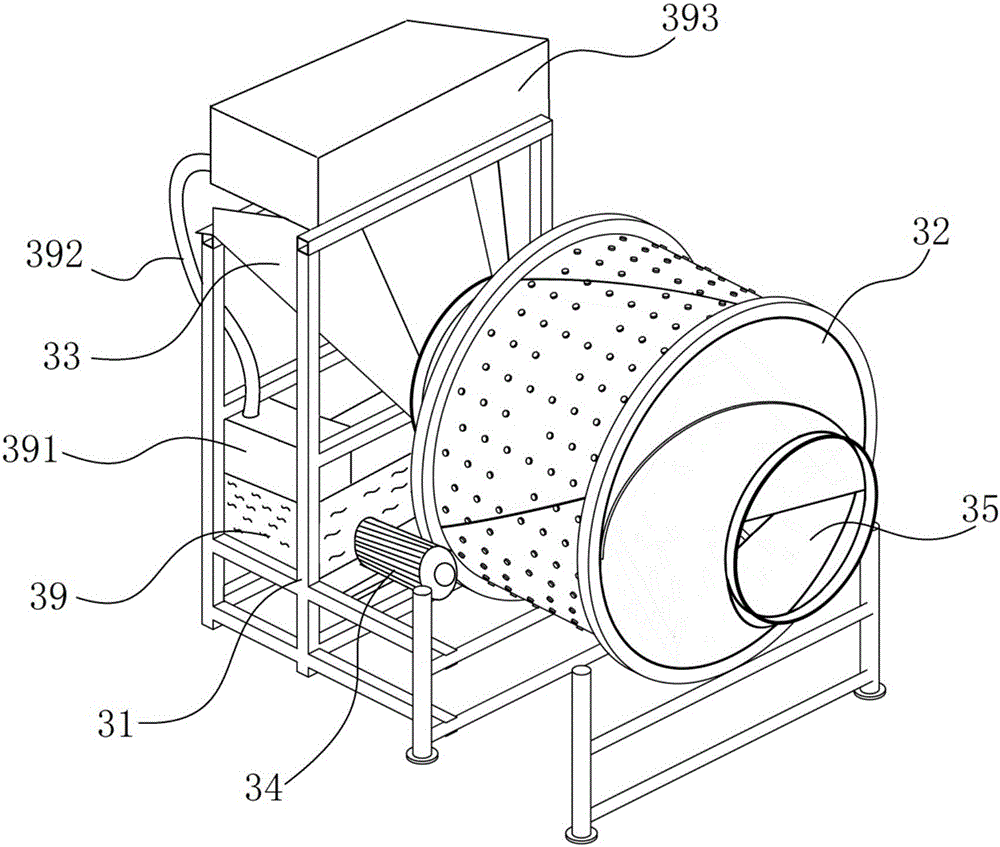

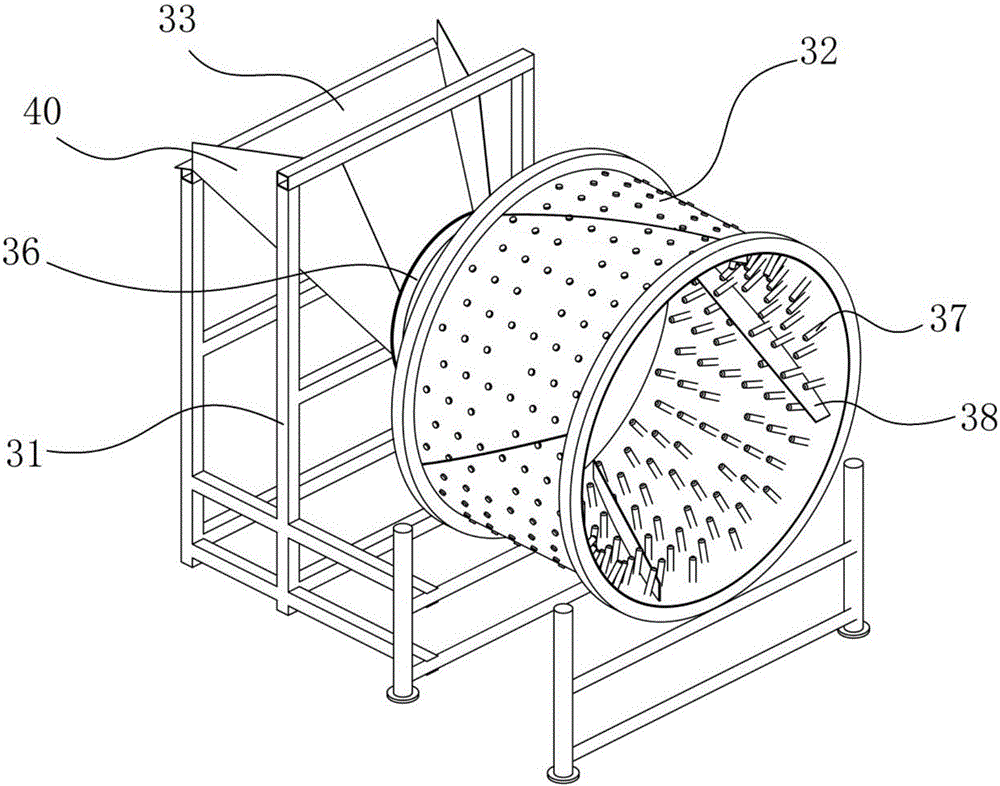

Onion cleaning, sorting and cutting integrated processing production line

InactiveCN106179945AImprove cleaning efficiencyEasy to cleanSievingScreeningProduction lineEngineering

The invention relates to an agricultural product processing production line. An onion cleaning, sorting and cutting integrated processing production line is composed of a vibration screen device, a first conveying device, a cleaning device, a second conveying device, a sorting device and cutting devices. The tail end of the vibration screen device is connected to the start end of the first conveying device. The tail end of the first conveying device is connected to the feeding end of the cleaning device. The discharging end of the cleaning device is connected with the start end of the second conveying device. The tail end of the second conveying device is connected to a feeding port of the sorting device. The sorting device comprises a plurality of discharging ends. The multiple cutting devices are arranged below the discharging ends. The production line is simple in structure, scientific, reasonable, small, exquisite and high in cleaning efficiency and cleaning degree. The comprehensive excellent beneficial effects that the sorting vibration screen process is stable, the amplitude is uniform, the screening efficiency is high, and the precision is high are achieved; and the onion cleaning, sorting and cutting integrated processing production line has the beneficial effects that the cutting efficiency and cutting precision are high, and cutting is smooth, and the work efficiency of the production line is improved integrally.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Structure of speaker

InactiveUS20050123166A1Manufacturing EaseEase of assemblyPlane diaphragmsFrequency/directions obtaining arrangementsBobbinLoudspeaker

A structure of speaker is disclosed. The disclosed speaker structure includes at least a bobbin, a coil, a membrane, and a magnetic assembly. The coil is wound around the side surface of the bobbin, and the membrane is disposed at end of the bobbin. Besides, the magnetic assembly is suspended in a through hole of the bobbin and have one end adhered to the membrane.

Owner:DELTA ELECTRONICS INC

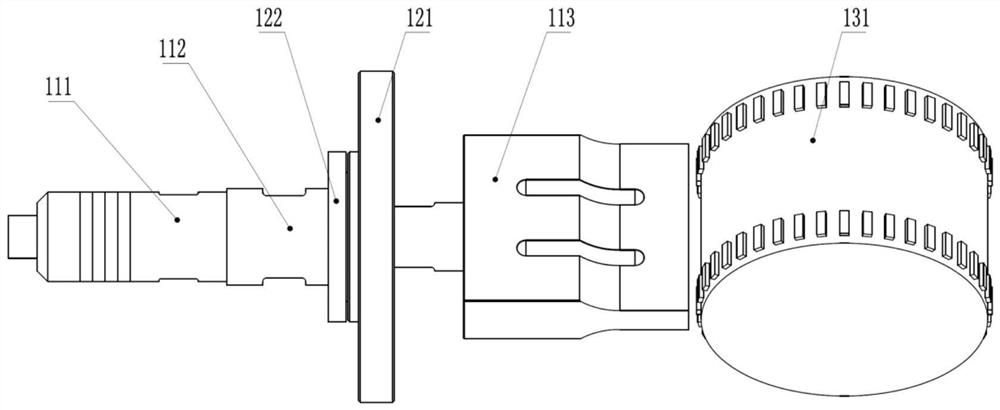

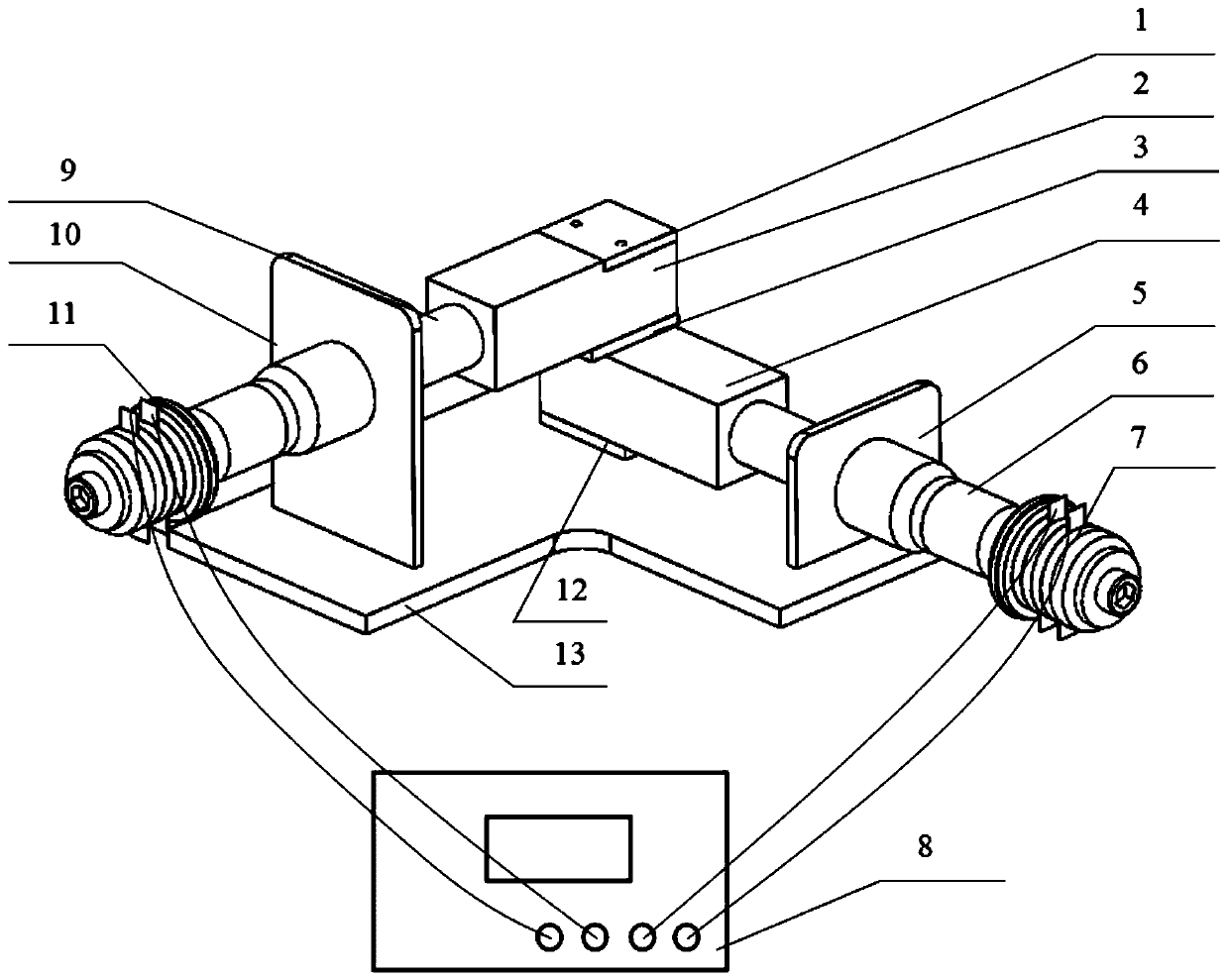

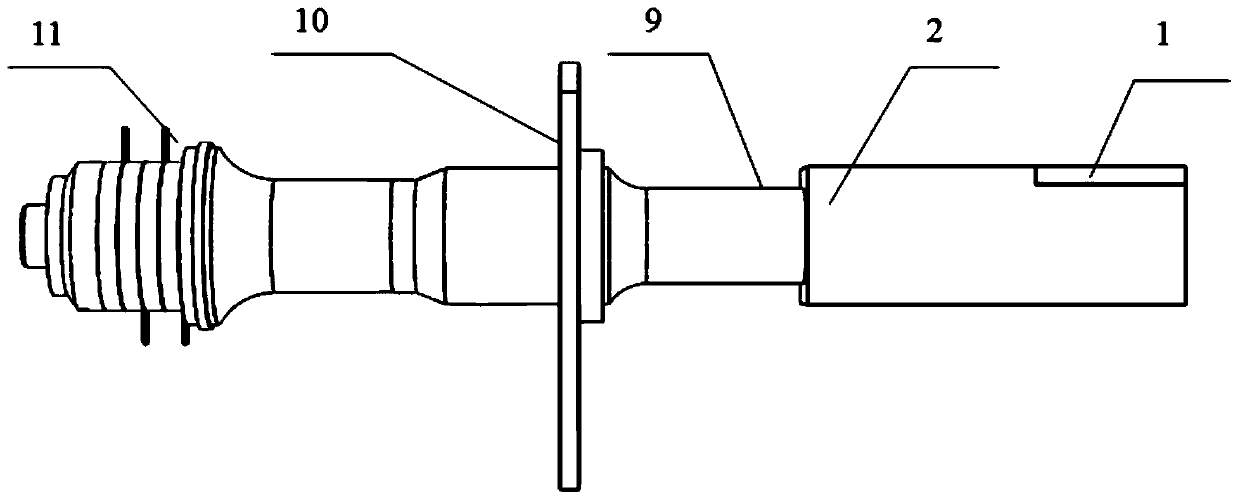

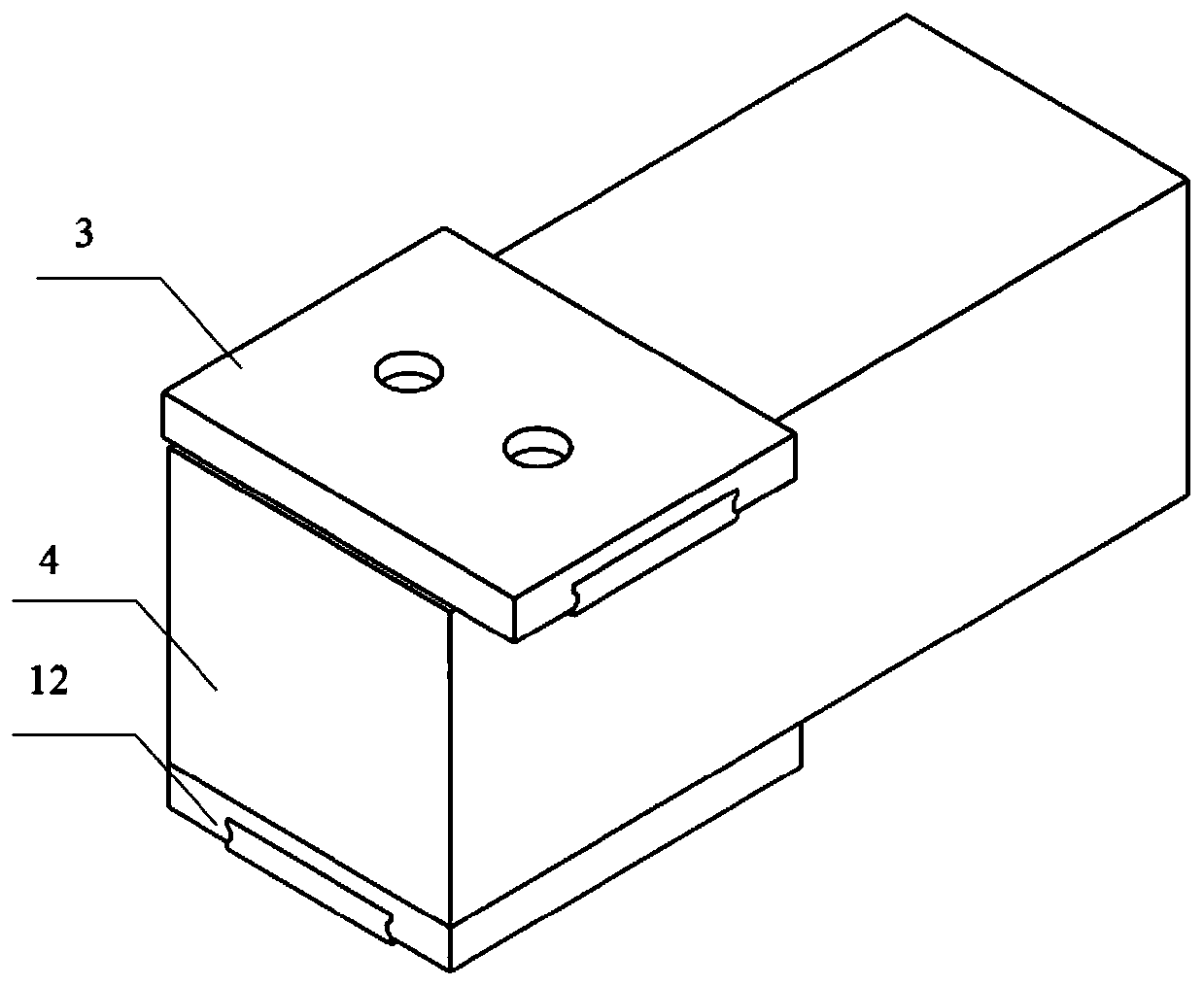

Ultrasonic cutting tool

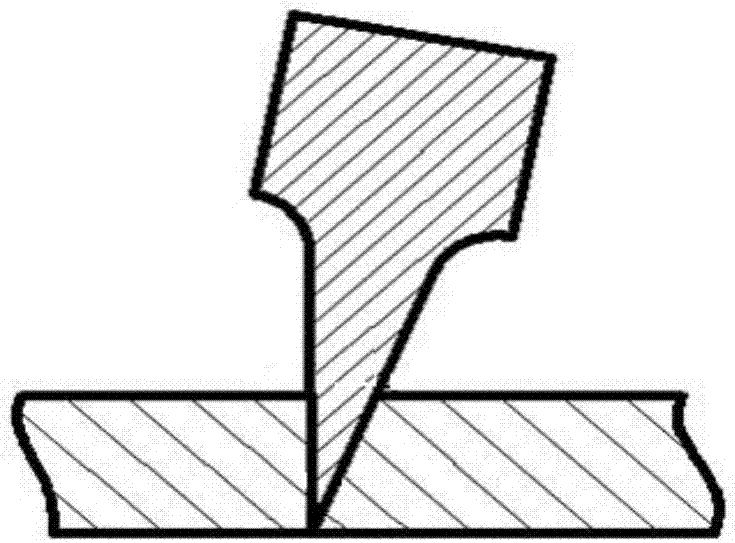

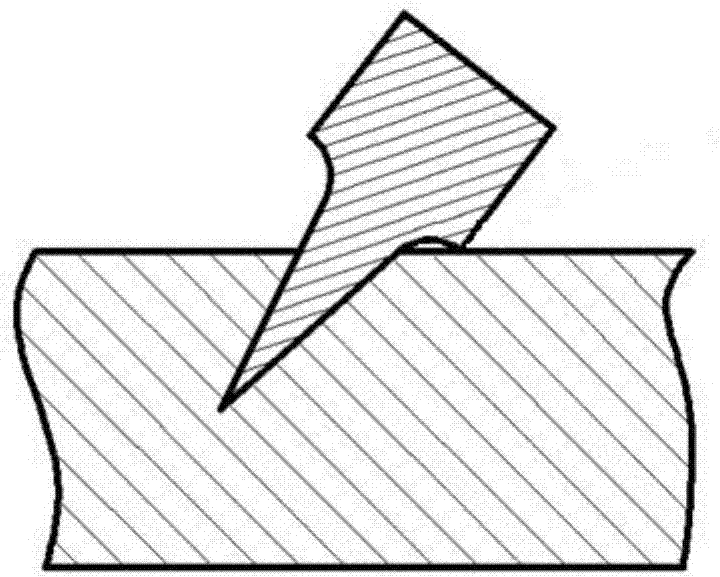

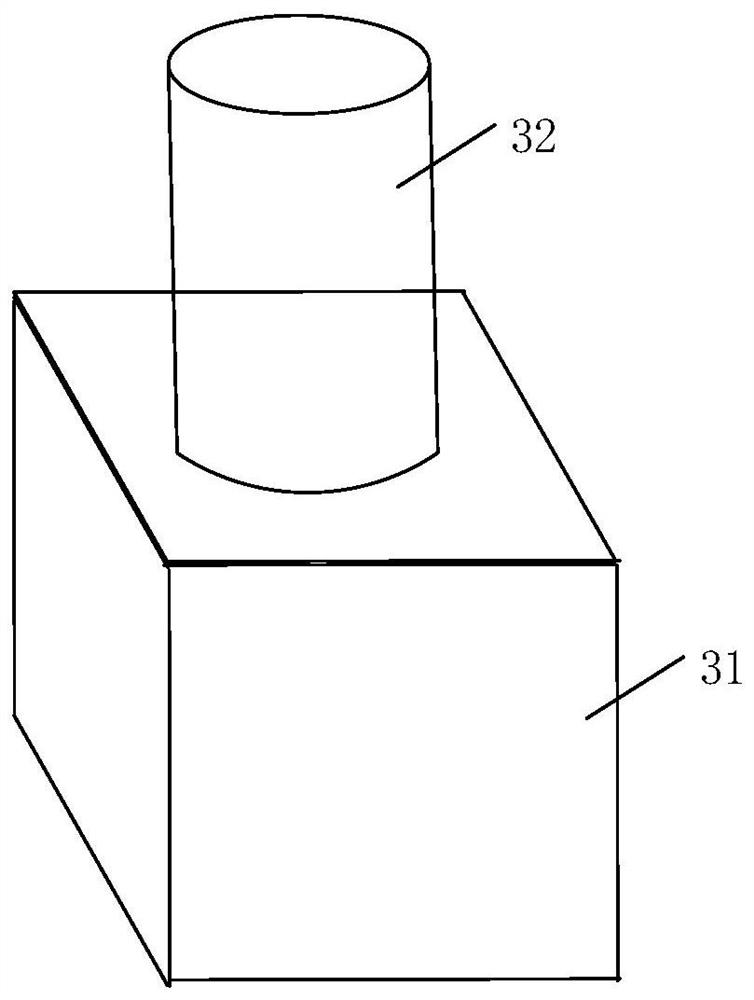

InactiveCN107139228AImprove vibrationUniform amplitudeMetal working apparatusVibration amplitudeTransducer

The invention discloses an ultrasonic cutting tool. The ultrasonic cutting tool comprises a transducer, a variable amplitude rod, a changeover mechanism and a blade, wherein the transducer is connected with the variable amplitude rod; the top of the changeover mechanism is connected with the variable amplitude rod; and the bottom of the changeover mechanism is connected with the blade. According to the ultrasonic cutting tool, the blade and the changeover mechanism resonate in the same vibration mode under the same frequency, the blade well vibrates, vibration amplitude is uniform, obvious pitch surfaces do not exist on the blade, and the phenomenon of local tool sticking is avoided; besides, the blade is of a flakelike structure, an edge is relatively long, cutting depth is relatively large, processing range is relatively wide, and difference of cut angles of the two ends of a cutting surface and interference between the upper end of the cutting tool and a material are avoided; and the changeover mechanism can be manufactured through an aluminium alloy, cost is reduced, the flakelike blade can be manufactured through stainless steel or alloy steel, hardness is much higher than that of a titanium alloy, the cutting tool can be utilized to cut relatively hard materials, and utilization range of the ultrasonic cutting tool is greatly increased.

Owner:沈阳赫声装备科技有限公司

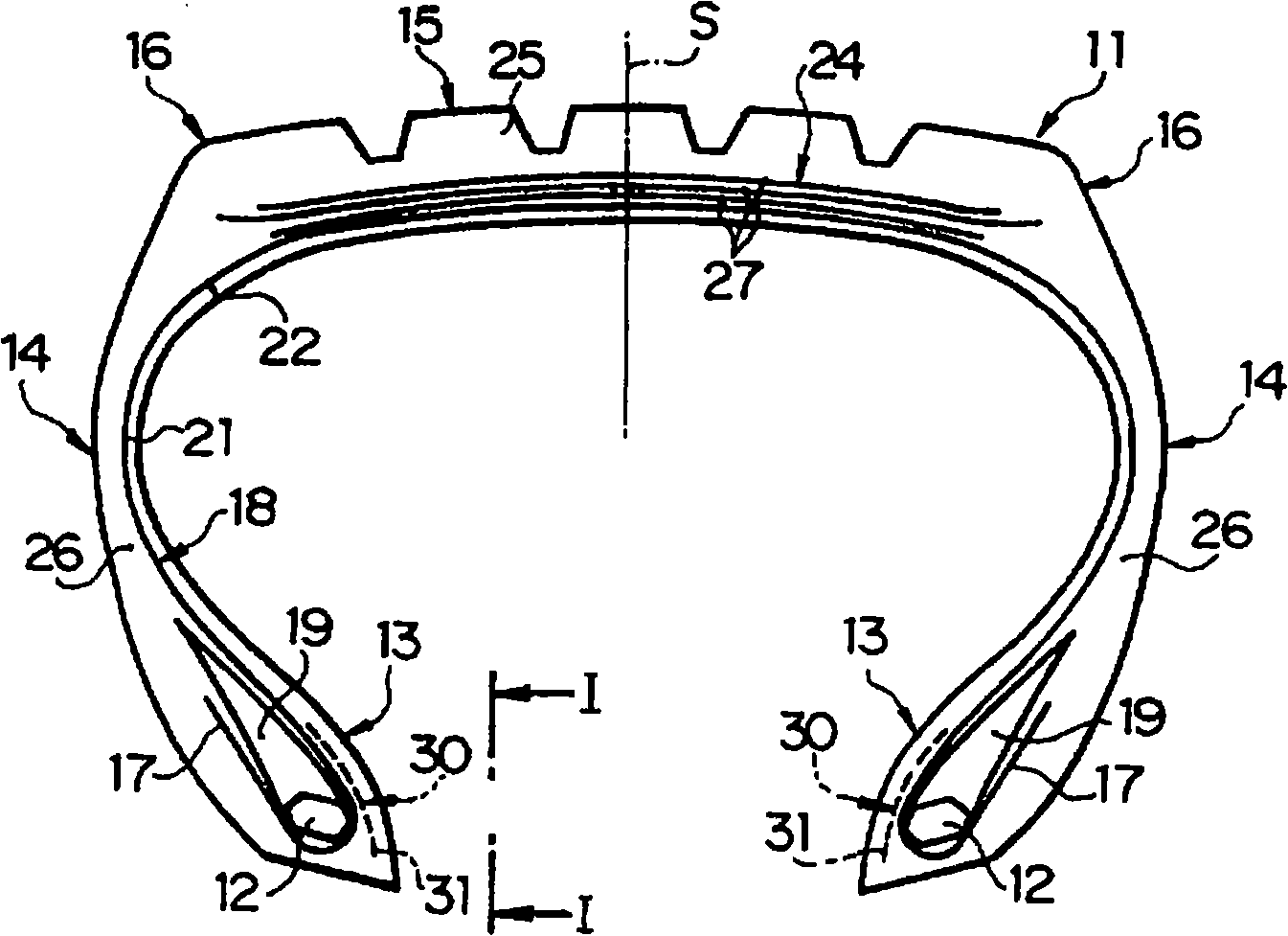

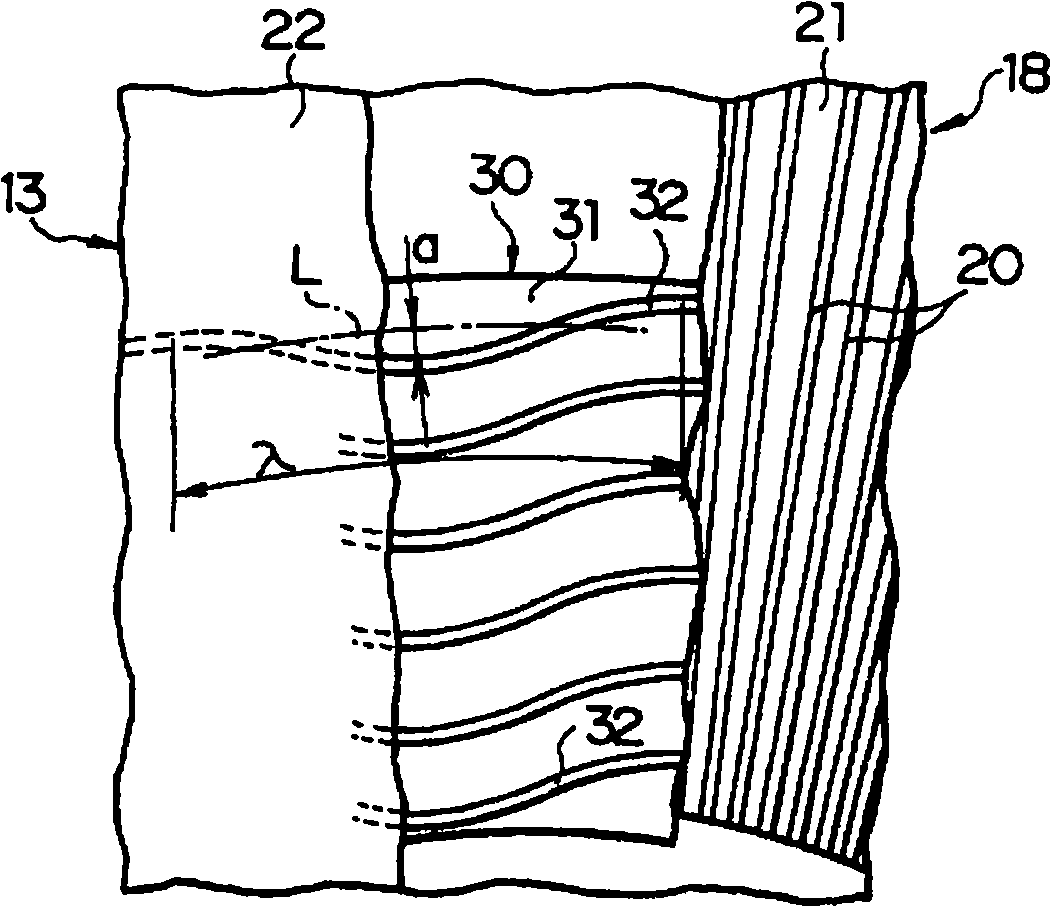

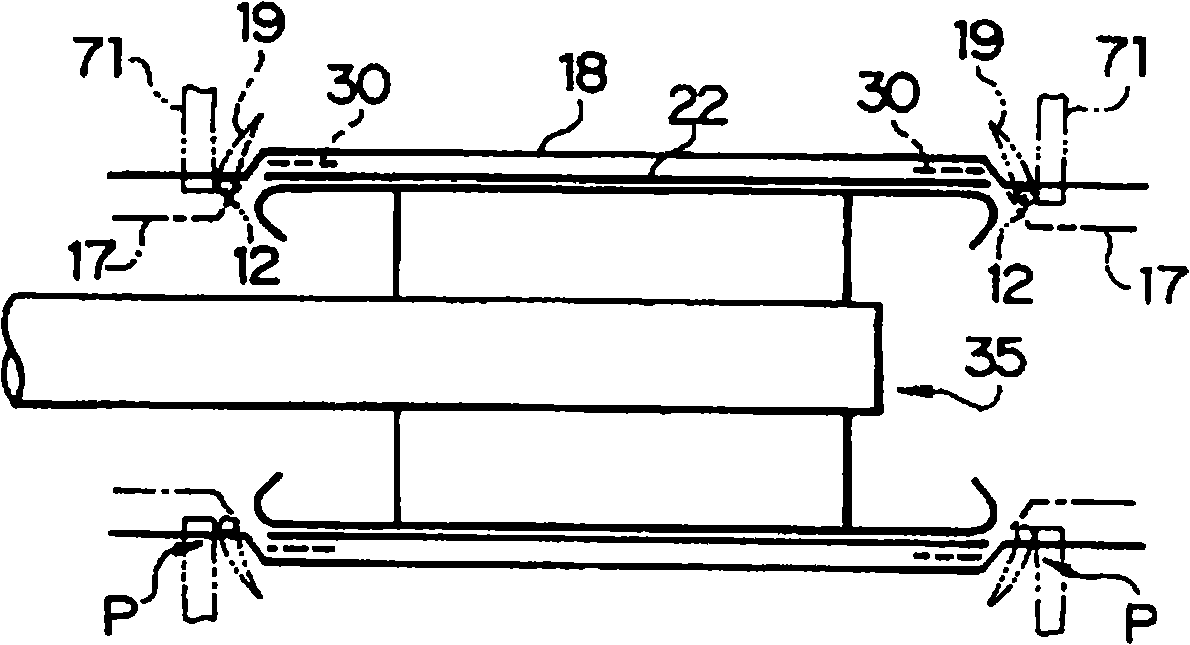

Tire manufacturing method and apparatus

InactiveCN102056734AImprove performanceReduce the amplitudeTyresRope making machinesWave shapeEngineering

A cord reinforcing layer (30) can be molded at high efficiency while being easily controlled, and the amplitude or wavelength of wave-shaped steel cords (32) can be made uniform over the entire cord reinforcing layer (30). When multiple wave-shaped steel cords (32) (ribbon-like body (37)) are wound on a cylindrical molding drum (35) to mold the cylindrical cord reinforcing layer (30), since the amount of elongation is reduced moving away, in the axial direction, from a set position P for a bead core (12), the amount of elongation provided in advance for the wave-shaped steel cords (32) near the set position P approaches the amount of elongation based on swelling deformation of the wave-shaped steel cords (32) at a position away from the set position P. In this way, the amplitude and / or the wavelength of the wave-shaped steel cords in the tire can be made uniform over the entire cord reinforcing layer (30).

Owner:BRIDGESTONE CORP

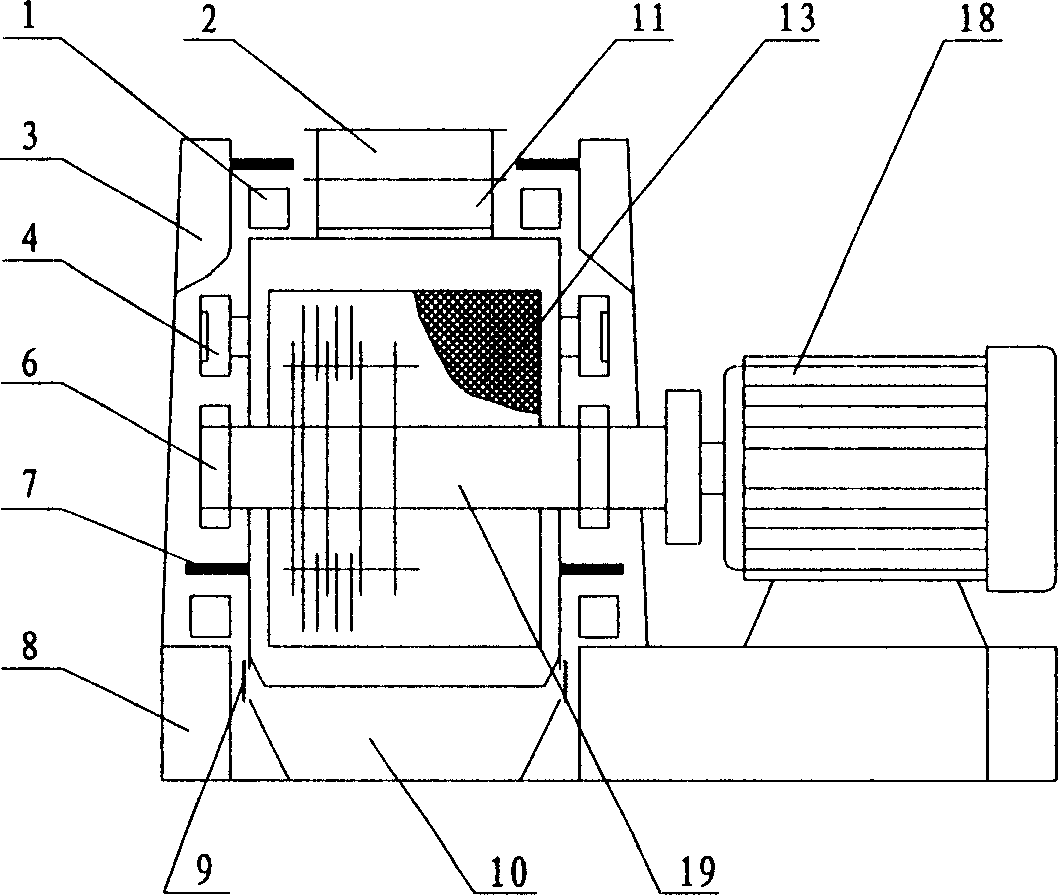

Crushing machine

InactiveCN1651145AReduce consumptionEliminate loosening problemsGrain treatmentsMetallic materialsEngineering

A pulverizer without pollution and noise is composed of mainshaft, rotor, hammer plates, feeding inlet, discharging outlet, sieving plate, base, supporting frame, vibrators, seated vibration damper between base and the assemblage consisting of toothed plate, sieving plate, gate and said inlet and outlet, and the pressing vibration damper between supporting frame and assemblage.

Owner:JIANGSU MUYANG GRP CO LTD

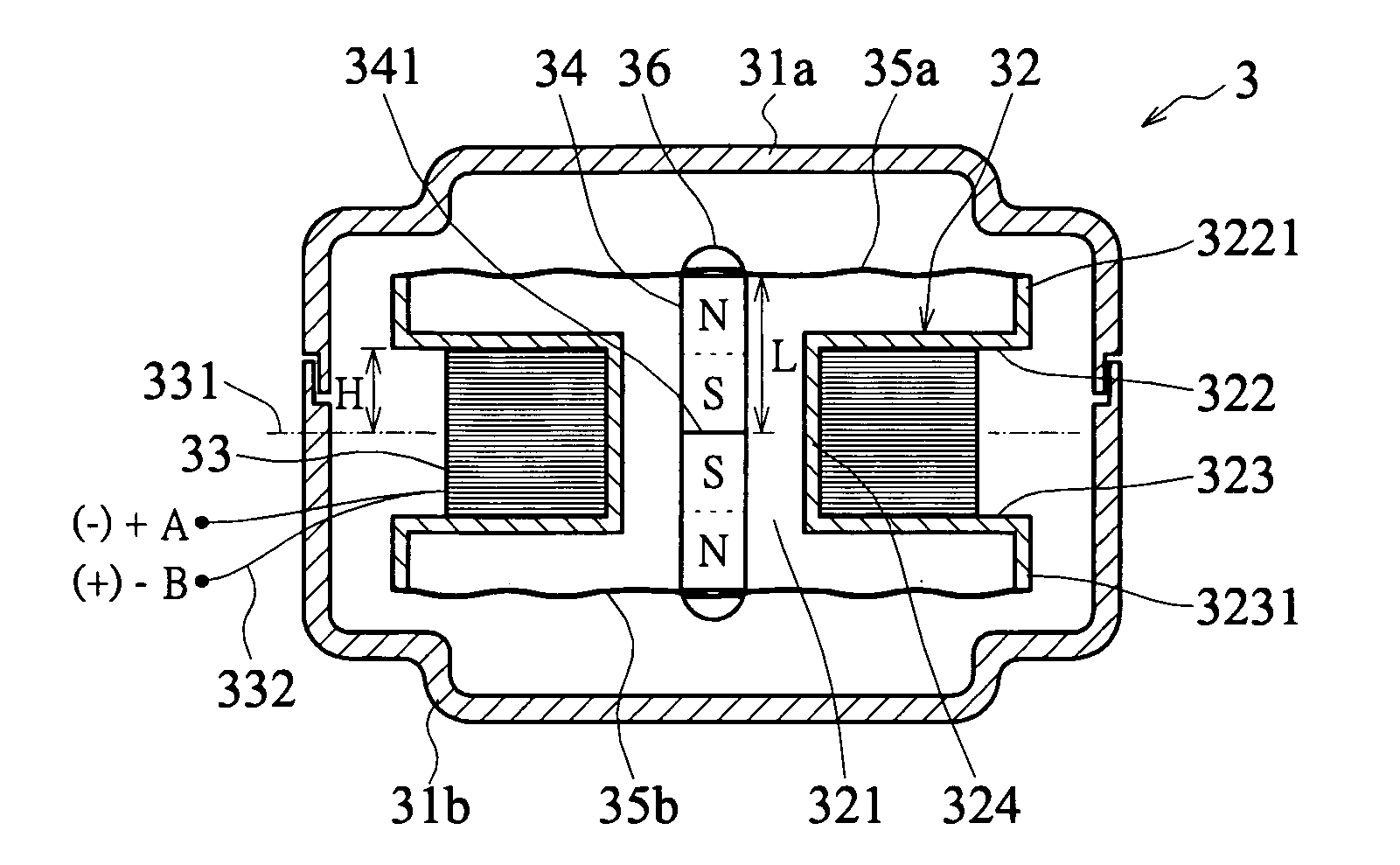

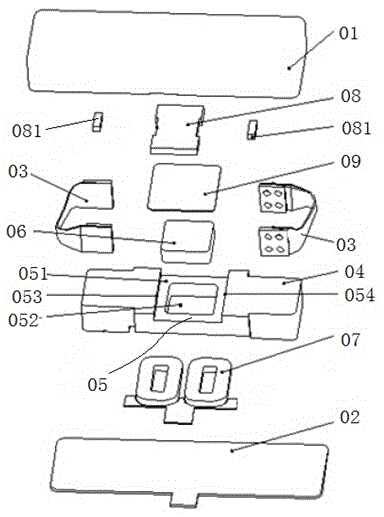

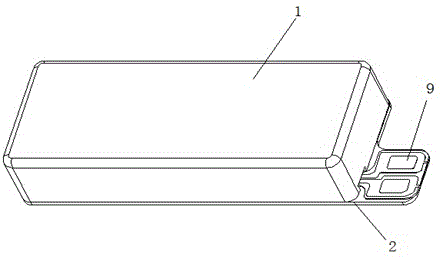

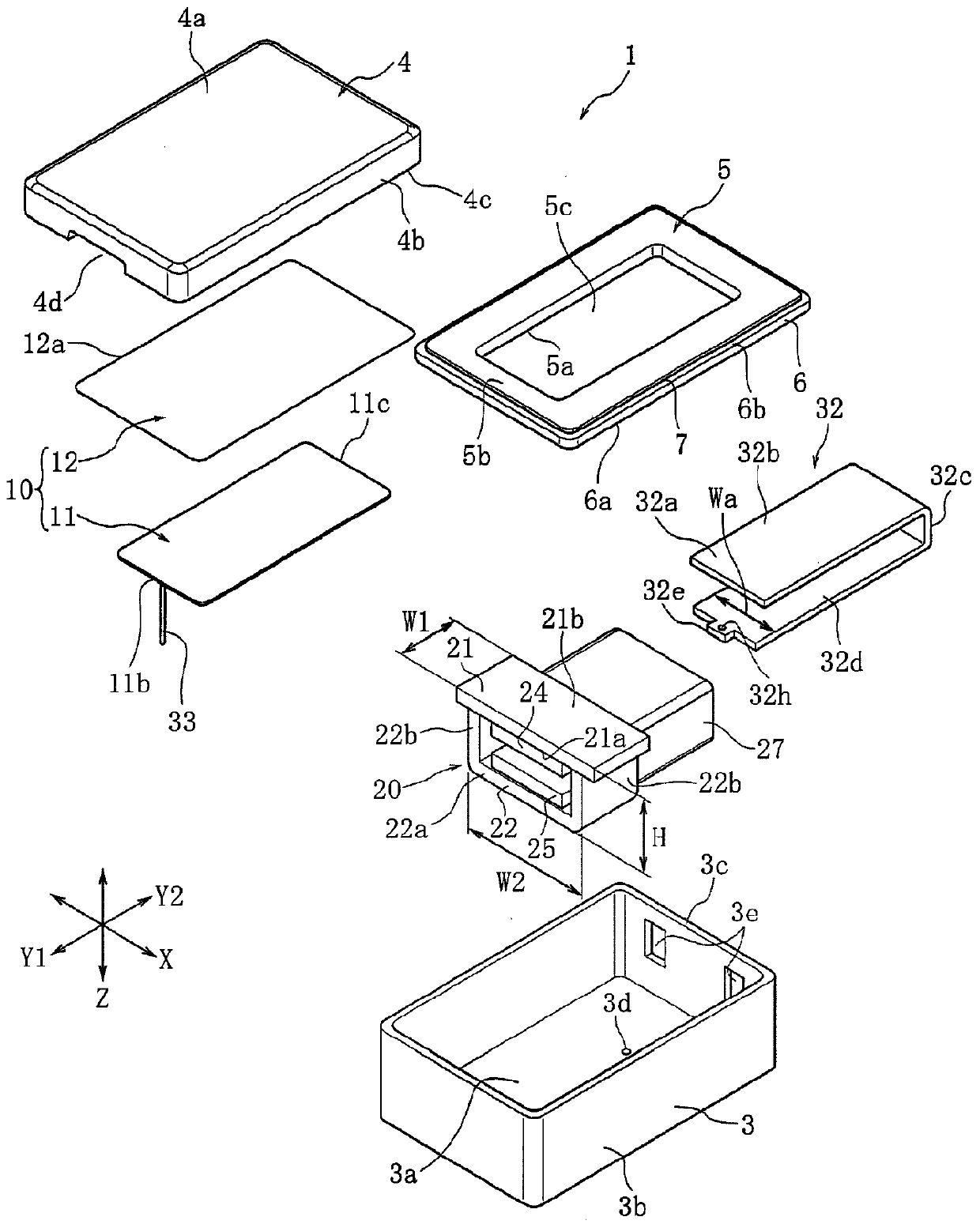

Horizontal-vibration linear motor of low magnetic leakage

InactiveCN104868689AAvoid Magnetic InterferenceReduce manufacturing costPropulsion systemsElectric machineEngineering

The invention provides a horizontal-vibration linear motor of low magnetic leakage. The motor comprises a casing, a cover plate, a vibration assembly and a solenoid, vibration assembly is hung inside the mounting space by being positioned via elastic support pieces positioned on the two opposite inner walls of the casing, and when the solenoid is electrified, the vibration assembly vibrates in a reciprocating manner in the direction basically parallel with the bottom of the casing, and the two elastic support pieces are stretched and compressed. The vibration assembly comprises a mass bock connected with the elastic support pieces and permanent magnets mounted on the mass block. A magnetic blocking plate covers the mass block in a fit manner and further covers the permanent magnets, the material of the magnetic blocking plate is No.430 stainless steel, and the thickness of the magnetic blocking plate ranges from 0.2 to 0.5mm. According to the horizontal-vibration linear motor of low magnetic leakage, the magnetic field intensity at the outer side of the magnetic blocking plate is controlled below 500GS, components of a mobile phone or game machine at the outer side of the magnetic blocking plate are prevented from interference of the magnetic field, the production cost is reduced, and the linear motor is conducive to production scale enlargement of domestic enterprises.

Owner:JINLONG MACHINERY & ELECTRONICS CO LTD

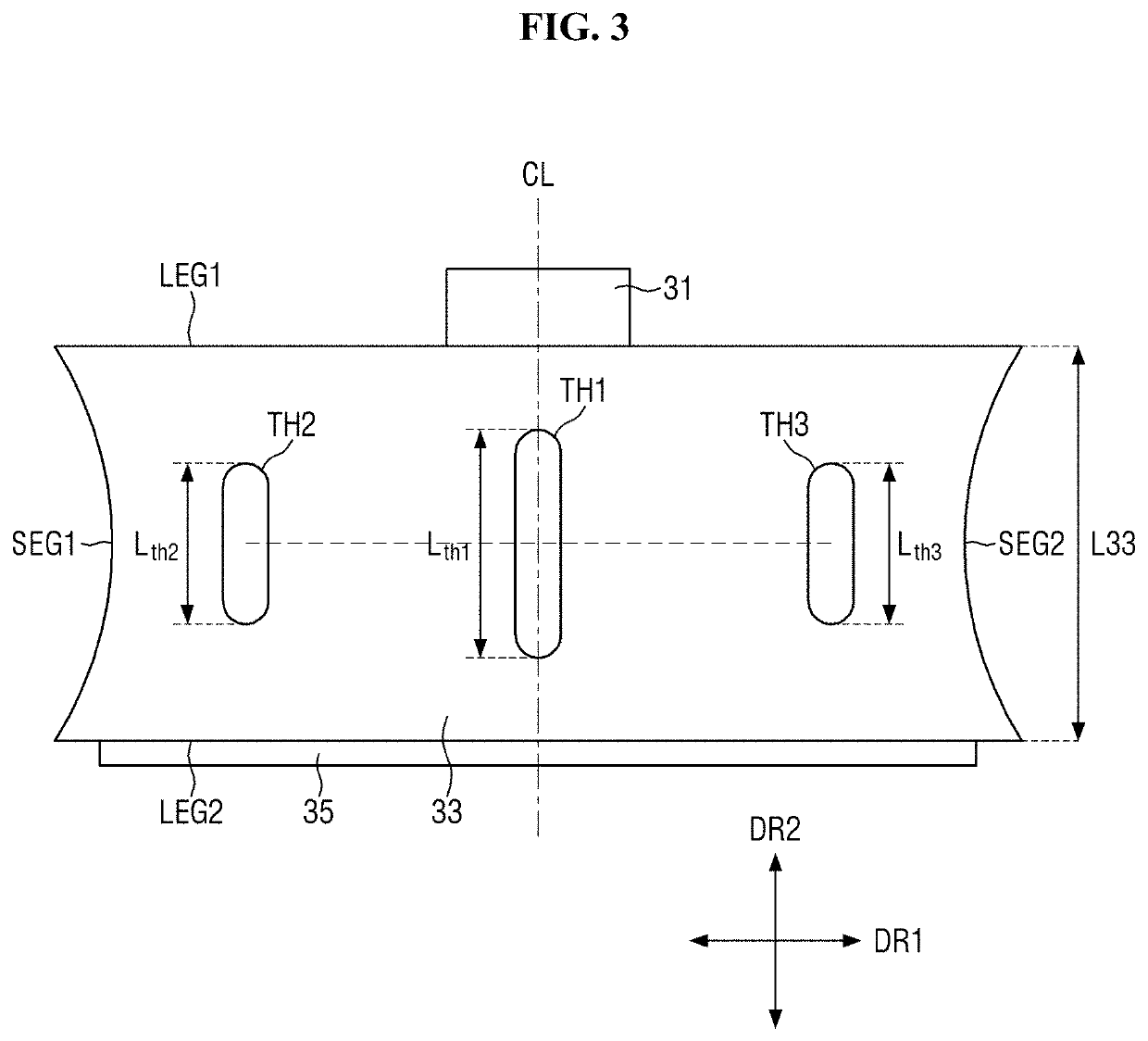

Ultrasonographic device

InactiveUS20070010744A1Easy to drivePromote generationUltrasonic/sonic/infrasonic diagnosticsMechanical vibrations separationUltrasound deviceTransmission amplitude

A small ultrasound diagnostic device is provided at a low cost that enables the appropriate control by a single power supply unit so as to give a predetermined transmission power to a driving waveform different for each mode without excess or deficiency and without affecting properties of the driving waveform. The ultrasound diagnostic device includes: an ultrasound generation unit (1) that transmits ultrasound; a waveform generation unit (2) that generates a single pulse or a burst pulse whose duty factor is variable in units of a time that is a period corresponding to a frequency outside a frequency band of the ultrasound generation unit (1) so as to drive the ultrasound generation unit (1); and a single power supply unit (3) that determines an amplitude of a driving waveform generated by the waveform generation unit (2). Thereby, an acoustic power of the transmitted ultrasound can be controlled without making the transmission amplitude variable.

Owner:KONICA MINOLTA INC

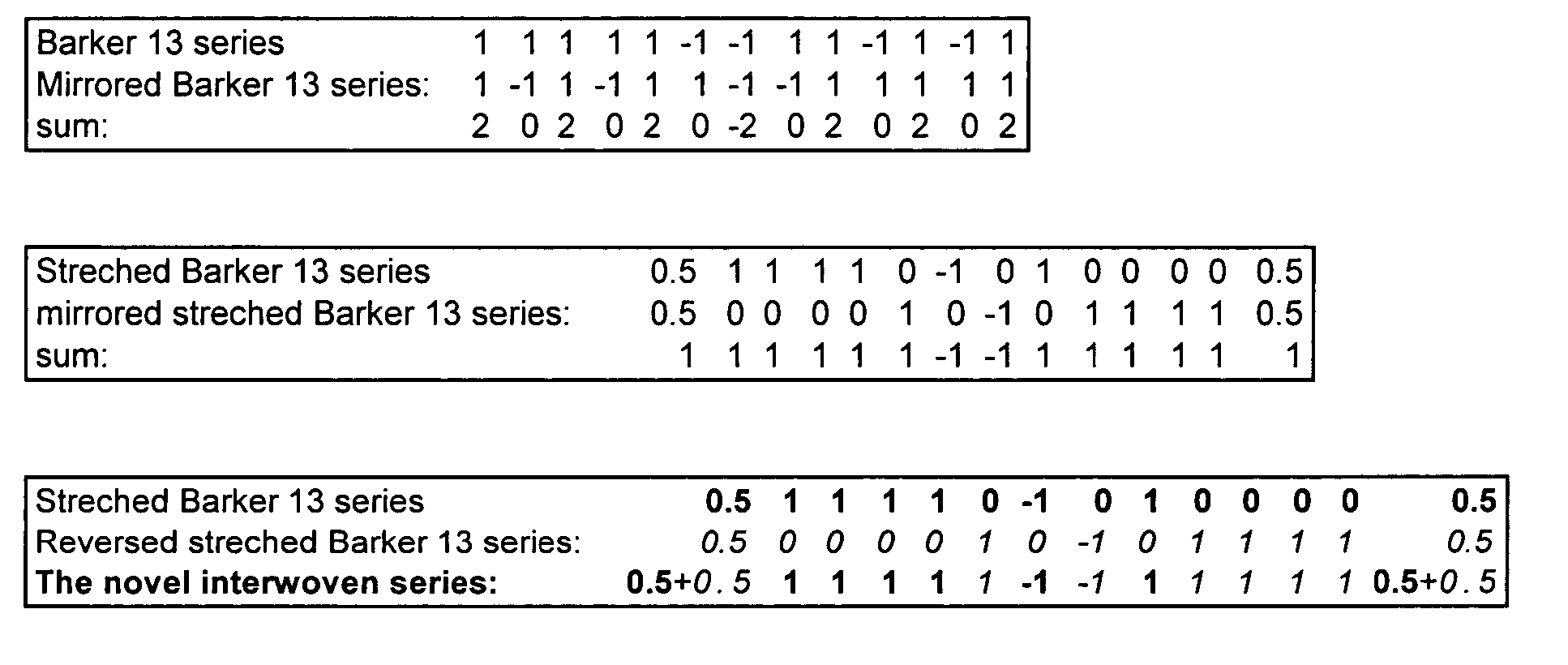

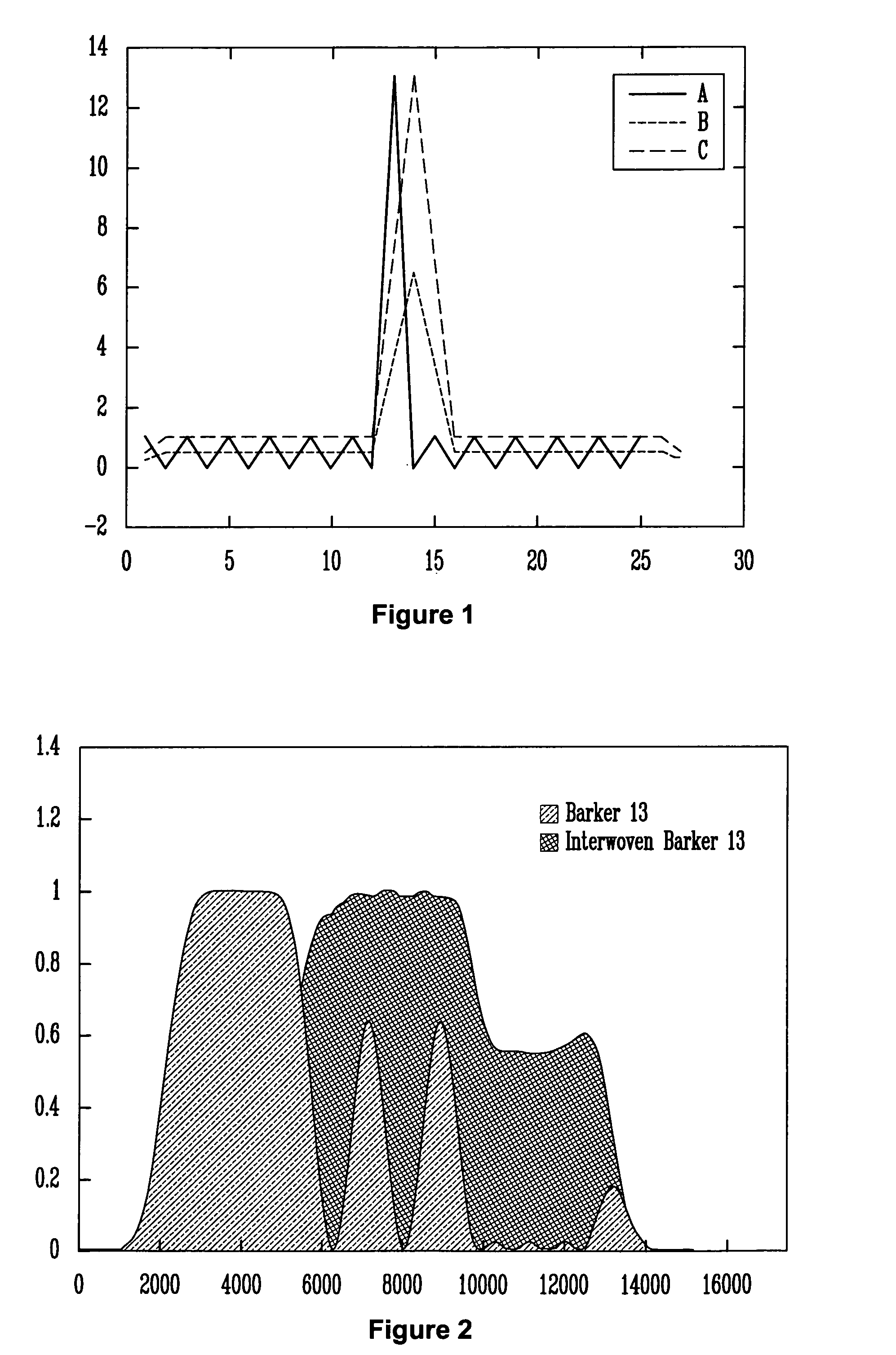

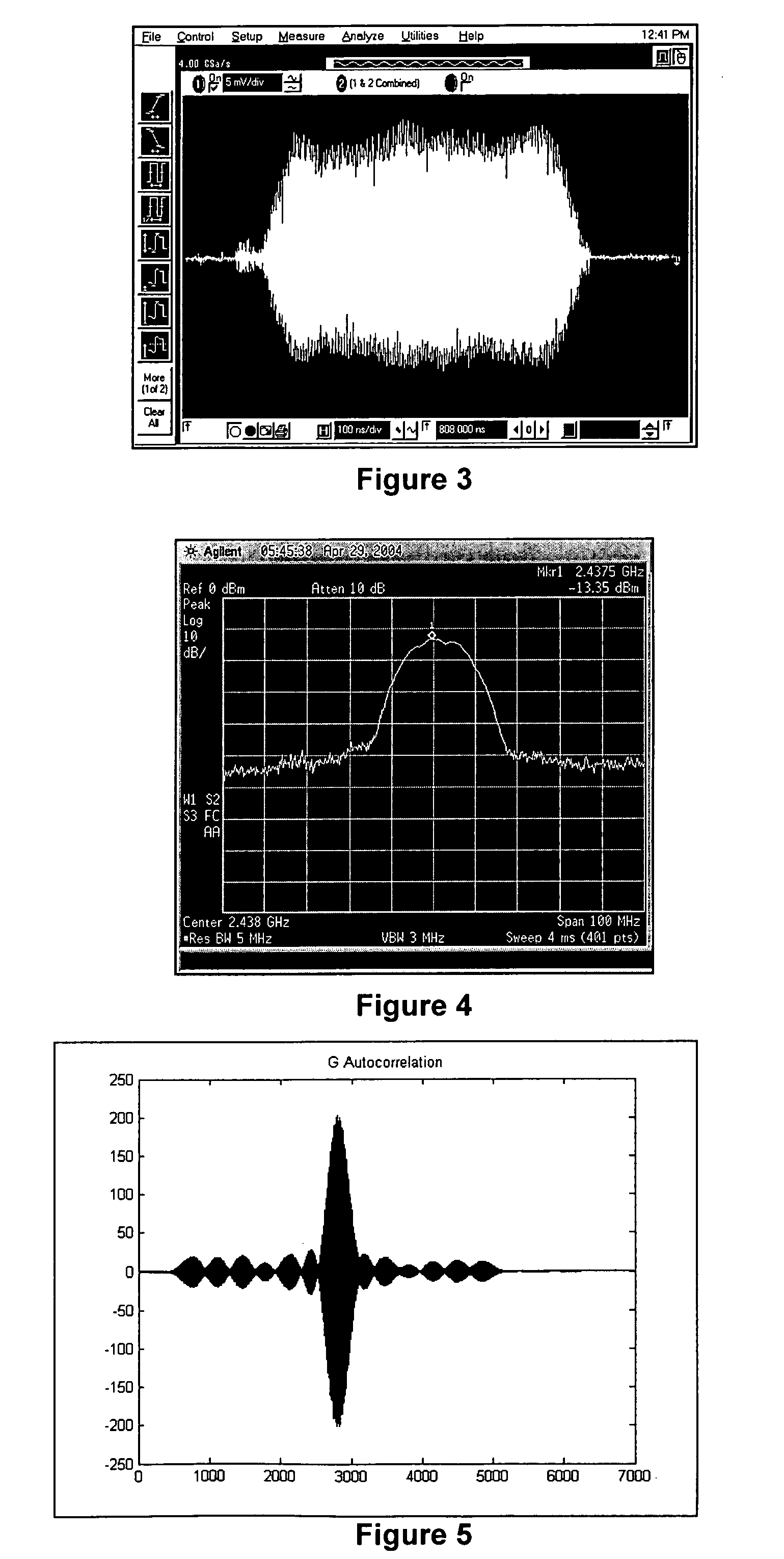

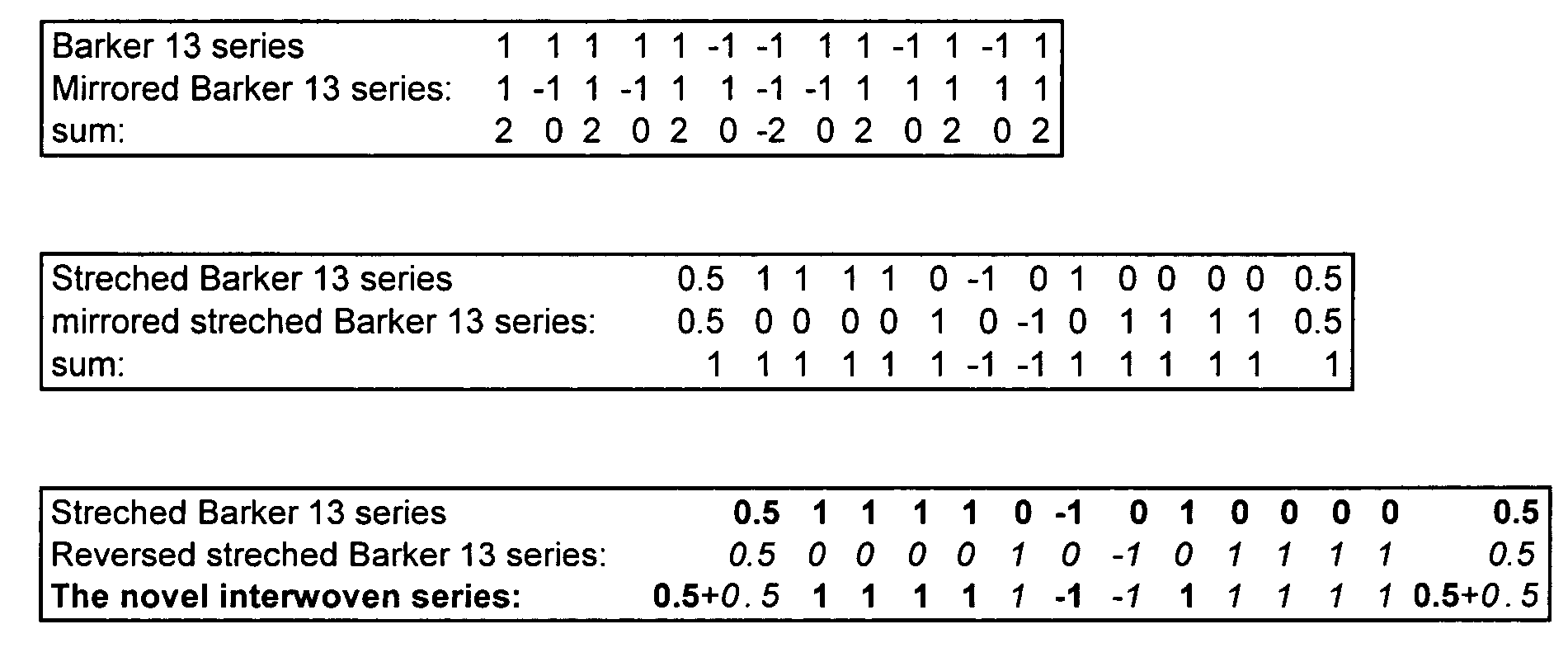

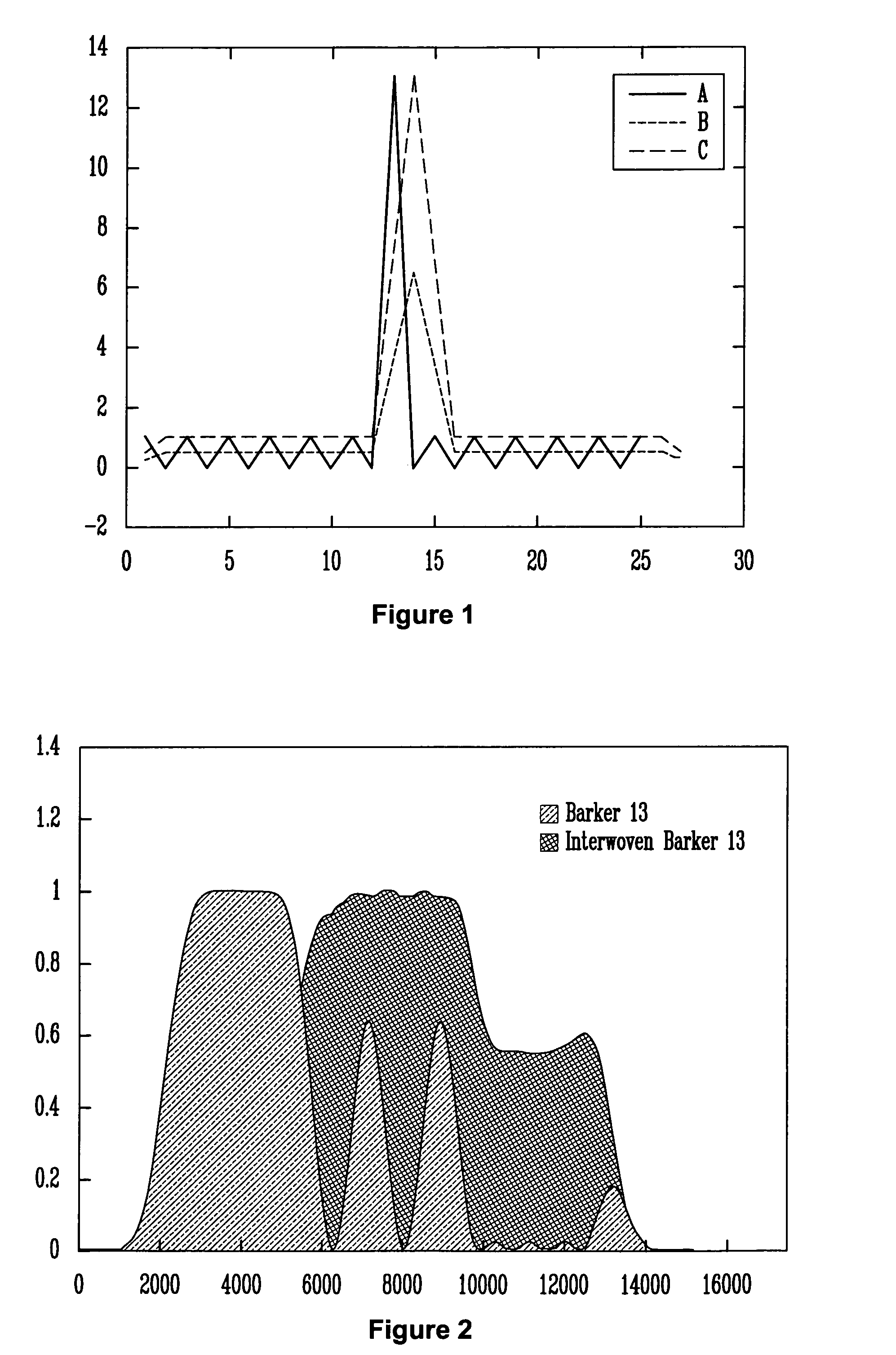

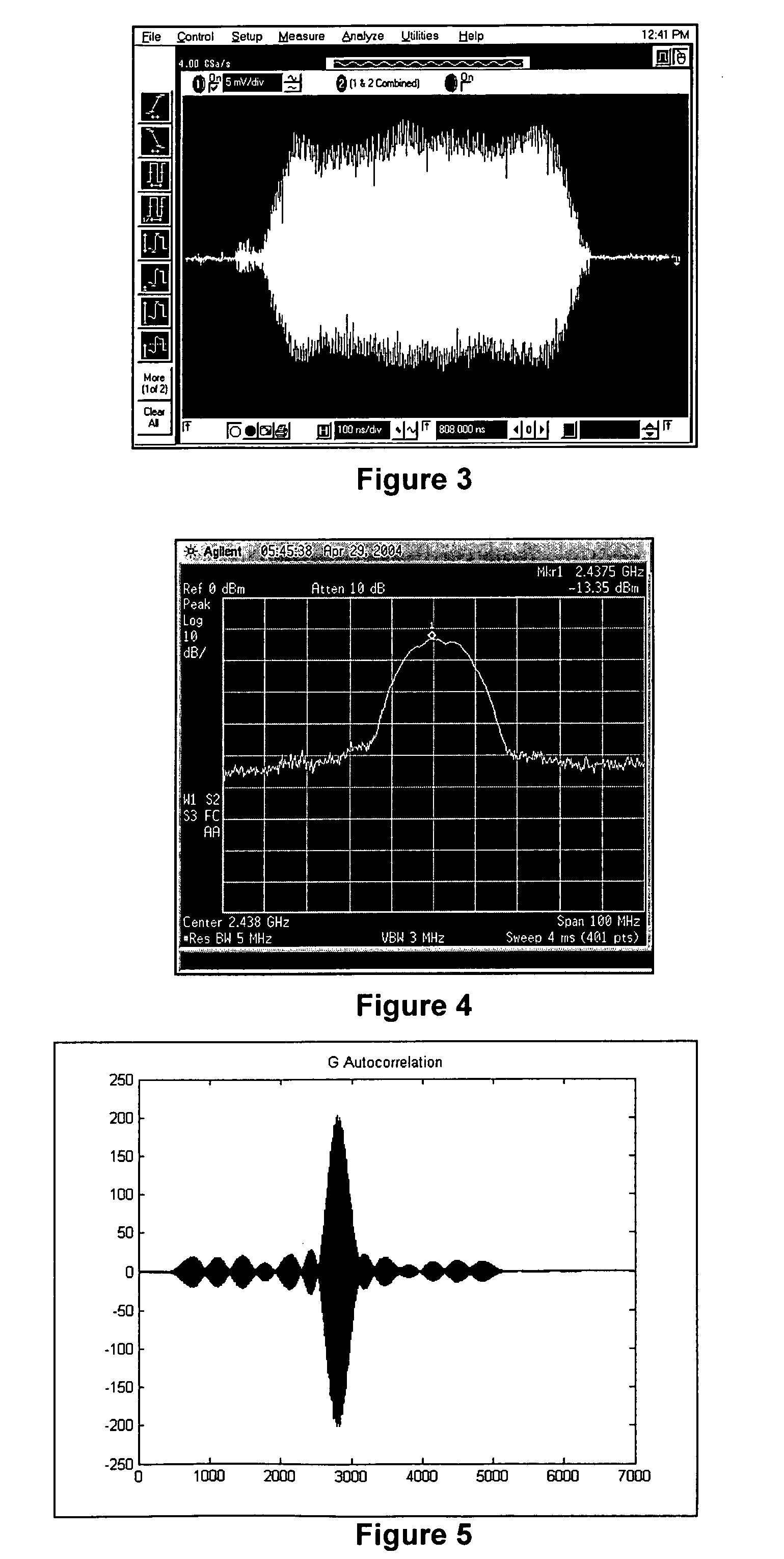

Method for interwoven spreading codes

InactiveUS20060171447A1Increased uniformity in amplitudeLimited bandwidthCode conversionCode division multiplexBarker codeComputer science

An interwoven spreading code is formed by a stretched spreading code series at a first frequency and a mirror of the stretched spreading code series at a second frequency. The interwoven spreading code can be used to spread a baseband signal. Data can be recovered through correlation of a received signal with the interwoven spreading code. The spreading code used in forming the interwoven spreading code can be a Barker code.

Owner:VISHAY INTERTECHNOLOGY INC

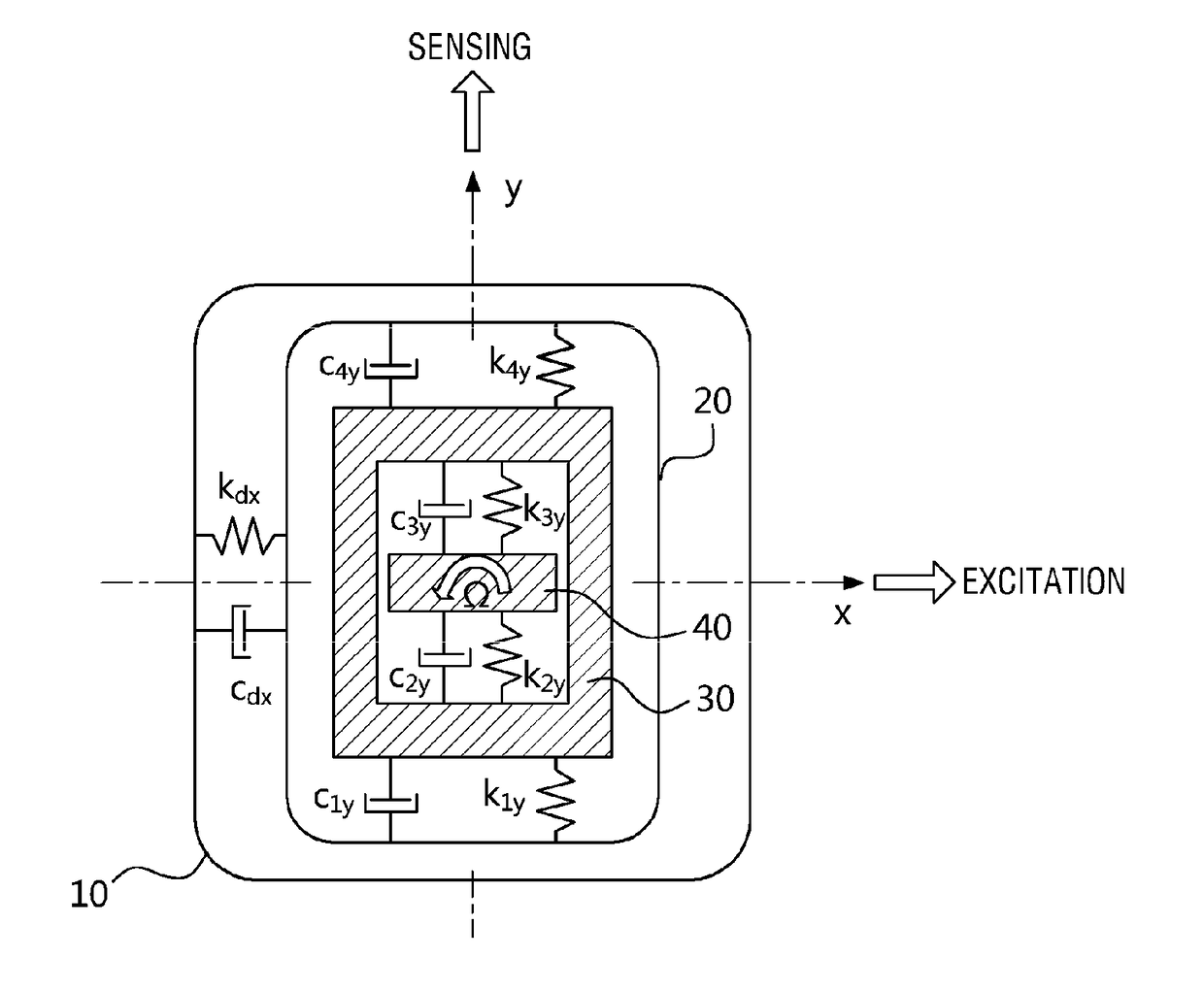

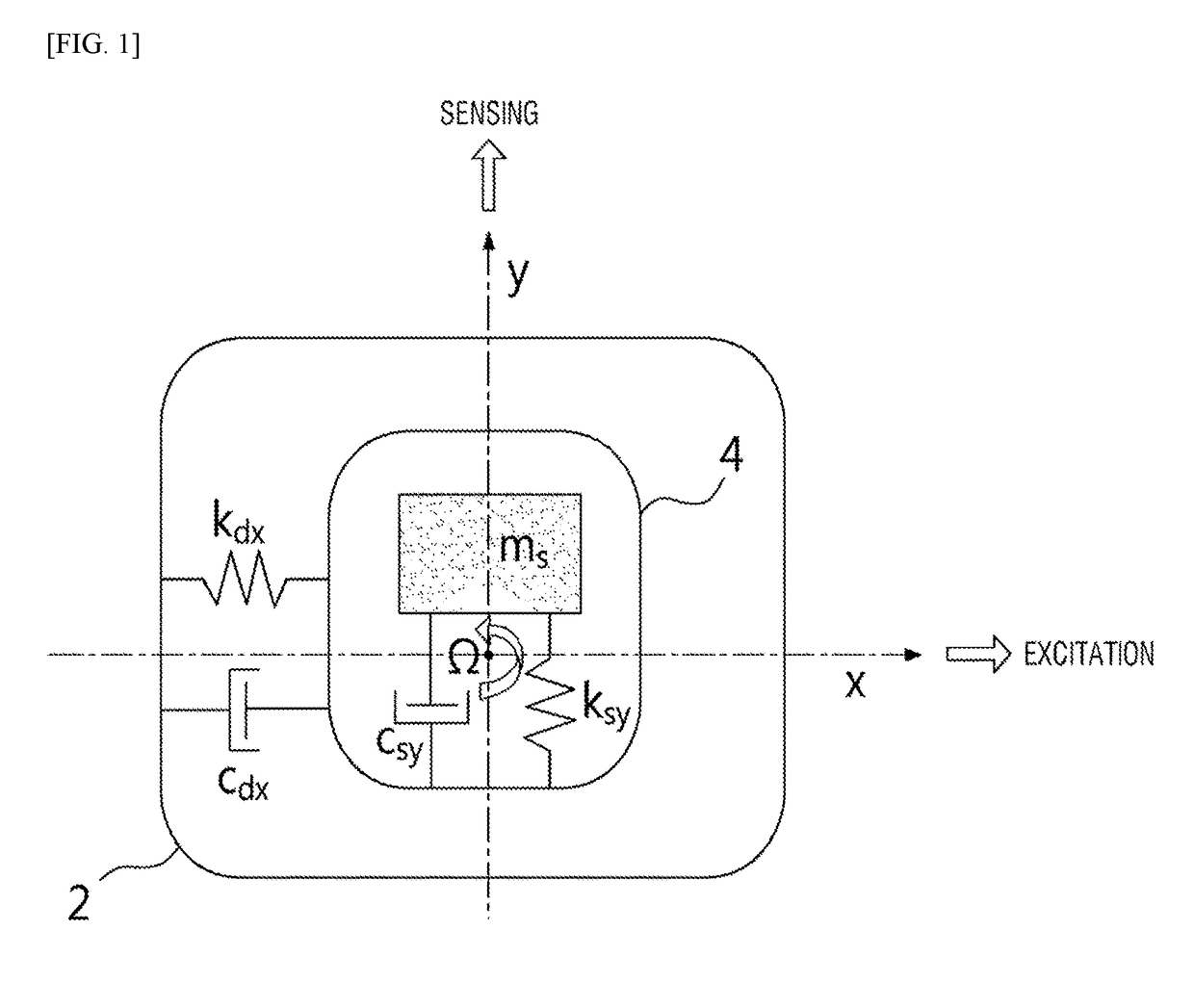

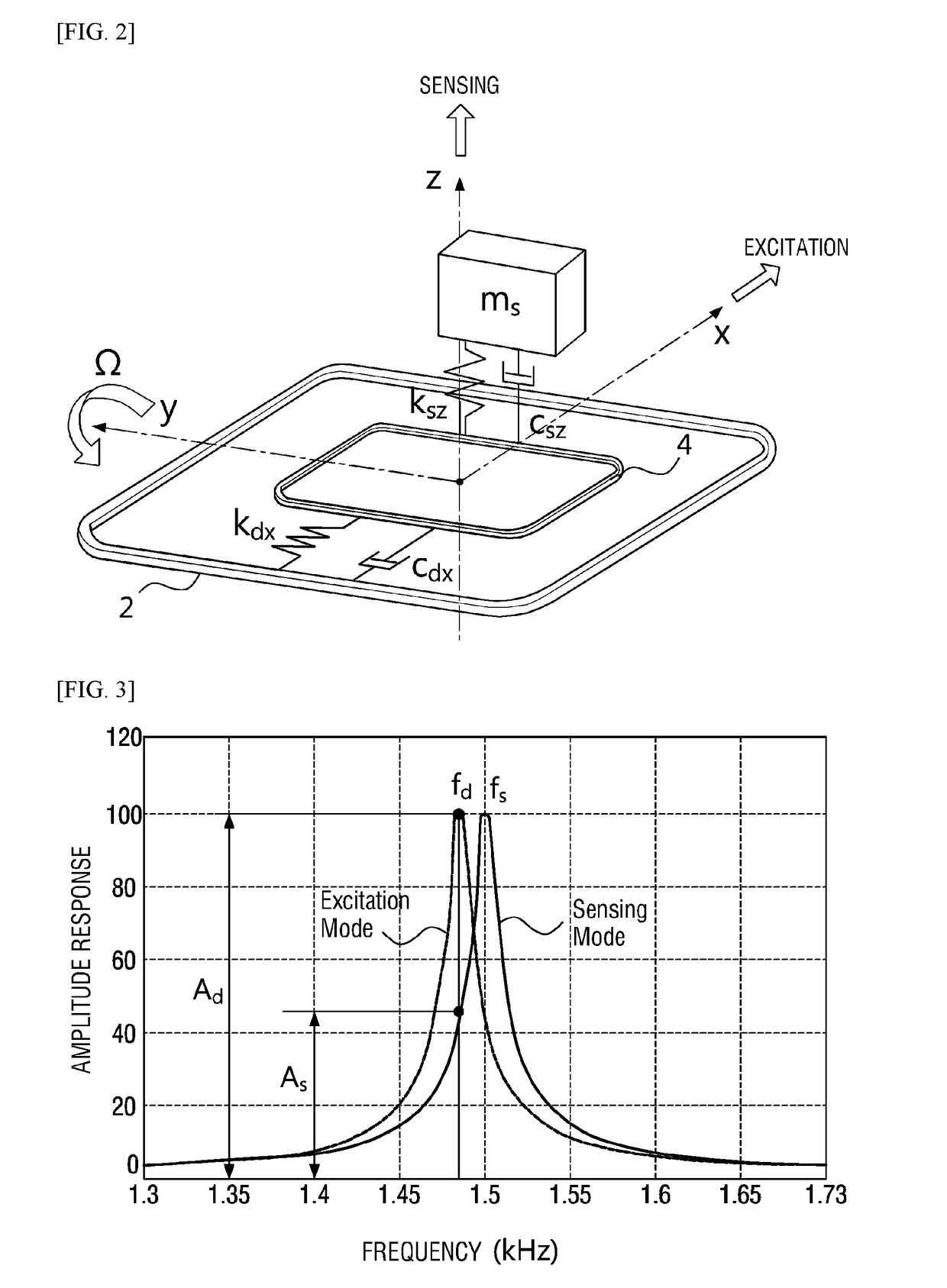

MEMS gyroscope having 2-degree-of-freedom sensing mode

InactiveUS20180135985A1Uniform amplitudeEasy to manufactureSpeed measurement using gyroscopic effectsPiezoelectric/electrostrictive devicesAngular velocityDegrees of freedom

A MEMS gyroscope including: a frame arranged parallel to a bottom wafer substrate; a sensor mass body excited at one degree of freedom in an excitation mode, and of which the displacement is sensed at two degrees of freedom by a Coriolis force in a sensing mode when an external angular velocity is input to the frame; and at least two sensing electrode for sensing a displacement of the sensor mass body, the displacement being sensed at the two degrees of freedom, wherein the sensor mass body comprises an inner mass body and an outer mass body surrounding the inner mass body, the outer mass body and the frame are connected by a first support spring, and the outer mass body and the inner mass body are connected by a second support spring.

Owner:SHIN SUNG C&T

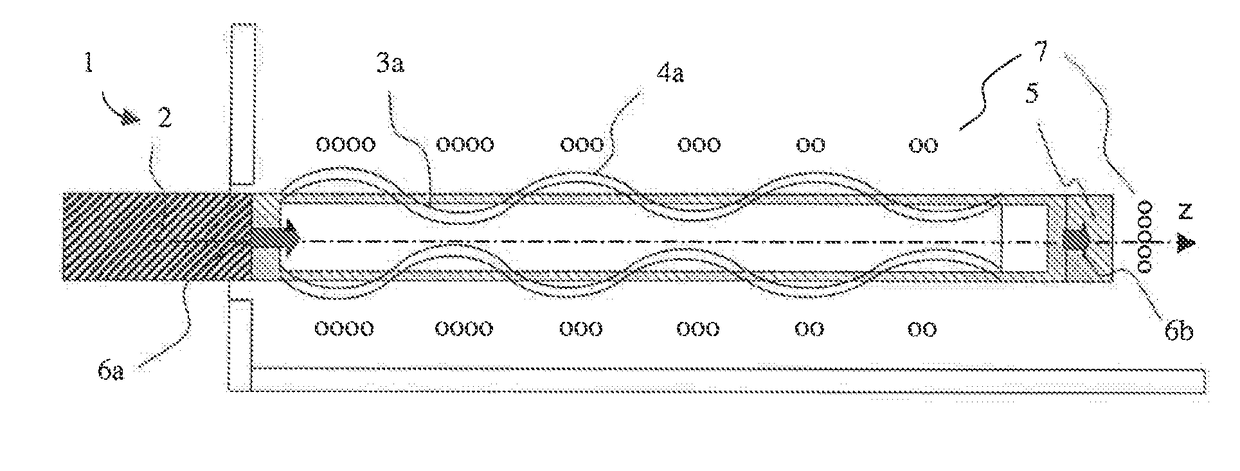

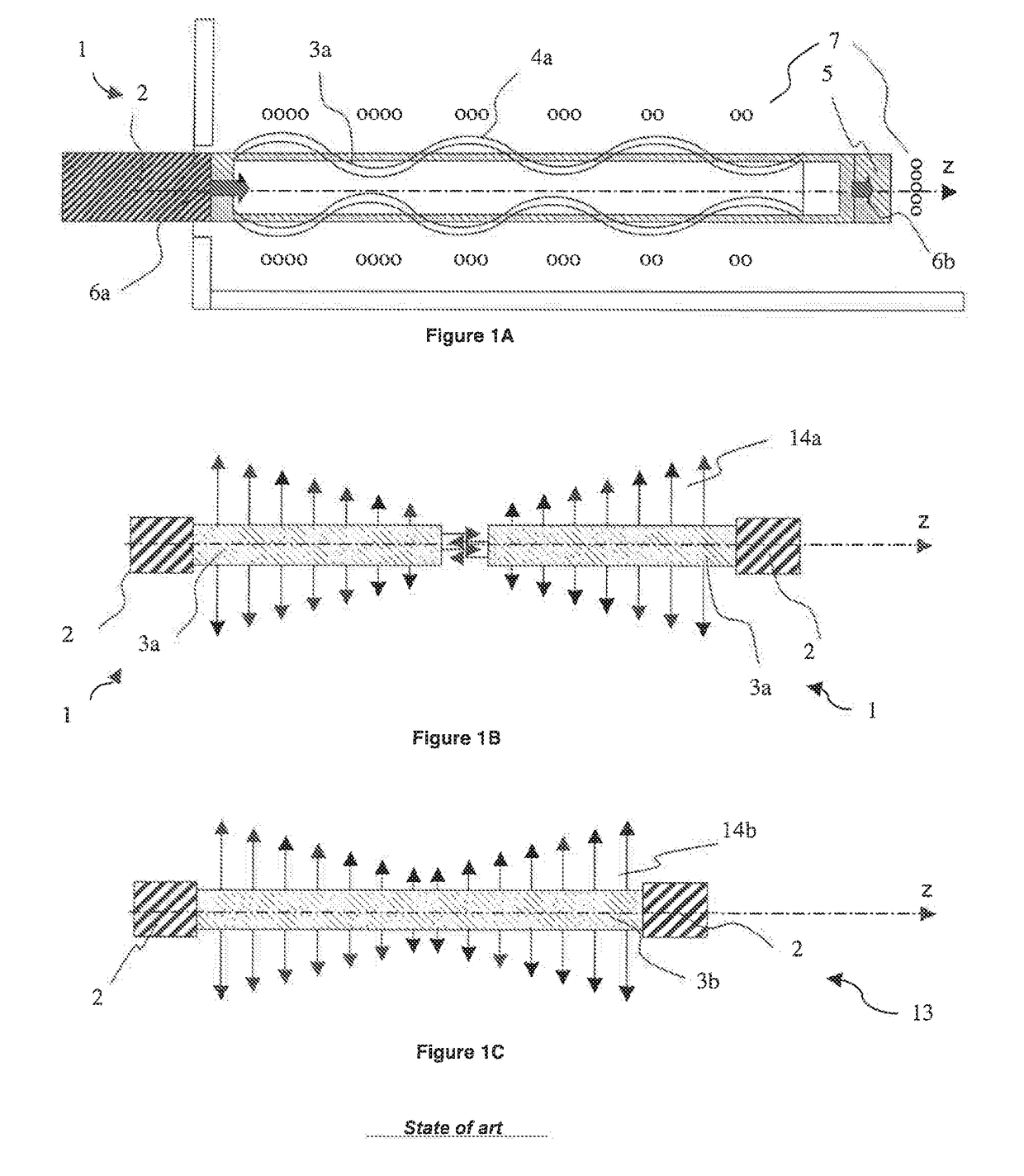

Modular, submersible ultrasonic tubular transducer

ActiveUS20170341109A1Big vibrationUniform amplitudePiezoelectric/electrostrictive resonant transducersMechanical vibrations separationUltrasonic sensorPre stress

The ultrasonic tubular transducer is activated at the centre thereof by two symmetrical electromechanical converters. The vibration generated by the two electromechanical converters is converted and then transmitted to the tube via a coupler. The ultrasonic transducer can be vibrationally isolated from the interfaces thereof by caps equally suitable for connecting the transducer to a stationary frame, a free end or another similar ultrasonic transducer. A device for pre-stressing electromechanical converters has a hole bored at the centre thereof in order to allow cables from the transducer as well as from adjacent transducers to pass therethrough.

Owner:CEDRAT TECH

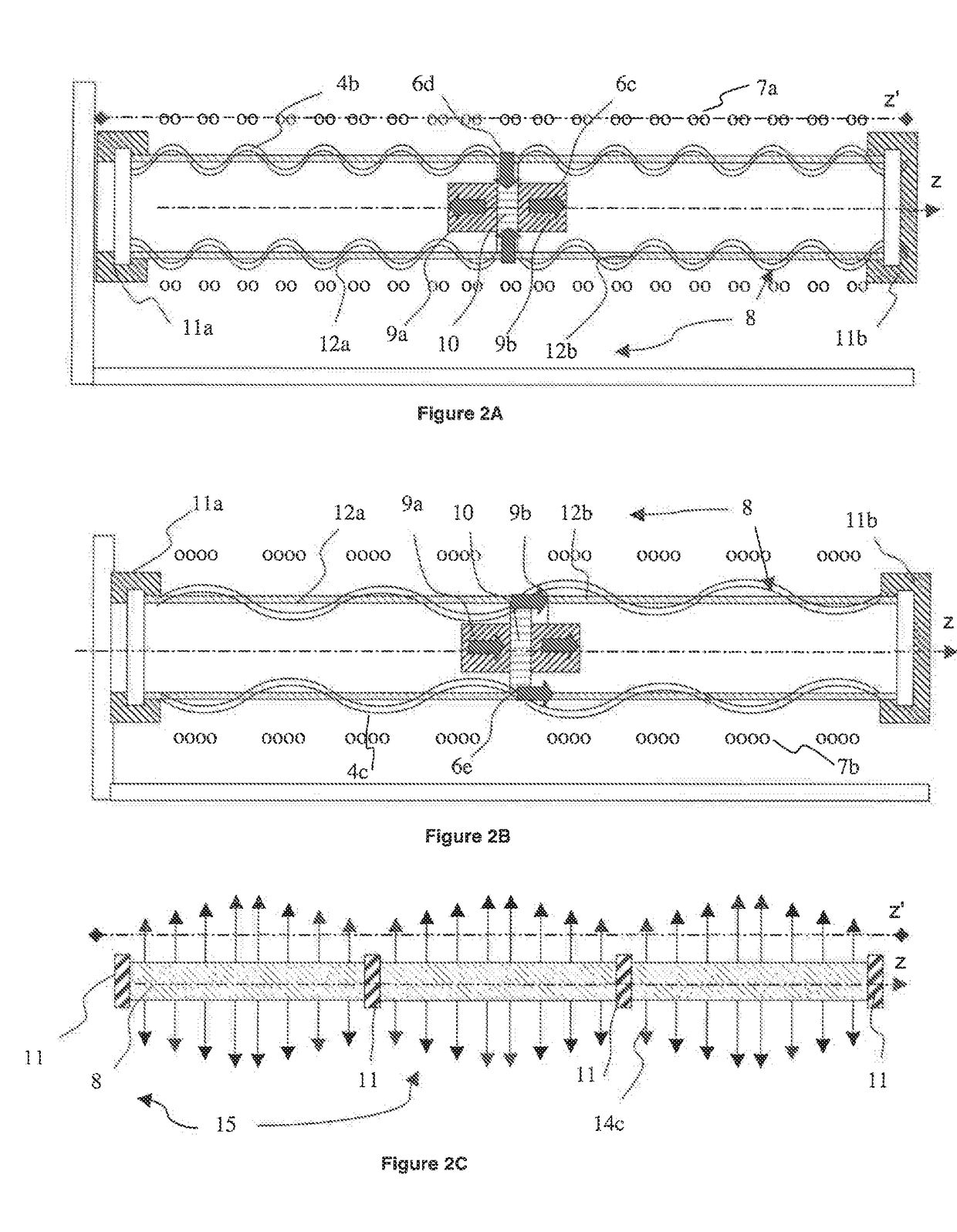

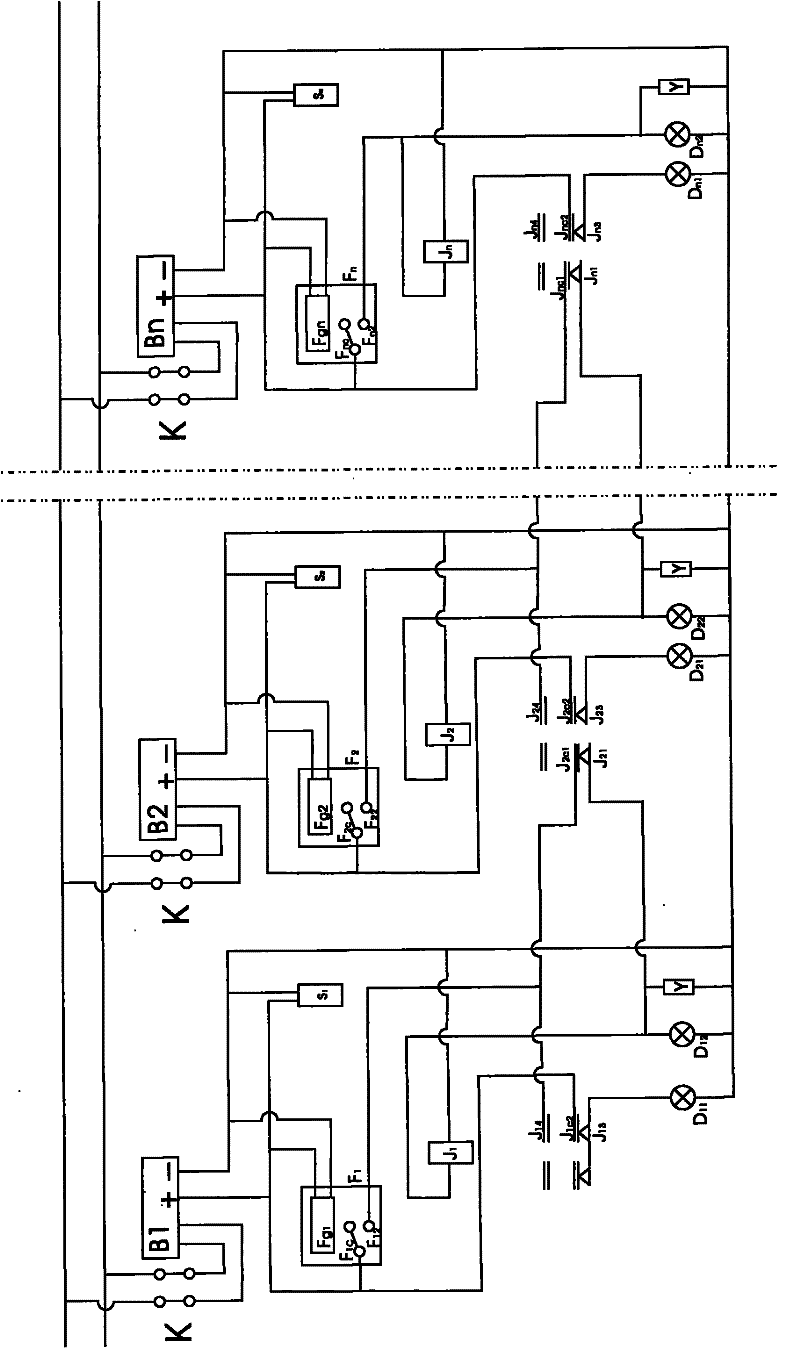

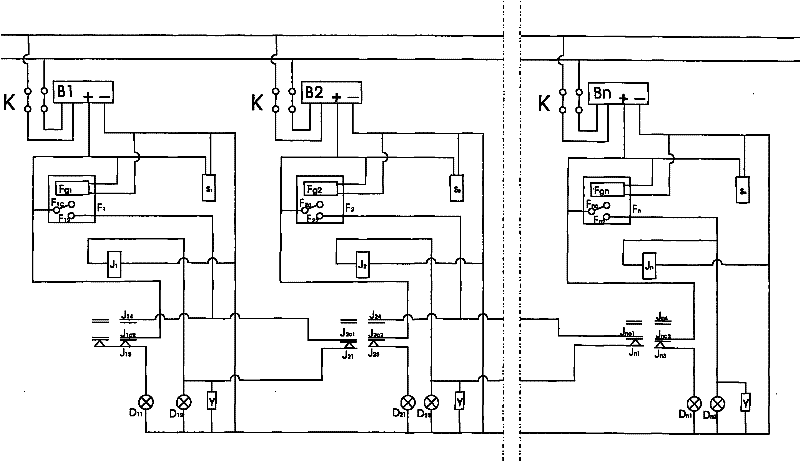

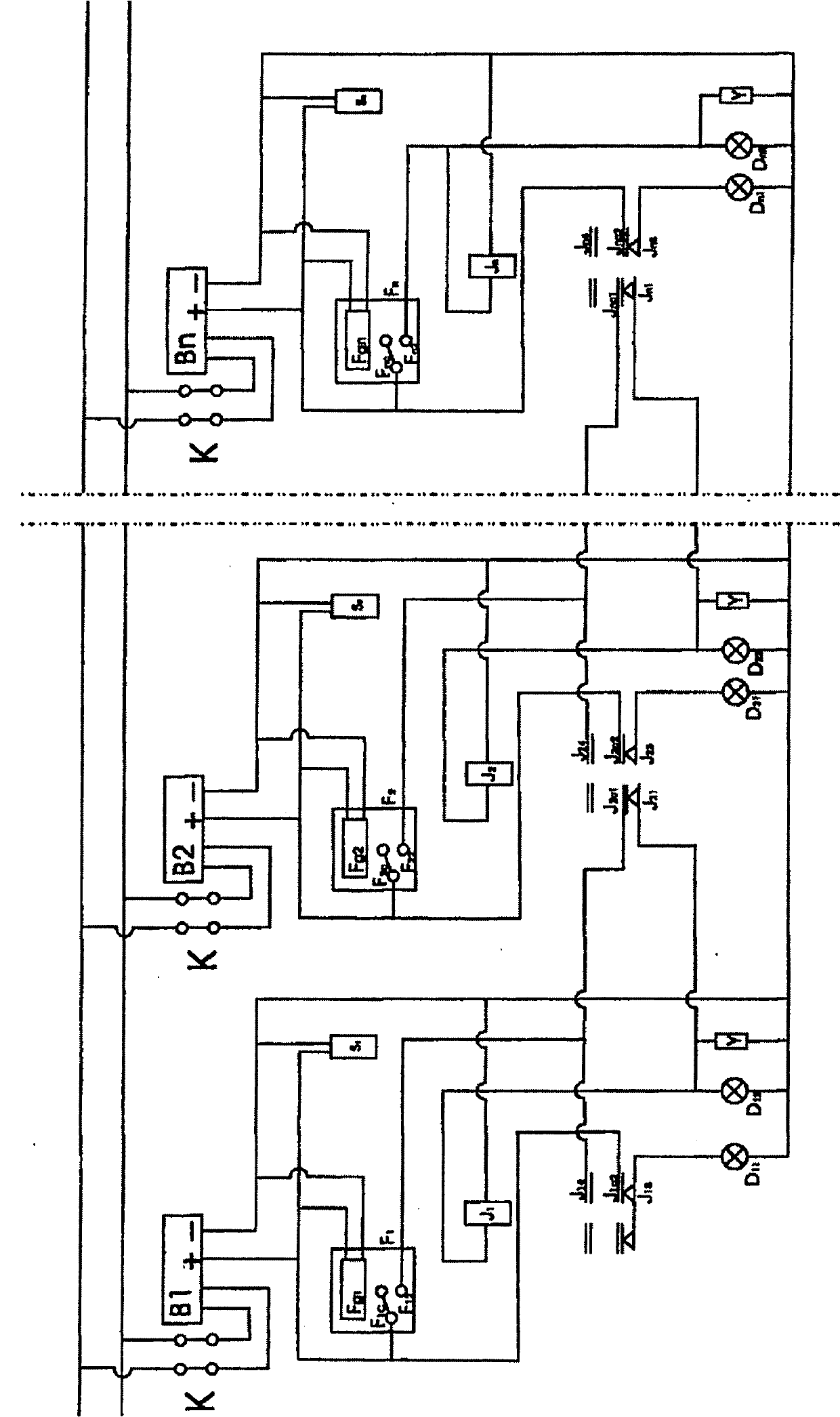

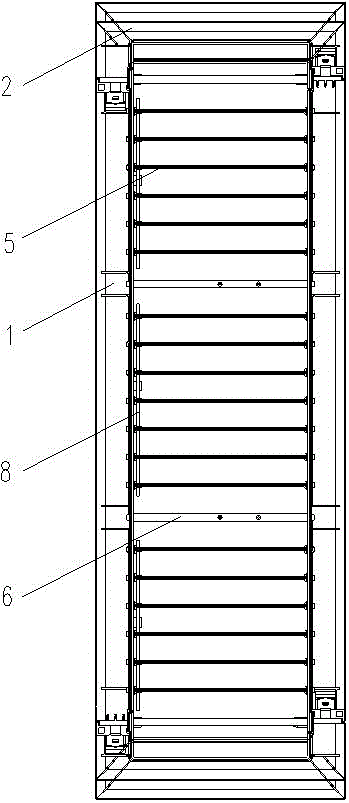

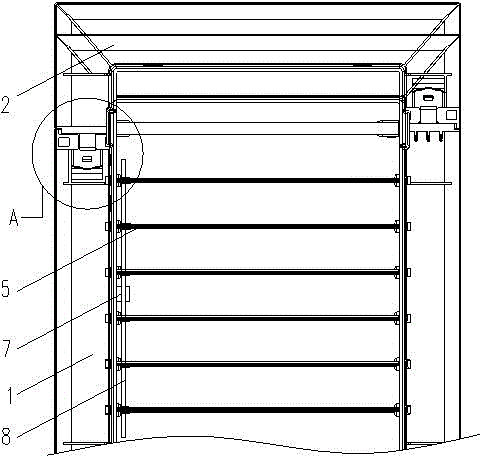

Anti-collision circuit for automobiles travelling in foggy roads and devices thereof

InactiveCN102194329AAvoid rear-end traffic accidentsAvoid damageArrangements for variable traffic instructionsAnti-collision systemsRear-end collisionVisibility

The invention relates to an anti-collision circuit for automobiles travelling in foggy roads and devices thereof, wherein the circuit consists of a plurality of groups of circuits which are composed of safety switches, transformers, far infrared emitters, far infrared receivers, relays, green lights and red lights; and the devices consist of upright columns (1), lamp brackets (2), lamp holders (3) and electrical boxes (4), and the interval and the number of the devices are determined according to local climatic conditions and visibility in the foggy weather. The invention has the advantages that automobiles traveling on foggy roads are uniformly spaced, thus the automobiles are prevented from suffering from traffic accidents, i.e. rear-end collisions; and the anti-collision circuit and the devices thereof disclosed by the invention are also suitable for uniformly-spaced traveling of automobiles on a bridge floor, the carrying capacity, and the vibration frequency and the amplitude of vibration of the bridge floor are uniformed and no crowding of the automobiles on the bridge floor is ensured, so that the damage to a bridge is prevented and the service life of the bridge is prolonged.

Owner:胡延节

Foggy road vehicle anti-collision circuit and devices thereof

InactiveCN104200706AAvoid rear-end traffic accidentsAvoid damageAnti-collision systemsVisibilityRear-end collision

Disclosed are a foggy road vehicle anti-collision circuit and devices thereof. The foggy road vehicle anti-collision circuit is composed of various circuits formed by safety switches, transformers, far infrared emitters, far infrared receivers, relays, green lights and red lights, the devices are composed of stand columns (1), light holders (2), light bases (3) and electric appliance boxes (4), and spacing distance and numbers of the devices are determined according to local climatic conditions and visibility of foggy days. The foggy road vehicle anti-collision circuit and the devices thereof have the advantages that road vehicles on foggy days can travel at equal intervals, road accidents of vehicle rear-end collision can be prevented, the foggy road vehicle anti-collision circuit and the devices thereof are also suitable for traveling of bridge road vehicles at equal intervals, bridge road carrying capacity, vibration frequency and amplitude are uniform, bridge road vehicles can be prevented from being jammed, damages to a bridge can be prevented, and the service life of the bridge can be prolonged.

Owner:胡延节

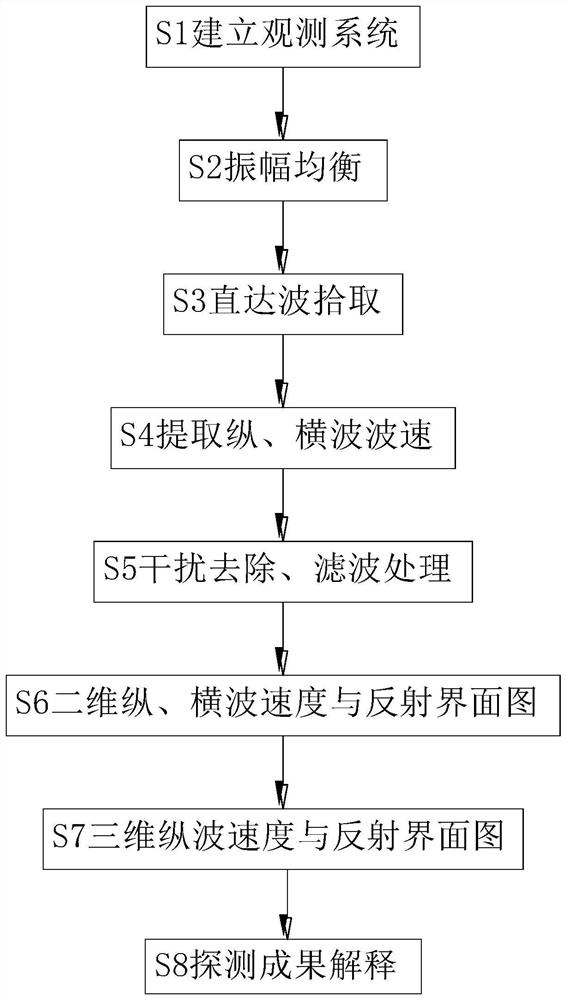

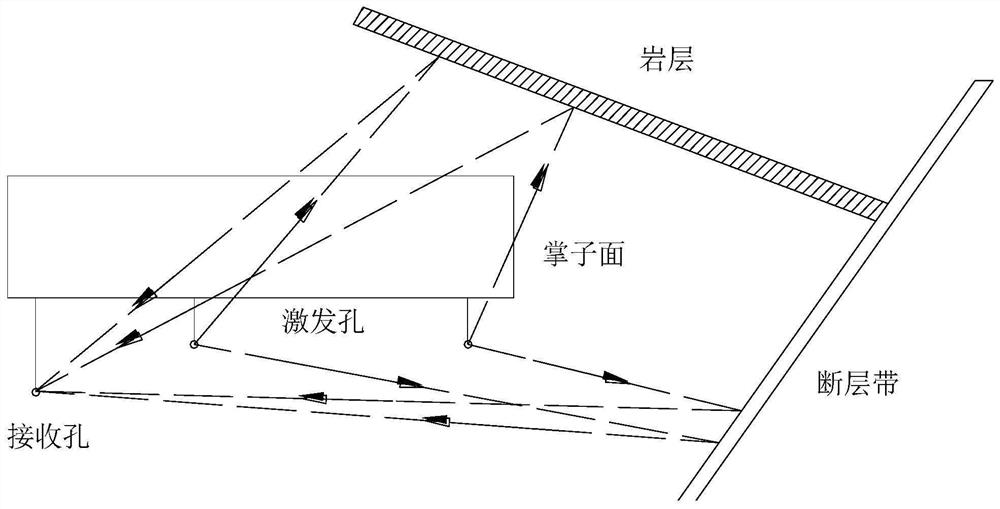

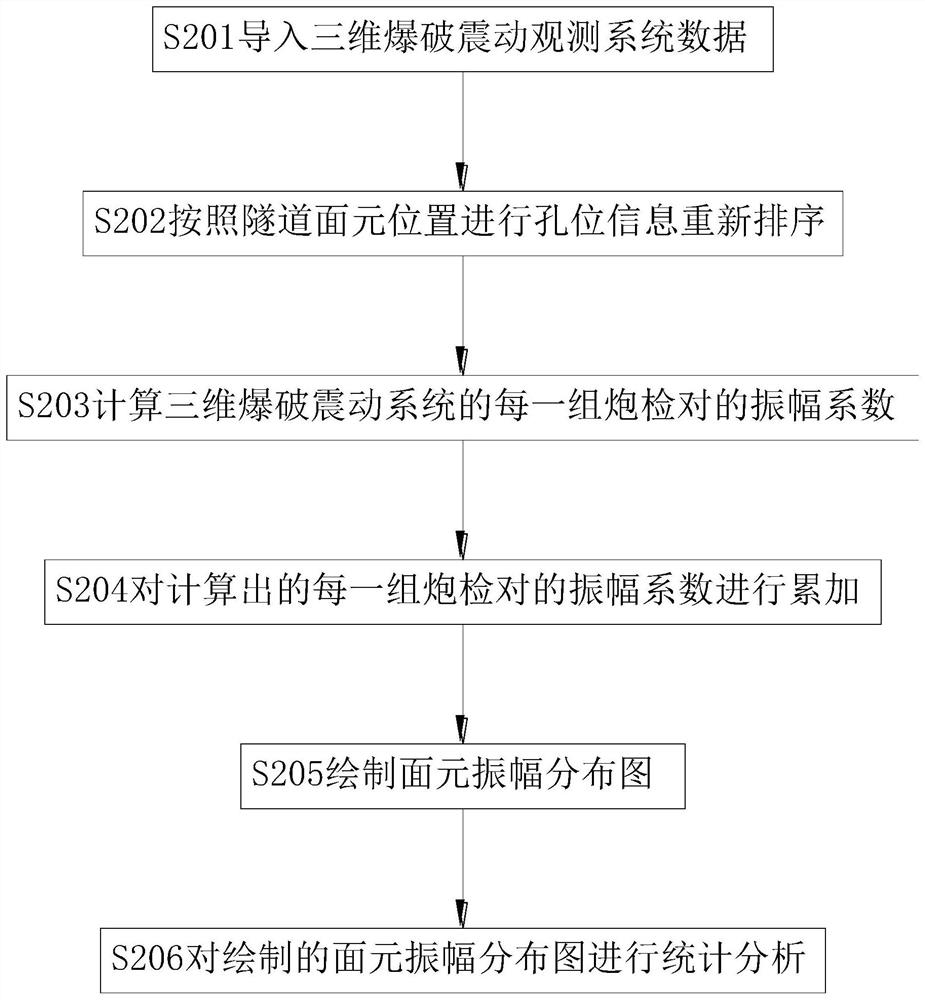

Three-dimensional three-component advanced refined geological prediction method

InactiveCN111929728AUniform amplitudeGuaranteed Seismic SignalSeismic signal processingObservation systemMechanical engineering

The invention discloses a three-dimensional three-component advanced refined geological prediction method. The invention belongs to the technical field of tunnel engineering. The method comprises thesteps of establishing an observation system, performing amplitude equalization and direct wave pickup, then extracting longitudinal and transverse wave velocities, and carrying out interference removal and filtering processing; preparing a two-dimensional longitudinal and transverse wave velocity and reflection interface diagram and a three-dimensional longitudinal wave velocity and reflection interface diagram; and finally, explaining a detection result, wherein polymer gel is used as a coupling agent; an orifice is blocked by a high-absorption attenuation material, interference wave can be suppressed, seismic wave signals are secured, meanwhile, a loop open-circuit triggering timing mode is adopted; the loop is bound on a seismic source; when the seismic source explodes to generate vibration propagation, the loop is exploded to trigger collection, there is no relation with detonator delay in the explosion generation process, trigger time errors basically do not exist under the condition that the bound loop does not fall off the seismic source, and through two-dimensional and three-dimensional refined geological prediction, the effects of tunnel dynamic design construction and cost saving can be achieved.

Owner:高军

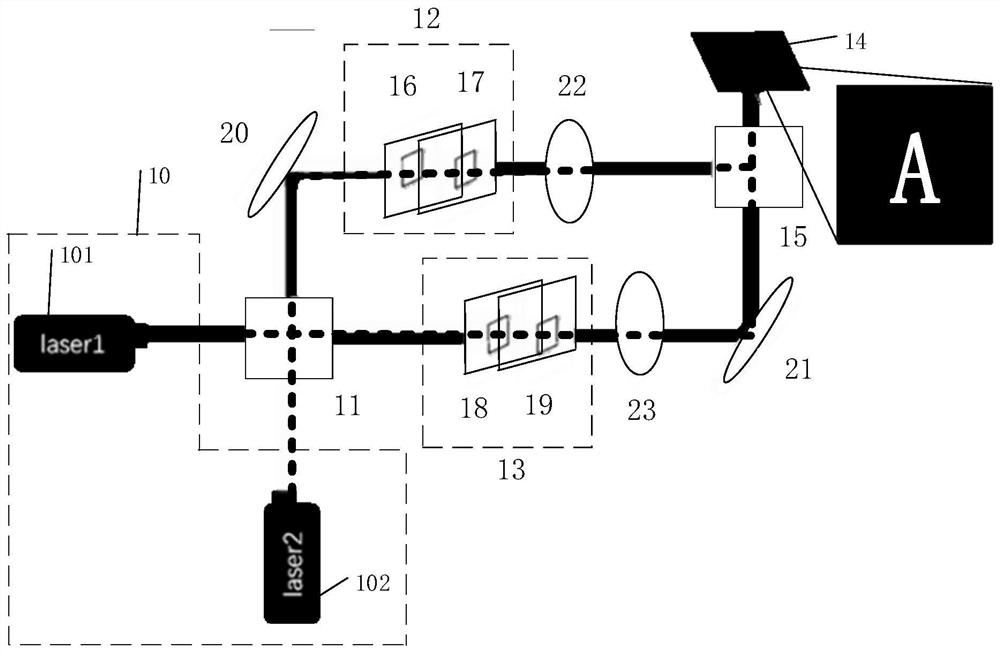

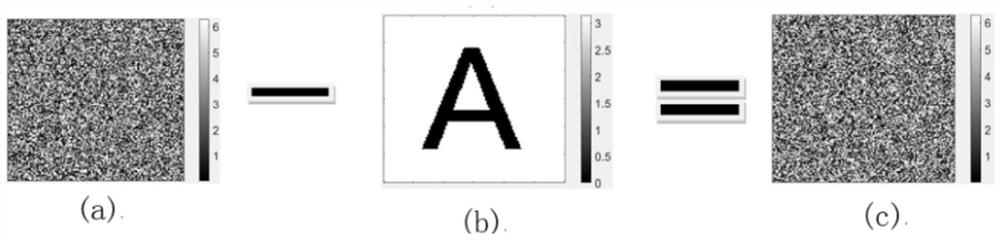

Image decryption method

ActiveCN111929926AUniform amplitudeImprove image qualityNon-linear opticsReference imageComputer science

The application belongs to the technical field of metasurface application, and provides an image decryption method, the image decryption method is applied to an image decryption system, and the imagedecryption system comprises a preset light source, a first phase change material metasurface group and a second phase change material metasurface group; a first sub-laser is controlled to be incidentto the first phase change material metasurface group, and a second sub-laser is controlled to be incident to the second phase change material metasurface group; the first sub-laser is modulated by reference image information to generate first modulated light, and the first modulated light is emitted from the first phase change material metasurface group and then focused to an imaging area; the second sub-laser is modulated by the reference image information to generate second modulated light, and the second modulated light is emitted from the second phase change material metasurface group andthen focused to the imaging area; and the encrypted information in the imaging area is obtained according to interference signals generated by the first modulated light and the second modulated light.According to the embodiment of the invention, the problem that the encrypted information obtained by decryption is missing or unclear is solved.

Owner:SHENZHEN UNIV

Method for interwoven spreading codes

InactiveUS7394845B2Uniform amplitudeHigh energyCode conversionCode division multiplexBarker codeComputer science

An interwoven spreading code is formed by a stretched spreading code series at a first frequency and a mirror of the stretched spreading code series at a second frequency. The interwoven spreading code can be used to spread a baseband signal. Data can be recovered through correlation of a received signal with the interwoven spreading code. The spreading code used in forming the interwoven spreading code can be a Barker code.

Owner:VISHAY INTERTECHNOLOGY INC

Randomly spliced air port and production method thereof

InactiveCN105135649AIncrease rotational resistanceUniform amplitudeAir-flow control membersGratingEngineering

The invention discloses a randomly spliced air port which comprises two main frames. The main frames are connected with concave side frames through buckles. An auxiliary buckle and a main buckle are installed on the main frames respectively; and an auxiliary buckle and a main buckle are installed on the concave side frames respectively. Air grating blades and supporting rods are installed between the two main frames, damping blocks are installed on the main frames, and linkage strips are installed on the damping blocks and connected with the air grating blade. Therefore, an air grating can be randomly spliced, the damping blocks can increase rotating resistance of the air grating blades, and the linkage strips make the range of the air grating blades consistent and uniform.

Owner:倪丹

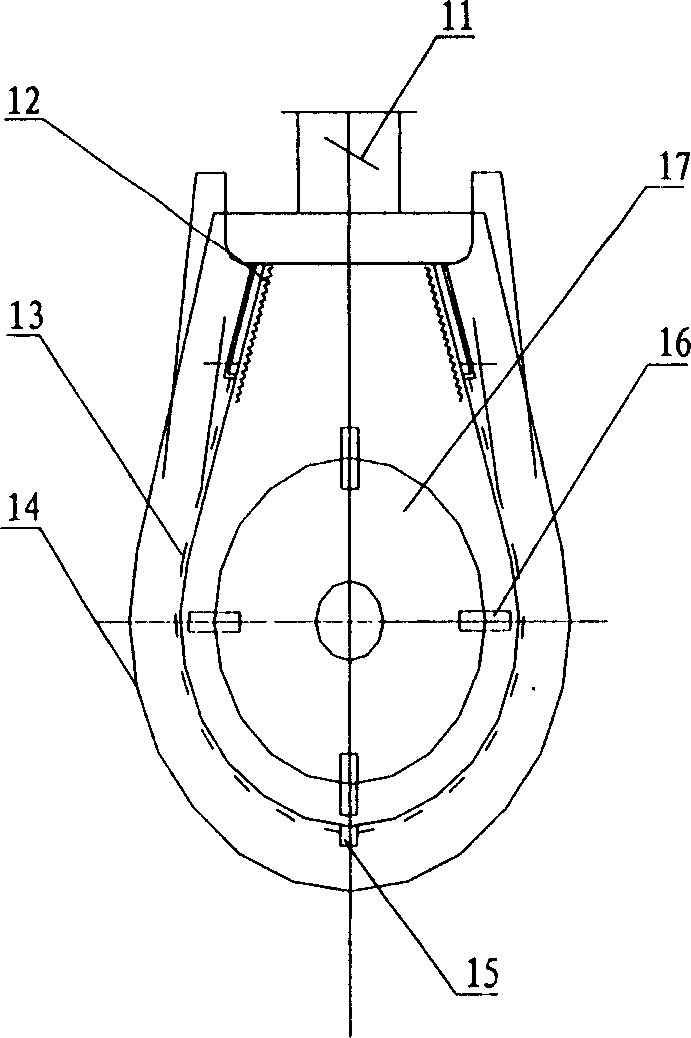

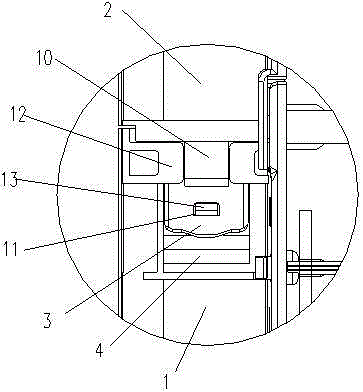

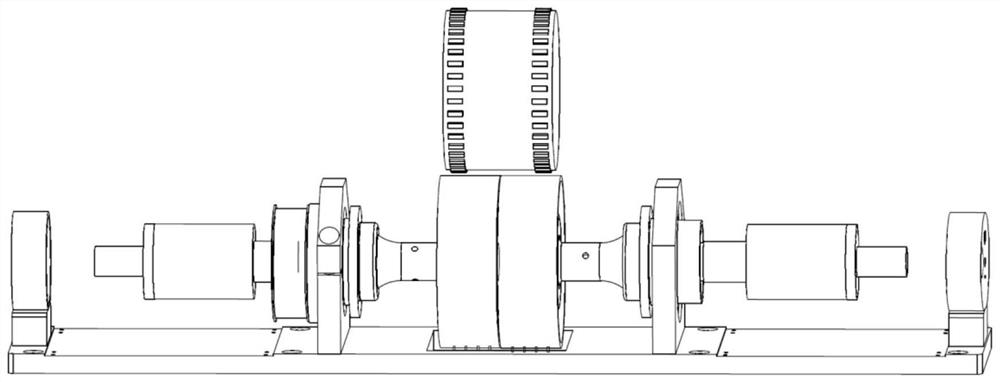

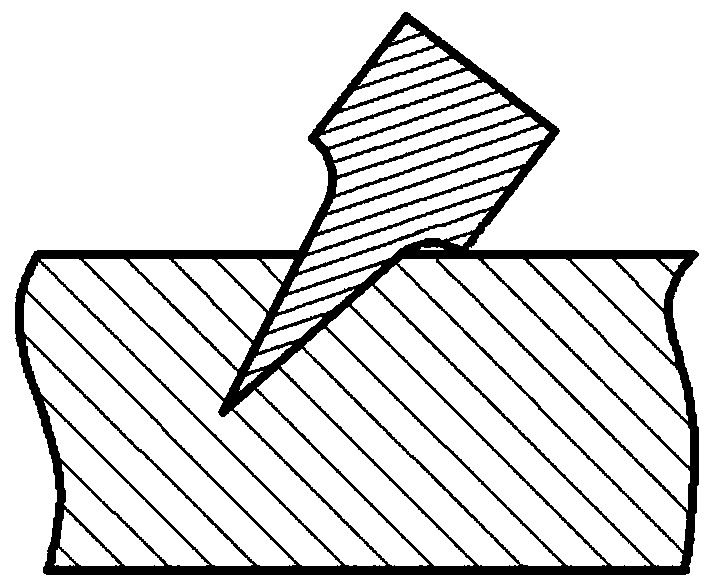

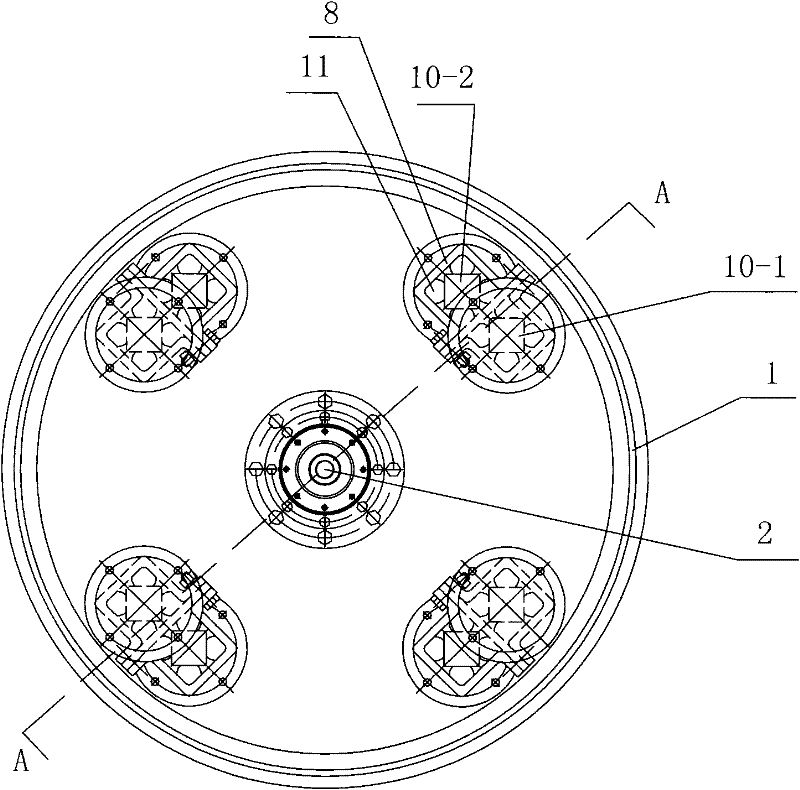

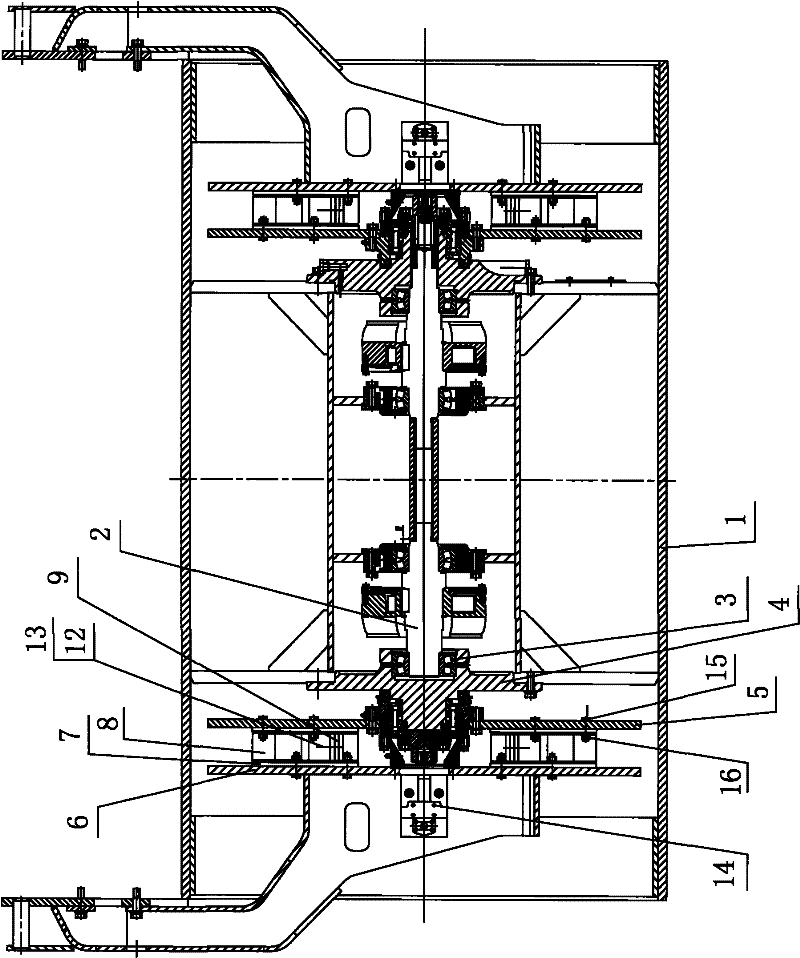

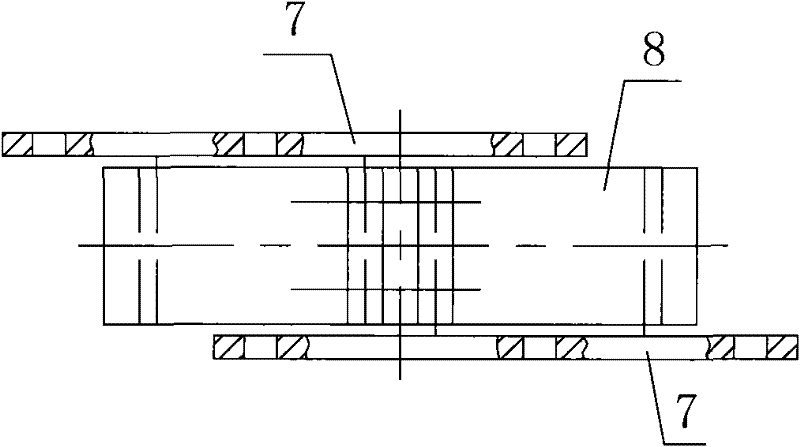

Longitudinal-radial coupled vibration double-roller ultrasonic rolling welding device

PendingCN112810162AUltrasonic isolation is effectiveImprove the vibration effectCircular discButt joint

The invention relates to the technical field of ultrasonic equipment, and aims to provide a longitudinal-radial coupled vibration double-roller ultrasonic rolling welding device. The longitudinal-radial coupled vibration double-roller ultrasonic rolling welding device comprises an ultrasonic vibration part and a fixed clamping part, wherein the ultrasonic vibration part comprises a double-roller seam welding tool head and ultrasonic transducer switches, the double-roller seam welding tool head is arranged coaxial with the ultrasonic transducer switches; the double-roller roll welding tool head is composed of two T-shaped roll welding tool heads which are in butt joint, disc structures at the ends of the two T-shaped roll welding tool heads are connected through bolts to achieve symmetrical arrangement, and the ends of axial amplitude-change poles of the two T-shaped roll welding tool heads are each connected with an ultrasonic transducer; coaxial conductive slip rings are respectively arranged at the end parts of the outer sides of the two ultrasonic transducers; and the fixed clamping part comprises a set of synchronous belt wheels, two sets of fixed shells and two sets of bearings. According to the longitudinal-radial coupled vibration double-roller ultrasonic rolling welding device, it can be ensured that the ultrasonic vibration part achieves the optimal vibration effect at the resonant frequency of the ultrasonic vibration part, and the high-speed rotation function of the ultrasonic vibration part is achieved; and stable feeding is achieved while welding is conducted, the problem of material extrusion in the welding process is solved, and better welding sealing is achieved on different material thicknesses.

Owner:HANGZHOU SUCCESS ULTRASONIC EQUIP

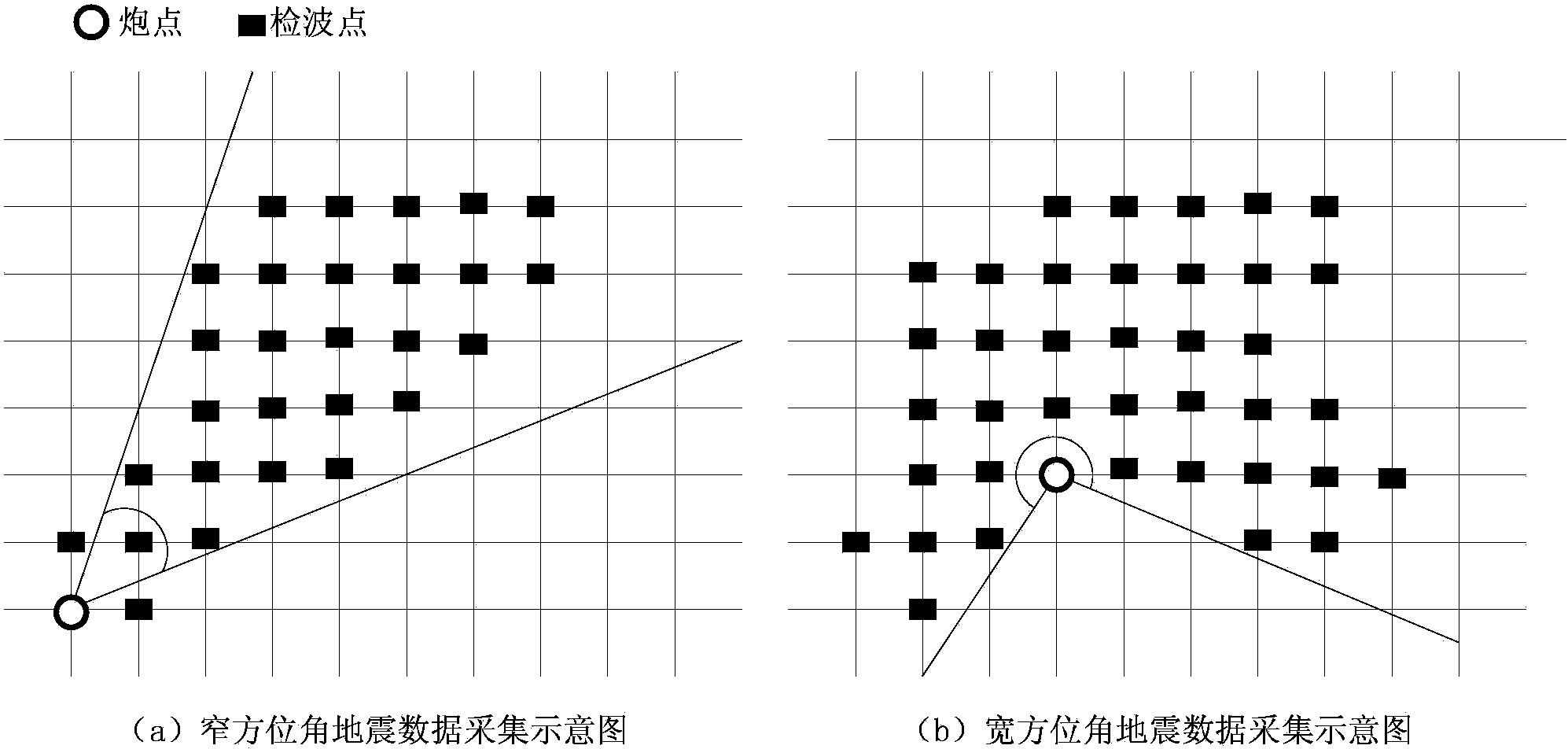

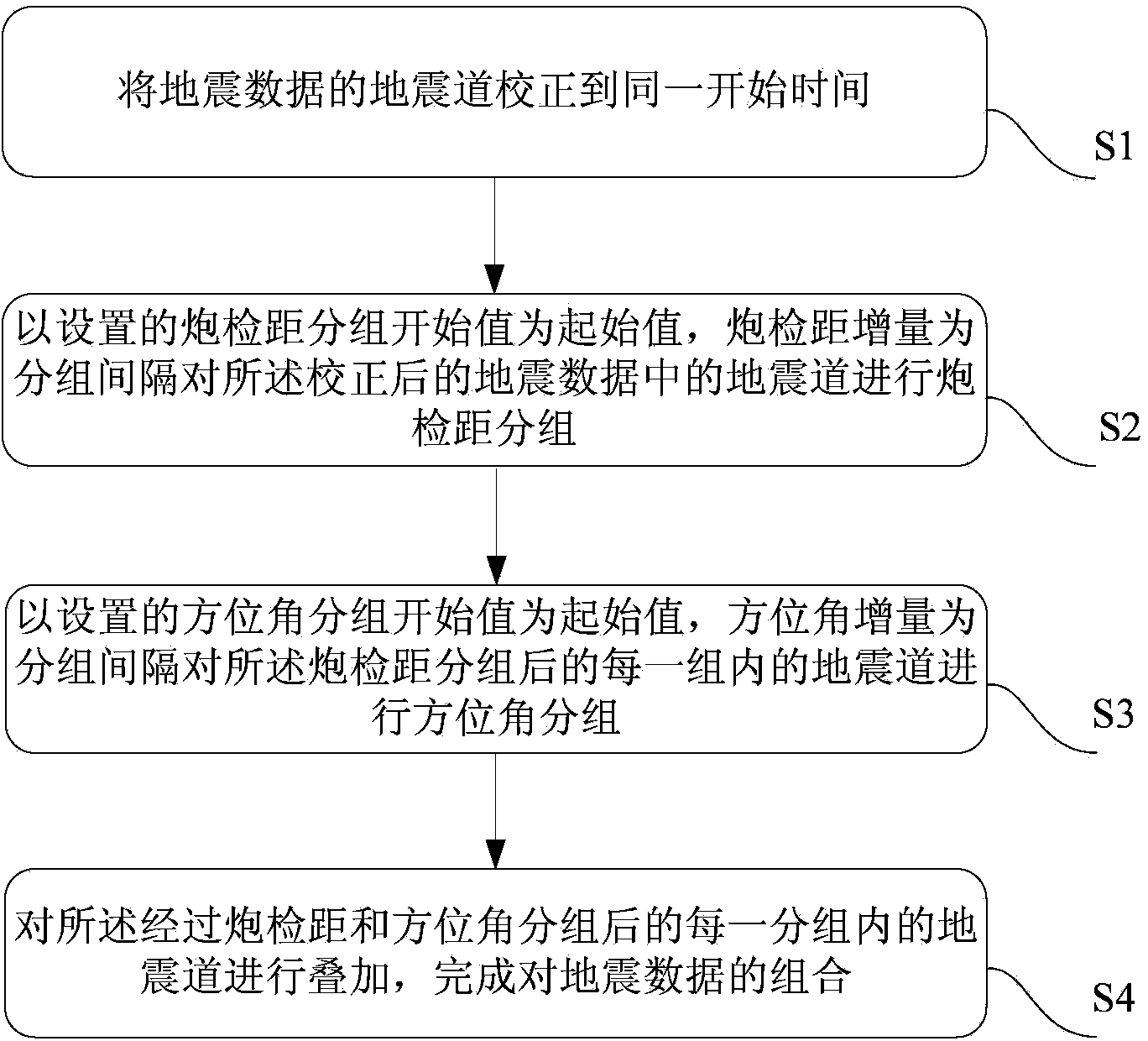

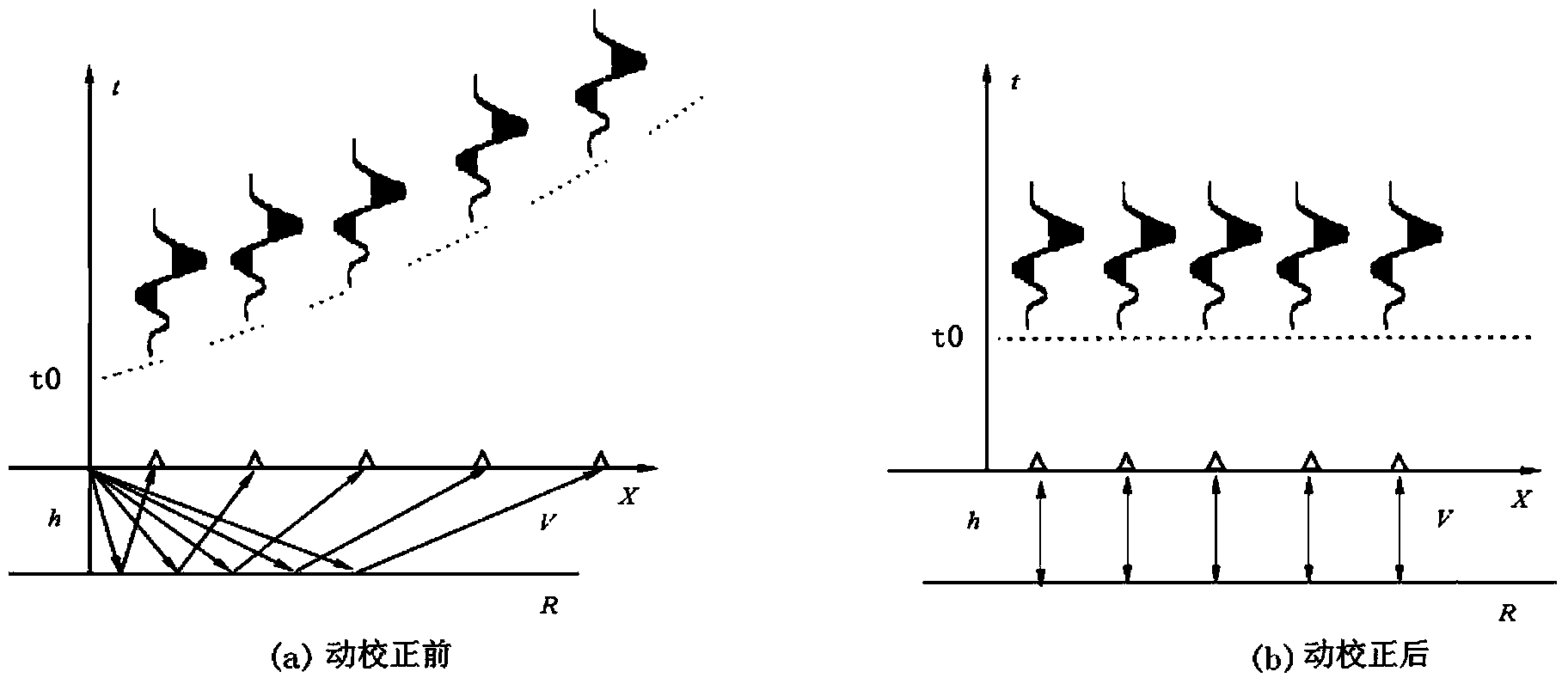

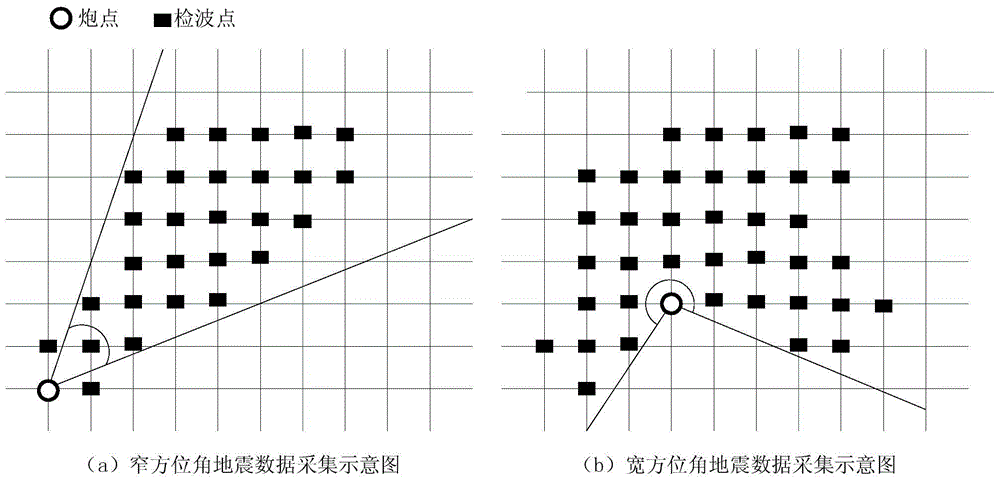

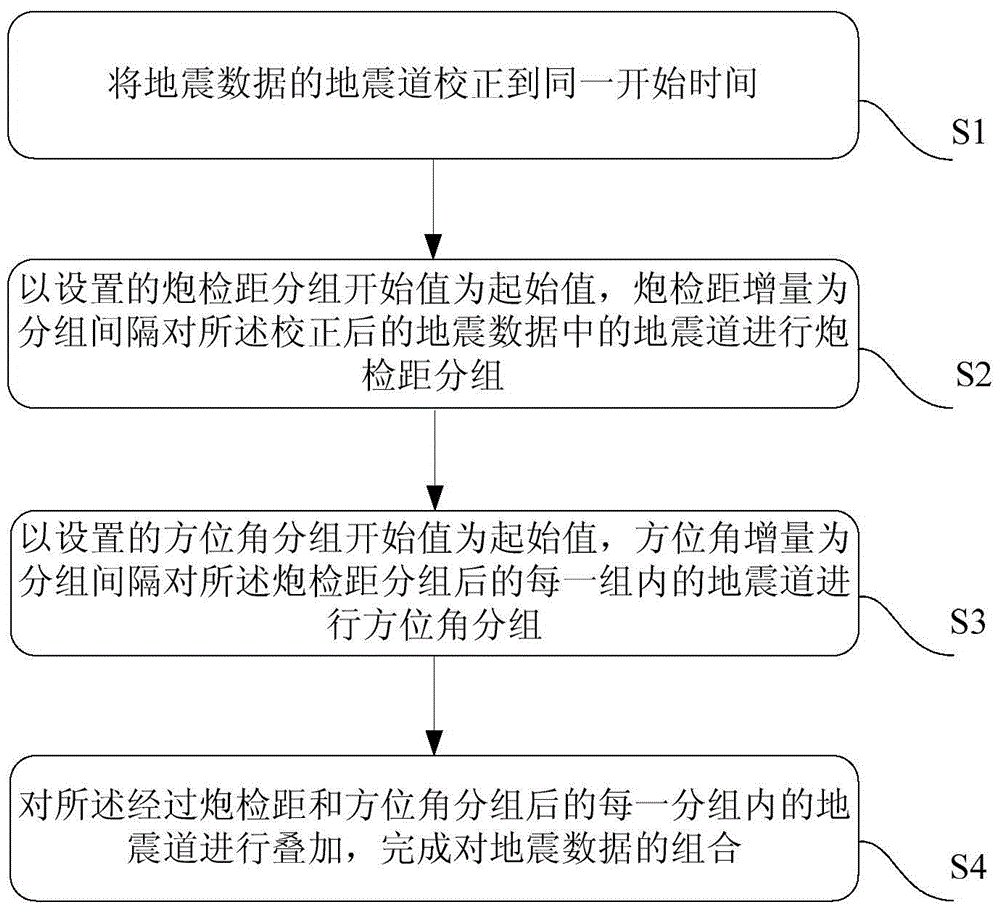

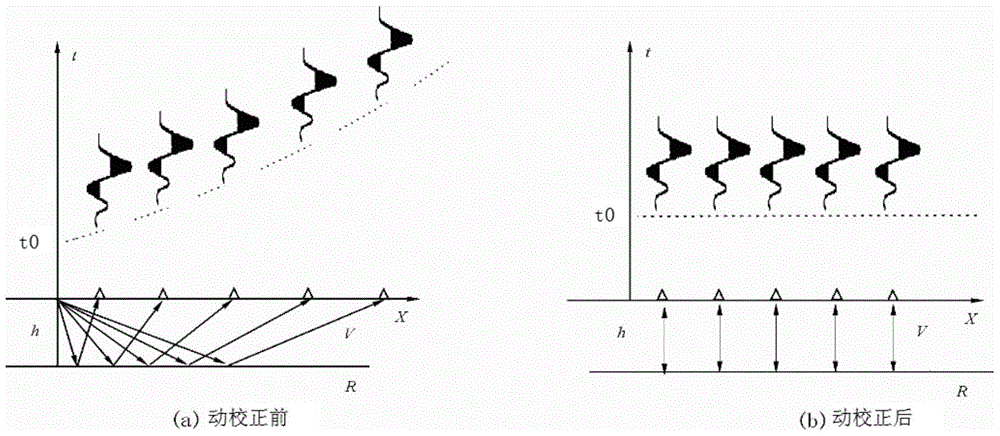

Earthquake data combination method, apparatus and system

ActiveCN104166160AImprove overlay effectReduce raw data impactSeismic signal processingCombined methodSignal-to-noise ratio (imaging)

The invention provides an earthquake data combination method, apparatus and system. The method comprises: correcting seismic channels of earthquake data to the same starting time; carrying out offset distance grouping and azimuth grouping on the earthquake data after correction; and performing superposition on the seismic channels in each group after the offset distance grouping and azimuth grouping are performed, and finishing combination of the earthquake data. By using each embodiment of the invention, at the time when the earthquake data is compressed, the influence on original data is reduced, and the spatial distribution characteristic and the effective information of the original data are well maintained. According to the invention, at the time when the earthquake data with wide azimuth angles is compressed, the signal-to-noise ratio of the earthquake data after compression can also be improved, and convenience is provided for subsequent earthquake data processing and interpretation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

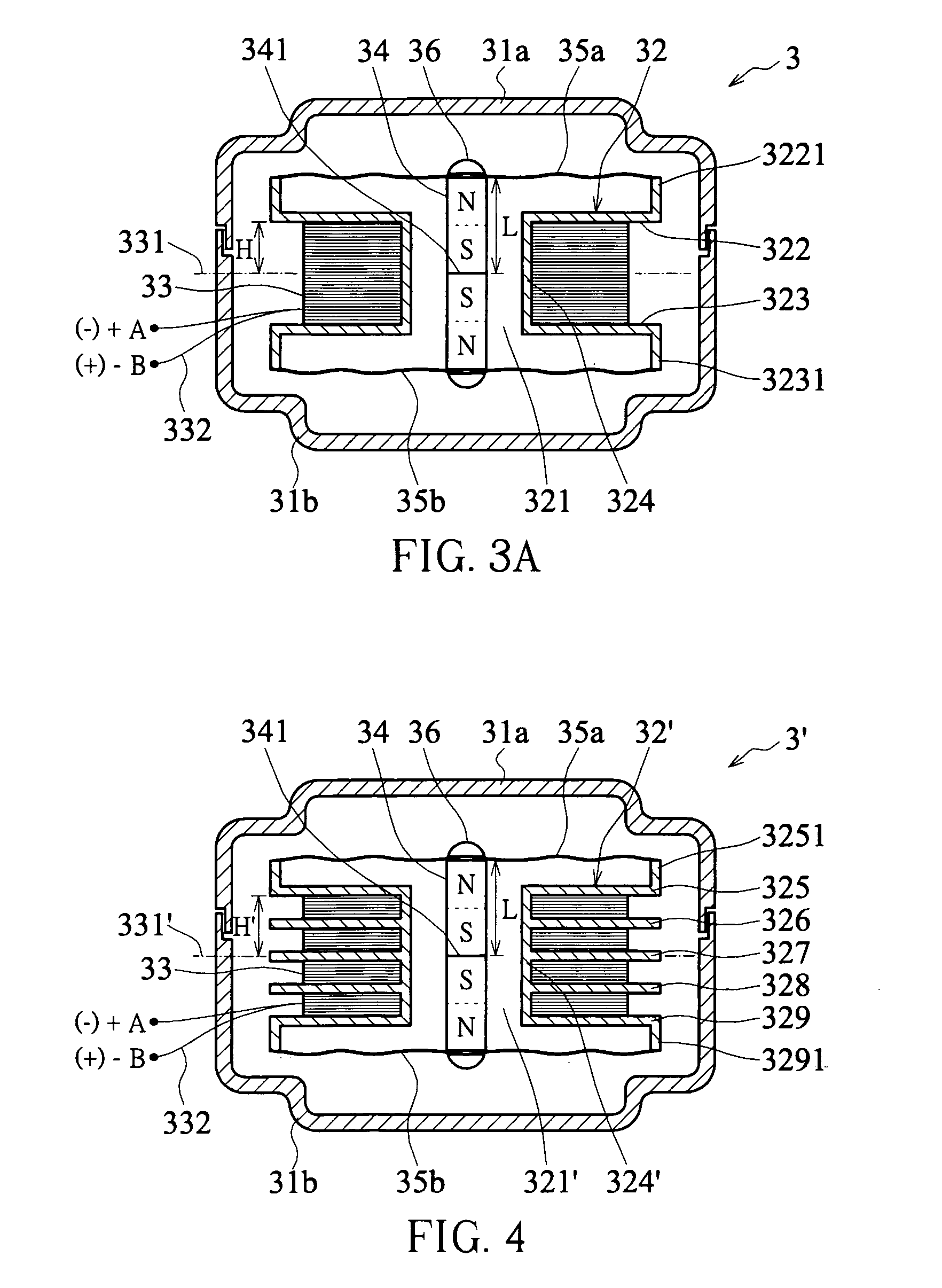

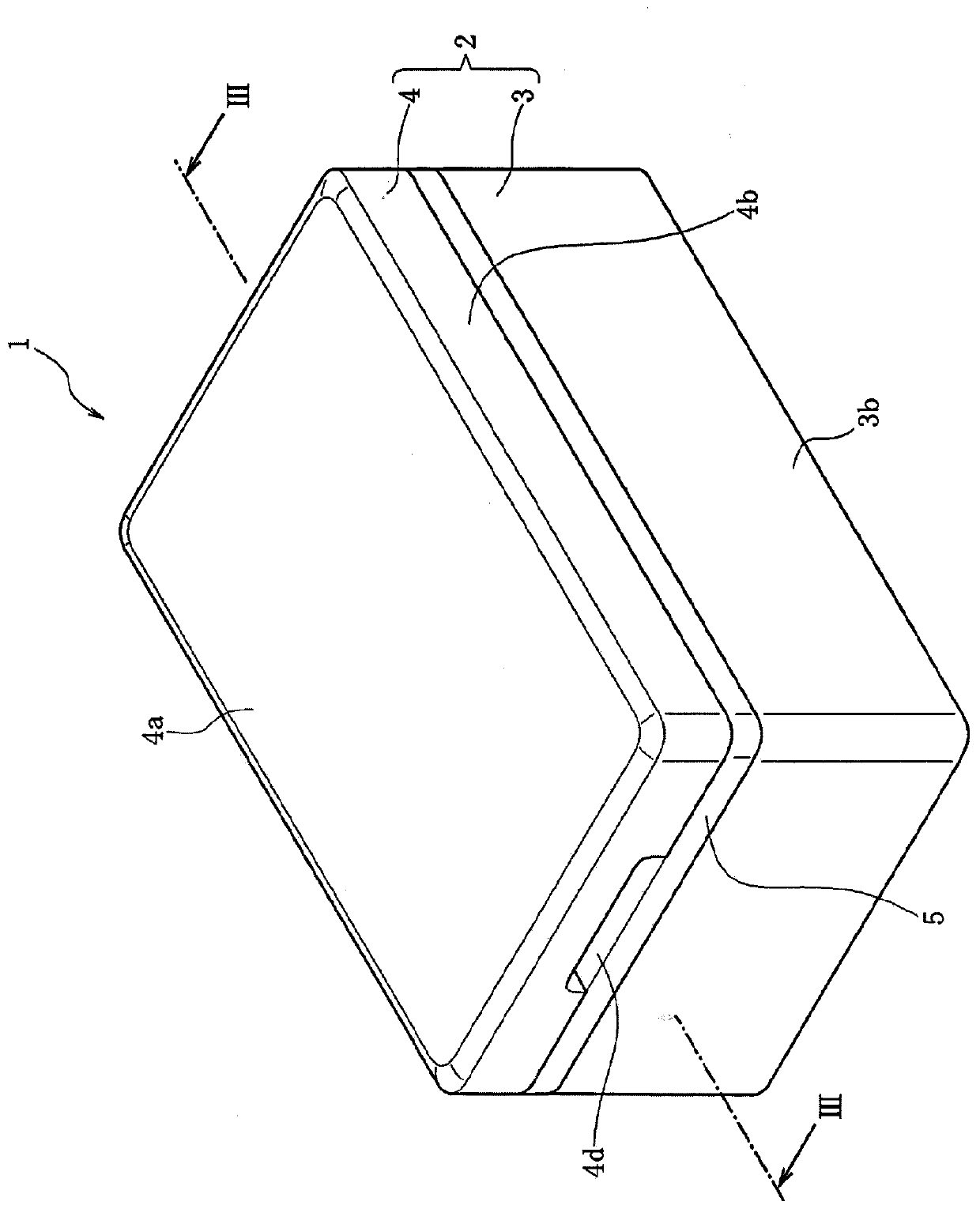

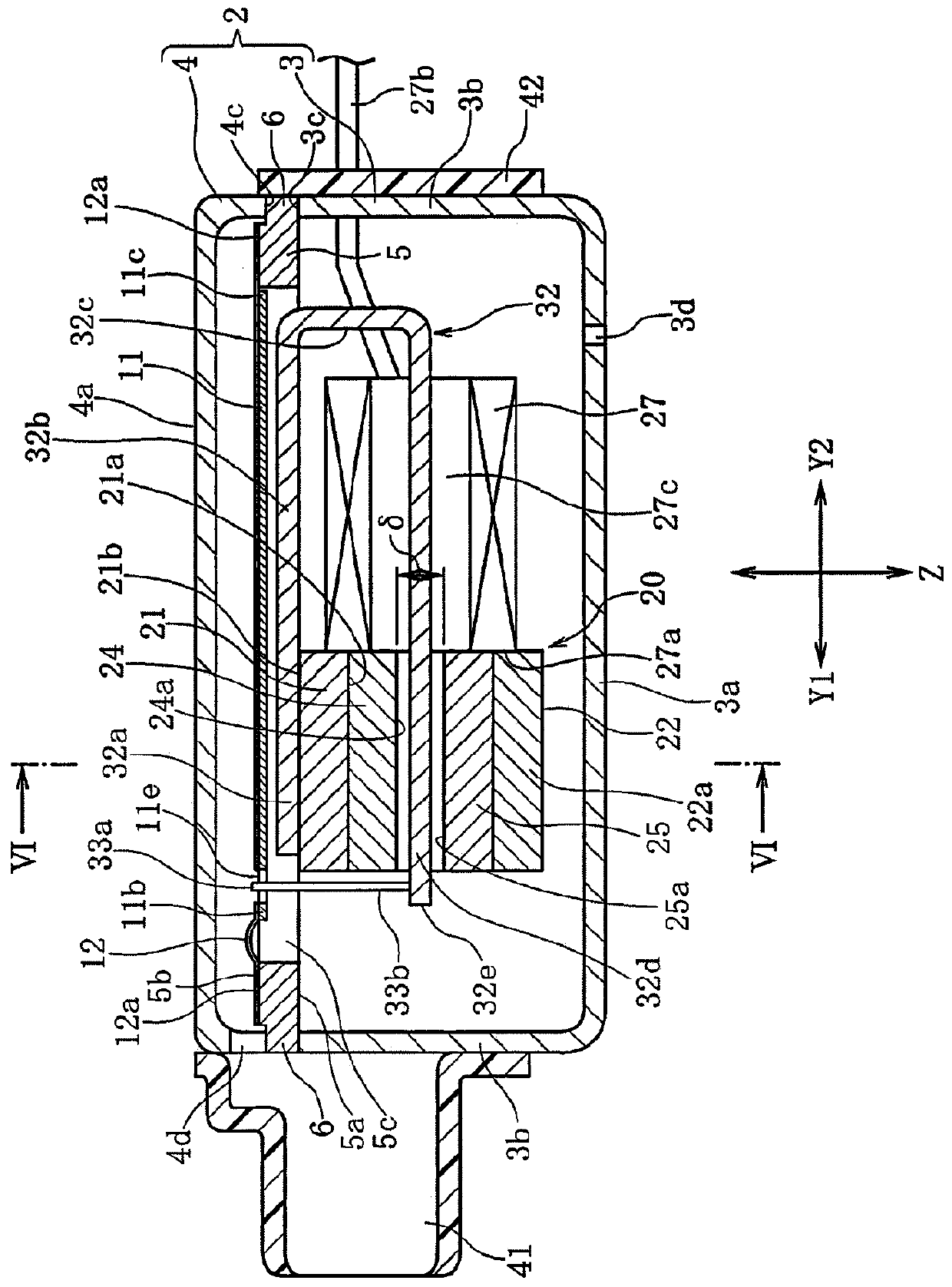

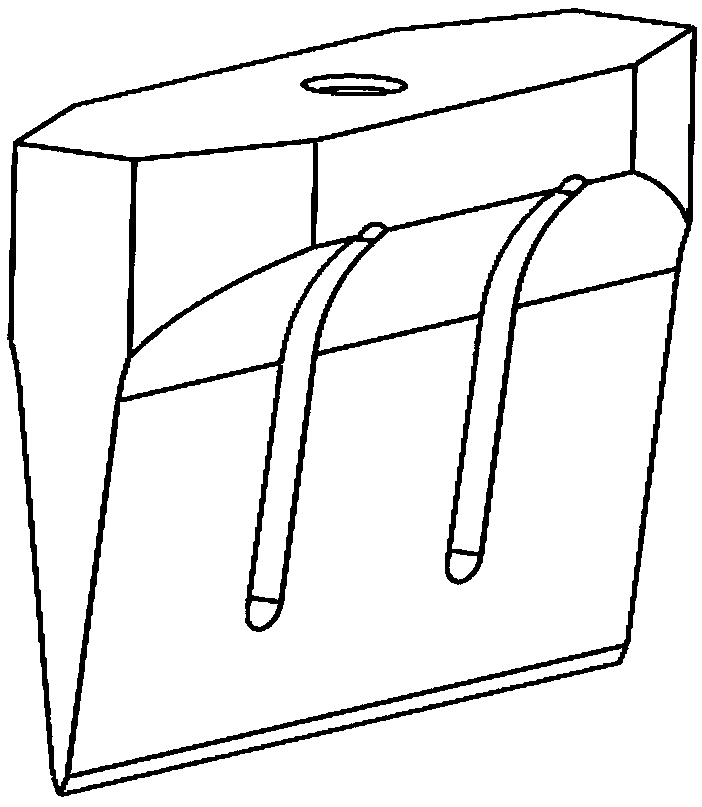

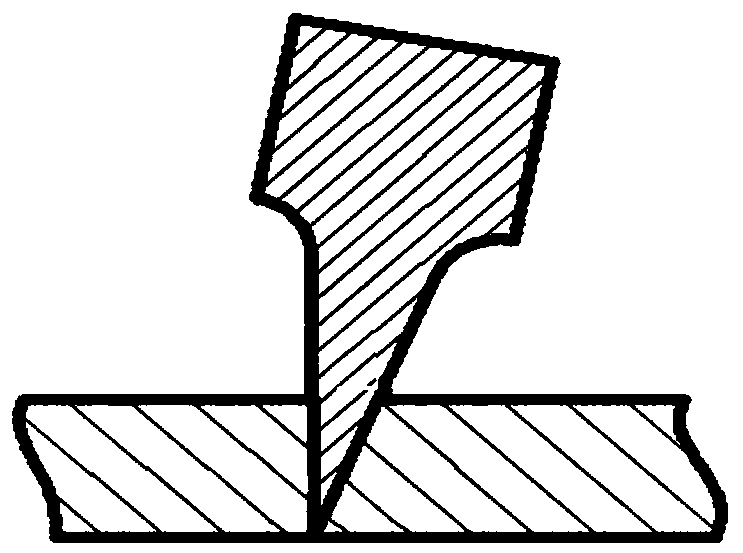

Sound producing device and method for manufacturing same

InactiveCN109891912AUniform amplitudeSuppress changesElectrical transducersWelding/soldering/cutting articlesEngineeringSpot welding

According to the present invention, an armature 32 has a fixed part 32a, an extending part 32b, a bent part 32c, and a movable part 32d. The moveable part 32d of the armature 32 is inserted into a coil 27 to face magnets 24, 25, and the fixed part 32a overlaps an outer surface 21b of a yoke 21. Two edge parts 32f, 32f of the fixed part 32a and the outer surface 21b of the yoke 21 are subjected tolaser spot welding to form welded parts 51, 51, 52, 52 in four locations.

Owner:ALPS ALPINE CO LTD

An ultrasonic cutting tool

InactiveCN107139228BImprove vibrationUniform amplitudeMetal working apparatusVibration amplitudeTransducer

The invention discloses an ultrasonic cutting tool. The ultrasonic cutting tool comprises a transducer, a variable amplitude rod, a changeover mechanism and a blade, wherein the transducer is connected with the variable amplitude rod; the top of the changeover mechanism is connected with the variable amplitude rod; and the bottom of the changeover mechanism is connected with the blade. According to the ultrasonic cutting tool, the blade and the changeover mechanism resonate in the same vibration mode under the same frequency, the blade well vibrates, vibration amplitude is uniform, obvious pitch surfaces do not exist on the blade, and the phenomenon of local tool sticking is avoided; besides, the blade is of a flakelike structure, an edge is relatively long, cutting depth is relatively large, processing range is relatively wide, and difference of cut angles of the two ends of a cutting surface and interference between the upper end of the cutting tool and a material are avoided; and the changeover mechanism can be manufactured through an aluminium alloy, cost is reduced, the flakelike blade can be manufactured through stainless steel or alloy steel, hardness is much higher than that of a titanium alloy, the cutting tool can be utilized to cut relatively hard materials, and utilization range of the ultrasonic cutting tool is greatly increased.

Owner:沈阳赫声装备科技有限公司

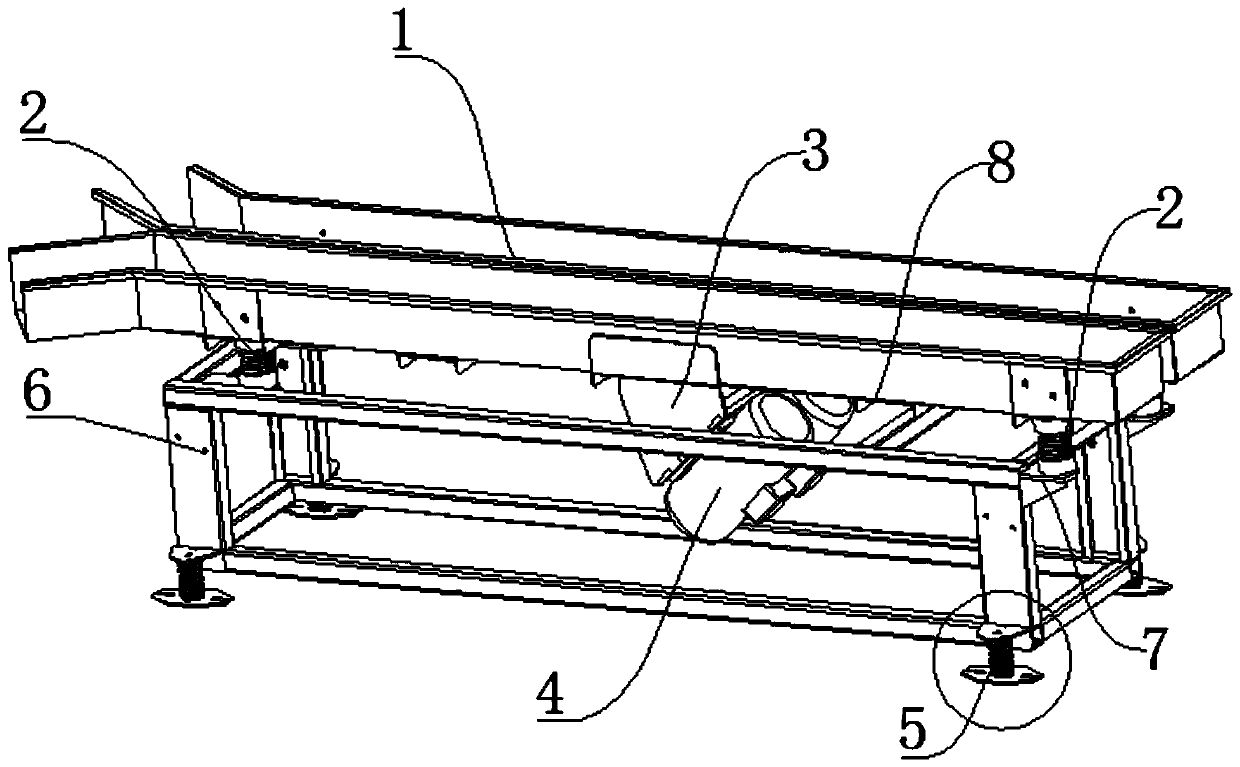

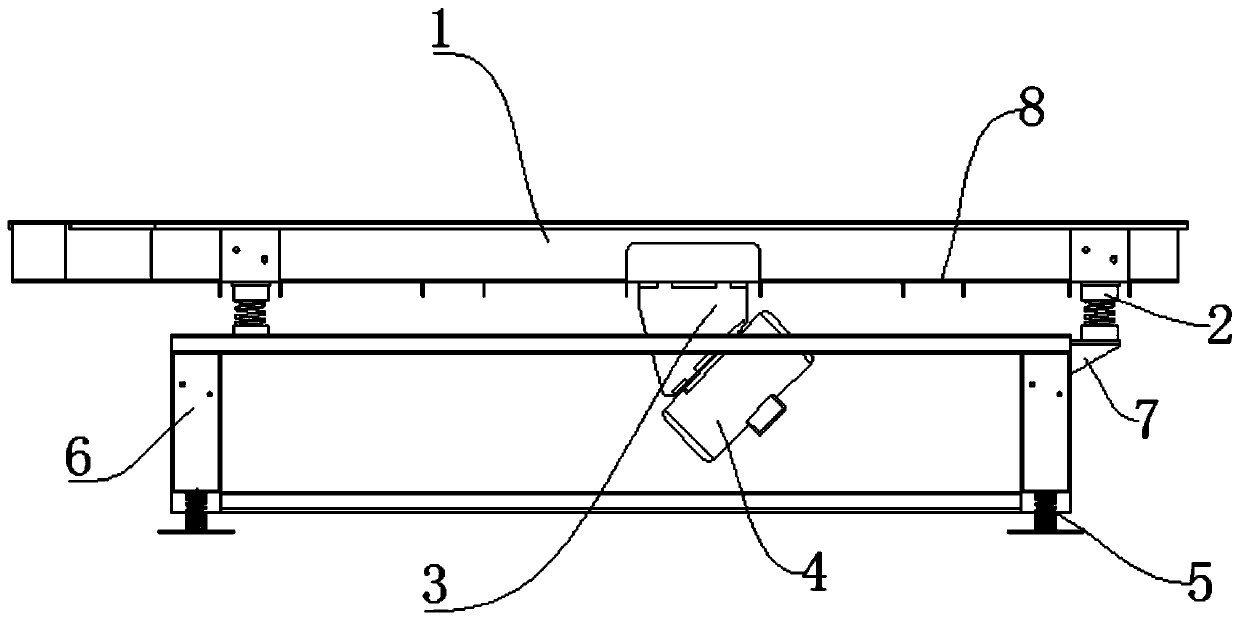

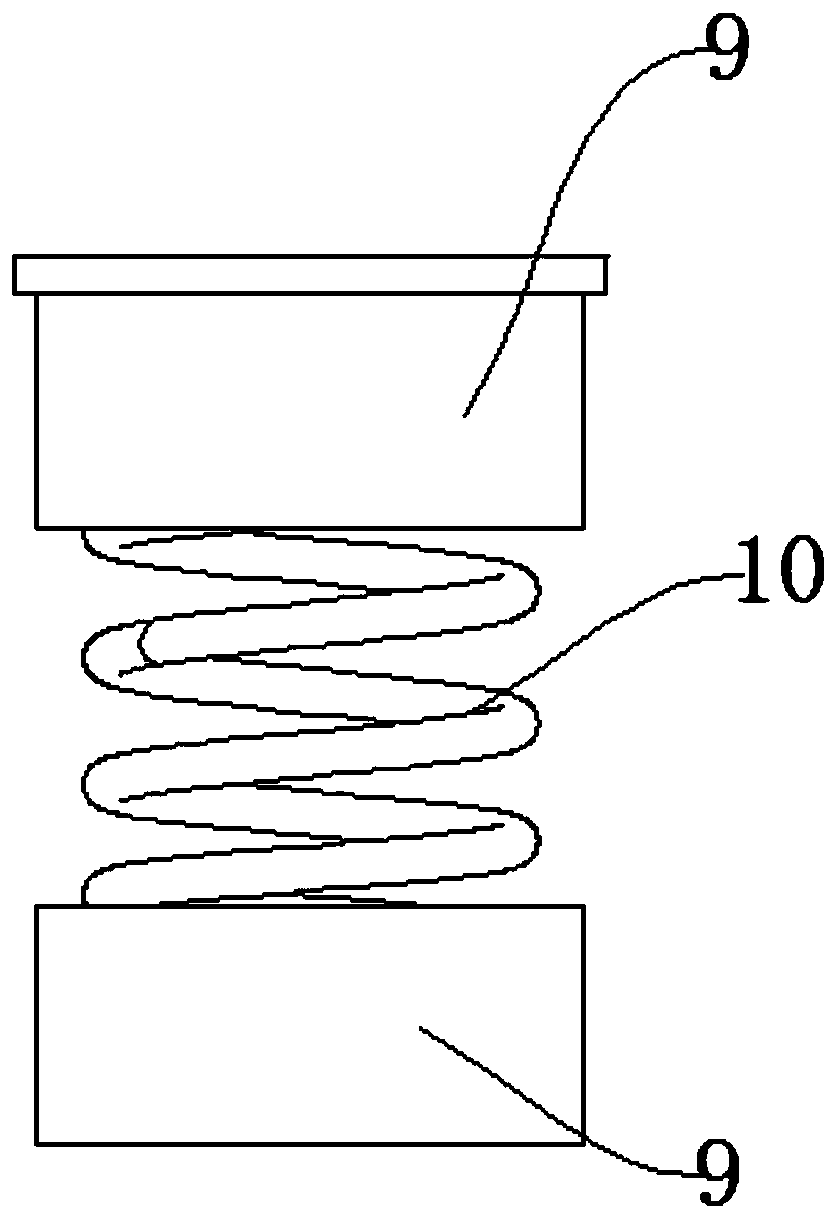

Vibrating discharging device on color sorting machine

The invention discloses a vibrating discharging device on a color sorting machine, and relates to the technical field of color sorting machines. The vibrating discharging device on the color sorting machine comprises double-row discharging hoppers, spring supporting assemblies, a motor base, vibrating motors, shock absorption bases, a discharging hopper supporting frame, fixing bases, reinforcingconnecting frames, spring limiting rings, first shock absorption supporting springs, upper fixing plates, second shock absorption supporting springs, bottom antiskid plates and foundation bolt fixinggrooves. The shock absorption bases are arranged on the four corners of the bottom of the discharging hopper supporting frame, the fixing bases are arranged on the four corners of the top of the discharging hopper supporting frame, and the spring supporting assemblies are arranged on the tops of the fixing bases. The double-row discharging hoppers are arranged on the tops of the spring supportingassemblies, the reinforcing connecting frames are arranged on the lower surfaces of the double-row discharging hoppers, and the motor base is arranged at the bottoms of the middles of the double-row discharging hoppers. According to the vibrating discharging device on the color sorting machine, the two vibrating motors which are opposite in rotating direction are adopted to provide the power, andmaterials can be rapidly and uniformly discharged in a high-frequency and small-amplitude mode. The vibrating discharging device on the color sorting machine comprises a shock absorption structure, and is low in noise, long in service life, simple in structure, low in cost and stable in performance.

Owner:SHENZHEN ZHONGRUIWEISHI PHOTOELECTRONICS CO LTD

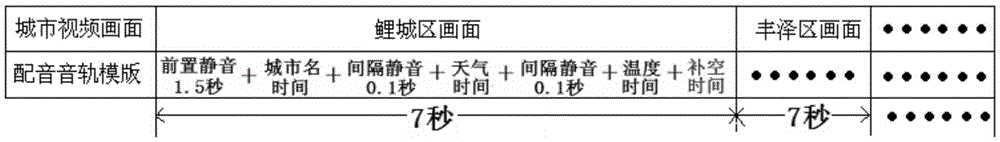

Automatic processing method and system for city window weather dubbing

ActiveCN104967789BUniform amplitudeSmooth connectionTelevision system detailsColor television detailsProgram qualitySpeech sound

The invention discloses an automatic processing method for city window weather dubbing of a TV weather forecast program. The method comprises the following steps: translation: translating city weather codes to obtain city names and weather and / or temperature entries; matching: matching the translated entries with the corresponding storage entries in a voice library; synthesizing: synthesizing the matched storage voice entries into audio data according to the sequence of the city name and weather and / or temperature; and time setting: by inserting mute date before and behind the entry audio data to generate dubbing data, enabling the time length of the dubbing data to be equal to a set time length. The invention also discloses a system adopting the method. The automatic dubbing synthesized voice is good in effect and can replace human voice, thereby improving program quality, avoiding external influence, freeing hosts, preventing mistake making and improving work efficiency by times.

Owner:福建省泉州市气象局

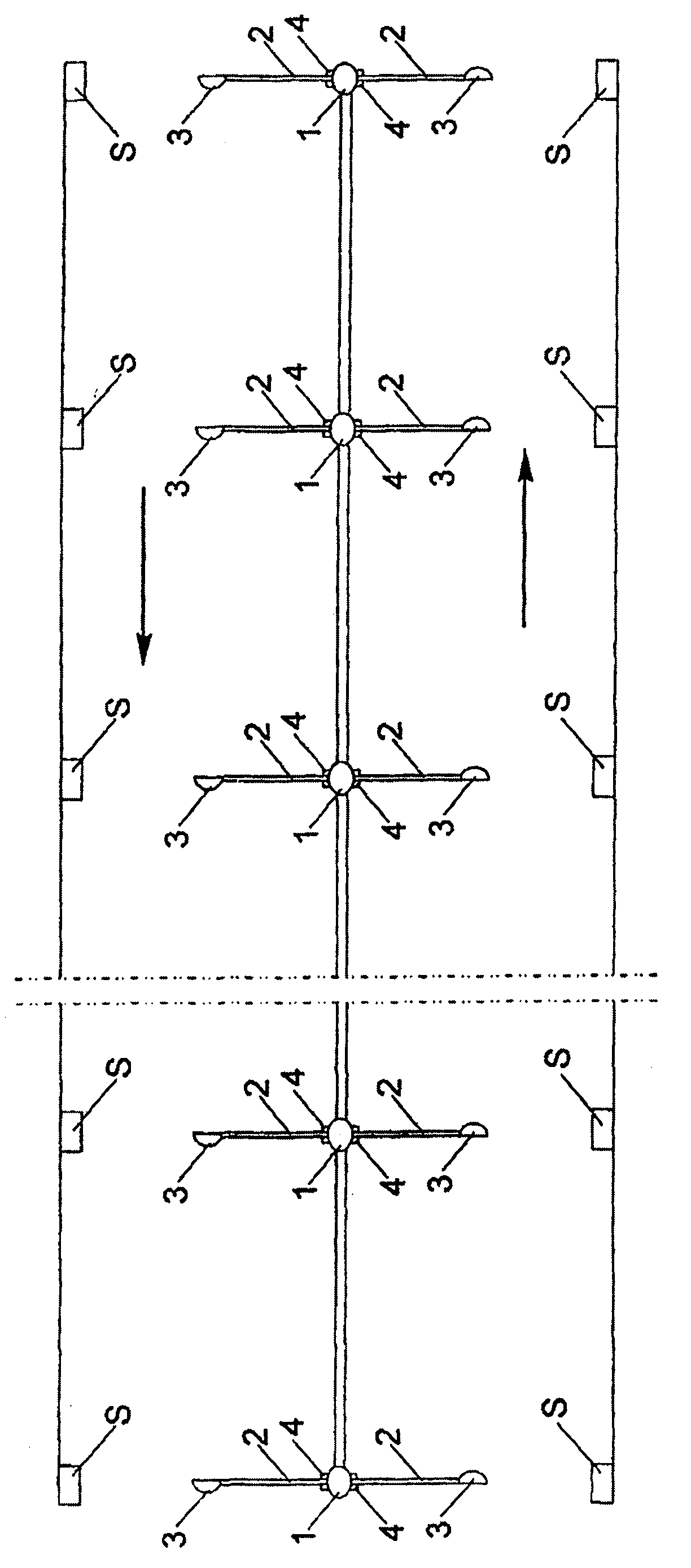

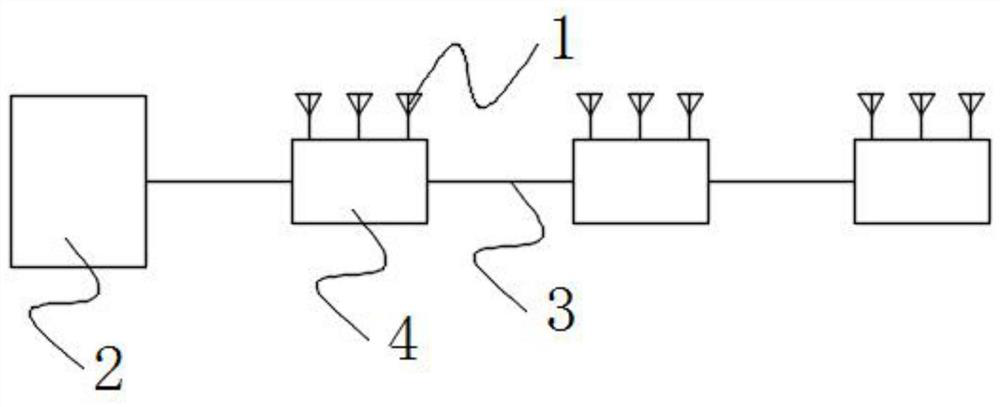

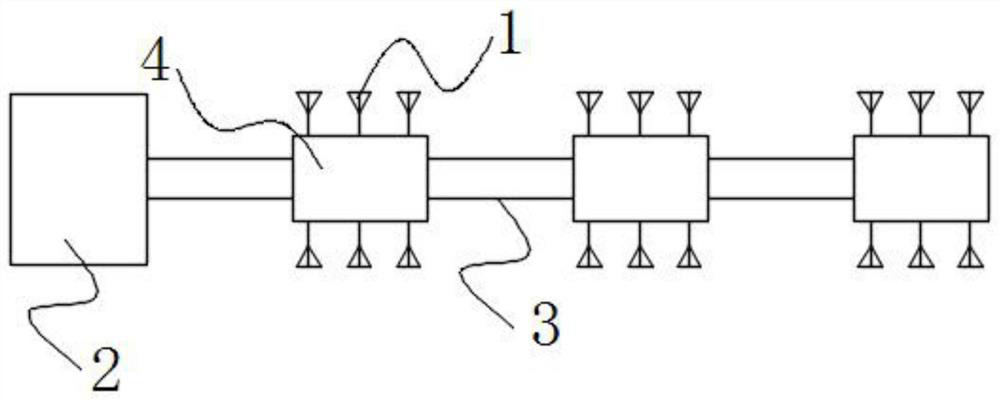

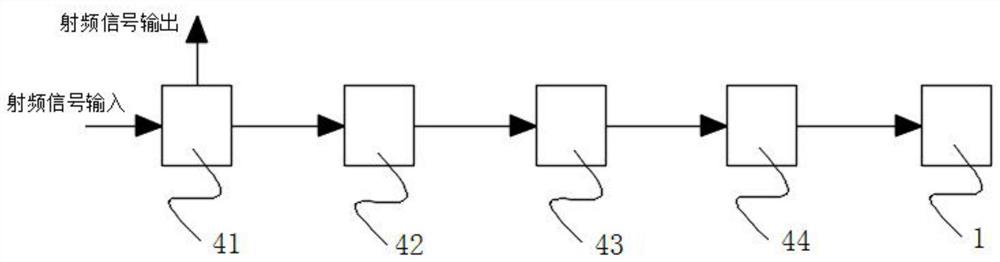

A system and method for equalizing distribution of indoor signals

ActiveCN110868721BConsistent powerImprove uniformityRadio transmissionNetwork planningDistribution systemEngineering

The invention discloses an indoor signal equalization distribution system, which includes an indoor micro base station and a plurality of radio frequency power equalizers connected in series through radio frequency transmission lines, the signal output port of the indoor micro base station is connected to the radio frequency power equalizer at the head end through the radio frequency transmission line The signal input port is connected, the branch signal output port of each said radio frequency power equalizer is respectively connected with a radiation antenna, each said radio frequency power equalizer, the radio frequency transmission line connected with the signal input port of the radio frequency power equalizer and connected The radiation antenna on the radio frequency power equalizer is a signal radiation node. The invention can make the 5G signal fully covered indoors, and the coverage, amplitude and phase of the signal are highly consistent, and the receiving effect of the mobile terminal is good.

Owner:内江喜马雅拉网络技术有限公司

A seismic data combination method, device and system

ActiveCN104166160BImprove overlay effectImprove signal-to-noise ratioSeismic signal processingOffset distanceStart time

The invention provides an earthquake data combination method, apparatus and system. The method comprises: correcting seismic channels of earthquake data to the same starting time; carrying out offset distance grouping and azimuth grouping on the earthquake data after correction; and performing superposition on the seismic channels in each group after the offset distance grouping and azimuth grouping are performed, and finishing combination of the earthquake data. By using each embodiment of the invention, at the time when the earthquake data is compressed, the influence on original data is reduced, and the spatial distribution characteristic and the effective information of the original data are well maintained. According to the invention, at the time when the earthquake data with wide azimuth angles is compressed, the signal-to-noise ratio of the earthquake data after compression can also be improved, and convenience is provided for subsequent earthquake data processing and interpretation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

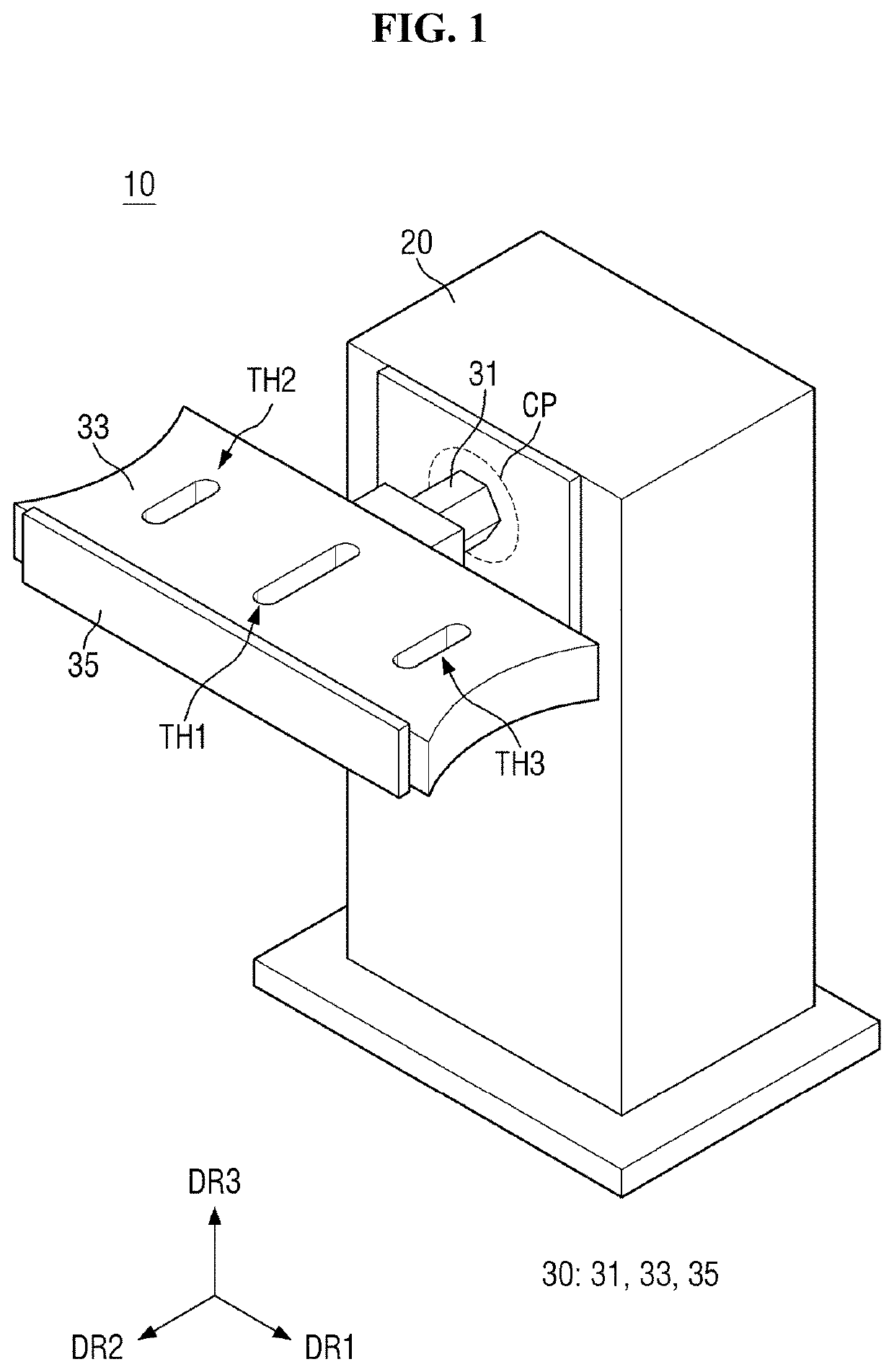

Apparatus for manufacturing display device and method of manufacturing display device

ActiveUS20200282660A1Uniform amplitudeMechanical vibrations separationDomestic articlesDisplay deviceEngineering

There is provided a an apparatus for manufacturing a display device. An apparatus for manufacturing a display device comprises a body generating ultrasonic vibration; and a horn including a horn body portion connected to the body and amplifying the ultrasonic vibration and a horn tip portion connected to the horn body portion and applying the ultrasonic vibration onto a bonding object, wherein the horn body portion includes at least one body groove surrounded by the horn body portion and completely penetrating the horn body portion in a thickness direction from the surface of the horn body portion.

Owner:SAMSUNG DISPLAY CO LTD

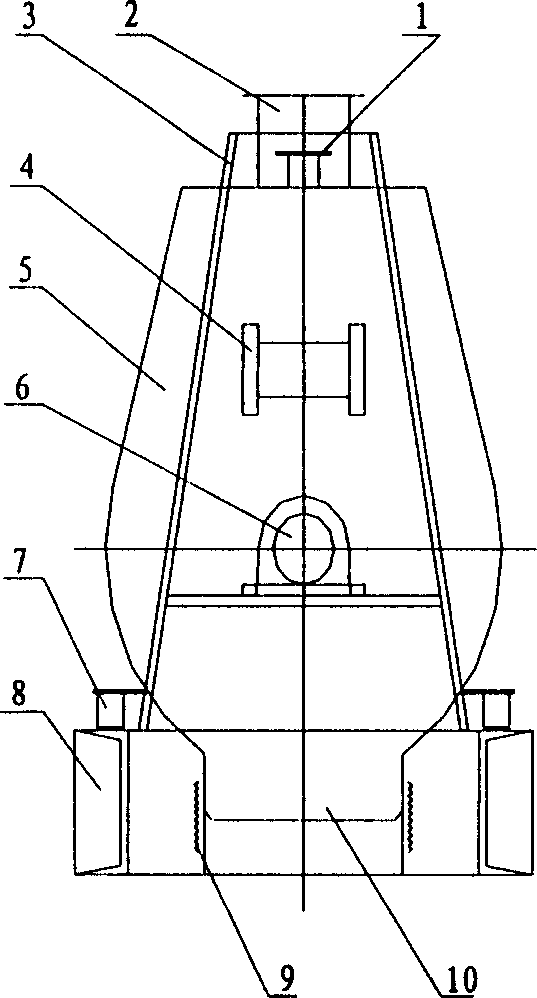

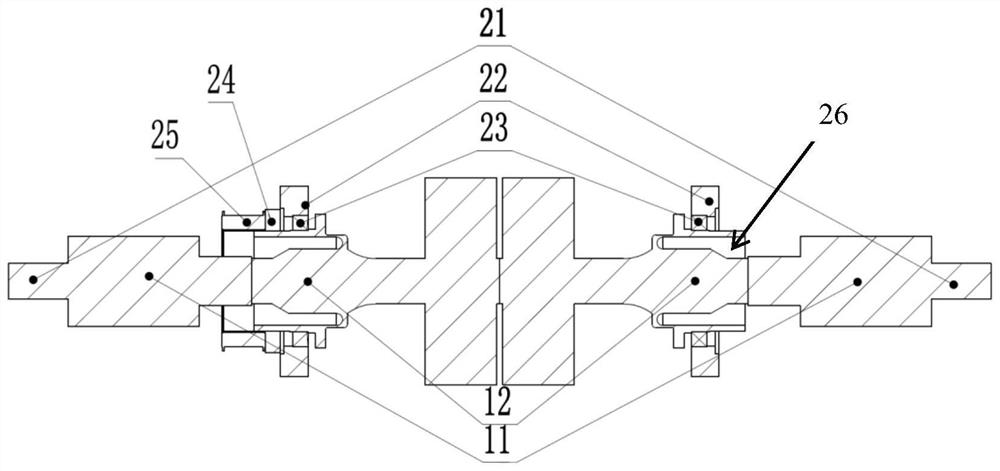

A New Vibratory Roller Vibration Reduction System

InactiveCN101749364BReasonable and novel structure designCompact installationVibration suppression adjustmentsVehicle frameAgricultural engineering

The invention discloses a novel vibration damping system for a vibratory road roller, which comprises two sets of rubber dampers arranged symmetrically on the left and right sides of the vibration axis; The upper frame support plate on the outside of the support plate and parallel to the shock absorber support plate and a plurality of rubber shock absorbers uniformly arranged between them along the circumferential direction; The shock absorber outer frame divided into two shock absorber chambers with the same structure by the shock absorber partition between the shock absorber support plates, two shock absorber cores respectively arranged in the inner middle of the two shock absorber chambers and A plurality of vibration-isolation rubbers are evenly and symmetrically arranged in the space between the shock absorber core and the inner wall of the shock absorber cavity. The invention is reasonable in design, reliable in performance and good in use effect. It changes the original working environment of the vibration-damping rubber from being sheared and stretched to a compressed state. While making full use of the performance of the rubber shock absorber, it also extends service life.

Owner:CHANGAN UNIV

A single-excitation two-dimensional ultrasonic vibration-assisted microfabrication platform

ActiveCN107335601BReduce lossesAvoid changeMechanical vibrations separationVibration amplitudePhase difference

The invention belongs to the field of ultrasonic processing technology in special processing technology. It discloses a single-excitation two-dimensional ultrasonic vibration-assisted micro-machining platform, which includes a right-angled bottom plate, a linear guide rail, upper and lower vibration blocks, a support plate, and a horn. Energizer, ultrasonic generator. The upper and lower vibrating blocks are arranged perpendicularly to each other along the feed and side cutting directions respectively. The lower vibrating block and the bottom plate, and the lower vibrating block and the upper vibrating block are connected through linear guide rails. The workpiece is fixed on the upper vibrating block through a threaded connection. piece. The vibration block and the horn, and the horn and the transducer are all connected by double-headed studs. Two sets of horns are fixed on the base plate through the support plate at the node. The two sets of transducers are connected to the same ultrasonic generator through wires. They output two ultrasonic signals at the same time and have a phase difference adjustment function. By adjusting the ultrasonic generator The amplitude and phase difference of the output signal are coupled to different elliptical vibration trajectories according to actual needs to achieve high-efficiency and high-precision processing.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com