Tire manufacturing method and apparatus

A manufacturing method and tire technology, which can be applied to auxiliary devices for rope making, tire parts, transportation and packaging, etc., can solve the problems of uneven amplitude and wavelength of corrugated steel cords, and can not fully improve the durability of the bead portion, etc. To achieve the effect of simple winding control, uniform amplitude, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

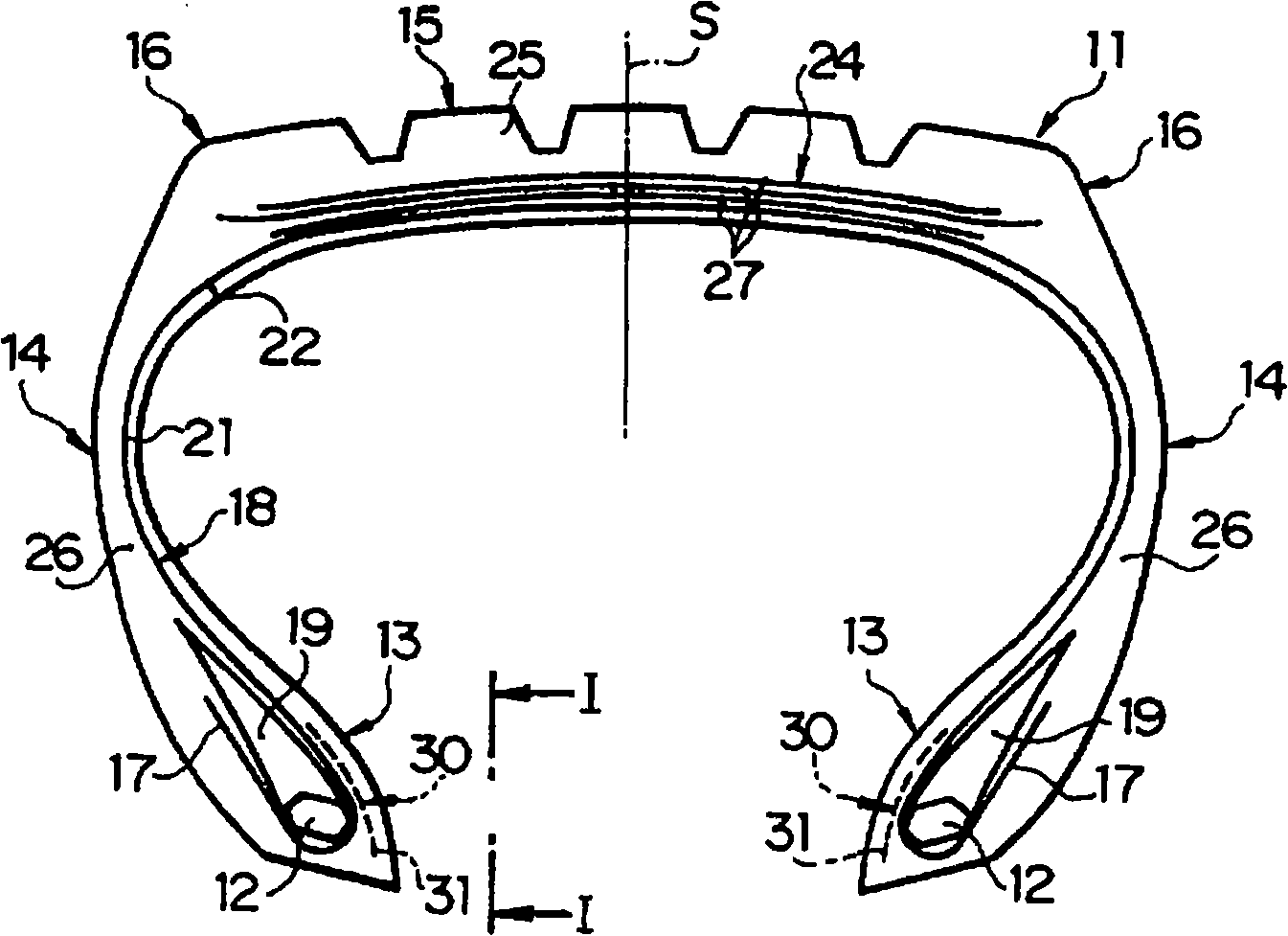

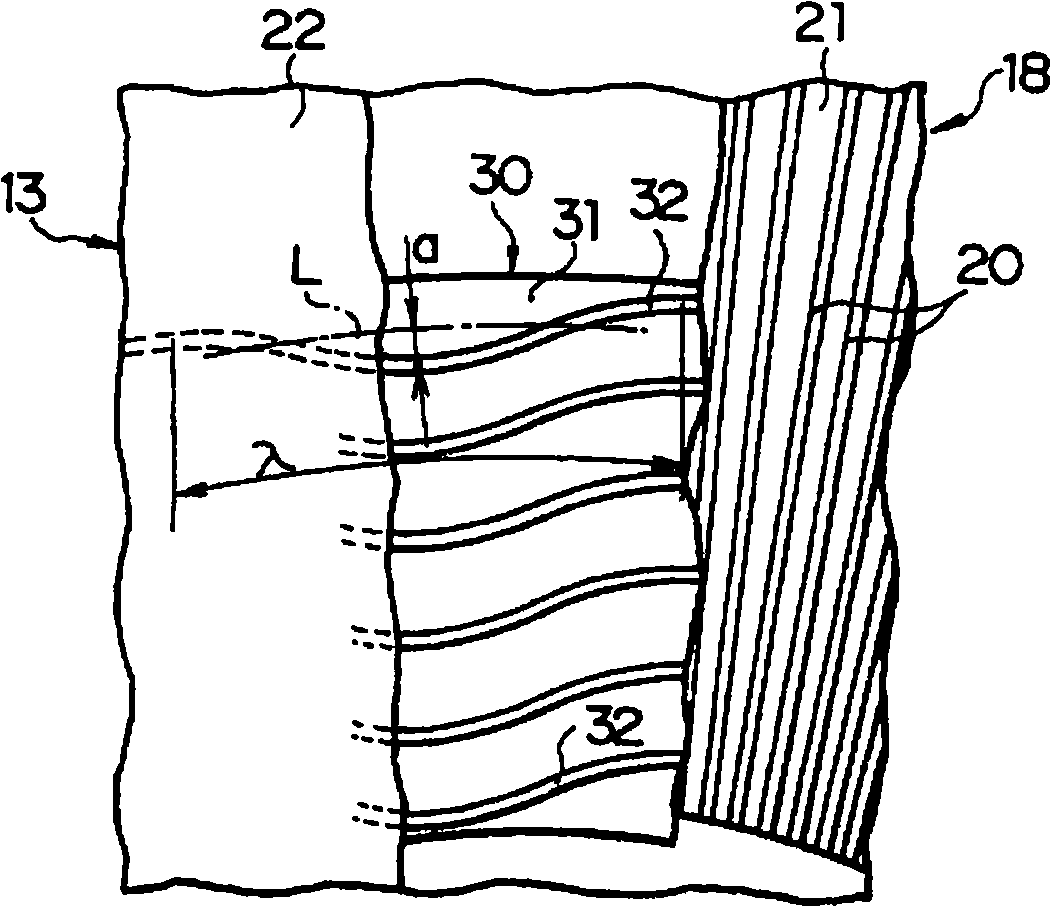

[0028] exist figure 1 and figure 2 In , reference numeral 11 denotes a vulcanized pneumatic radial tire that can be used for, for example, trucks, buses, and the like. The pneumatic radial tire 11 is provided with a pair of bead portions 13 in which a bead core 12 is embedded, and a pair of sidewall portions 14 respectively extending radially outward from the bead portions 13 . Reference numeral 15 denotes a substantially cylindrical tread portion. A pair of shoulder portions 16 is located between each axial end of the tread portion 15 and the radially outer end of each side wall portion 14 .

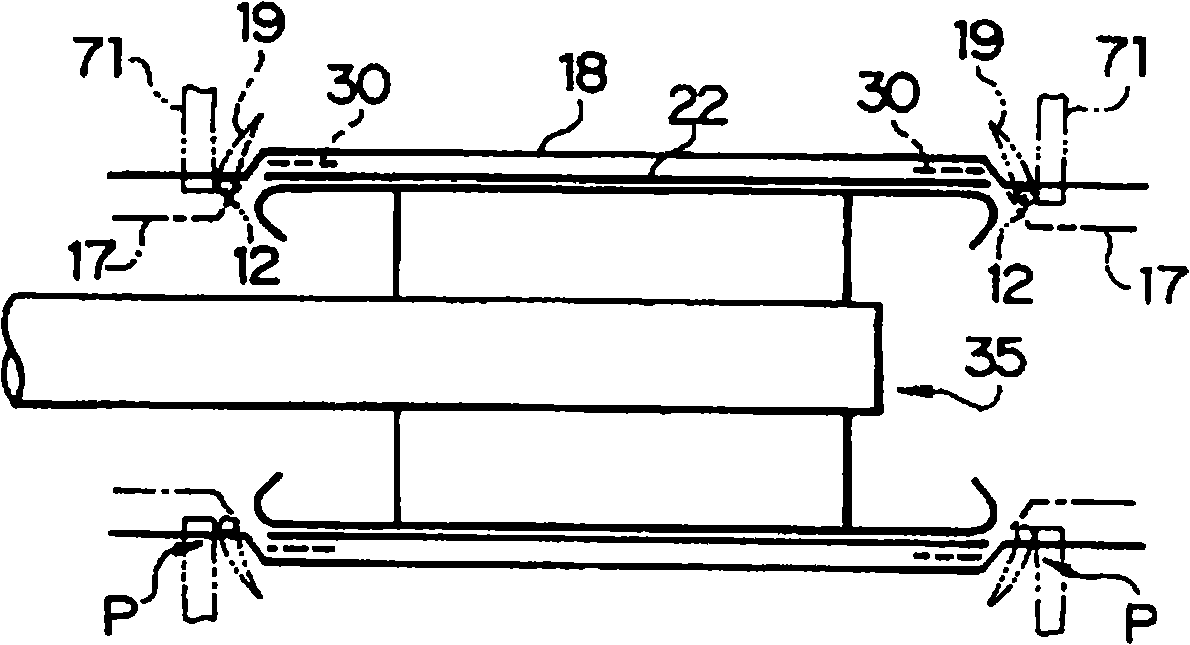

[0029] The pneumatic tire 11 also has a carcass layer 18 annularly extending between a pair of bead cores 12 to reinforce the sidewall portion 14 and the tread portion 15 . The two ends of the carcass layer 18 are folded around the bead core 12 and the filler 19, and the radial inner ends of the filler 19 are fixed by the bead core 12, thereby, the two ends of the carcass layer 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com