A single-excitation two-dimensional ultrasonic vibration-assisted microfabrication platform

A two-dimensional ultrasonic vibration and micromachining technology, which is applied in the direction of fluid using vibration, can solve the problems of small ultrasonic amplitude and affect the machining accuracy of the machine tool spindle, reduce energy loss, realize two-dimensional ultrasonic vibration auxiliary processing, high The Effect of Precision Ultrasonic Ellipse Machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

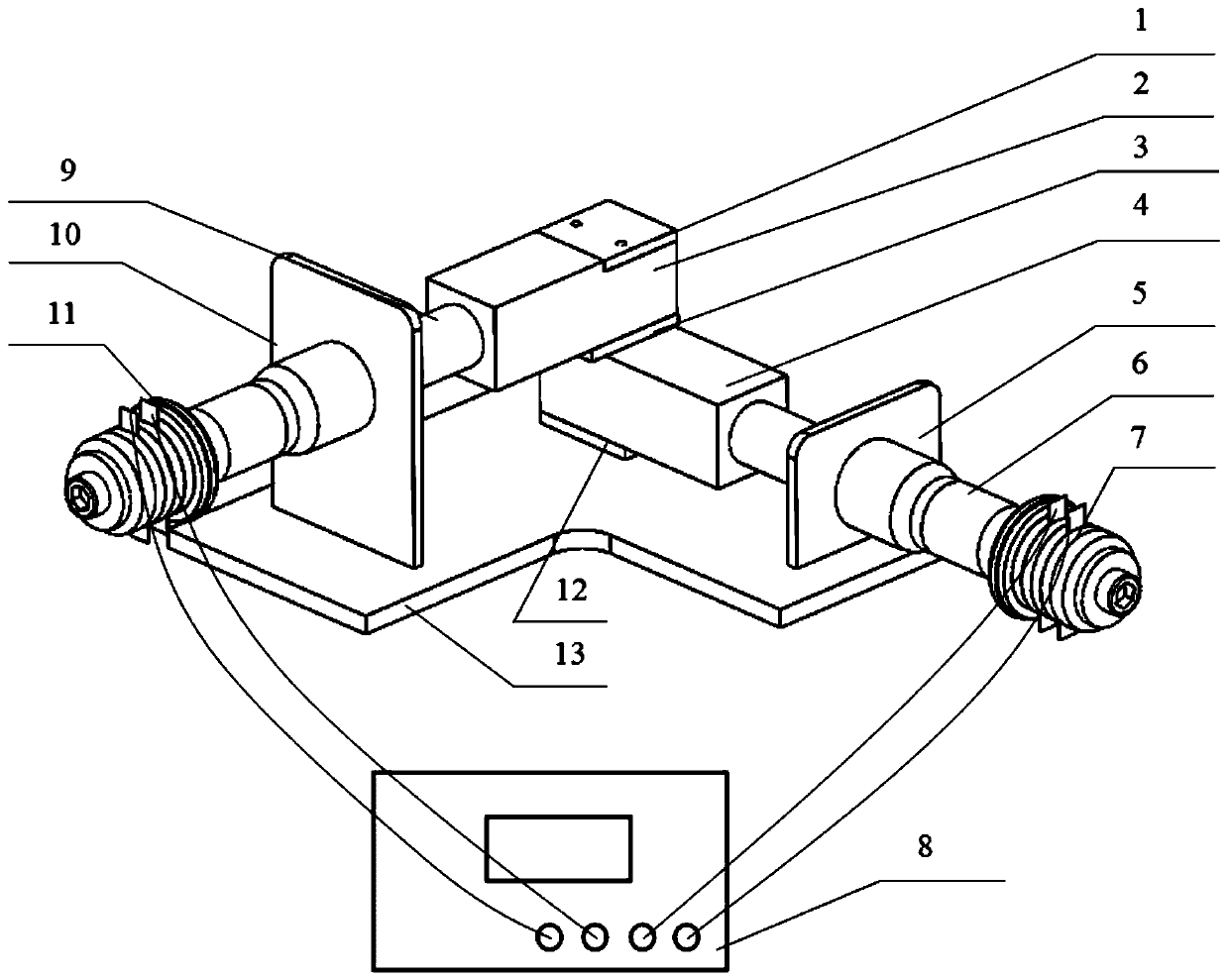

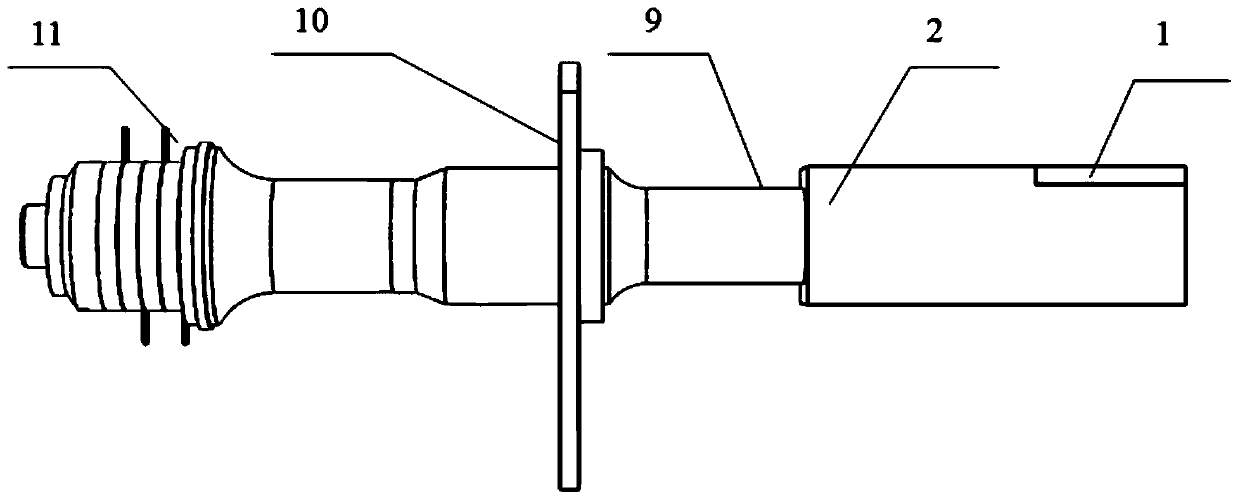

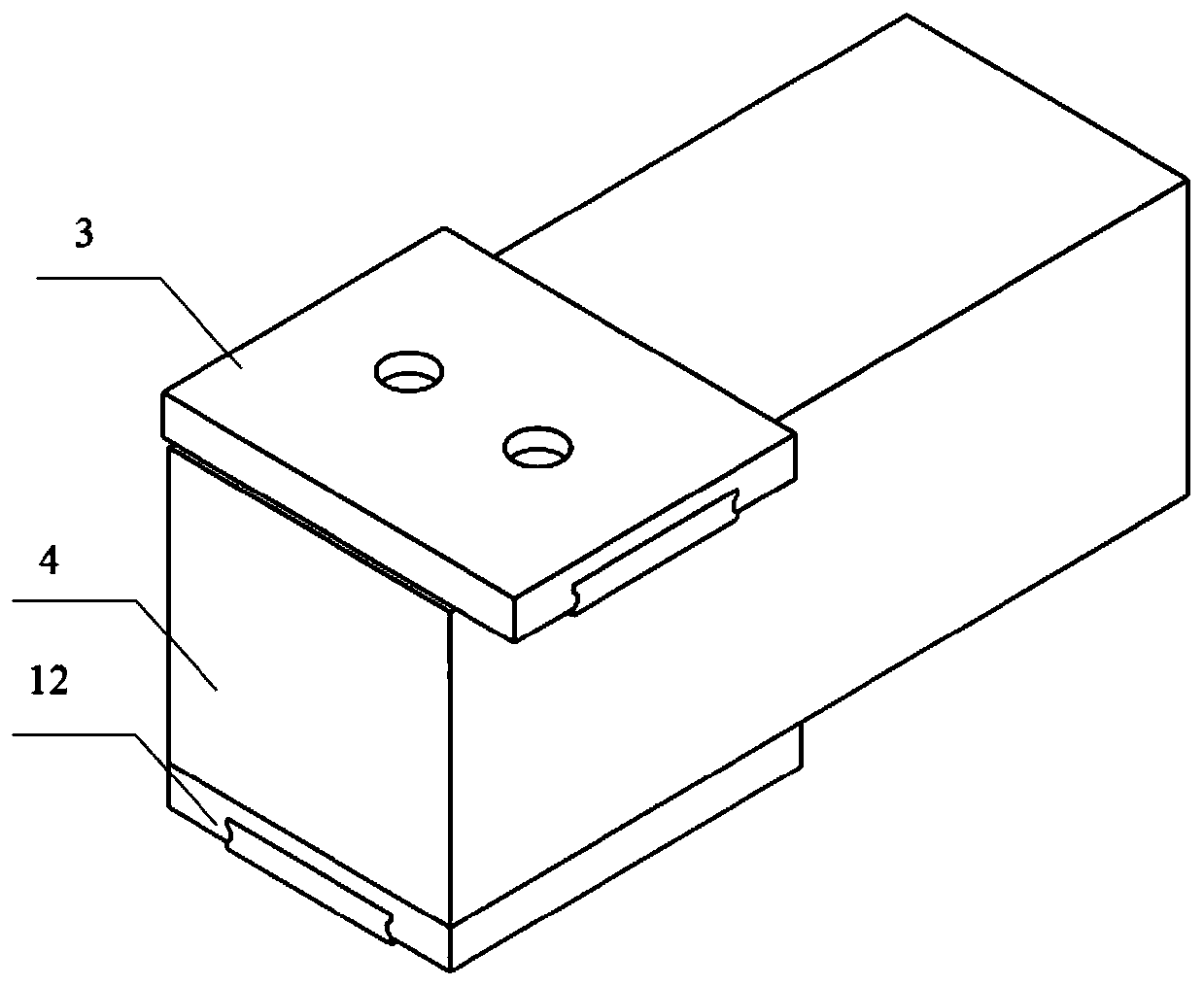

[0018] A single-excitation two-dimensional ultrasonic vibration-assisted microfabrication platform, such as figure 1 , figure 2 and image 3 As shown, the embodiment of the present invention includes: a right-angled bottom plate 13, an upper vibrating mass 2 and a lower vibrating mass 4 optimized according to the resonance frequency and formation, a linear guide rail A3 and a linear guide rail B12, a long support plate 10, a short support plate 5, Horn B6 and horn A9, transducer B7 and transducer A11, ultrasonic generator 8. The right-angled bottom plate is fixed on the machine table, the upper vibrating block 2 and the lower vibrating block 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com