A New Vibratory Roller Vibration Reduction System

A vibratory road roller and vibration damping system technology, which is applied in vibration suppression adjustment, mechanical equipment, springs/shock absorbers, etc., can solve the problems of poor operating comfort for road roller drivers, loss of vibration energy, and poor vibration damping effect , to achieve the effects of avoiding adverse effects, uniform amplitude, and stable and reliable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

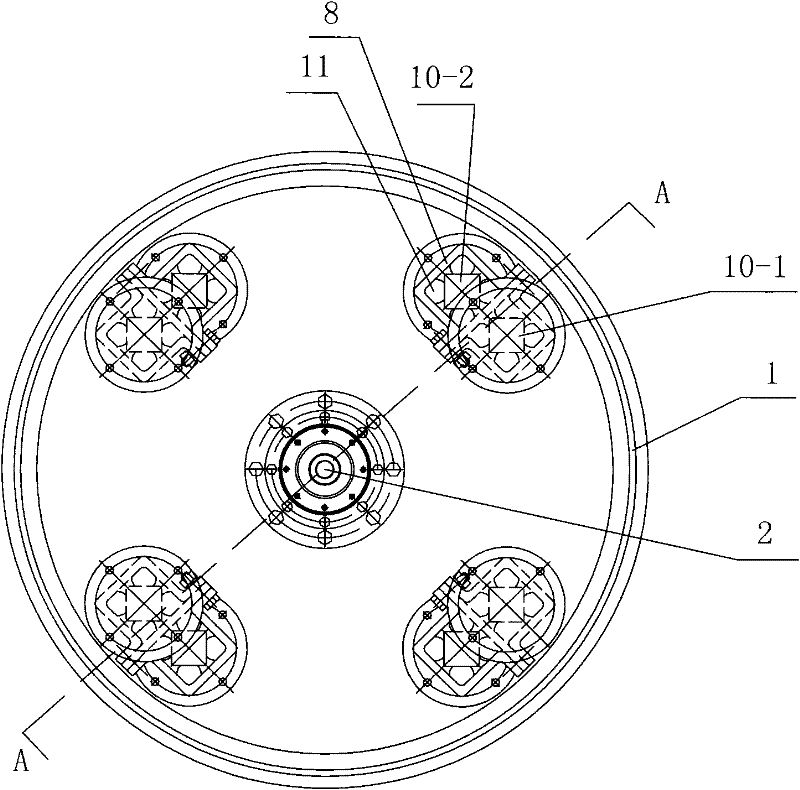

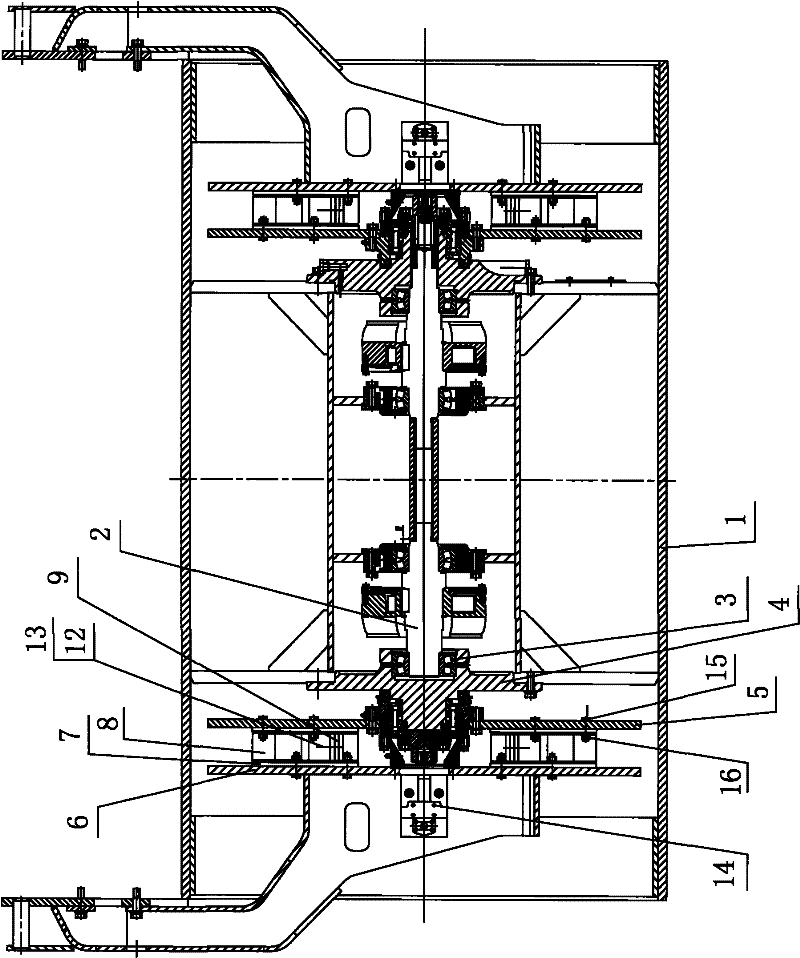

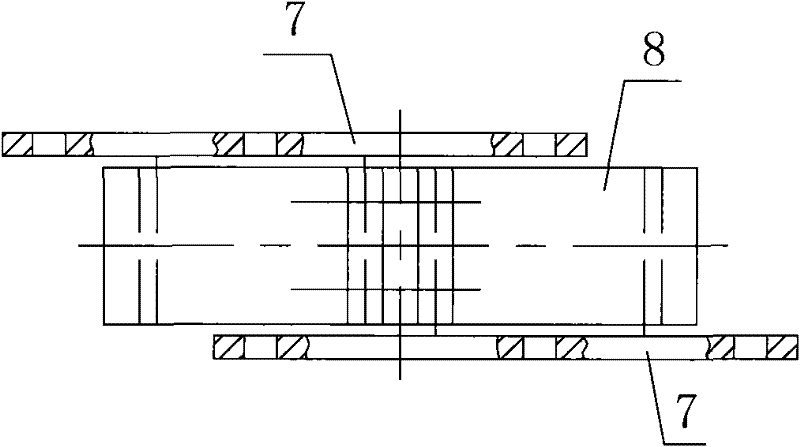

[0036] like figure 1 , figure 2 As shown, the present invention includes two groups of rubber shock absorber groups symmetrically arranged on the left and right sides of the vibrating shaft 2 provided on the vibrating steel wheel 1 of the vibratory road roller. In the left and right shaft seats 4, the shaft seats 4 are fixedly installed in the vibrating steel wheel 1 through a support. The rubber shock absorber group includes a shock absorber support plate 5 installed vertically and coaxially on the shaft seat 4, and an upper vehicle that is located outside the shock absorber support plate 5 and is used to support and fix the upper frame of the vibratory roller. Frame support plate 6 and a plurality of rubber shock absorbers evenly arranged between the shock absorber support plate 5 and the upper frame support plate 6 along the circumferential direction, and the upper frame support plate 6 is arranged in parallel with the shock absorber support plate 5 . The rubber shock a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com