Horizontal-vibration linear motor of low magnetic leakage

A linear motor, flux leakage technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problem of not being able to meet the low cost and good magnetic shielding effect at the same time, to improve the magnetic shielding effect, reduce production costs, left and right The effect of uniform amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

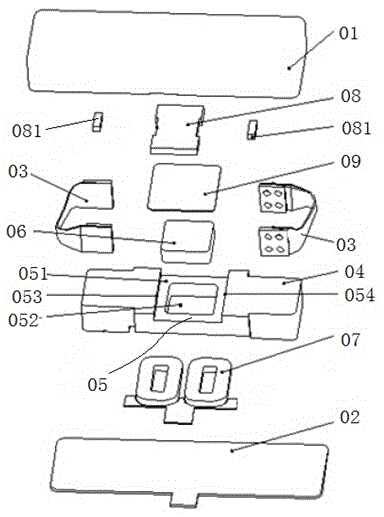

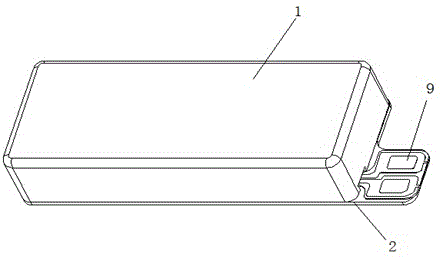

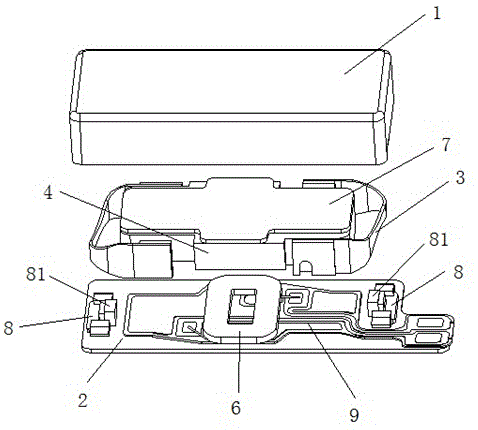

[0037] This embodiment provides a low magnetic flux leakage horizontal vibration linear motor, such as Figure 2-6 As shown, it includes a casing 1, a cover plate 2 which is installed on the casing 1 to form an installation space with the casing 1, and is suspended by the positioning of elastic supports 3 respectively installed on two opposite inner walls of the casing 1. The vibrating assembly installed in the installation space and the electromagnetic coil 6 arranged below the vibrating assembly, when the electromagnetic coil 6 is energized, the vibrating assembly reciprocates in a direction substantially parallel to the bottom surface of the casing 1, and vibrates During the process, the two elastic supports 3 are stretched and compressed.

[0038] Such as Figure 4 and Figure 5 As shown, the vibration assembly includes a mass block 4 connected to the elastic support 3, along the distribution direction of the two elastic supports 3 (ie Figure 5 shown in the left and ri...

Embodiment 2

[0054] This embodiment provides a low-flux leakage horizontal vibration linear motor, which is a deformation on the basis of Embodiment 1. The difference lies in the difference in the arrangement of the vibration assembly and the electromagnetic coil 6. In this embodiment, the vibration assembly includes an elastic support 3 connected mass block 4, an installation through hole 41 provided in the middle of mass block 4, and a permanent magnet 5 fixedly installed on mass block 4 by inserting into the above installation through hole 41, the thickness and quality of permanent magnet 5 Block 4 has the same thickness.

[0055] There are two electromagnetic coils 6, both of which are located directly below the mass block 4 and fixedly installed side by side on the top surface of the cover plate 2 along the distribution direction of the two above-mentioned elastic supports 3. The two electromagnetic coils 6 are arranged in series and face upward after being energized The magnetic pole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com