Hybrid power engine

A hybrid power and engine technology, applied in the field of hybrid power engines, can solve problems such as increased operating costs, failure to ignite, and large exhaust gas emissions, and achieve the effects of saving gasoline energy, reducing exhaust gas emissions, and realizing energy saving and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

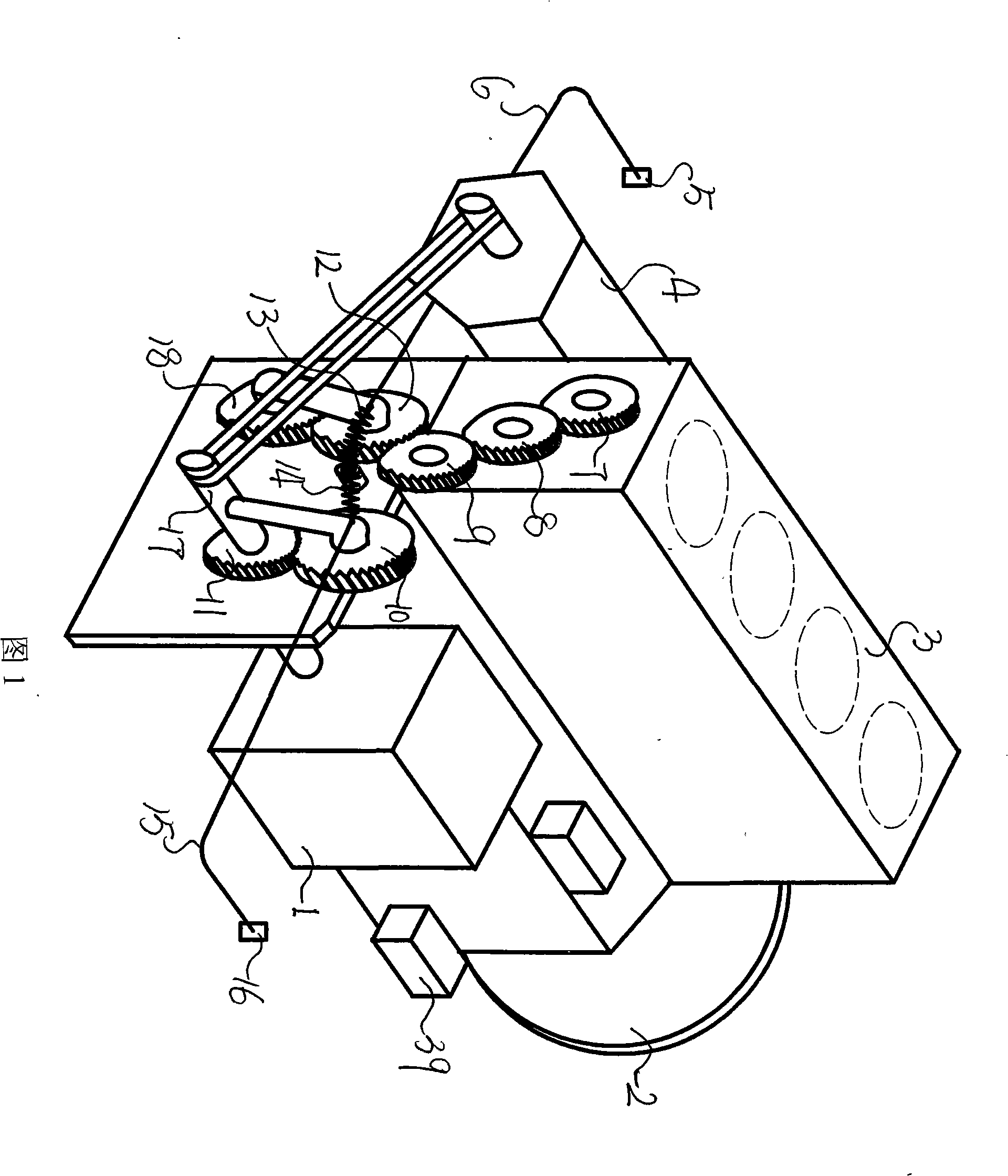

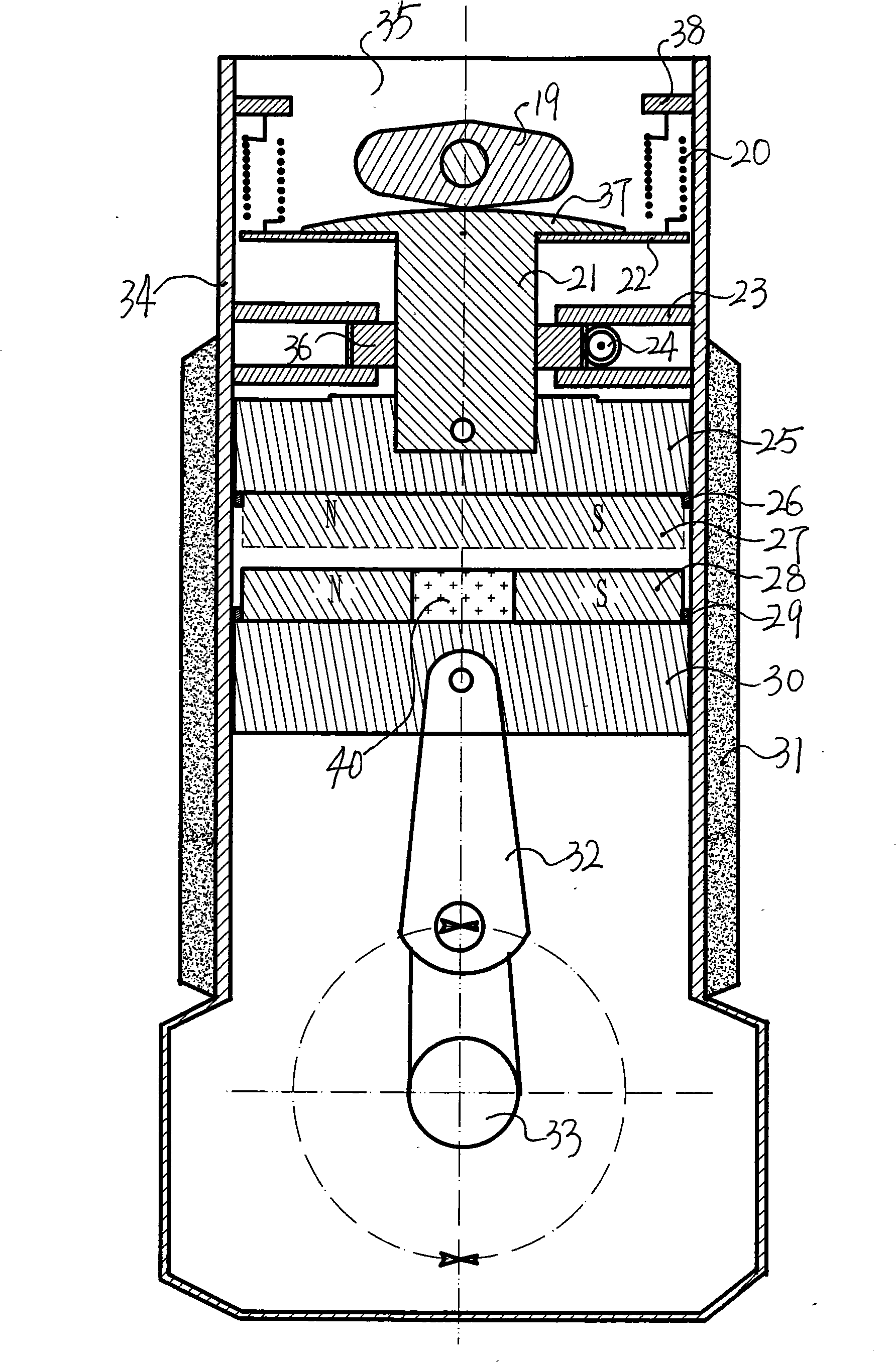

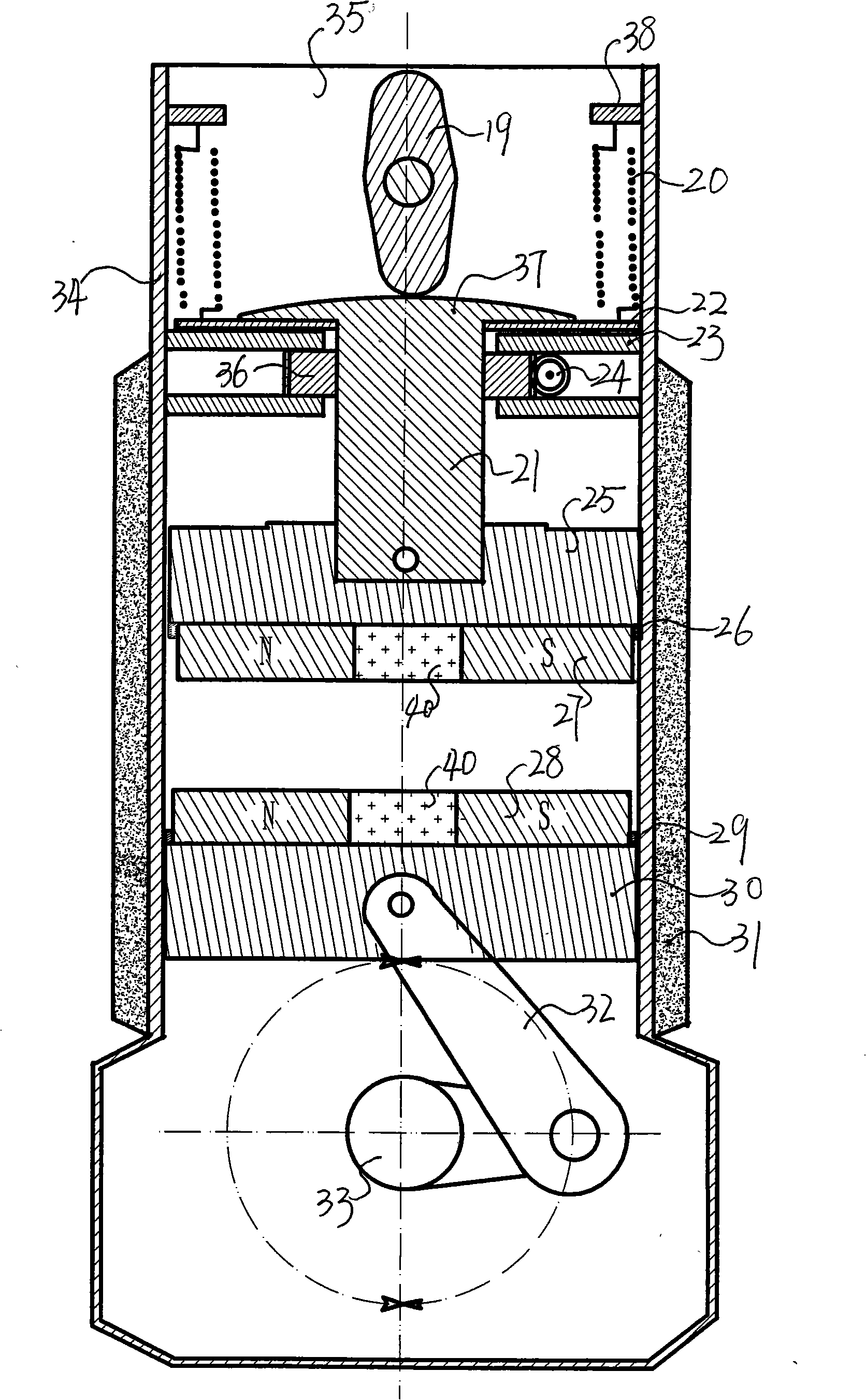

[0032] Figure 1, figure 2Shown, a kind of hybrid engine comprises engine 1, flywheel 2, working cylinder 3, engine main crankshaft 33, generator 4, and the output power of engine 1 is connected with generator 4 through belt pulley 17 transmission, and flywheel 2 is fixed on engine main On the crankshaft 33 , the piston in the working cylinder 3 is in drive connection with the main crankshaft 33 of the engine. In described working cylinder 3, be provided with magnetic working device 35, magnetic working device 35 is made up of two-way cam 19, upper connecting rod 21, upper magnetic force piston rotating gear 36, upper magnetic force piston rotating drive gear 24, upper magnetic force piston 25, upper Magnetic block 27, lower magnetic block 28, lower magnetic force piston 30, return spring 20 form; The upper link end cover positioning ring 22, the upper link end cover positioning ring 22 is suspended on the spring frame 38 provided on the inner side of the cylinder body 34 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com