Combined magnetic bearing

A magnetic levitation bearing and combined technology, applied in bearings, shafts and bearings, shafts, etc., can solve problems such as insufficient precision, late start, and friction that cannot meet the requirements, and achieve low mechanical wear, long life, and low noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific working conditions of the present invention will be described in detail below in conjunction with the accompanying drawings.

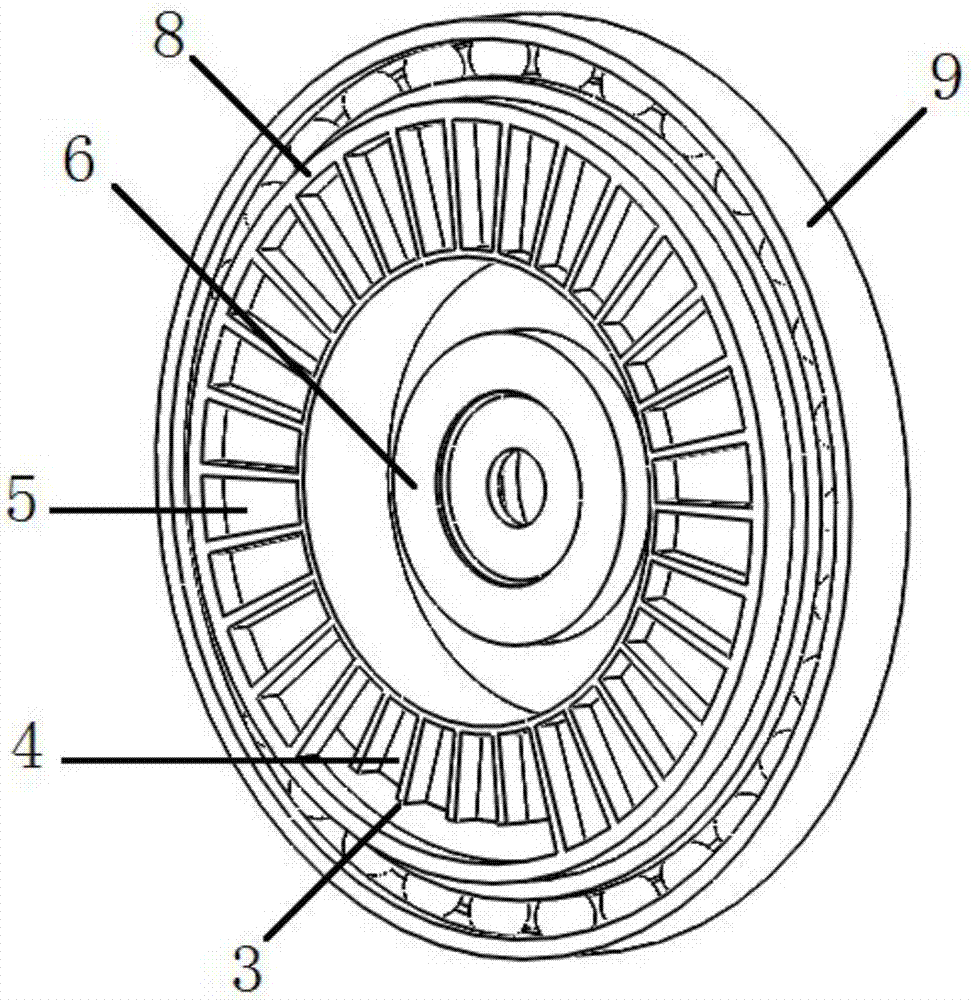

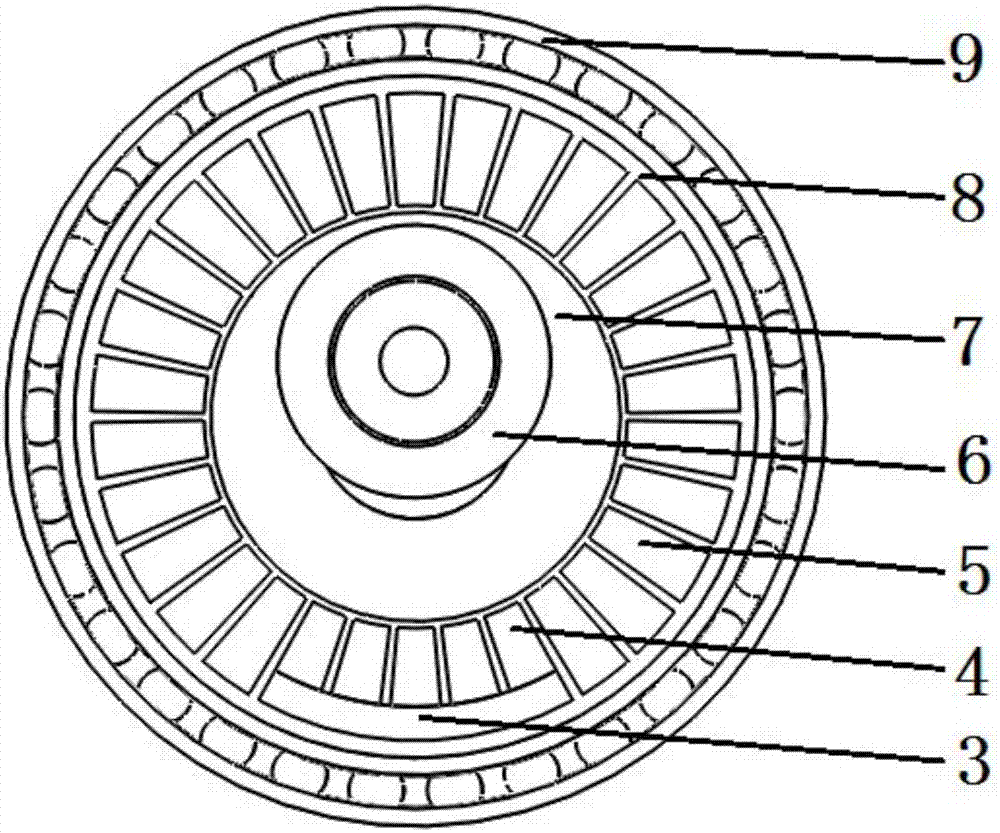

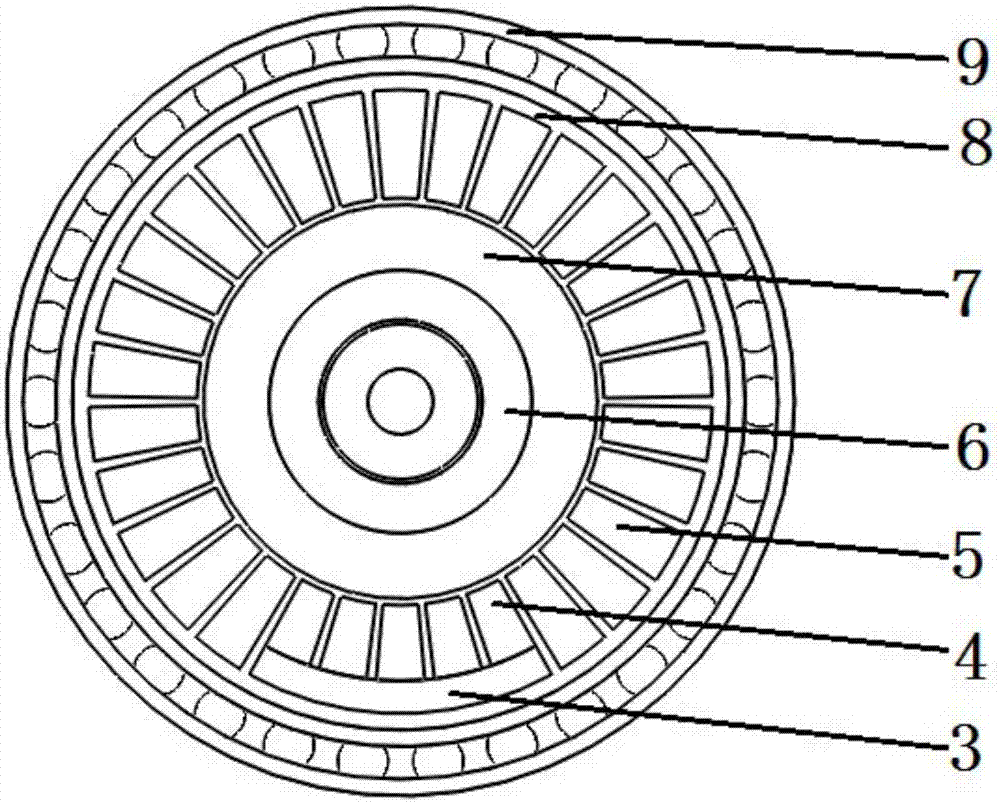

[0030] Such as Figure 1 to Figure 5 As shown, in a combined magnetic suspension bearing provided by the present invention, 5 large magnetic force magnets 4 and 25 small magnetic force magnets 5 are evenly arranged in a circular array, the N poles of the 30 bar magnets face the center of the circle, and the inner inner ring The magnet 6 and the 30 external bar magnets will be suspended on the upper position of the central axis due to the principle that the same poles repel each other. Also at the front and rear ends of the casing 8, there are respectively the rear magnetic plate 7, the front magnetic plate 2 and the inner ring magnet 6, and the inner ring magnet 6 is suspended in the middle due to the principle of repulsion of the same pole, and then the rear magnetic plate 7 and the front magnetic plate 2 are respectively welded o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com