Placket machine presser foot automatic adjustment mechanism and control method thereof

A technology of automatic adjustment and adjustment mechanism, applied in the direction of cloth pressing mechanism, sewing machine control device, sewing machine components, etc., can solve the problems of high labor intensity, low production efficiency, and high technical requirements, and achieve uniform and beautiful sewing stitches. Labor-intensive, easy to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

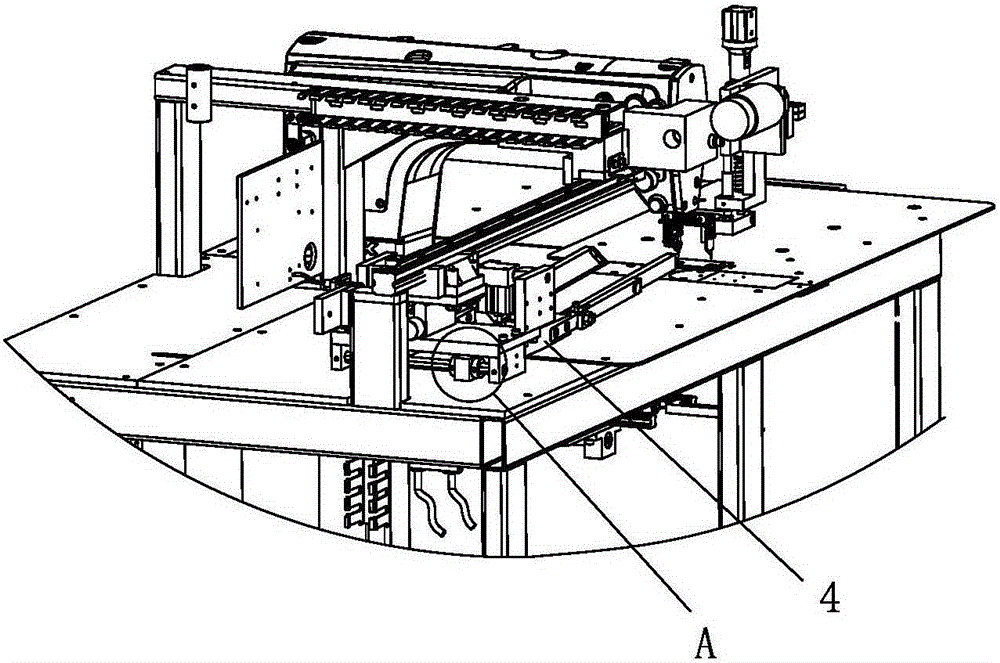

[0042] The present invention will be further described below with specific embodiment, see Figure 4 -12:

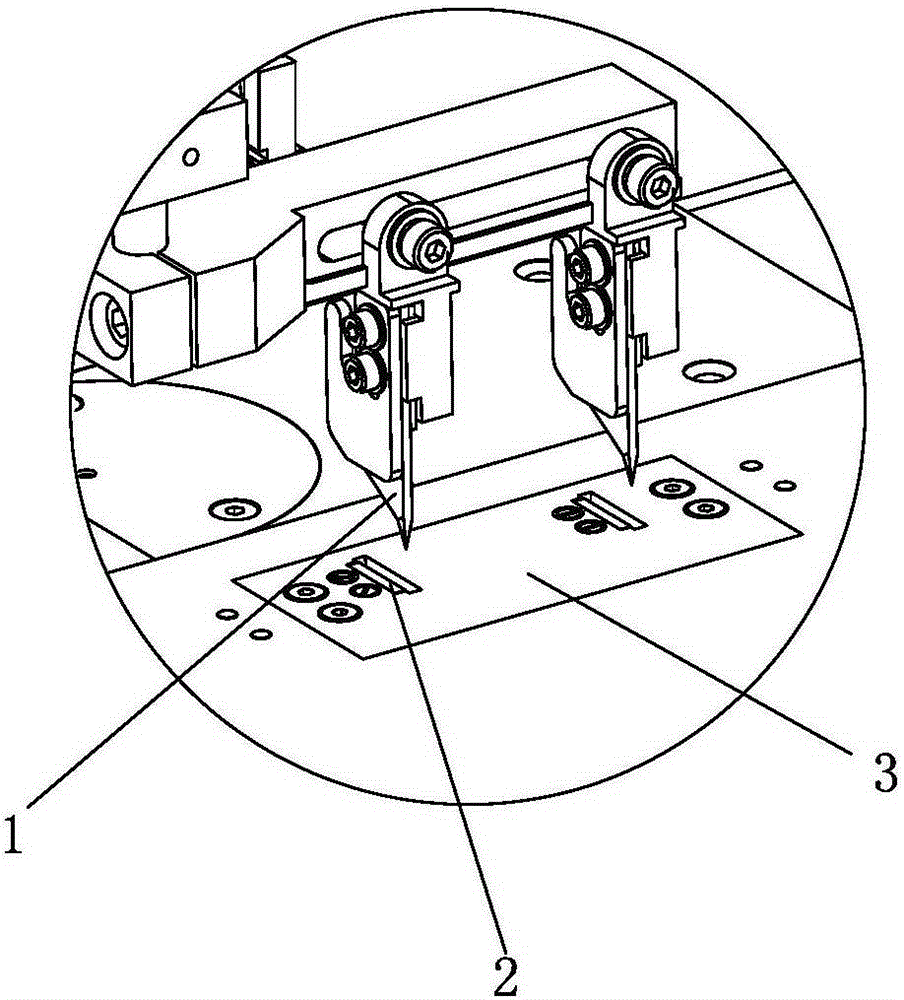

[0043] An automatic adjustment mechanism for the presser foot of a placket machine, comprising left and right presser foot arms 10, 20 and left and right presser feet 30, 40 arranged on the left and right presser foot arms 10, 20, mounted on the presser foot mounting frame 50 is provided with an adjustment mechanism, and the left and right presser arms 10, 20 are connected with the adjustment mechanism, and the adjustment mechanism moves to adjust the distance between the left and right presser arms 10, 20 and then adjusts the distance between the left and right presser arms 30, 40 The action of the adjustment mechanism is controlled by the control system, and the action of the adjustment mechanism is electronically controlled by the sewing machine.

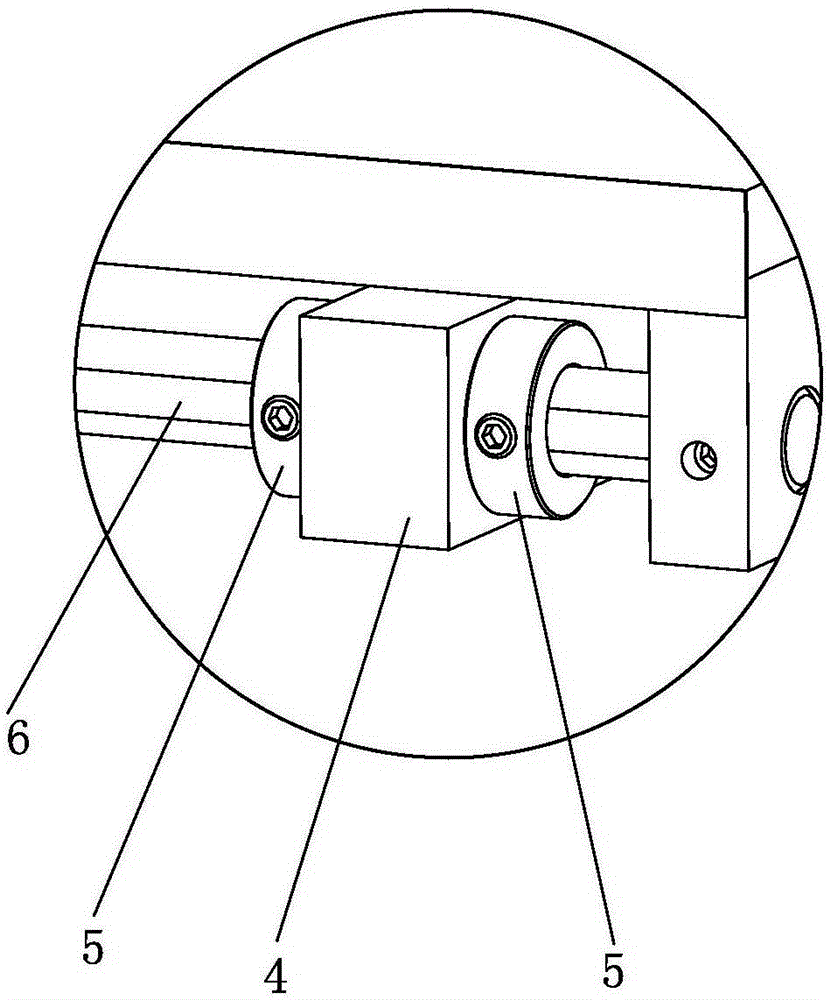

[0044] Above-mentioned regulating mechanism can adopt screw mandrel and motor, and specific structure is as follows: scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com