Corrugated carton forming process

A technology of corrugated box and forming process, which is applied in the direction of paper/cardboard containers, container manufacturing machinery, containers, etc. It can solve problems such as box corner leaks and carton wrapping corners, and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

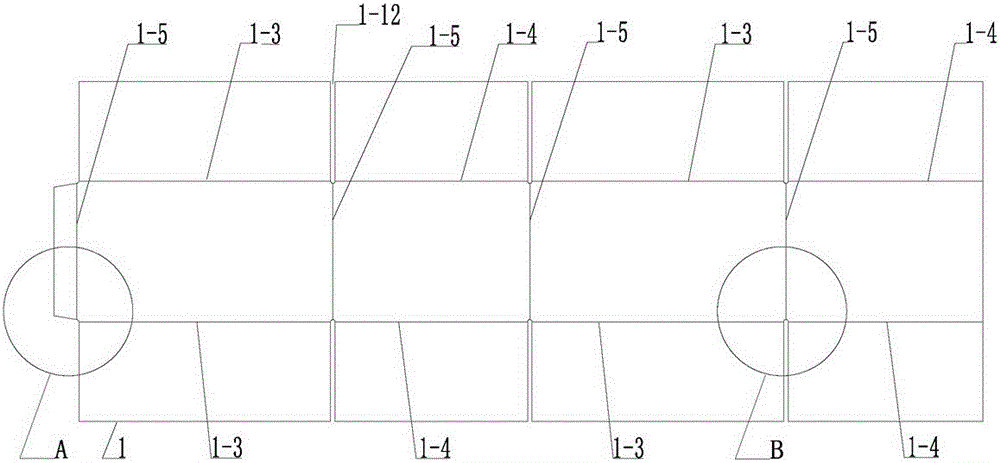

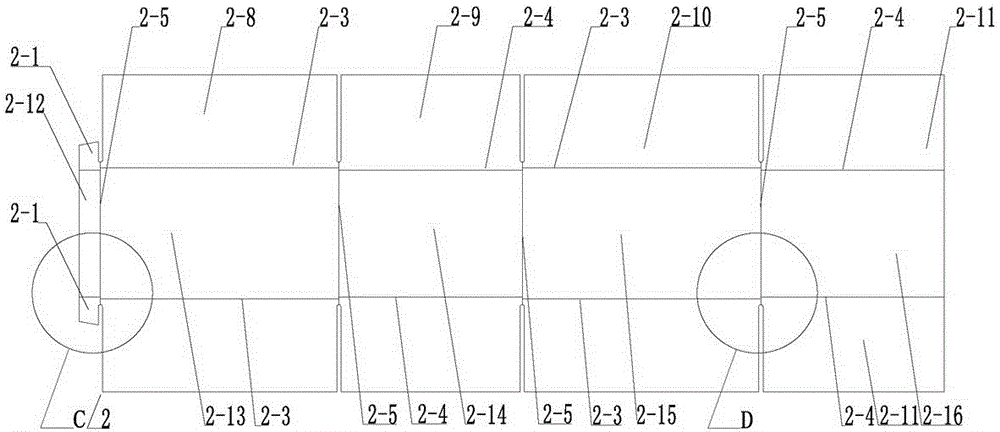

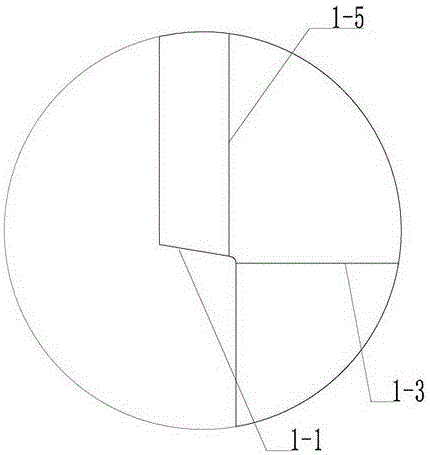

[0035] Depend on Figure 1 to Figure 16 Given, the present invention comprises the steps:

[0036] 1. Design the die-cutting process drawing of corrugated carton;

[0037] 2. Production and processing of corrugated cardboard through the die-cutting unit of the printing die-cutting and slotting machine or the automatic flat press;

[0038] 3. Glue and form the corrugated cardboard according to the process requirements;

[0039] 4. Reinforce the bonded corrugated cartons.

[0040] The die-cutting process diagram of the corrugated box for implementing the above-mentioned process route includes: integrally formed corrugated cardboard, the corrugated cardboard is divided into the first mark 2-13, the second mark 2-14, and the third mark 2- 15 and the fourth mark 2-16, the two sides of the first mark 2-13 are separated by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com