A composite pallet

A technology of pallets and boards, which is applied to rigid containers, containers, packaging, etc., can solve the problems of increasing pallet design and mold opening costs, and achieve the effect of reducing design and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

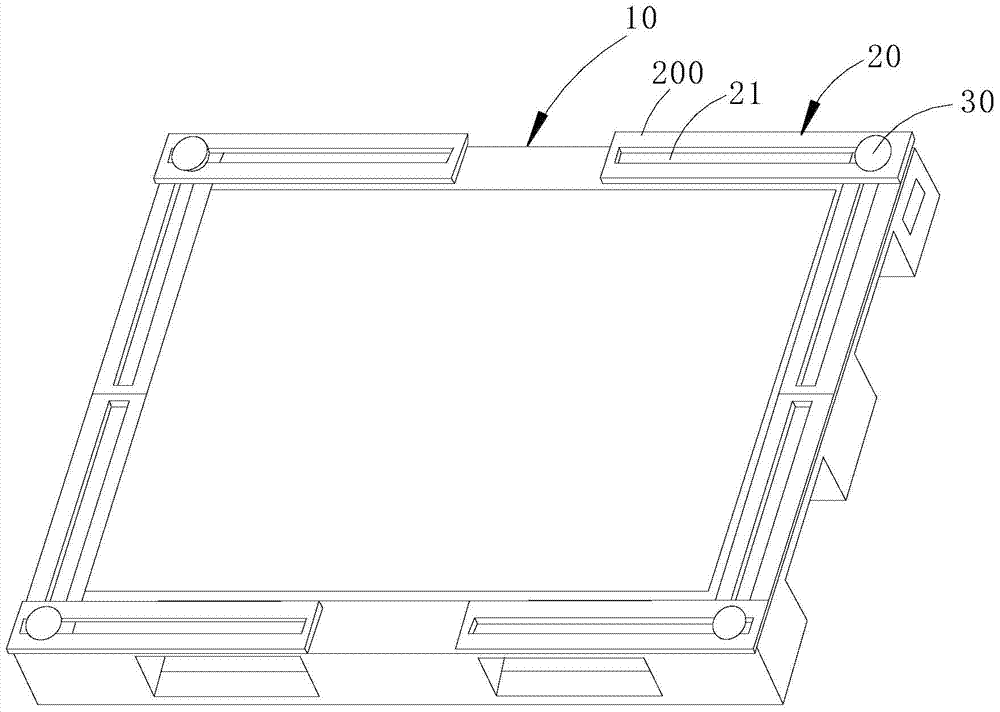

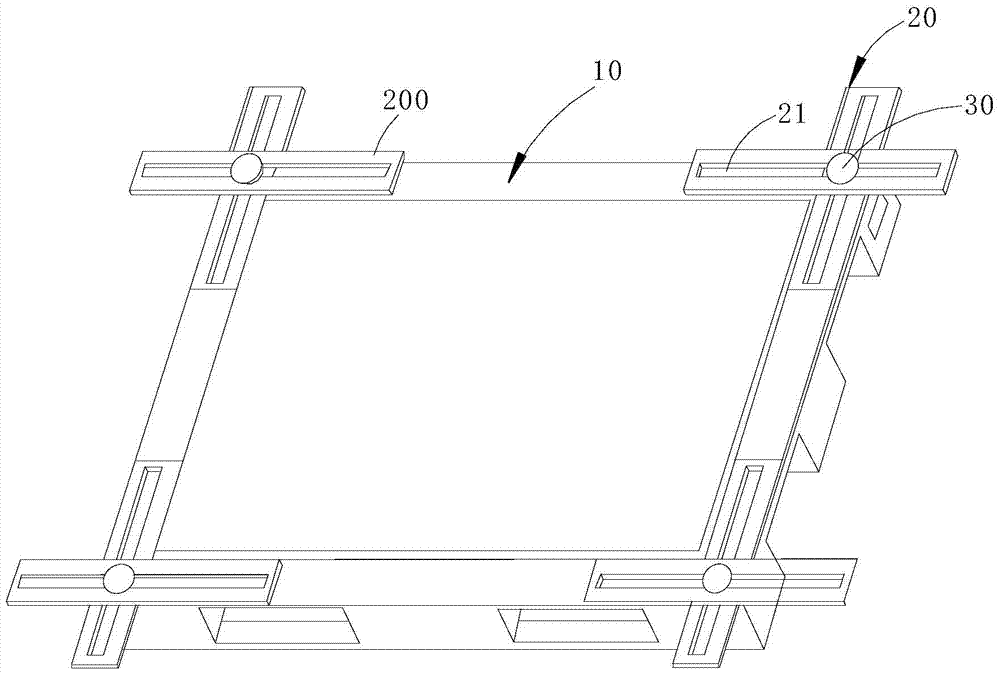

[0023] refer to figure 1 , the composite pallet of the present invention comprises a pallet body 10, an extension arm 20 and a fixing member 30, the extension arm 20 is provided with a through hole 21, and at least one extension arm 20 is respectively provided on each of the four corners of the pallet body 10 to fix The member 30 passes through the through hole 21 and movably fixes the extension arm 20 on the pallet body 10 .

[0024] The extension arm 20 of this embodiment has a board body 200 with a flat plate structure, and the through hole 21 is a long hole extending along the length direction of the board body 200. The fixing member 30 passes through the through hole 21 and fixes the board body 200 on the pallet. The top surface of the body 10. combine figure 2 As shown, two boards 200 are preferably arranged on each corner of the pallet body 10. After the assembly is completed, the extension arm 20 can extend along the four sides of the pallet body 10 by loosening the...

Embodiment 2

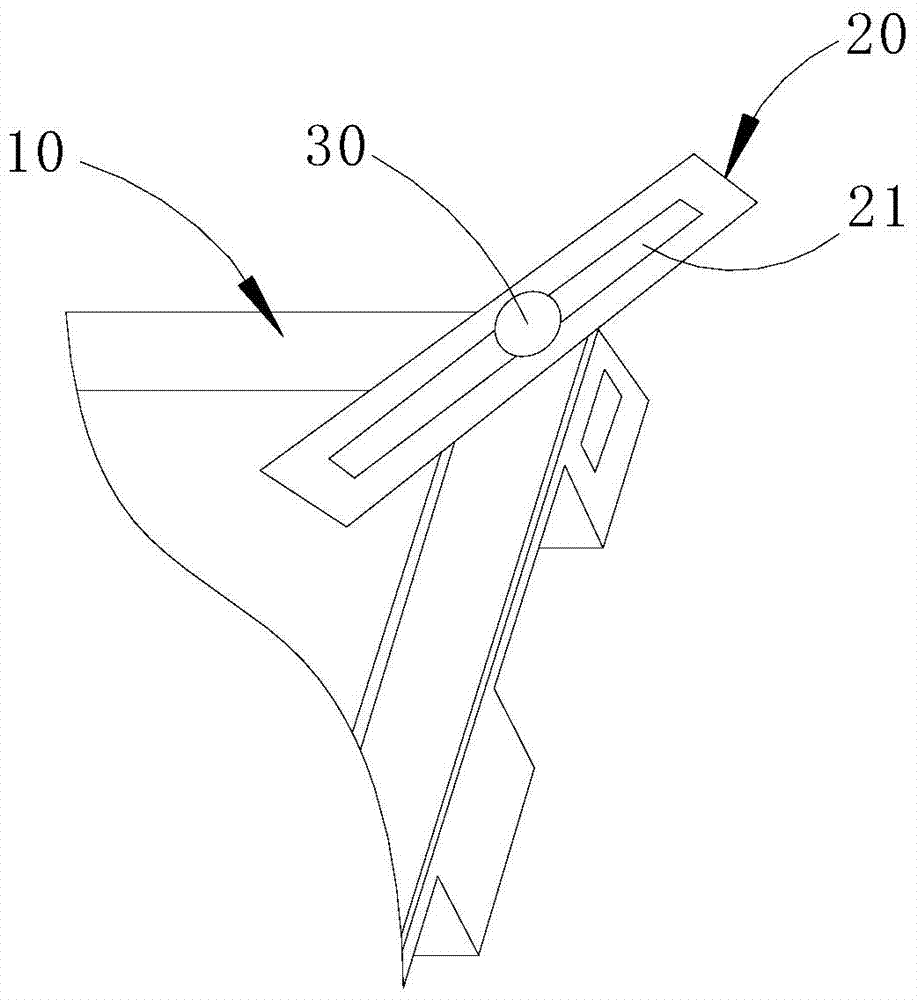

[0033] like Figure 5 As shown, the difference from Embodiment 1 is that the extension arm 20 of this embodiment includes a plate body 200 on the top surface and a side plate 201 perpendicular to the plate body 200, and a narrow and long through hole 21 is opened on the side plate 201, and the side plate The length of 201 is shorter than the board body 200, and the two fixing parts 30 pass through the through hole 21 and the side board 201 can be movably attached to the side wall of the pallet body 10, and can be located in the pallet body 10 through the side board 201 Set the hanging ear 20a on one side of the pallet or design the distance between the fixing part 30 and the outer wall of the pallet body 10, etc., so that the side plate 201 does not extend out of the pallet body 10, so as to avoid the side plates 201 of the adjacent two extension arms 20. interference, the board body 200 is closely attached to the top surface of the pallet body 10 as a bearing surface. Compar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com