Automatic packing machine for four corners of photo album

An automatic packaging machine, four-corner technology, applied in packaging and other directions, can solve the problems of low packaging efficiency, different levels of packaging difficulty, and high packaging costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiments of the present invention will be further described below in conjunction with the drawings:

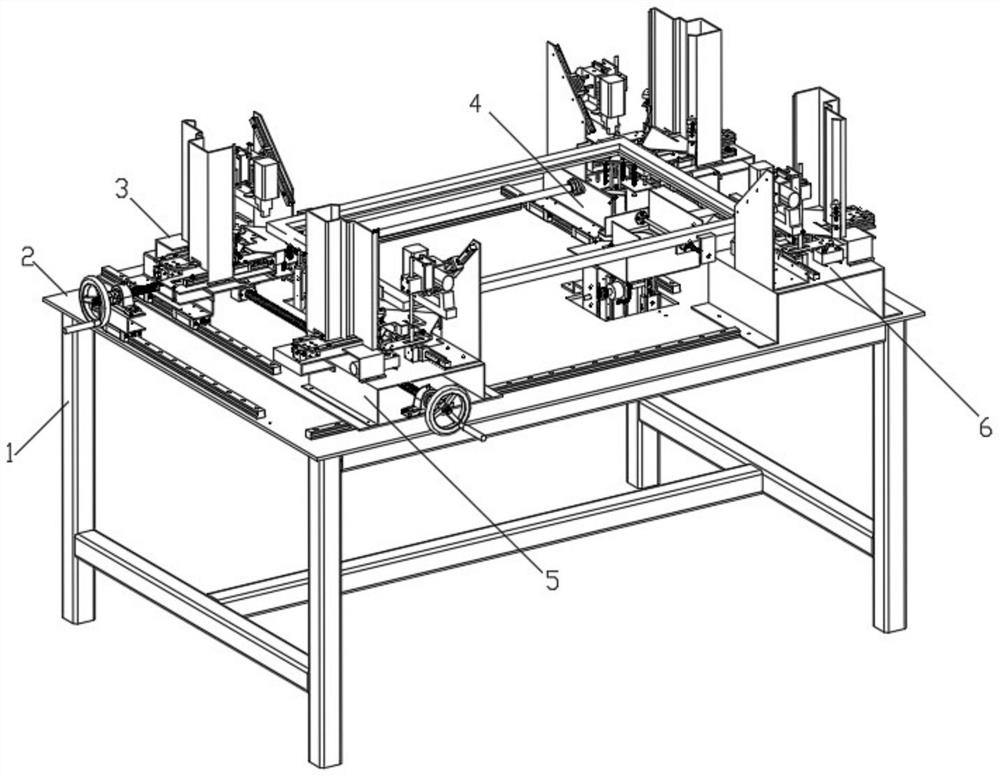

[0040] Such as figure 1 As shown, the four-corner automatic packaging machine for photo albums includes a frame 1, a workbench 2, a stroke adjustment mechanism provided on the workbench 2, multiple paper corner pushing mechanisms, multiple coding nail mechanisms, and a positioning and pressing mechanism.

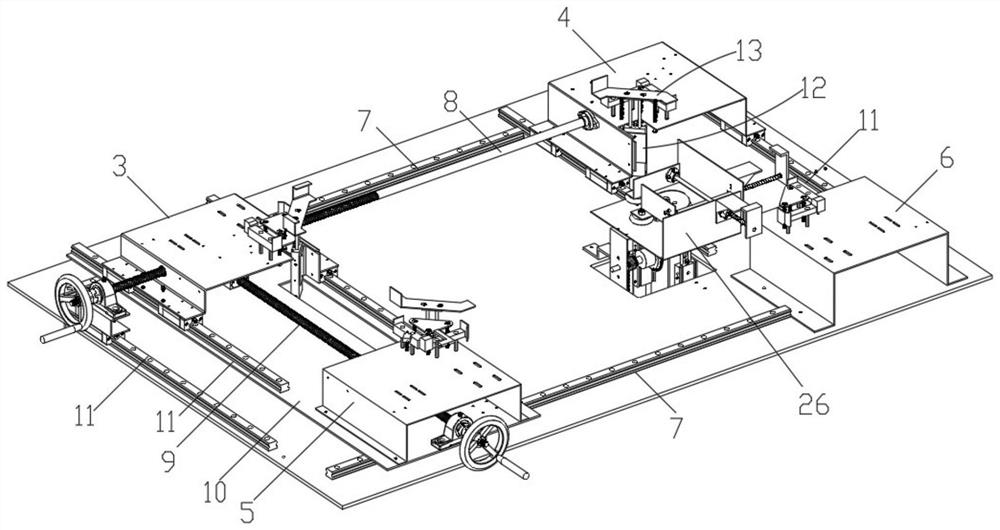

[0041] Preferably, such as figure 2 As shown, the stroke adjustment mechanism in this embodiment includes a first boss 3, a second boss 4, a third boss 5, a fourth boss 6, a horizontal screw 8 and a longitudinal screw 9. In this embodiment, the structures of the first boss 3, the second boss 4, the third boss 5, and the fourth boss 6 are similar, and all have an arch bridge structure. Among them, the first boss 3 and the third boss 5 are arranged on a sliding plate 10, and the sliding plate 10 is arranged on the workbench 2 through two transverse sliding r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com