Packaging machine

A technology of packaging machine and packaging manipulator, which is applied in the direction of packaging, etc., can solve the problems of cumbersome packaging process and complex structure of packaging machine, and achieve the effects of shortening the packaging cycle, realizing automatic operation and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

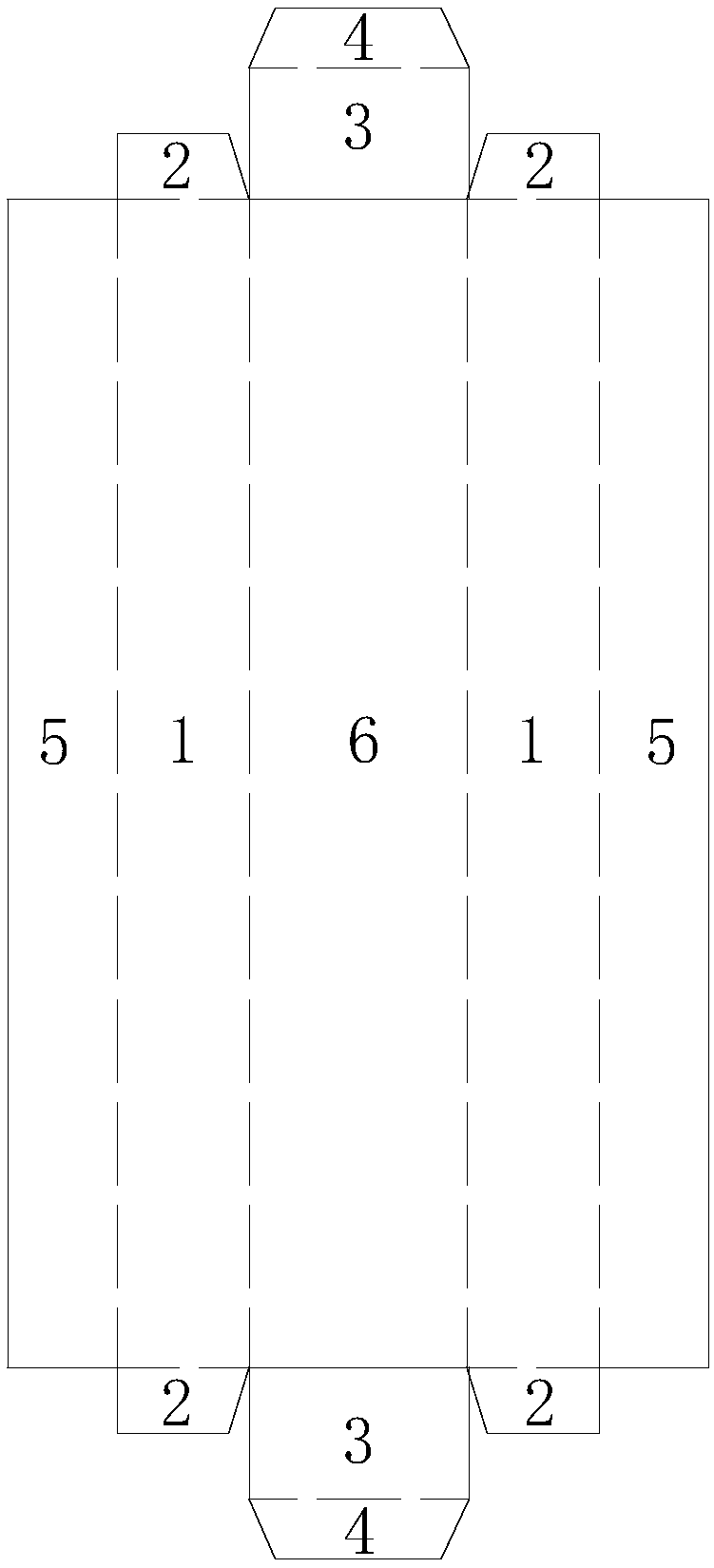

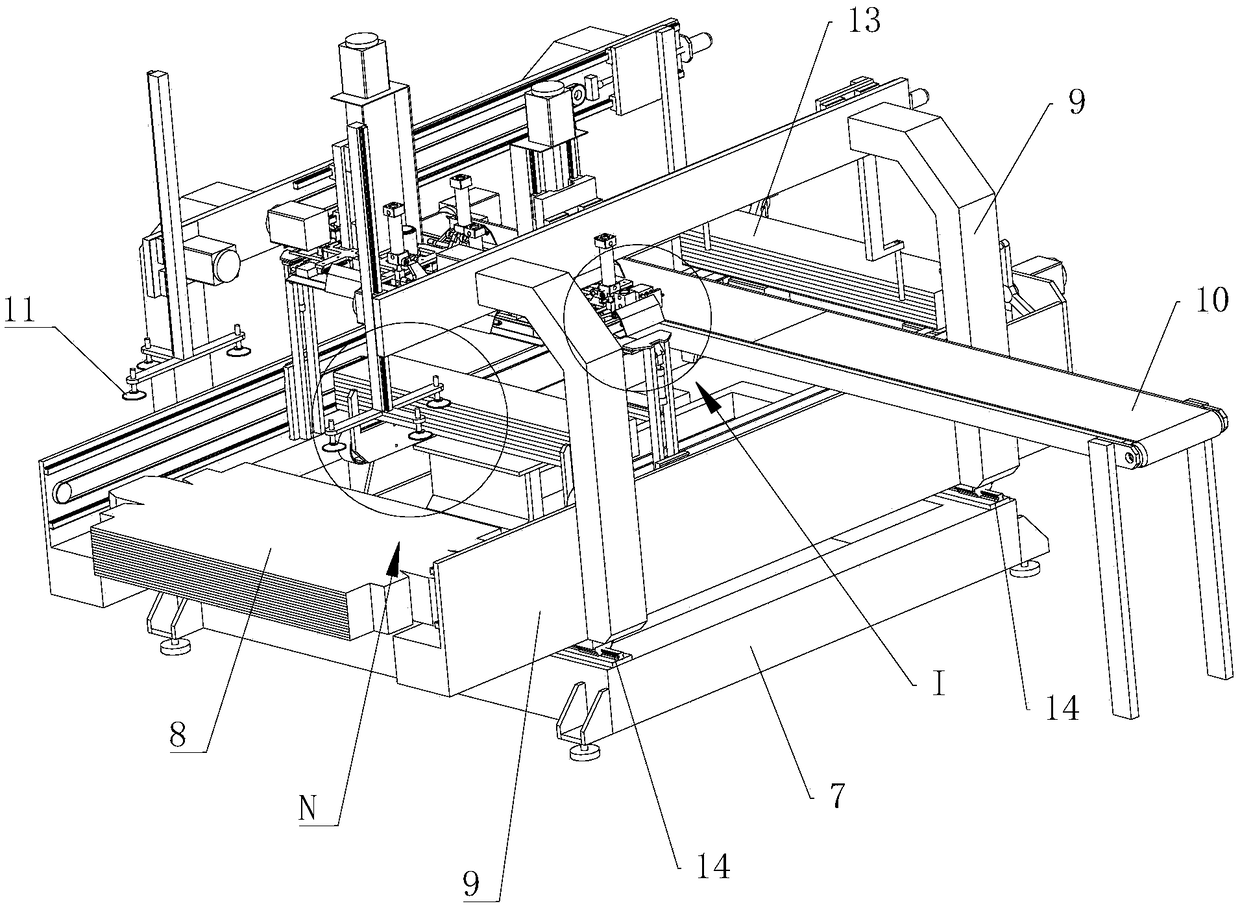

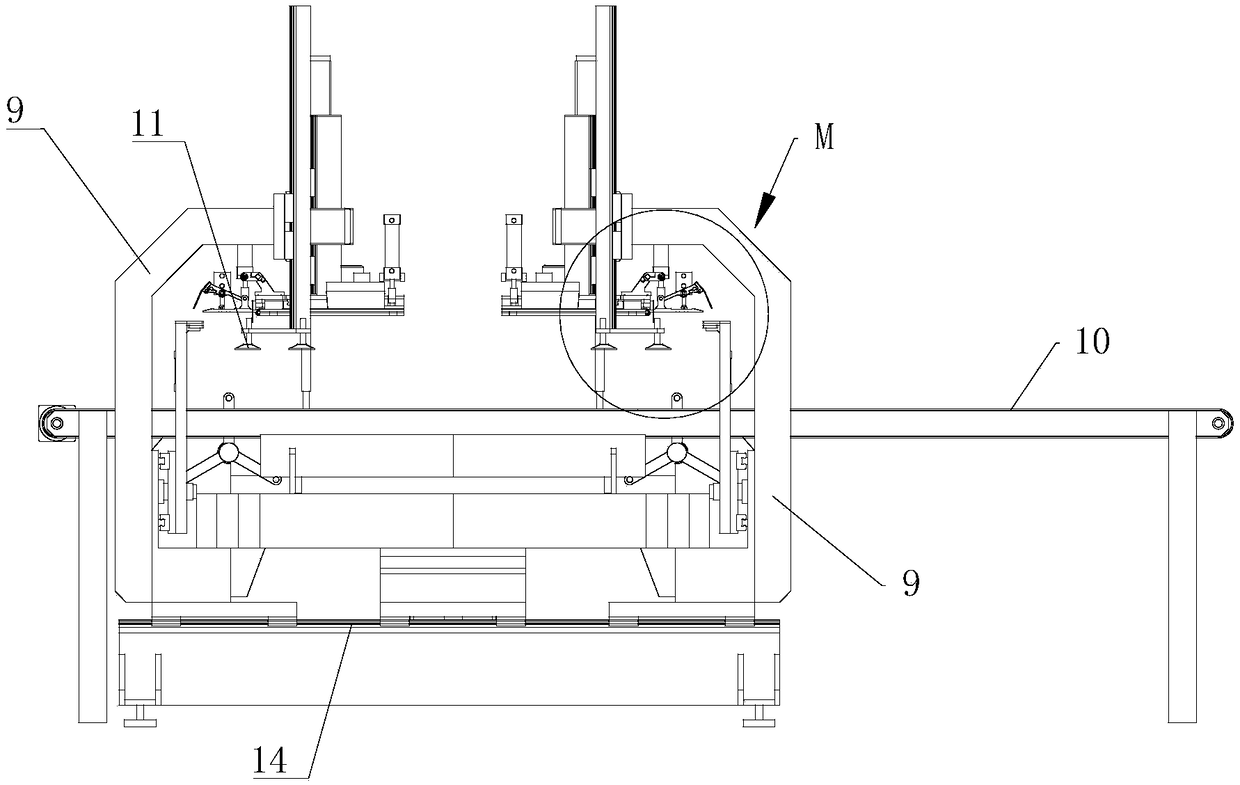

[0050] like figure 2 and image 3 As shown, the packaging machine of this embodiment includes a base 7, and a horizontal first guide rail 14 is arranged on the base 7. For the convenience of description, the direction of the first guide rail 14 is defined as the X-axis here, and the direction perpendicular to the X-axis is defined as the X-axis. The horizontal direction is defined as the Y axis, and the vertical direction perpendicular to the X axis is defined as the Z axis. Two large arms 9 are arranged on the first guide rail 14, and a plurality of packing boxes 8 are stacked on one end of the base 7, and these packing boxes 8 are figure 1 The packing box in the unfolded state shown in , the other end is provided with stacked workpieces 13, the end where the packing box is placed is the entrance of the packing box, the end where the workpiece is placed is the entrance of the workpiece, and the length direction of the packing box 8 and the workpiece 13 is X The width direc...

Embodiment 2

[0074] like Figure 5 As shown, it is a schematic structural diagram of a packaging manipulator according to another embodiment of the present invention. Except that the packaging manipulator of this embodiment is different from the first embodiment, the rest of the structure is basically the same as it, and will not be repeated here.

[0075] The packing manipulator of this embodiment comprises a base 15, and the length of this base 15 is fixed, and the 3rd folding plate 18 is installed on the two ends of base 15 respectively, therefore, this packing manipulator can only be to the packing of fixed length. Box 8 is folded.

[0076] The first flap 16 on both sides of the base 15 can be set to one, or two or even more, as long as the carton surface 1 can be completely folded. Similarly, the fifth flap 20 The number can also be selected according to actual needs.

[0077] The distance between the corresponding first flaps 16 on both sides of the base 15 is realized by adjusting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com