Lamination device of a flat roll packaging machine

A roll packaging and stacking technology, applied in the field of flat roll paper packaging machines, can solve problems such as article movement, affecting packaging efficiency, affecting processing, etc., to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

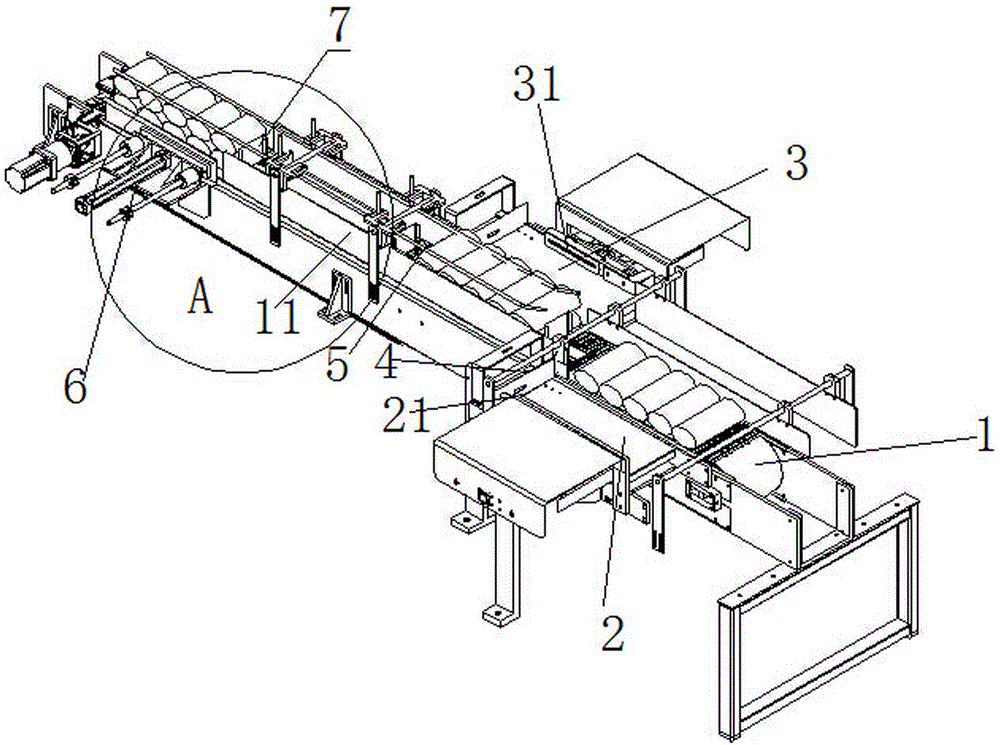

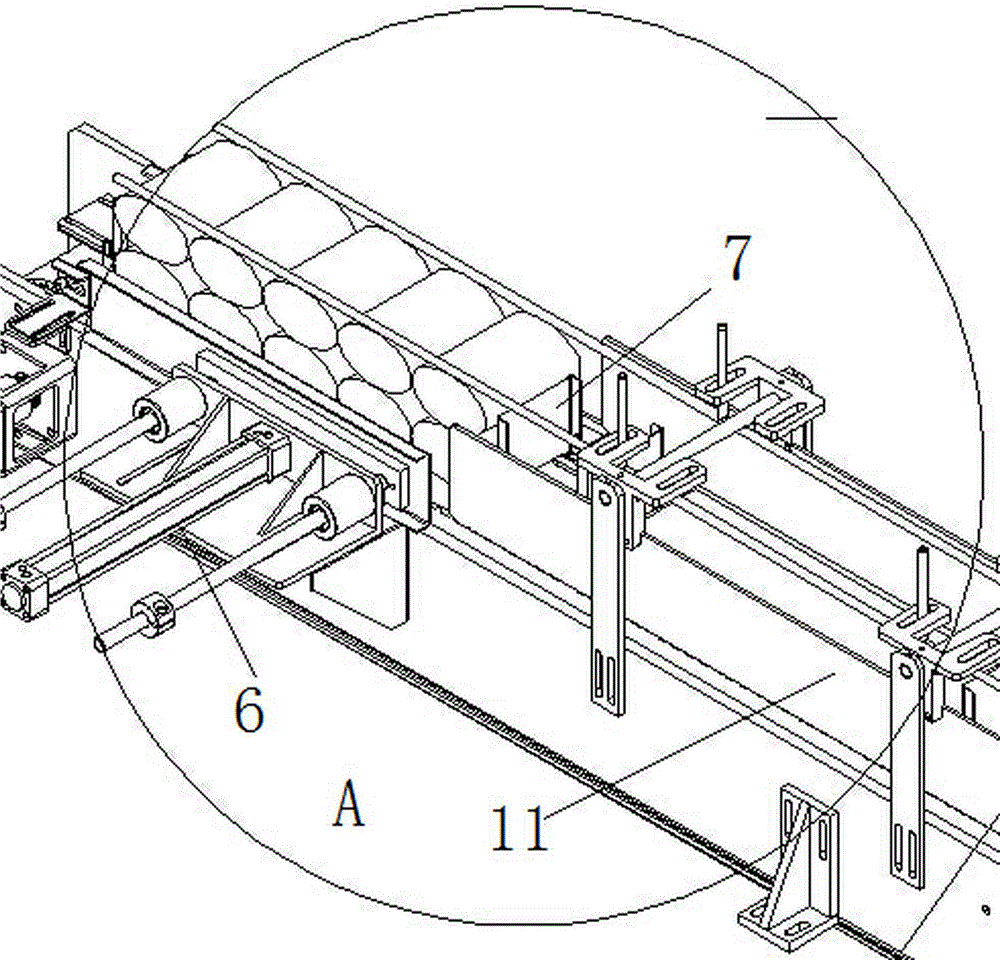

[0021] As a preferred embodiment of the present invention, with reference to the attached figure 1 , the present invention comprises conveying device 1, described conveying device 1 two sides are provided with baffle plate 11; Described conveying device 1 is also provided with first pushing platform 2 and second pushing platform 3 outside both sides respectively, described second The height of the delivery platform 3 is higher than the height of the first delivery platform 2; the first push platform 2 and the second push platform 3 are respectively equipped with a first push cylinder 21 and a second push cylinder 31; the delivery device 1 The end is also provided with a third pushing cylinder 6.

[0022] The present invention adopts two pushing platforms, first pushes the product from the first pushing platform onto the conveying device, then the conveying device starts to convey, when the product is conveyed to the position of the second pushing platform, the conveying device...

Embodiment 2

[0024] As another preferred embodiment of the present invention, with reference to the attached figure 1 , the present invention comprises conveying device 1, described conveying device 1 two sides are provided with baffle plate 11; Described conveying device 1 is also provided with first pushing platform 2 and second pushing platform 3 outside both sides respectively, described second The height of the delivery platform 3 is higher than the height of the first delivery platform 2; the first push platform 2 and the second push platform 3 are respectively equipped with a first push cylinder 21 and a second push cylinder 31; the delivery device 1 The end is also provided with a third pushing cylinder 6.

[0025] The present invention adopts two pushing platforms, first pushes the product from the first pushing platform onto the conveying device, then the conveying device starts to convey, when the product is conveyed to the position of the second pushing platform, the conveying ...

Embodiment 3

[0029] As the best embodiment of the present invention, with reference to the attached figure 1 , the present invention comprises conveying device 1, described conveying device 1 two sides are provided with baffle plate 11; Described conveying device 1 is also provided with first pushing platform 2 and second pushing platform 3 outside both sides respectively, described second The height of the delivery platform 3 is higher than the height of the first delivery platform 2; the first push platform 2 and the second push platform 3 are respectively equipped with a first push cylinder 21 and a second push cylinder 31; the delivery device 1 The end is also provided with a third pushing cylinder 6.

[0030] The present invention adopts two pushing platforms, first pushes the product from the first pushing platform onto the conveying device, then the conveying device starts to convey, when the product is conveyed to the position of the second pushing platform, the conveying device st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com