A kind of packaging method of flat roll toilet paper

A packaging method and technology for toilet paper, applied in the field of toilet paper packaging, can solve problems such as affecting product packaging, warping at both ends of the product, and difficulty in accurate positioning of the product, and achieve the effect of saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

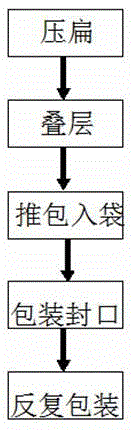

[0036] As a preferred embodiment of the present invention, refer to the accompanying figure 1 , the steps of the present invention are as follows:

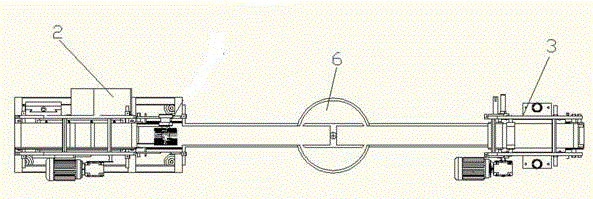

[0037]The first step, flattening: the material is conveyed by the conveying device 1 to the first flattening mechanism 2, the material is flattened in the first flattening mechanism 2, and the material flattened by the first flattening mechanism 2 is conveyed by the conveying device 1 to the steering device At 6 places, the material is turned by the turning device 6 at both ends, and the turned material is conveyed by the conveying device 1 to the secondary flattening mechanism 3 for secondary flattening;

[0038] The second step, lamination: the material after secondary flattening is transported to the first pushing platform 10 and the second pushing platform 11 on both sides of the main conveying mechanism 9 through the two side conveying mechanisms 8. The material of the push platform 10 is pushed to the main conveying mechani...

Embodiment 2

[0043] As another preferred embodiment of the present invention, refer to the accompanying figure 1 and 2 , the steps of the present invention are as follows:

[0044] The first step, flattening: the material is conveyed by the conveying device 1 to the first flattening mechanism 2, the material is flattened in the first flattening mechanism 2, and the material flattened by the first flattening mechanism 2 is conveyed by the conveying device 1 to the steering device At 6 places, the material is turned by the turning device 6 at both ends, and the turned material is conveyed by the conveying device 1 to the secondary flattening mechanism 3 for secondary flattening;

[0045] The second step, lamination: the material after secondary flattening is transported to the first pushing platform 10 and the second pushing platform 11 on both sides of the main conveying mechanism 9 through the two side conveying mechanisms 8. The material of the push platform 10 is pushed to the main con...

Embodiment 3

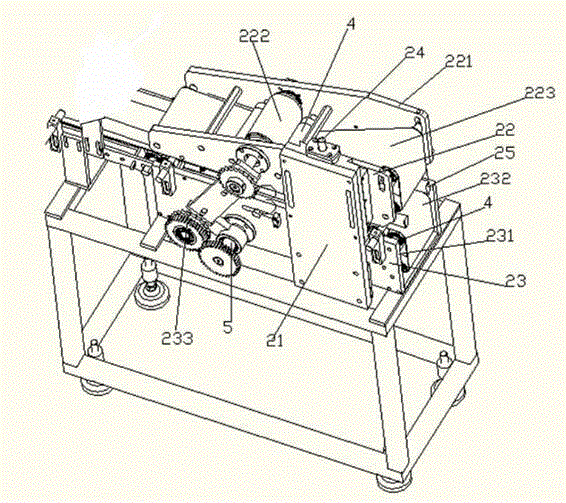

[0058] As another preferred embodiment of the present invention, refer to the accompanying figure 1 , 3 And 4, the step of the present invention is as follows:

[0059] The first step, flattening: the material is conveyed by the conveying device 1 to the first flattening mechanism 2, the material is flattened in the first flattening mechanism 2, and the material flattened by the first flattening mechanism 2 is conveyed by the conveying device 1 to the steering device At 6 places, the material is turned by the turning device 6 at both ends, and the turned material is conveyed by the conveying device 1 to the secondary flattening mechanism 3 for secondary flattening;

[0060] The second step, lamination: the material after secondary flattening is transported to the first pushing platform 10 and the second pushing platform 11 on both sides of the main conveying mechanism 9 through the two side conveying mechanisms 8. The material of the push platform 10 is pushed to the main co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com