Nanocrystalline antibacterial packaging paper and preparation method

A nanocrystalline and packaging paper technology, applied in paper, papermaking, physical treatment of paper, etc., can solve the problems of easy shedding of antibacterial agents and poor antibacterial effect, achieve excellent antibacterial effect, reduce the use of organic adhesives, and be resistant to breakage. Good degree and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

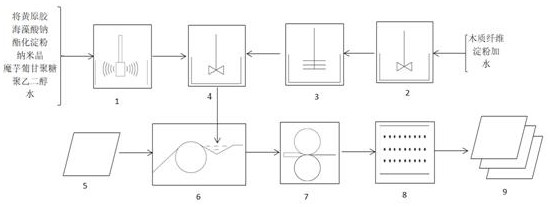

Method used

Image

Examples

Embodiment 1

[0037] Preparation of S1 fine slurry: the colloidal particle size is 15nm, SiO 2 The content is 35%, Na 2Silica sol with an O content of 0.6%, xanthan gum, sodium alginate, nano-zinc oxide with a D50 particle size of 6nm, konjac glucomannan, and polyethylene glycol were added to water, and ultrasonically dispersed under 800W ultrasonic waves for 1.5h. can;

[0038] Preparation of S2 beating material: add pre-bleached and cleaned wood fiber and pre-gelatinized starch into water, stir evenly at 65°C, and then beat until the beating degree is 30-35°SR;

[0039] Preparation of S3 antibacterial coating liquid: mix the fine slurry and beating material evenly, and use a twist frame double planetary mixer for mixing. The rotation speed is 135r / min and the revolution speed is 30r / min;

[0040] Preparation of S4 nanocrystalline antibacterial wrapping paper: at 70g / m 2 The food packaging paper is used as the base paper. The base paper is fed into the coating machine, and the antibact...

Embodiment 2

[0045] Preparation of S1 fine slurry: the colloidal particle size is 10nm, SiO 2 The content is 30%, Na 2 Silica sol with an O content of 0.01%, xanthan gum, sodium alginate, nano-zinc oxide with a D50 particle size of 4nm, konjac glucomannan, and polyethylene glycol were added to water, and ultrasonically dispersed under 500W ultrasonic waves for 1h, that is Can;

[0046] Preparation of S2 beating material: add pre-bleached and cleaned wood fiber and pre-gelatinized starch into water, stir evenly at 60°C, and then beat until the beating degree is 30-35°SR;

[0047] Preparation of S3 antibacterial coating liquid: Mix the fine slurry and beating material evenly, and use a twist frame double planetary mixer for mixing. The rotation speed is 120r / min and the revolution speed is 20r / min;

[0048] Preparation of S4 nanocrystalline antibacterial wrapping paper: at 60g / m 2 The food wrapping paper is the base paper. The base paper is fed into the coating machine, and the antibacte...

Embodiment 3

[0053] Preparation of S1 fine slurry: the colloidal particle size is 12nm, SiO 2 The content is 32%, Na 2 Silica sol with an O content of 0.3%, xanthan gum, sodium alginate, nano-zinc oxide with a D50 particle size of 5nm, konjac glucomannan, and polyethylene glycol were added to water, and ultrasonically dispersed under 600W ultrasonic waves for 1h, that is Can;

[0054] Preparation of S2 beating material: add pre-bleached and cleaned wood fiber and pre-gelatinized starch into water, stir evenly at 62°C, and then beat until the beating degree is 30-35°SR;

[0055] Preparation of S3 antibacterial coating liquid: Mix the fine slurry and beating material evenly, and use a twist frame double planetary mixer for mixing. The low-speed stirring part adopts a rotation speed of 60r / min and a revolution speed of 20r / min. The rotation speed is 150r / min and the revolution speed is 20r / min;

[0056] Preparation of S4 nanocrystalline antibacterial wrapping paper: at 65g / m 2 The food pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com