High-antifogging polystyrene sheet suitable for special food packaging and manufacturing method thereof

A polystyrene sheet material and manufacturing method technology, applied in the directions of packaging, wrapping paper, transportation and packaging, etc., can solve the problems of unable to meet packaging requirements, poor anti-fog performance, etc., to improve anti-fog performance, meet packaging requirements, The effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The high anti-fog polystyrene sheet suitable for special food packaging provided by the invention has the following composition (%): GPPS (general-purpose polystyrene) 90-95%; K resin 5-10%.

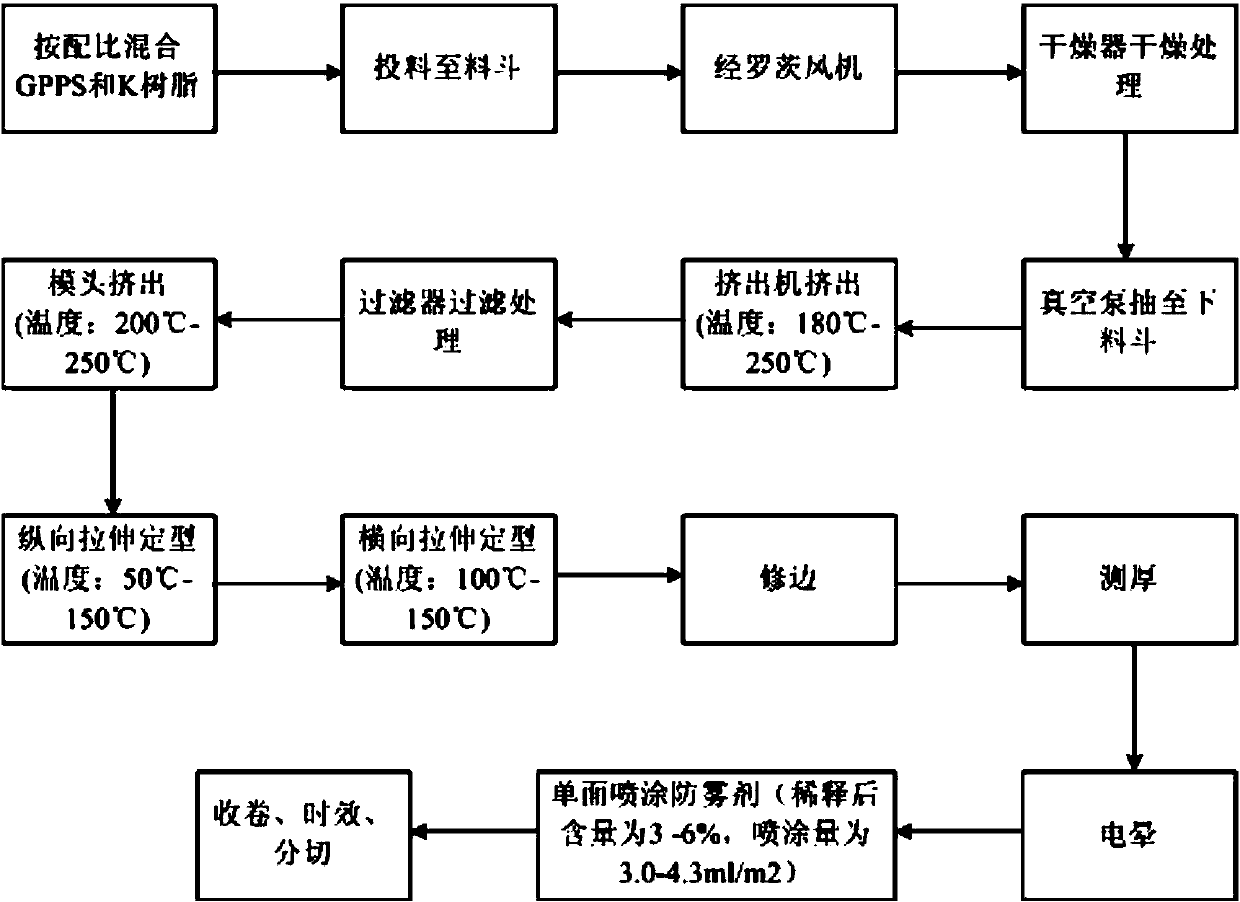

[0027] In the present invention, the processing technology of polystyrene sheet is as figure 1 shown, including:

[0028] 1. First weigh GPPS and K resin according to the weight ratio, and mix them evenly; put the mixed raw materials into the hopper, and blow them to the dryer for drying treatment through the Roots blower;

[0029] 2. The mixture is drawn from the dryer by a vacuum pump and sent to the lower hopper of the extruder;

[0030] 3. The above mixture is melted and extruded on the extruder, and the melting temperature is controlled between 180°C and 250°C;

[0031] 4. After the impurities are filtered out by the filter, the molten material is sent to the die for extrusion and cast into a thick sheet. The temperature in the die is controlled between 200°C and 250°C;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com