Composite sheet for medicine packaging, and Chinese herbal honeyed pill wrappage prepared from composite sheet

A composite sheet and packaging technology, applied in household packaging, packaging, packaging food, etc., can solve the problems of inability to meet the packaging requirements of honey pills, lack of packaging sheets, and reduced efficacy, and achieve high peel strength and light-proof performance. Barrier performance, easy preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

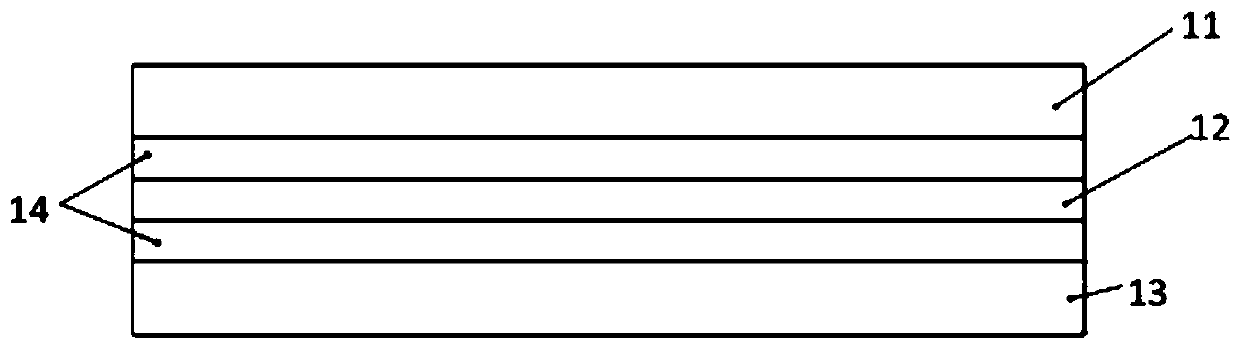

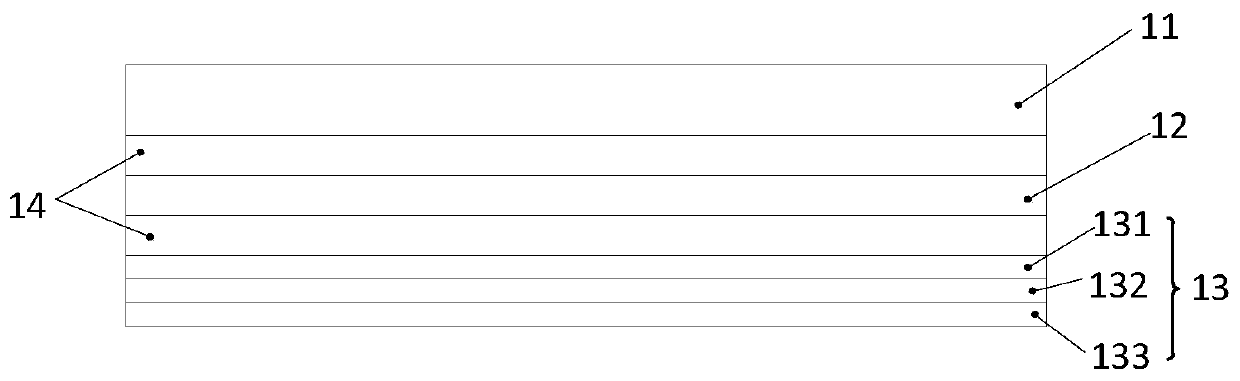

[0037] Embodiment 1: Preparation of the inner layer of the composite sheet of the present invention

Embodiment 1-1

[0038] Example 1-1: Preparation of PA co.PE co-extrusion composite film

[0039] raw material:

[0040] Polyamide (PA, produced by DSM in the Netherlands, using the brand name PA6-F136-E2);

[0041] Adhesive resin for co-extrusion of maleic anhydride grafted linear low density polyethylene (produced by Lyondell-Basell, using brand LLDPE 3060);

[0042] Linear low density polyethylene (LLDPE, produced by DuPont Dow, DOWLEX TM 2045G).

[0043] Preparation:

[0044] A three-layer co-extrusion film blowing unit is used. The unit is equipped with three extruders. The three raw materials are converted into weight ratios according to the design thickness of the finished film, and are automatically supplied to the silos of each extruder. Each extruder will be different The raw materials are heated and melt-extruded to the co-extrusion die head. The melt-extrusion temperature of PA6-F136-E2 is 250℃~280℃. LLDPE 3060 melt extrusion temperature is 230℃~260℃, DOWLEX TM The melt ...

Embodiment 1-2

[0046] Example 1-2: Preparation of PP co.PP co-extruded composite film

[0047] raw material:

[0048] 30-35% SEBS modified polypropylene (SEBS-PP, produced by Holland Wittenberg Company, use brand SEBS-PP8967);

[0049] 5%-10% SEBS modified polypropylene (SEBS-PP, produced by the Wittenberg Company of the Netherlands, using the brand name SEBS-PP5969).

[0050] Preparation:

[0051] Use three-layer co-extrusion down-blowing, water-cooled PP film blowing unit, use two of the extruders, the two raw materials are designed according to the thickness of the finished film and 30-35% SEBS modified polypropylene and 5%-10% SEBS modified The non-toxic polypropylene is automatically supplied to the silo of each extruder at a ratio of 2:1, and each extruder heats and melts the two raw materials and extrudes them to the co-extrusion die. The film blowing process temperature is set as 185°C to 210°C for the first section of the extrusion barrel, 200°C to 220°C for the second section ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com