High viscosity paste quantitative filling ceramic rotary valve

A rotary valve, high-viscosity technology, used in valve operation/release devices, valve details, multi-port valves, etc., can solve the problem of hole blockage or installation position, pressure valve too dirty or leaking, pressure valve air flow Improper adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

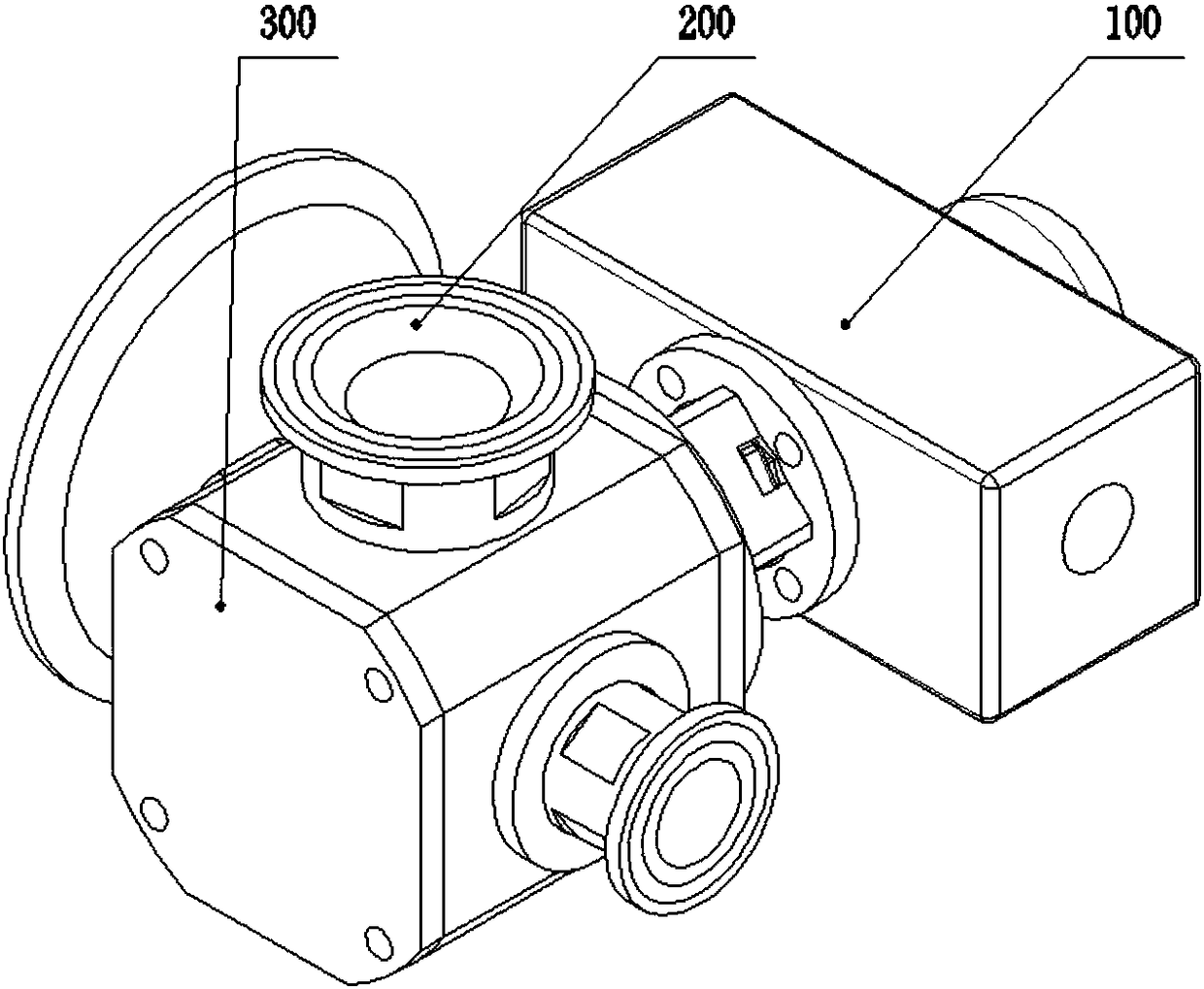

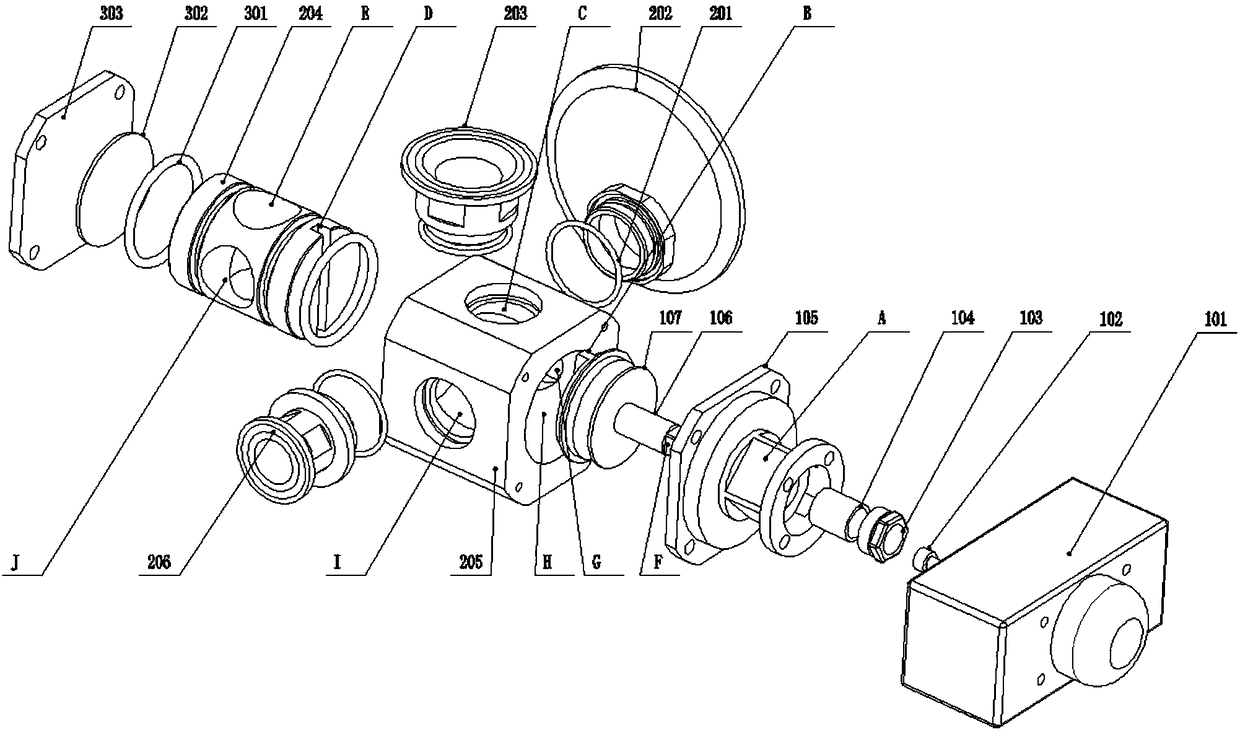

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0023] Due to easy hole blockage or installation position, improper adjustment of pressure valve gas flux, pressure valve too dirty or air leakage, etc., the present invention designs a ceramic rotary valve for quantitative filling of high-viscosity paste, and its main technical scheme is as follows .

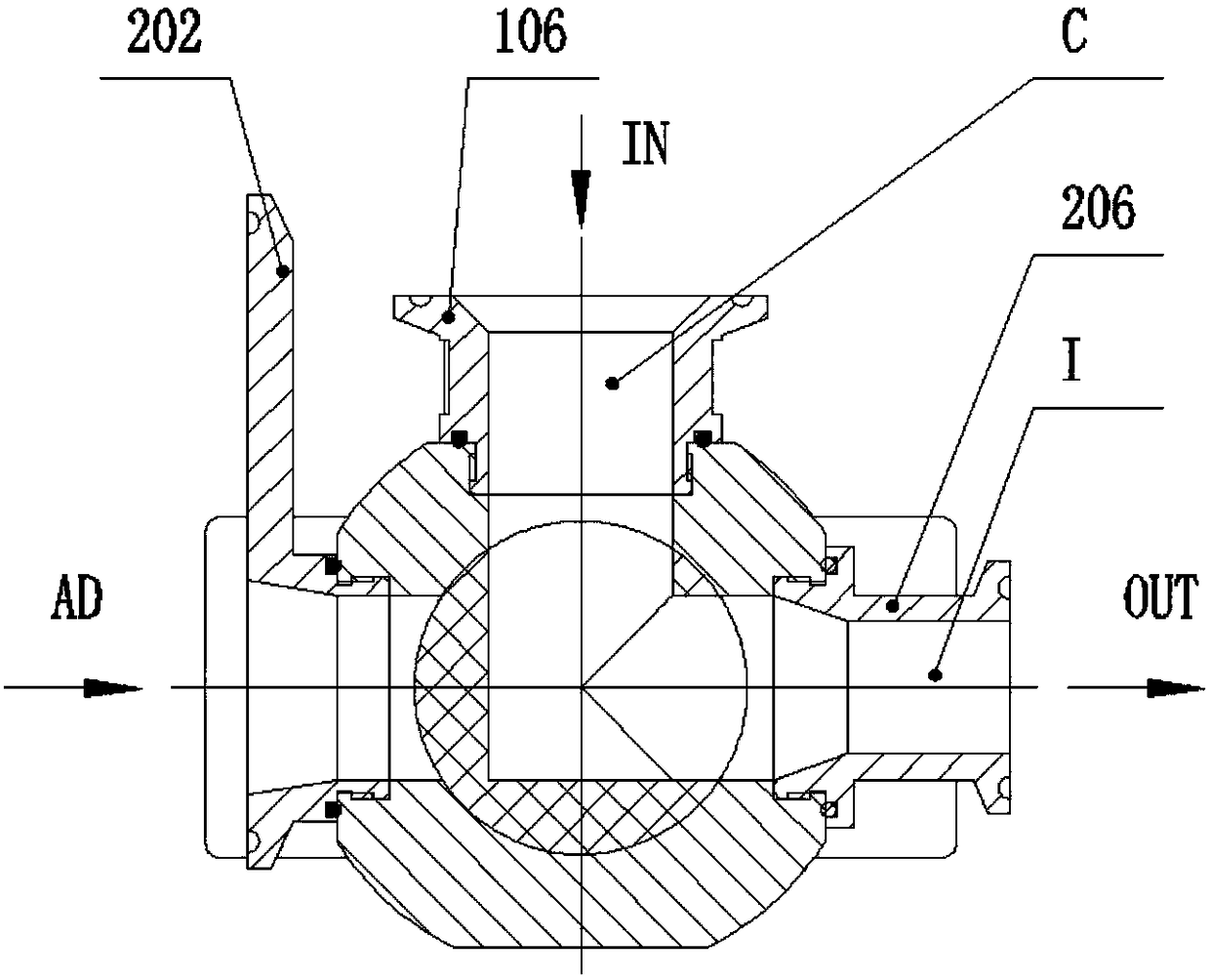

[0024] In the present invention, the valve core 204 and the rotary valve body 205 are designed as ceramic materials, the valve core 204 is designed as two outlets, and the rotary valve body 205 is designed as four outlets. After the rotary valve body is driven, the quantitative filling of paste can be realized under the drive of the valve core 204, thereby forming a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com