A kind of liquor filling equipment

A filling equipment and liquor technology, applied in packaging, liquid bottling, bottle filling, etc., can solve the problems of increased labor costs and large errors, and achieve the effects of high filling efficiency, reduced labor intensity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

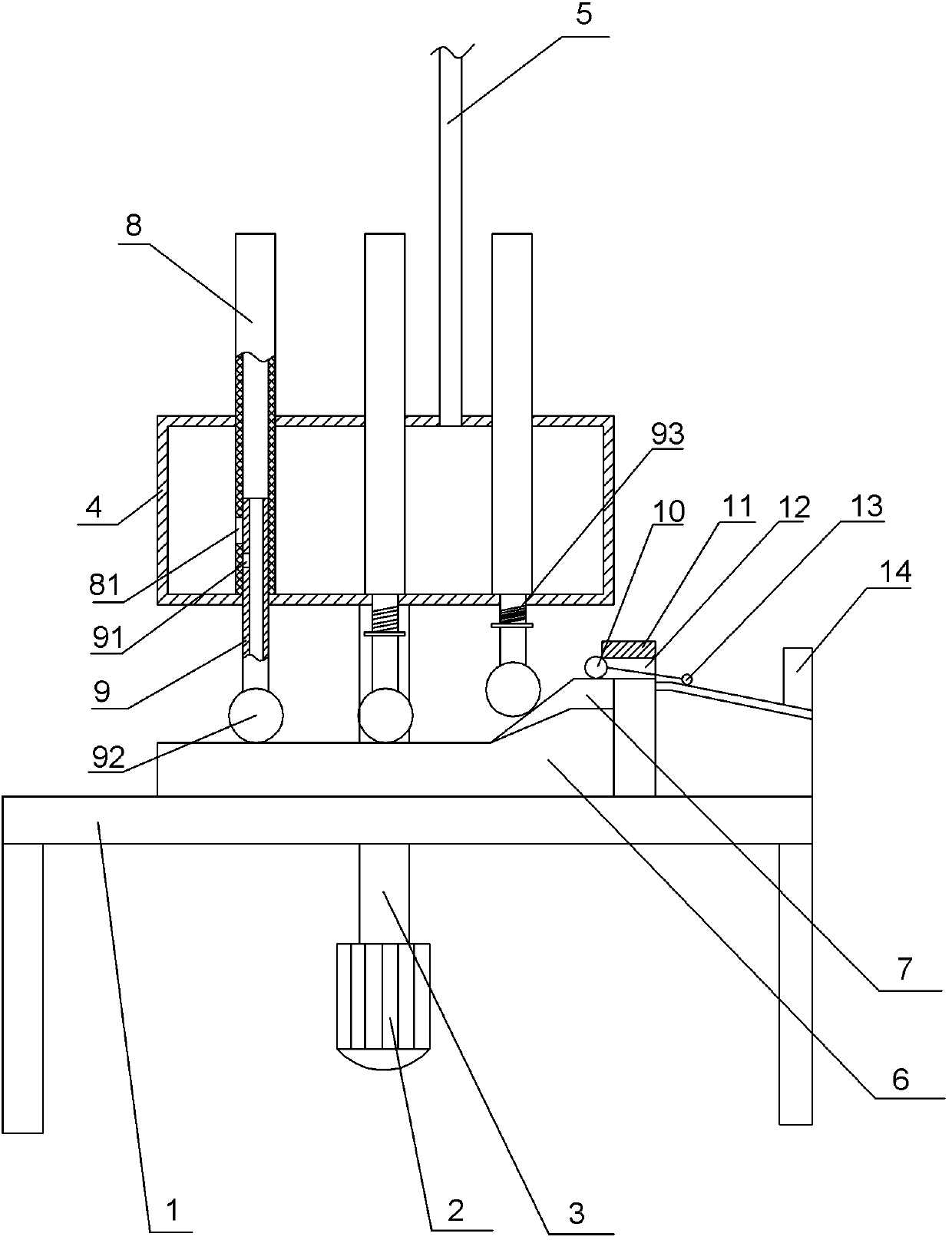

[0024] Such as figure 1 Shown:

[0025] A kind of liquor filling equipment of this embodiment comprises a frame 1, the table top of the frame 1 is circular, the wine filling chamber 4 is installed above the table top of the frame 1, the wine filling chamber 4 is a closed cylinder, and the wine filling chamber 4 The center of the bottom surface is welded to the rotating shaft 3, the rotating shaft 3 is connected to the frame 1 through the bearing, the servo motor 2 is connected with the bolts on the frame 1, the output shaft of the servo motor 2 is welded to the rotating shaft 3, and the servo motor 2 and the rotating shaft 3 can also be used Belt transmission, the rotation of the servo motor 2 drives the rotation of the wine pouring chamber 4.

[0026] A vertical wine outlet pipe 8 is evenly arranged along the circumference of the wine filling chamber 4, the lower end surface of the wine outlet pipe 8 is coplanar with the lower end surface of the wine filling chamber 4, and t...

Embodiment 2

[0034] The difference between this embodiment and Embodiment 1 is that the rotation of the wine filling chamber 4 is not driven by the servo motor 2, but is driven by a turbine installed in the wine inlet pipe 5. The turbine is coaxially welded with the wine filling chamber 4, and the wine filling The chamber 4 is connected with the wine inlet pipe 5 in rotation, and the turbine is driven to rotate by the liquor flow in the wine inlet pipe 5, and the turbine rotates to drive the wine filling chamber 4 to rotate, which can save the servo motor 2 to drive the wine filling chamber 4 to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com