Rice crust forming machine

A technology of forming machine and rice cooker, applied in dough extruder, food forming, food preparation, etc., can solve the problem of unsolved quantitative extrusion, prevent material liquid from remaining around the piston cylinder, facilitate later maintenance, eliminate The effect of sanitary corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

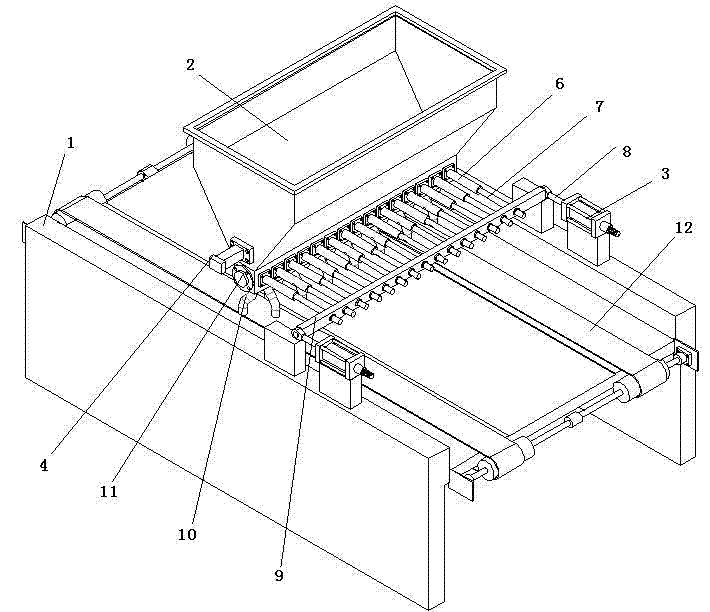

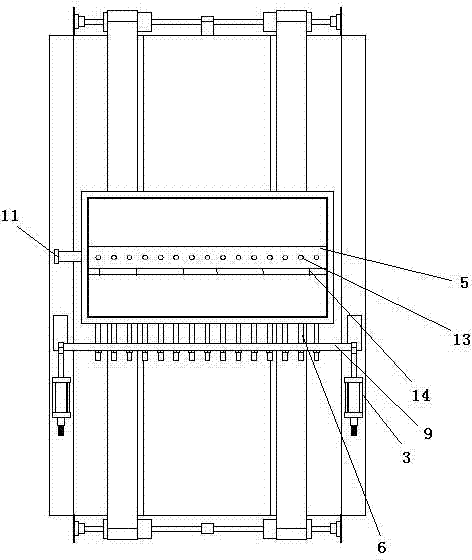

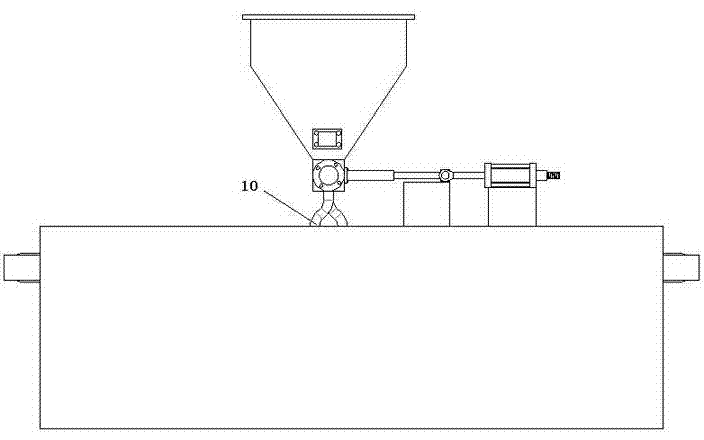

[0026] The present invention will be further described in detail below with reference to the accompanying drawings.

[0027] like figure 1 , 2 , 3 and 4, the crisper rice forming machine includes a frame 1, and the frame 1 is provided with a feed bin 2 for storing the raw rice raw material liquid and a cylinder 3 for controlling the outflow of the raw crispy rice raw material liquid for molding, and the feed bin 2 Stirring motors 4 for stirring raw rice raw material liquid are arranged on both lateral sides, and an automatic feeding device (not shown in the figure) is connected to the feeding bin 2, for example, it can be a cylinder-driven dumping action, which can make the cylinder Connected to feed bin 2.

[0028] The lower part of the feed bin 2 is provided with a discharge area 5 for letting the rice raw material liquid flow out and a diverter valve 11 for controlling the connection between the discharge area 5 and the feed bin 2. The discharge area 5 is connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com