System for thermostatically preparing low-melting point alloy and quantitatively filling and application method thereof

A quantitative filling and low melting point technology, applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of cumbersome procedures and difficult operation of liquid low melting point alloys, achieve light weight, improve heating efficiency, and reduce volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

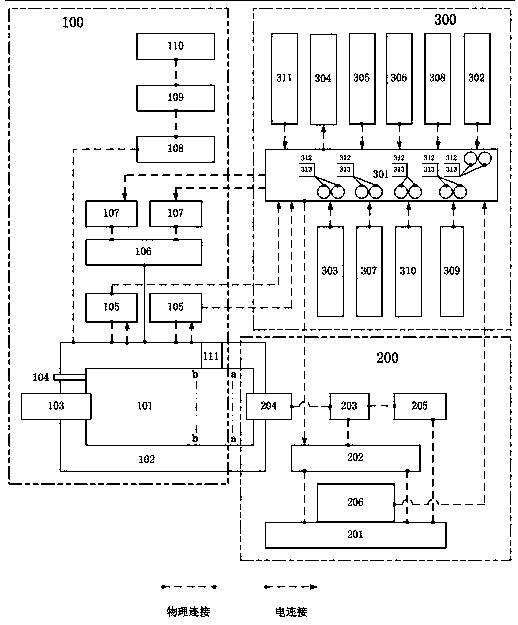

[0059] Such as figure 1 As shown, a constant temperature preparation of low melting point alloy and quantitative filling system, including constant temperature preparation module 100, quantitative filling module 200 and control module 300; constant temperature preparation module 100 is used to prepare liquid low melting point alloy 101 and keep the temperature constant, quantitative The filling module 200 can use the liquid low-melting point alloy 101 produced by the constant temperature preparation module 100 as the raw material according to the set volume filling value input by the user to realize quantitative filling. The liquid low-melting-point alloy 101 and the quantitative filling module 200 add the quantitative volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com