Quantitative liquid filling machine

A filling machine and liquid technology, applied in the field of machinery, can solve the problems of high price, human injury, high labor intensity, etc., and achieve the effect of simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

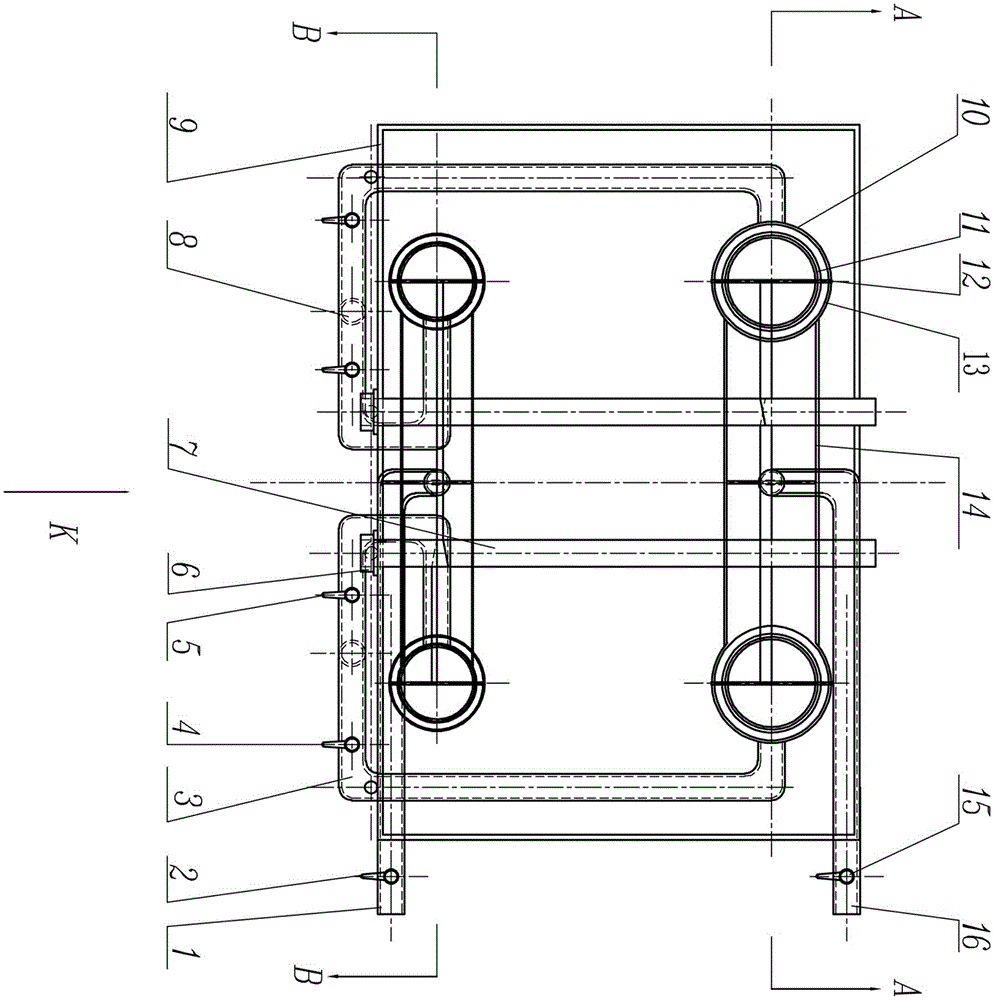

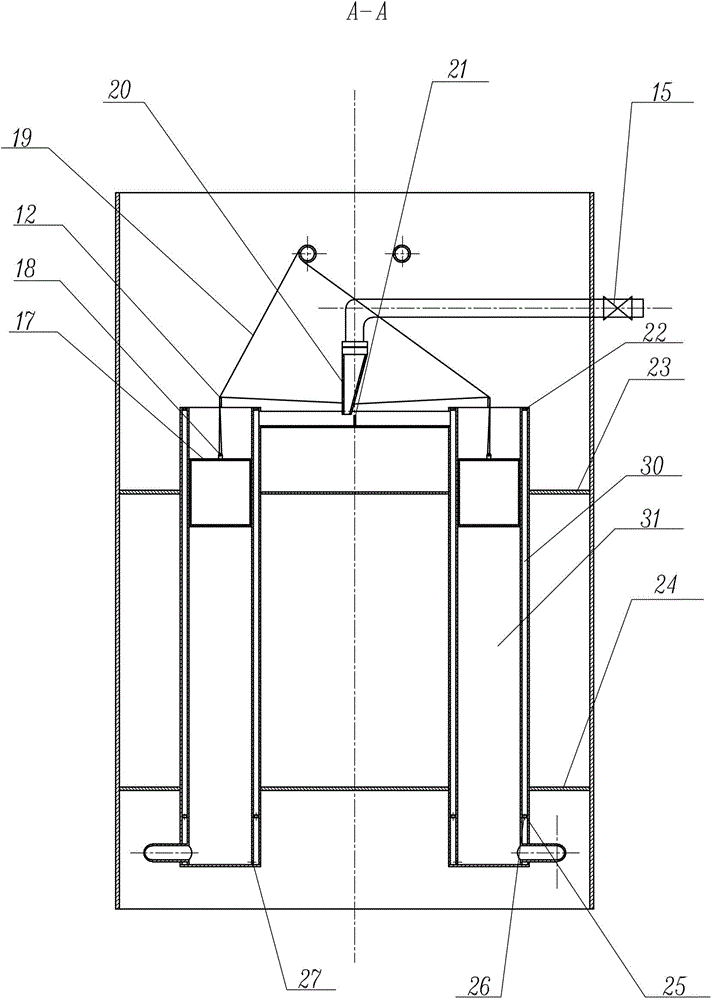

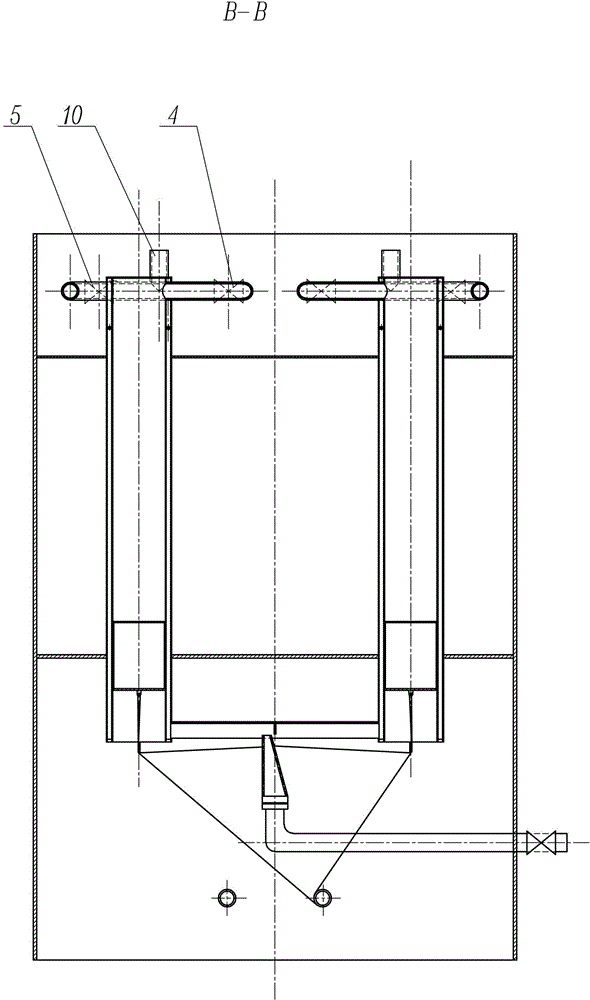

[0021] The present invention will be further described below in conjunction with accompanying drawing: Figure 1 to Figure 4 It is a structural diagram of the first embodiment. It can be seen from the figure that the present invention is composed of a fixed frame 9, a raw material barrel 10, a liquid input part, a liquid product output part, a quantitative adjustment device, and a liquid level indicator device.

[0022] The raw material barrel 10 is made up of two solvent barrels and two solute barrels, and the raw material barrel 10 is fixed on the fixed frame 9 with the upper and lower support plates 23, 24. The raw material barrel is a double-layer cylindrical structure, and the inner and outer barrels 13, 11 The space in the inner cylinder forms the liquid input channel 30, and the inner space of the inner cylinder forms the liquid storage chamber 31; the upper and lower partitions 22, 25 are arranged between the inner and outer cylinders of the raw material barrel, and so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com