Automatic quantitative filling system for tissue culture solution

A filling system and technology for liquid, which is applied in the field of automatic quantitative filling system for tissue culture liquid, which can solve the problems of difficult control of filling volume, easy solidification or precipitation, uneven distribution of nutrients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

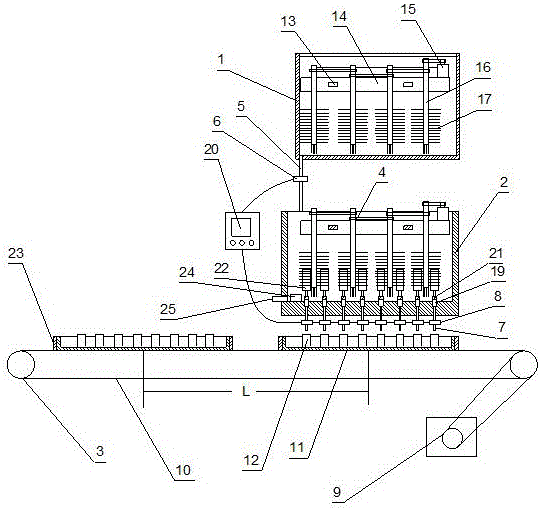

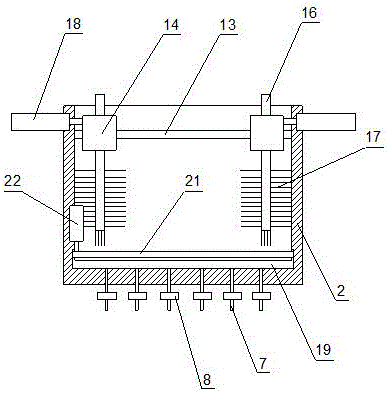

[0025] Such as figure 1 As shown, an automatic quantitative filling system for tissue culture liquid of the present invention includes a high-level configuration tank 1, a low-level storage box 2 and a transmission device 3,

[0026] A stirring device 4 is arranged in the high-position configuration tank 1 and the low-position storage box 2;

[0027] The high-level configuration tank 1 communicates with the low-level storage tank 2 through the delivery pipe 5, and the delivery pipe 5 is provided with a solenoid valve 6;

[0028] The bottom of the low-level storage tank 2 is provided with a plurality of evenly distributed liquid outlet pipes 7, the liquid outlet pipes 7 are vertically arranged and the lower end runs through the bottom plate of the storage tank 2, and each liquid outlet pipe 7 is provided with an electromagnetic flow control A valve 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com