Full-automatic aluminum plastic packaging equipment for pharmacy

An aluminum-plastic packaging, fully automatic technology, applied in the field of packaging, can solve the problems of missing directional capsules, uneven number of directional capsules, and the machine cannot run normally, and achieves the effect of adjustable interference storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

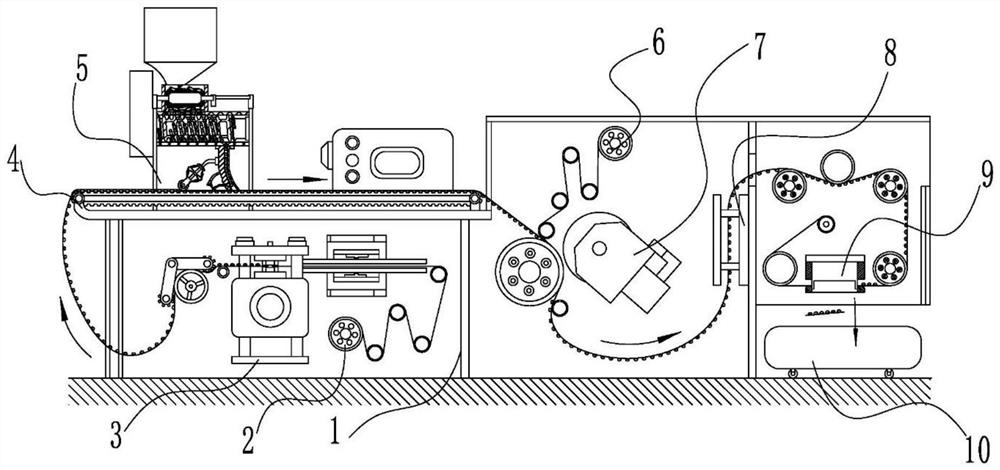

[0055] see Figure 1-5 , in an embodiment of the present invention, a fully automatic aluminum-plastic packaging equipment for pharmaceuticals, including:

[0056] Rack 1;

[0057] The pvc conveying member 2 is relatively rotatably arranged inside the frame 1;

[0058] The preheating forming device 3 is fixed inside the frame 1 and is located above the pvc conveying part 2;

[0059] The pulley set 4 is relatively rotatably arranged on the upper surface of the frame 1, and the surface of the pulley set 4 is uniformly provided with grooves;

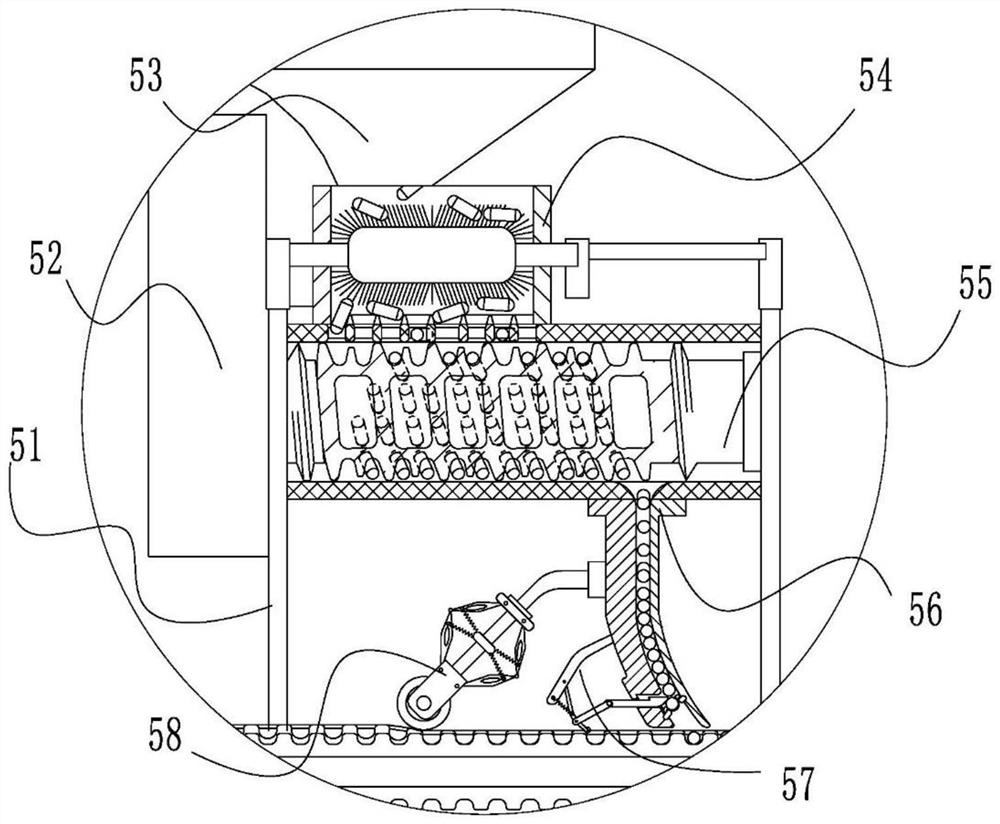

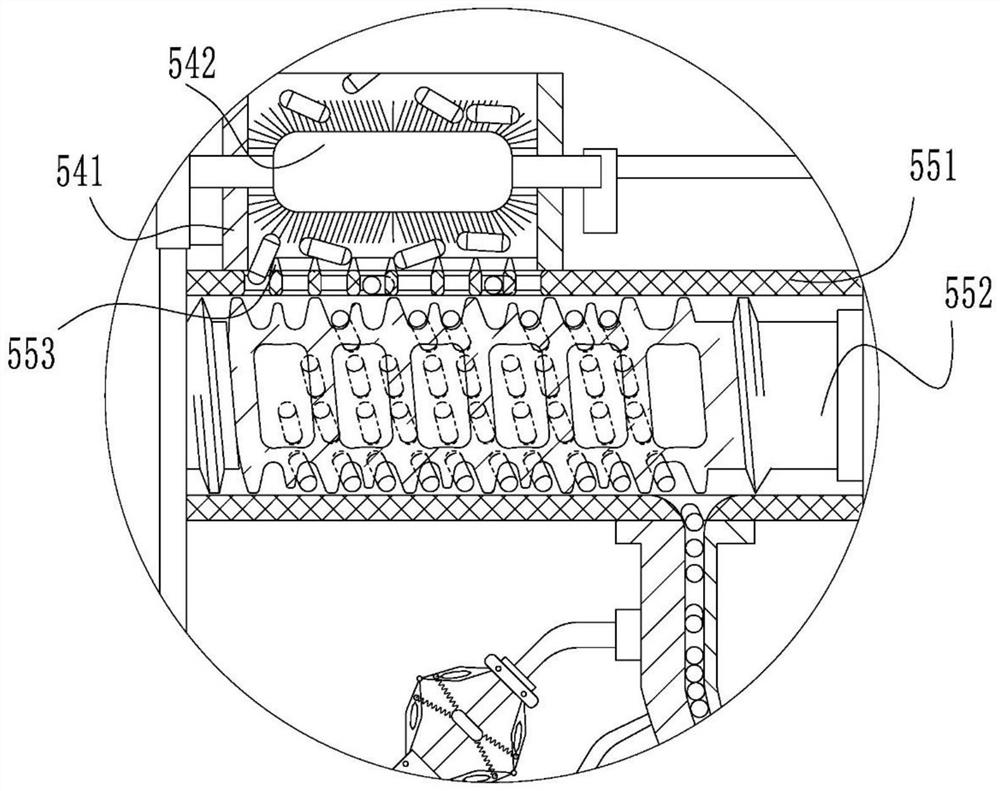

[0060] The feeding assembly 5 is fixed on the upper surface of the frame 1 and is located directly above the input end of the pulley group 4;

[0061] The aluminum foil conveying member 6 is relatively rotatably arranged inside the frame 1, and is located on the side close to the output end of the pulley set 4;

[0062] The heat-sealing device 7 is relatively rotatably arranged inside the frame 1 and is located below the aluminum foil c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com