Method for removing harmful algae in water body by adopting electro-Fenton

A water body and algae technology, applied in chemical instruments and methods, water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems such as time-consuming, low current efficiency, secondary pollution, etc., to avoid flocculation and precipitation, and reduce reaction time shortening, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

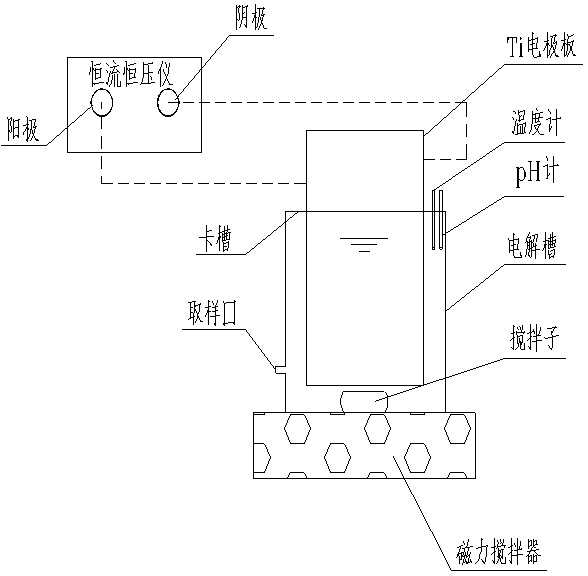

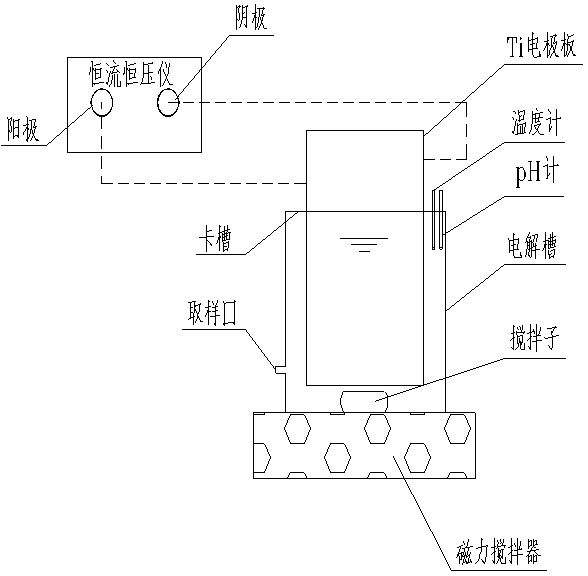

[0022] Taking the treatment of high-concentration Microcystis aeruginosa liquid as an example, the process flow is as follows: figure 1 shown. The volume of algal liquid to be treated is 1.0 L, and the current density is 3.0 mA / cm 2 , the rotor speed is 200 r / min, and the initial cell density of algae liquid is 2.25×10 6 Individuals / mL, the concentration of ferrous sulfate is 1.0 mM, the concentration of hydrogen peroxide is 20.0 mM, and sodium sulfate is 50.0 mM as the electrolyte. The pH value is adjusted to 4.0 with dilute sulfuric acid. After electrolysis for 30 min, the effluent algae liquid becomes transparent and the algae cells are basically completely broken. removed, the algae cell density drops to 2.45×10 3 / mL, the removal rate reached 100%.

Embodiment 2

[0024] Taking the treatment of high-concentration Microcystis aeruginosa liquid as an example, the process flow is as follows: figure 1 shown. The volume of algal liquid to be treated is 1.0 L, and the current density is 3.0 mA / cm 2 , the rotor speed is 150 r / min, and the initial cell density of algae liquid is 2.25×10 6 A / mL, the concentration of ferrous sulfate is 1.5 mM, the concentration of hydrogen peroxide is 18.0 mM, and sodium sulfate is 55.0 mM as the electrolyte. The pH value is adjusted to 5.0 with dilute sulfuric acid. After electrolysis for 30 min, the effluent algae liquid becomes transparent and the algae cells are basically completely broken. removed, the algae cell density drops to 3.2×10 3 / mL, the removal rate was 100%.

Embodiment 3

[0026] Taking the treatment of high-concentration Microcystis aeruginosa liquid as an example, the process flow is as follows: figure 1 shown. The volume of algal liquid to be treated is 1.0 L, and the current density is 3.0 mA / cm 2 , the rotor speed was 200 r / min, the total amount of microcystin MCLR (intracellular and extracellular) in the initial algae fluid was 110.0 μg / L, the concentration of ferrous sulfate was 0.8 mM, the concentration of hydrogen peroxide was 25.0 mM, and sodium sulfate was 45.0 mM as The electrolyte was adjusted to pH 4.0 with dilute sulfuric acid and electrolyzed for 60 min. The total amount of microcystin MCLR in the effluent was about 13.0 μg / L, and the removal rate reached 88.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com