Sterilization module and sterilization equipment

A technology of sterilization equipment and modules, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of limited types of bacteria, inability to purify, low reaction rate, etc. Simple and reasonable effect

Active Publication Date: 2018-08-28

GD MIDEA ENVIRONMENT APPLIANCES MFG +1

View PDF4 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the technology of photocatalytic oxidation to remove pollutants will encounter the problem of low reaction rate in the actual due process, and cannot quickly realize the purification function; at the same time, the speed of photocatalytic sterilization is also very slow, and can kill limited number of germs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

[0044] Example 1, TiO2, doped Fe, and graphene and activated alumina

example 2

[0045] Example 2, WO3, doped with Ag and F, and carbon nanotubes and activated carbon

example 3

[0046] Example 3, CuO or Cu2O, doped with Mg and P, and polyaniline polymer and diatomaceous earth

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Login to View More

Abstract

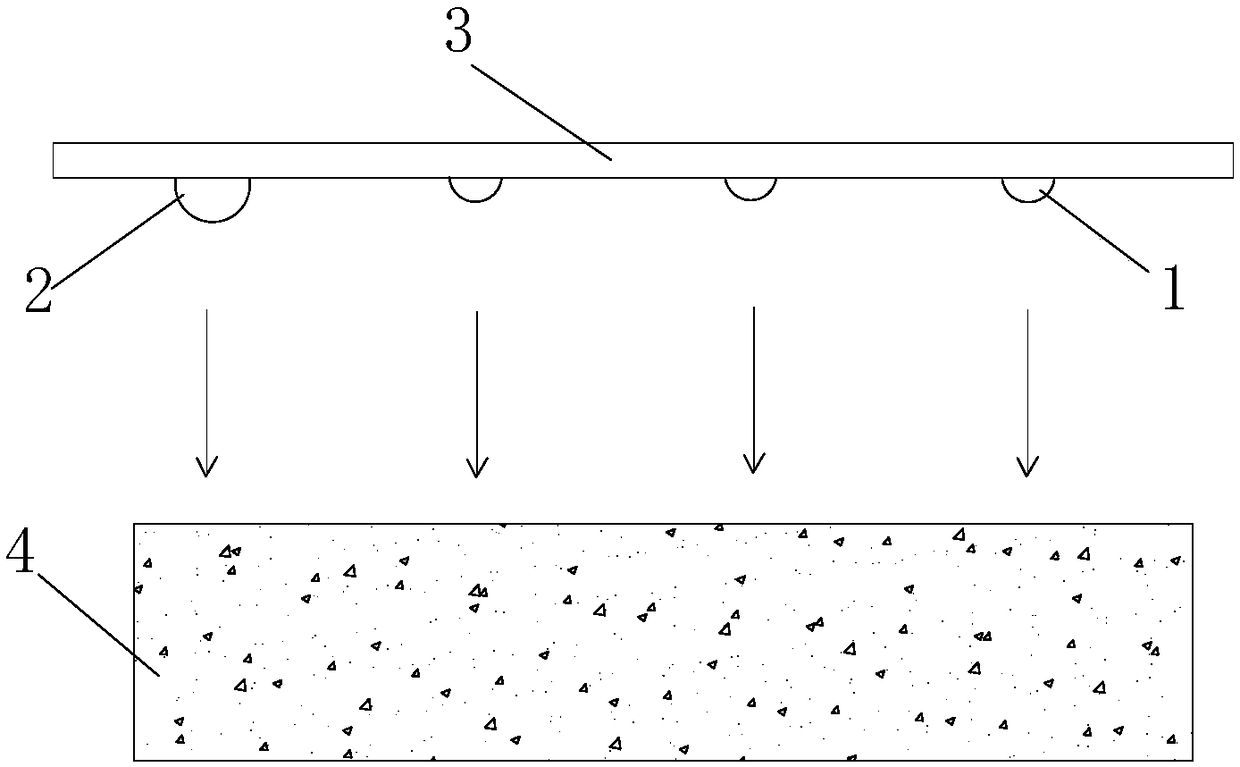

The invention relates to the sterilization field, in particular to a sterilization module and sterilization equipment. The sterilization module comprises a light emitting diode lamp bank, photocatalytic materials and a deep ultraviolet lamp element, wherein the light emitting diode lamp bank, the photocatalytic materials and the deep ultraviolet lamp element are arranged on the front side of a substrate; the light emitting diode lamp bank is used for emitting visible light of 400 nanometers or above or ultraviolet light of 300-400 nanometers to the photocatalytic materials; the photocatalyticmaterials are used for receiving the light wave of the light emitting diode lamp bank and generating a free radical with high oxidability; the deep ultraviolet lamp is arranged on the front side of the substrate and is used for emitting deep ultraviolet 300 nanometers or below to the photocatalytic materials. According to the sterilization module, the light emitting diode lamp element serves as the motivation light source of the photocatalytic materials and is used for emitting visible light of 400 nanometers or above or ultraviolet light of 300-400 nanometers to the photocatalytic materials,the photocatalytic materials are used for receiving the light wave of the light emitting diode lamp bank and generating the free radical with the high oxidability, sterilization and VOCs (Volatile Organic Compounds) purification are realized, and an effect on thoroughly purifying indoor gas pollutant is achieved.

Description

Technical field [0001] The present invention relates to the field of sterilization, in particular to sterilization modules and sterilization equipment. Background technique [0002] With the modernization of industry, environmental pollution has brought serious effects on people's health. People's ideas gradually shifted to the purification of indoor living environment. Commonly used indoor air purification devices usually use filtration and adsorption to treat pollutants, but this method can only be simply adsorbed, which is likely to cause secondary pollution problems, and cannot fundamentally purify and remove pollutants. Since 1972, the method of photocatalytic air purification has gradually become an emerging technology and has been favored by people. Its biggest advantage is that this photocatalytic method can remove most pollutants under the irradiation of ultraviolet light sources, including small molecules such as aldehydes and ketones and large molecules of benzene; a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A61L9/20A61L9/18B01D53/86B01D53/72A61L101/10

CPCA61L9/18A61L9/205A61L2209/212B01D53/8668B01D2255/802B01D2257/708B01D2259/804

Inventor 刘智

Owner GD MIDEA ENVIRONMENT APPLIANCES MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com