Method for preparing cellulosic fibers and hemicellulose solution simultaneously

A cellulose fiber and hemicellulose technology, applied in fiber raw material processing, textiles and papermaking, etc., can solve the problems of low concentration and expensive membrane modules, and achieve a green process, improve economic feasibility, and the principle is practical Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

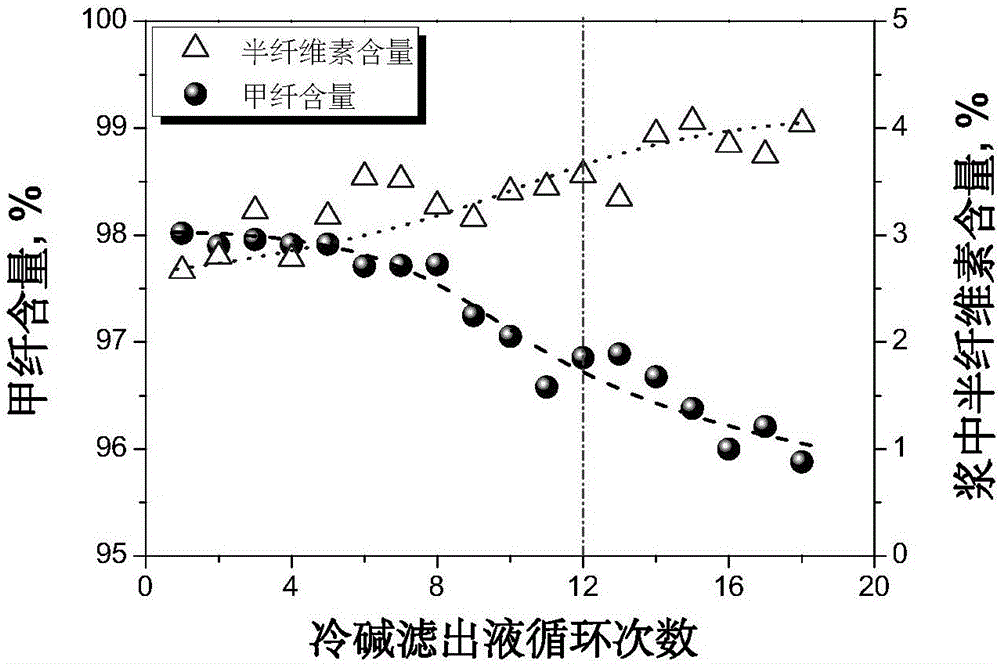

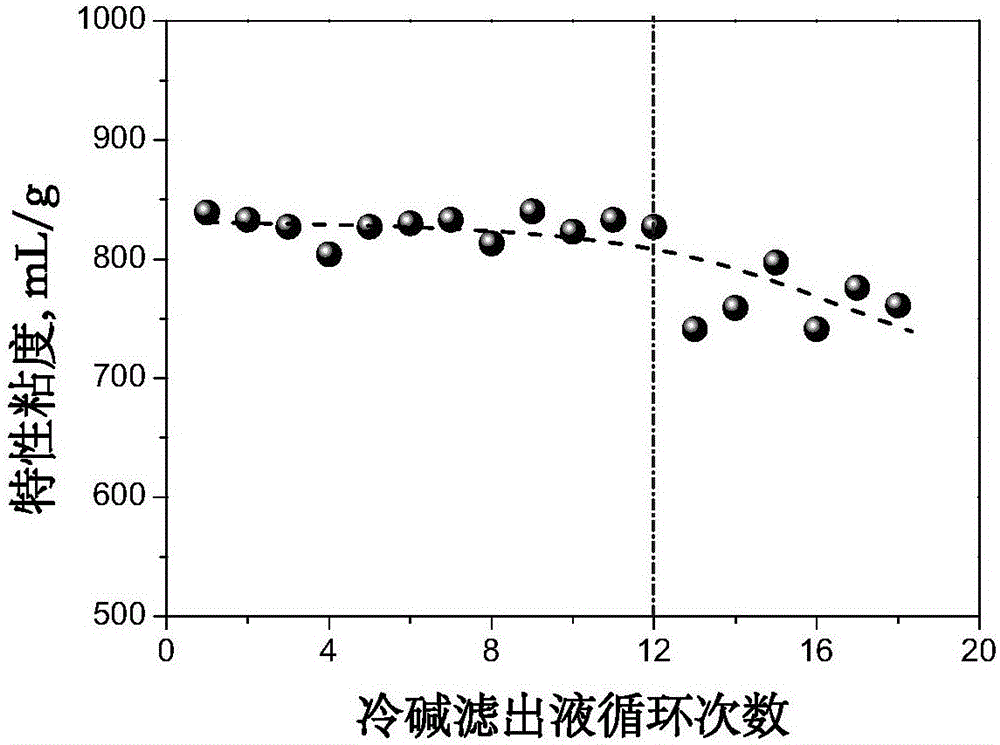

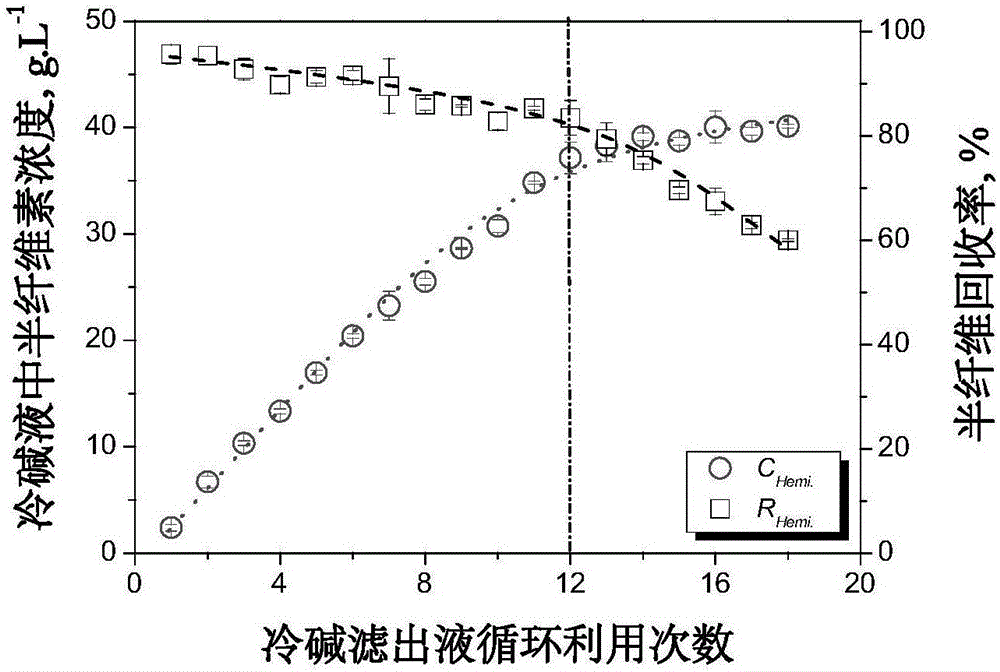

[0026] Purification of bleached kraft bamboo pulp by multiple cycles of cold caustic filtrate to obtain high-concentration hemicellulose solution

[0027] (1), cold alkali impregnation of (high whiteness) chemical pulp: the high whiteness chemical pulp is impregnated for 60 minutes with a mass fraction of 8% and a temperature of 25°C in cold alkali solution, and the pulp concentration is 5%, to obtain (high purity) fiber cellulose fiber and cold lye containing hemicellulose;

[0028] (2) Efficient separation of cellulose fibers: After the cold alkali impregnation, use a twin-roll press to efficiently separate the high-purity cellulose fibers and cold lye obtained after the treatment in step (1); The concentration is controlled at 40%, and the obtained cold caustic filtrate is used together with a small amount of soda liquor to impregnate the next batch of chemical pulp with cold caustic;

[0029] (3) Recycling of the cold caustic filtrate: pump the cold caustic filtrate and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com