Device and process for converting calcium process desulfurization into temperature difference crystallizing ammonia process desulfurization

An ammonia-based desulfurization and calcium-based technology, which can be applied to temperature difference crystallization ammonia-based desulfurization devices, transformation of the original calcium-based desulfurization device of thermal power plants, or new-build desulfurization fields. , secondary pollution and other problems, to achieve the effect of eliminating secondary pollution, improving environmental protection and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

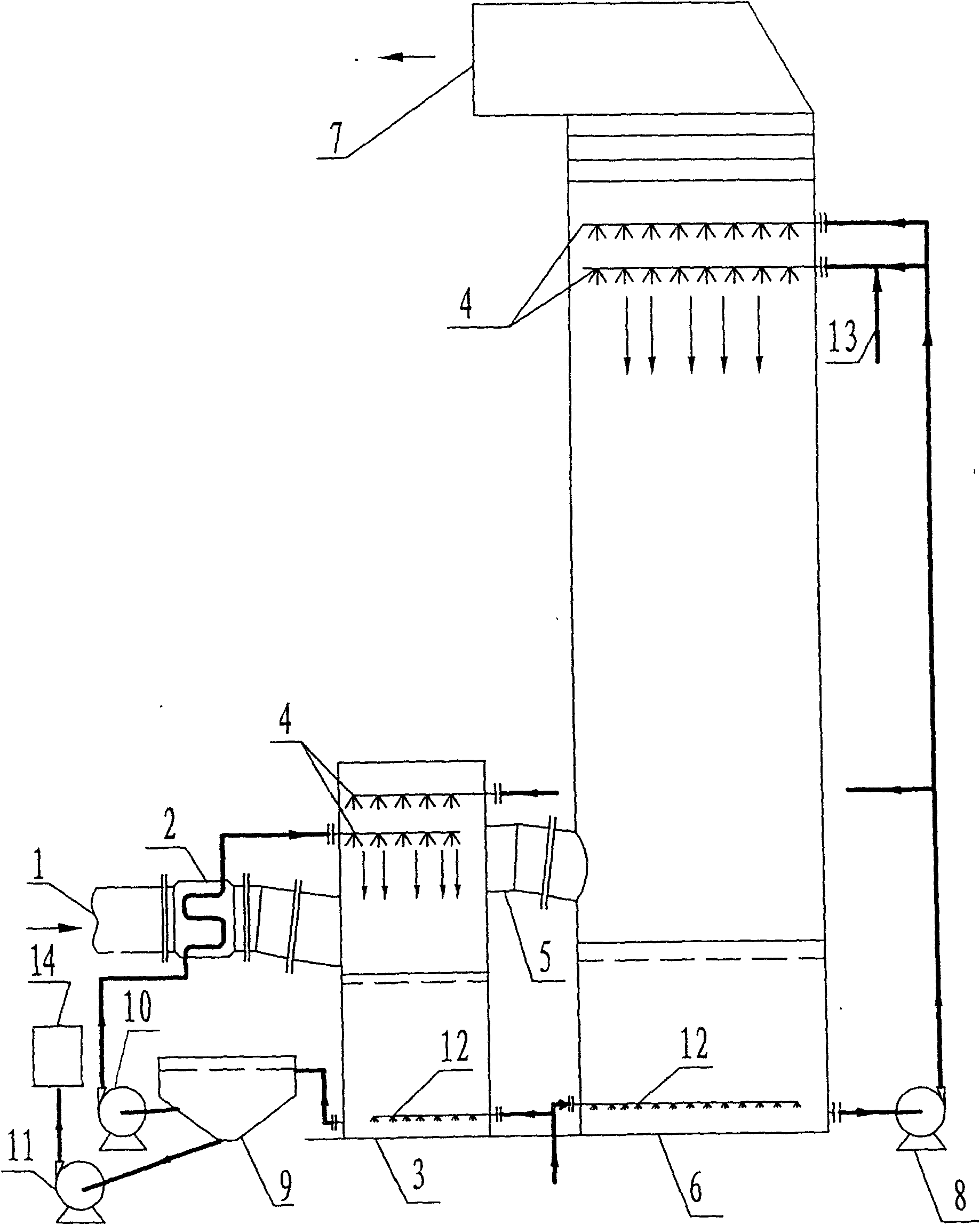

[0019] Depend on figure 1 As shown, it includes desulfurization tower (6), thickener (3), gas-liquid heat exchanger (2), circulation pump (8), concentration circulation pump (10), magma pump (11), concentration and crystallization tank (9), drying system (14); desulfurization tower (6), circulation pump (8), magma pump (11), drying system (14) are the equipment in the calcium method desulfurization; thickener (3) The lower part is provided with a gas distributor (12), and its upper part is provided with a nozzle (4), and the nozzle (4) is 2-3 layers, which are respectively connected with the circulation pump (8) or the gas-liquid heat exchanger (2) by pipelines; The nozzles (4) of the desulfurization tower (6) are arranged on 2-4 floors, the nozzles (4) in the desulfurization tower (6) are connected to the circulation pump (8) by pipelines, and the liquid replenishment pipe (13) is connected to the inside of the desulfurization tower (6). The bottom nozzle (4) is connected; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com