Production method of foam slurry core-filled building block capable of being quickly condensed under steam-curing-free condition

A technology of foam slurry and production method, which is applied in building materials, ceramic molding workshops, ceramic molding machines, etc., can solve problems such as easy cracking of walls, poor durability, and large drying shrinkage, and achieve the effect of preventing secondary pollution

Active Publication Date: 2012-08-15

绿建科技集团新型建材高技术有限公司

View PDF7 Cites 30 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At the same time, this type of thermal insulation block can overcome the existing problems of low surface strength, poor durabi

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

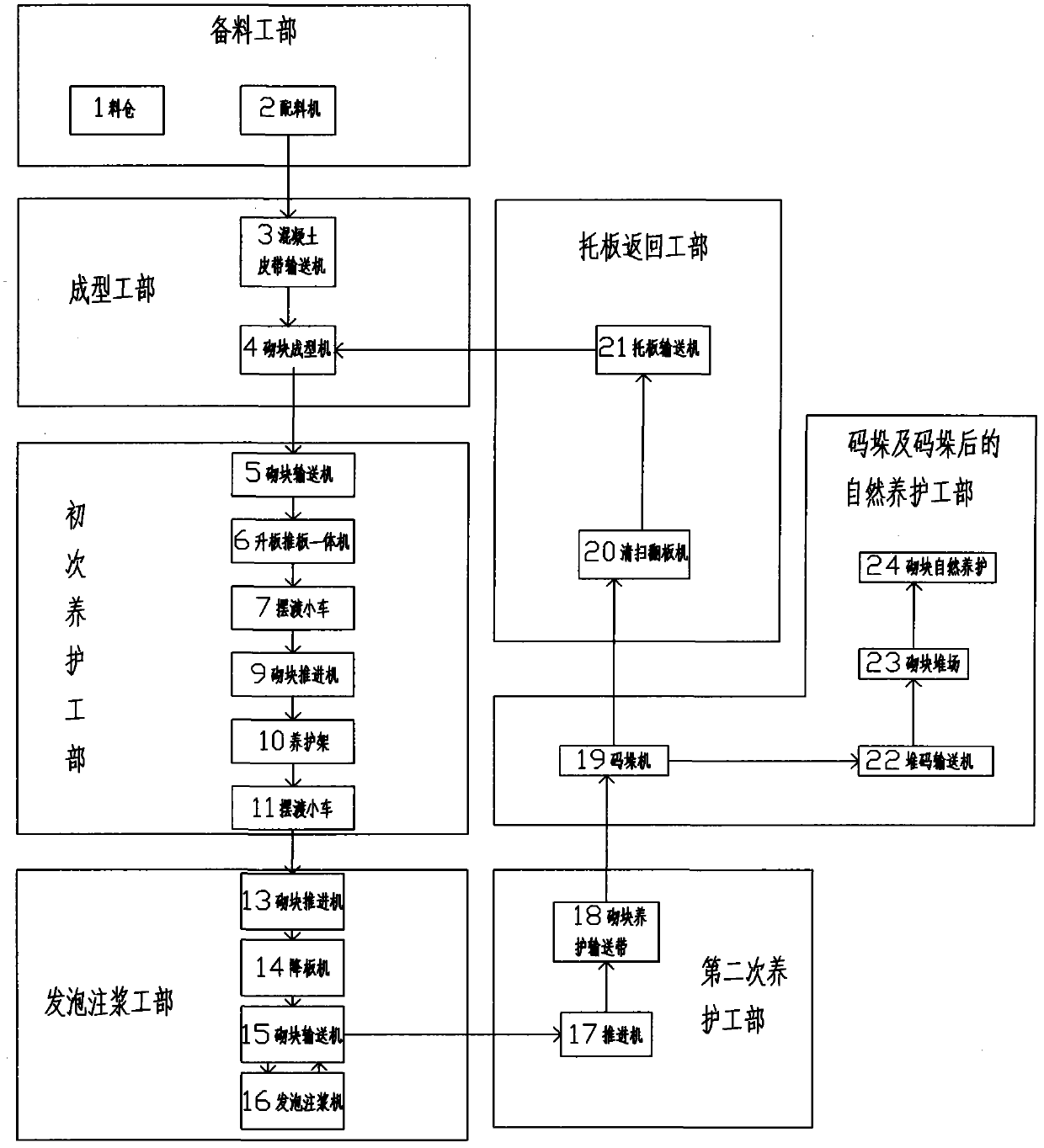

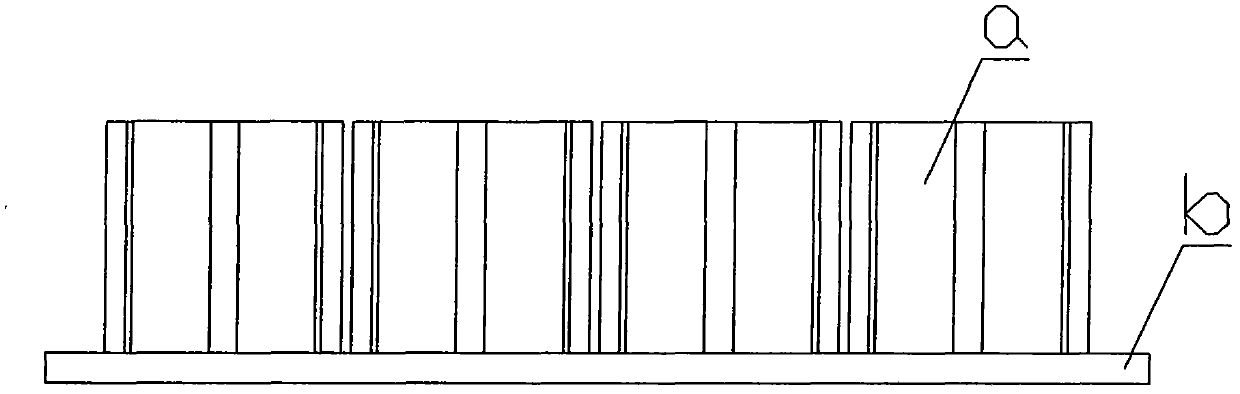

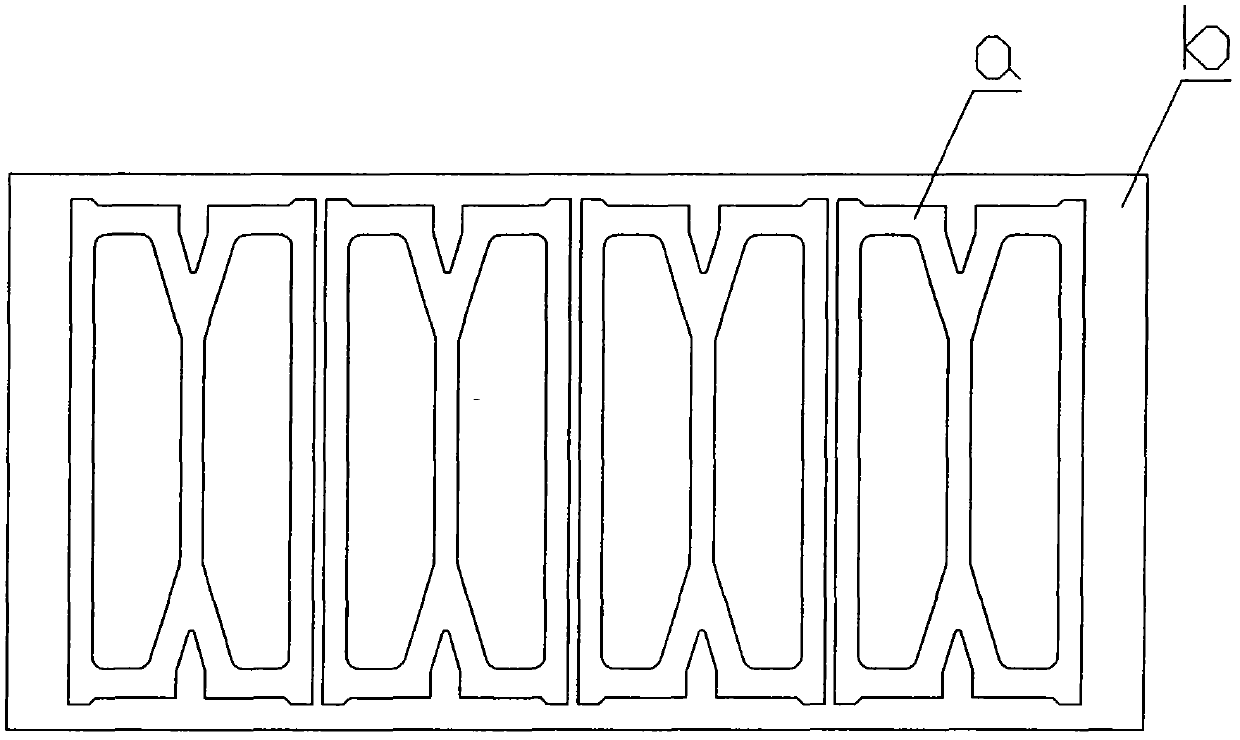

The invention provides a production method of a foam slurry core-filled building block capable of being quickly condensed under a steam-curing-free condition, belonging to the technical field of building block production. The invention aims to provide an automatic production method for producing a foam slurry core-filled building block under a steam-curing-free condition. The technical key points are as follows: the production method sequentially comprises the following steps of: preparing materials, molding, carrying out primary maintenance, carrying out foam slurry core filling, carrying out secondary maintenance, stacking, naturally maintaining after stacking, and returning a supporting plate; after molding a hollow building block by carrying out material preparation and molding, entering the primary maintenance step; after the hollow building block has a certain strength, entering the foam slurry core filling step to inject slurry to form a core-filled heat-preservation building block; then, carrying out the secondary maintenance; after the foam slurry is condensed, entering the stacking step and the natural maintenance step after the stacking step; then, entering the natural maintenance step; after stacking, returning the supporting plate back to the building block molding step through the step of returning the supporting plate; and then, carrying out the next cycle of circulation.

Description

technical field [0001] The invention relates to a production method of a block, in particular to a production method of a fast-setting foam slurry core-filled block under the condition of avoiding steam curing. Background technique [0002] The foam slurry core-filled composite thermal insulation block is a new type of composite thermal insulation block. The foam slurry is poured into the cavity of the hollow block as the thermal insulation core material, and the composite thermal insulation block is produced after the foam slurry solidifies. It overcomes the main defects and problems existing in the existing thermal insulation blocks and thermal insulation materials. For example, the existing thermal insulation wall materials in my country have poor fire resistance and short service life; It is easy to cause damage; the block production process is complicated, the production cost is high, and the construction is complicated. Realized the upgrading of various types of therm...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B28B15/00B28B11/24E04C1/41

Inventor 谢怀宇

Owner 绿建科技集团新型建材高技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com