Method for recycling positive material of waste lithium iron phosphate battery

A technology for lithium iron phosphate batteries and cathode materials, which is applied to the field of recycling and utilization of waste lithium iron phosphate power batteries, can solve the problems of complex processes, difficulty in obtaining lithium iron phosphate materials, and difficulty in meeting large-scale industrial production, and achieves recycling. Simple process, uniform particle distribution and less equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Place the used lithium iron phosphate battery on the CT-3008W-5V3A-T CT-3008W-5V3A-T Xinwei cycle test equipment and discharge it at a discharge rate of 1C (170mA / g) and a discharge voltage of 0.05V;

[0033] 2) Mechanically disassemble the discharged lithium iron phosphate battery in a fume hood, and screen out the positive plate;

[0034] 3) Ultrasonic peel off the positive electrode sheet in deionized water, the ultrasonic frequency is 50KHz, and the stirring speed is 300 rpm to make the lithium iron phosphate positive electrode material fall off, remove the aluminum foil and dry it in a drying oven at a drying temperature of 80°C;

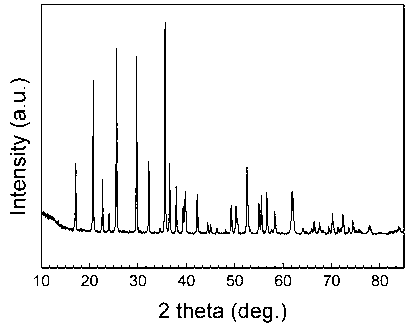

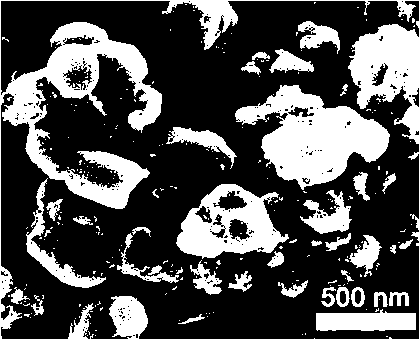

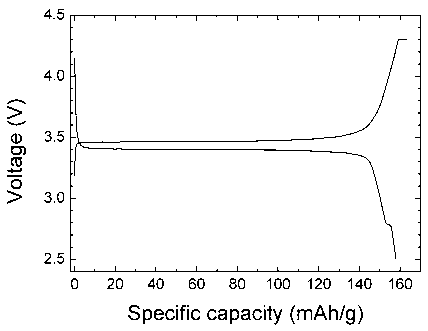

[0035]4) Ball mill the dried lithium iron phosphate cathode material, the ball milling speed is 400 revolutions per minute, and the ball milling time is 6 hours. The element ratio determined by ICP is Li:Fe:P=1.2:1:1; then 2g iron phosphate Lithium cathode material needs to add 2.225g lithium hydroxide monohydrate, 8.379g iron phospha...

Embodiment 2

[0040] 1) Place the used lithium iron phosphate battery on the CT-3008W-5V3A-T CT-3008W-5V3A-T Xinwei cycle test equipment and discharge it at a discharge rate of 3C (510mA / g) and a discharge voltage of 0.1V;

[0041] 2) Mechanically disassemble the discharged lithium iron phosphate battery in a fume hood, and screen out the positive plate;

[0042] 3) Ultrasonic peel off the positive electrode sheet in deionized water, the ultrasonic frequency is 80KHz, and the stirring speed is 200 rpm to make the lithium iron phosphate positive electrode material fall off, remove the aluminum foil and dry it in a drying oven at a drying temperature of 100°C;

[0043] 4) Ball mill the dried lithium iron phosphate cathode material, the ball milling speed is 300 revolutions per minute, and the ball milling time is 8 hours. The element ratio determined by ICP is Li:Fe:P=1.2:1:1.1; then 2g iron phosphate Lithium cathode material needs to add 2.225g lithium hydroxide monohydrate, 8.190g iron phos...

Embodiment 3

[0048] 1) Put the used lithium iron phosphate battery on the CT-3008W-5V3A-T CT-3008W-5V3A-T Xinwei cycle test equipment and discharge it at a discharge rate of 5C (850mA / g) and a discharge voltage of 0.1V;

[0049] 2) Mechanically disassemble the discharged lithium iron phosphate battery in a fume hood, and screen out the positive plate;

[0050] 3) Ultrasonic peel off the positive electrode sheet in deionized water, the ultrasonic frequency is 100KHz, and the stirring speed is 80 rpm to make the lithium iron phosphate positive electrode material fall off, remove the aluminum foil and dry it in a drying oven at a drying temperature of 120°C;

[0051] 4) Ball mill the dried lithium iron phosphate positive electrode material, the ball milling speed is 200 revolutions per minute, the ball milling time is 8 hours, the element ratio determined by ICP is Li:Fe:P=1.2:1:1; then 2g iron phosphate 0.379g of lithium hydroxide monohydrate needs to be added to the lithium positive electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com