Electret, dividing and cutting machine for non-weaving cloth

A technology of non-woven fabrics and slitting machines, which is applied in textiles and papermaking, textile material cutting, ultrasonic/sonic fiber processing, etc., which can solve the problems of time-consuming, increased filter material resistance, and increased filter material, etc., to reduce Production cost and equipment investment, product quality assurance, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

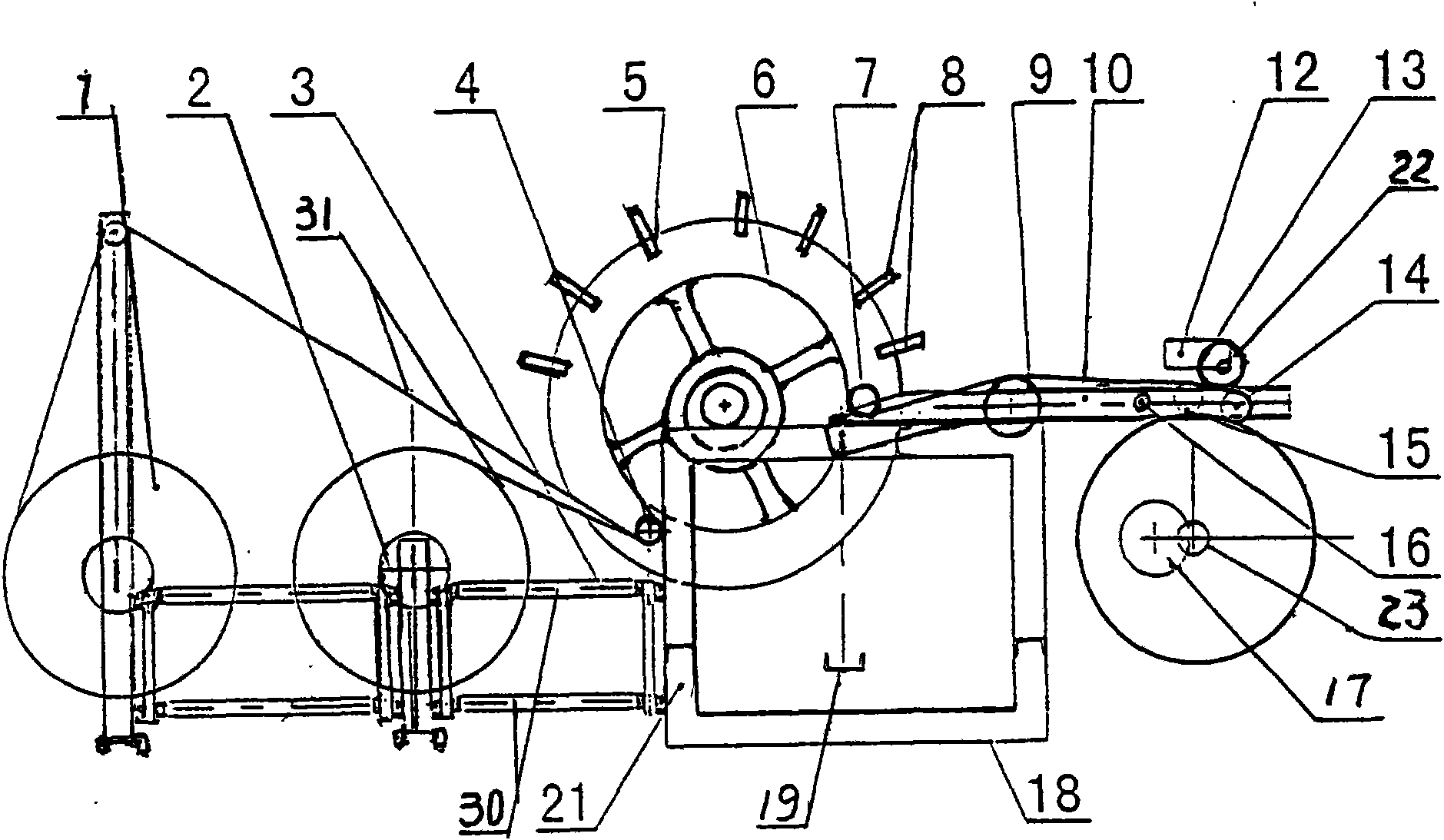

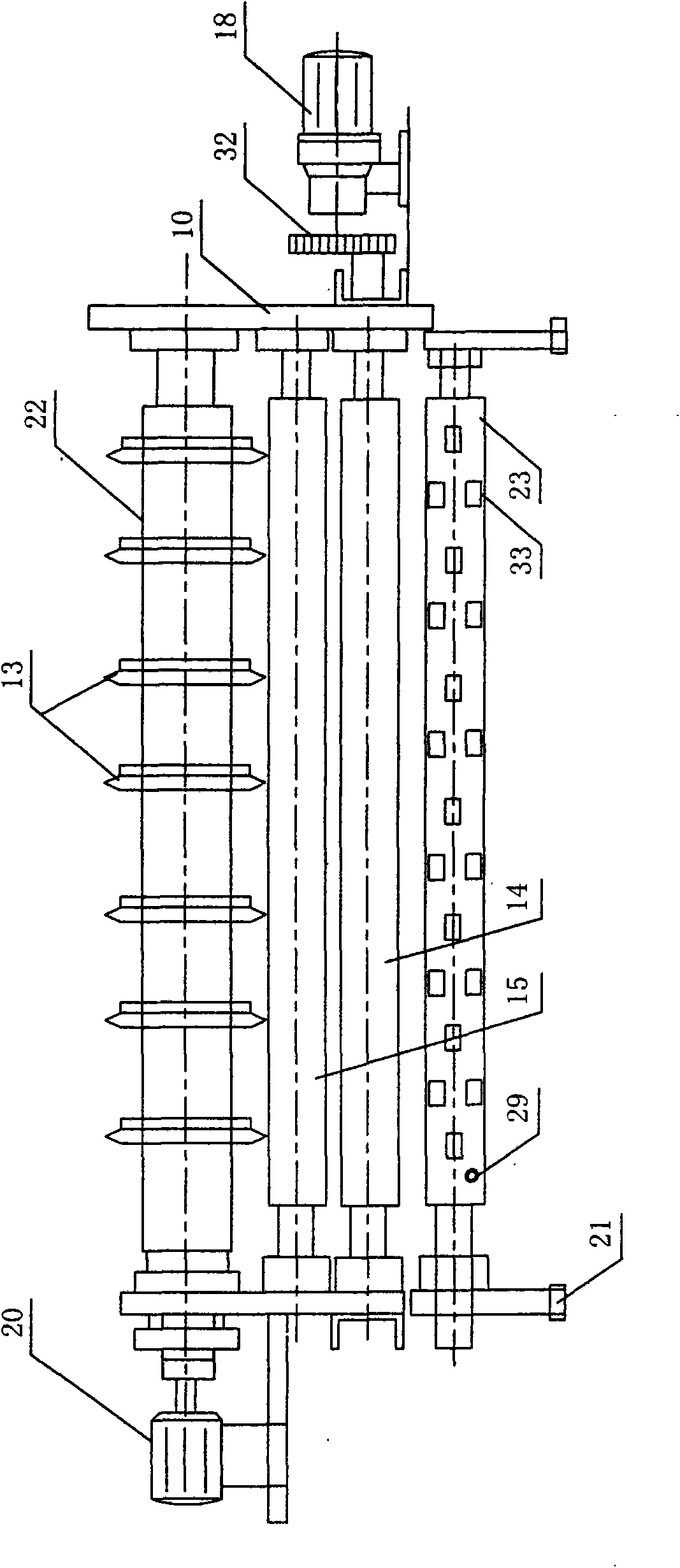

[0016] An electret and slitting machine for nonwoven fabrics includes an unwinding frame, a winding roller, a cloth pressing roller 14, an electret box 5, an electret cylinder 6, a pressurized cloth guide roller 7, a cloth guide roller swing shaft 9, a swing Frame 10, adjustable cloth cutting knife frame 12, cloth cutting knife 13, cloth cutting knife shaft 22, cloth pressing roller 14, cloth supporting roller 15, cloth inspection light source 16, cloth rolling tension controller 17, main drive motor 18, distribution Heavy assembly 19, cutter shaft motor 20, brake controller 24, quick clamping device 25 and air expansion shaft 23.

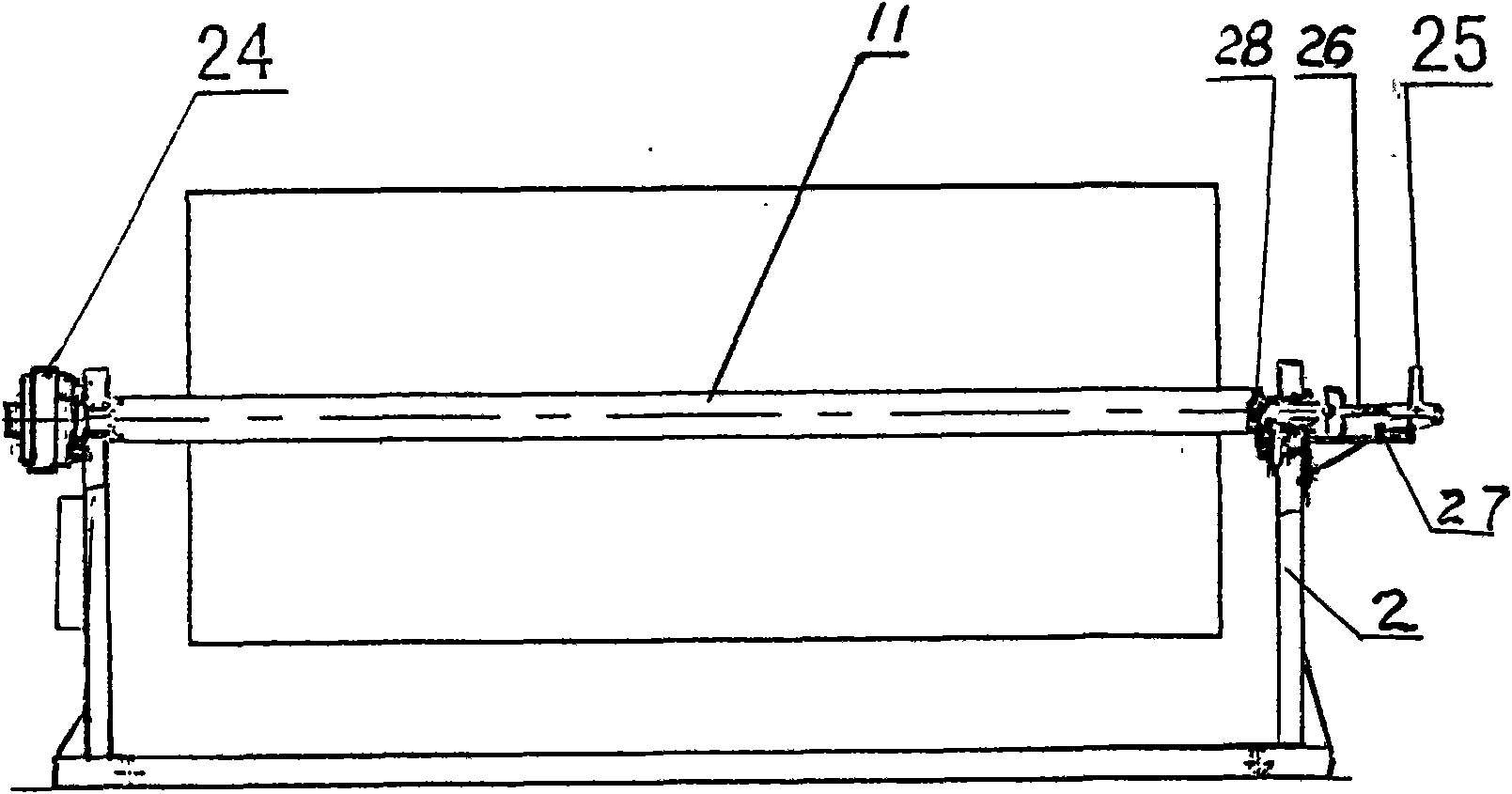

[0017] There are 1 to 4 unwinding racks. The unwinding frame is divided into main unwinding frame 2 and auxiliary unwinding frame 1. The two ends of the winding roller 11 are installed on the unwinding frame, and one end of the unwinding roller 11 is equipped with a brake controller 24, and the other end is equipped with a quick clamping device. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com