Reactor for producing acid phase with diphasic anaerobic digestion of urban biomass garbage

An anaerobic digestion and biomass technology, applied in the direction of gas production bioreactors, biochemical instruments, biomass pretreatment, etc., can solve the problems of high price, achieve good mixing effect, good anaerobic digestion environment, and avoid external air escape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

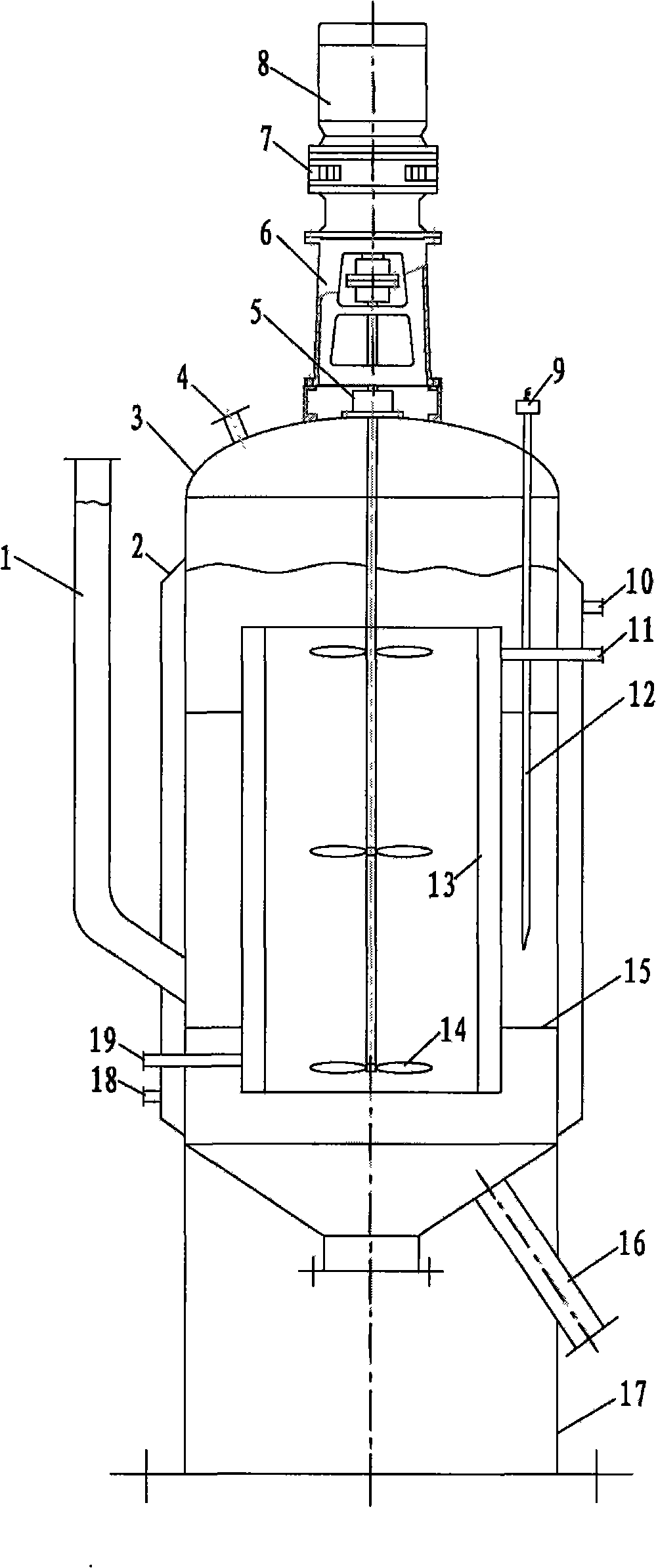

[0020] As shown in the accompanying drawings, the present invention has an airtight vertical still body 3, the outside of the kettle body 3 is welded with a heating honeycomb jacket 2, the inside of the honeycomb jacket 2 is fixed with a guide tube 13 through a steel frame 15, and the honeycomb jacket 2 The upper and lower sides are respectively provided with a jacket heating medium outlet 10 and a jacket heating medium inlet 18, and the upper and lower sides of the guide tube 13 are respectively provided with a guide tube heating medium outlet 11 and a guide tube heating medium inlet 19. The raw material inlet pipe 1 connected to the municipal biomass waste crushing pretreatment device is arranged on the side, and the acidification liquid discharge port 16 connected with the solid-liquid centrifugal separation device is provided at the bottom of the kettle body 3, and the top of the kettle body 3 is fixed in the center by the frame 6 The speed reducer 7 and the motor 8 connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com