A kind of ultra-high Vicat PVC modified colloidal particles

A modified rubber compound and Vicat technology, applied in the field of plastic granules, can solve the problems of low softening temperature of PVC Vicat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

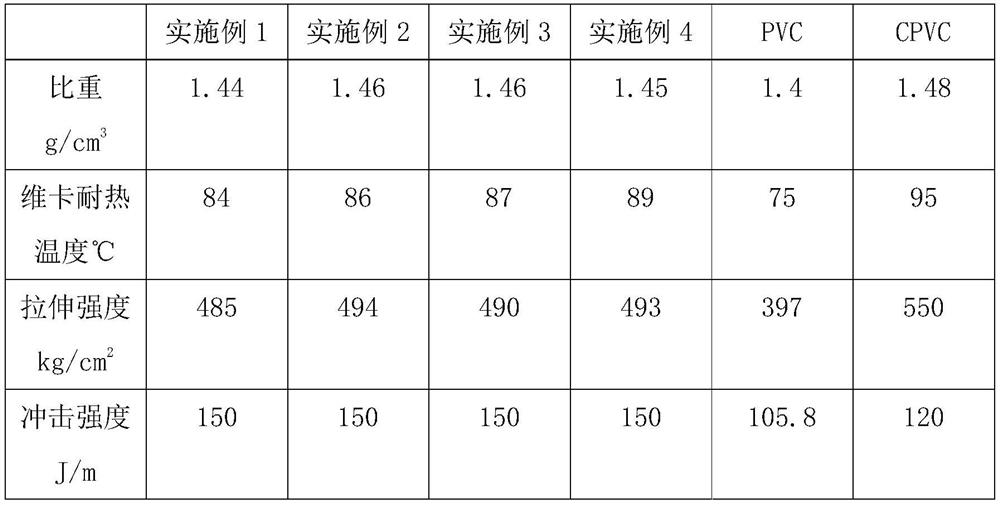

Examples

Embodiment 1

[0047] A kind of ultra-high Vicat PVC modified sizing material, is characterized in that, comprises the following components in parts by mass:

[0048] PVC 100 parts;

[0049] 95 parts of CPVC;

[0051] 10 parts of ethylene propylene rubber;

[0052] 70 parts of polyethylene glycol;

[0053] 3 parts of dioctyl phthalate;

[0054] 1 part of benzidine yellow G;

[0055] 3 parts of 2,6-di-tert-butyl-4-methylphenol.

[0056] Its preparation method is as follows:

[0057] Step 1, weighing the raw materials according to the above components, then adding PVC and CPVC to polyethylene glycol in turn for constant temperature and continuous stirring to obtain a suspension dispersion;

[0058] Step 2, adding ethylene-propylene rubber into the suspension dispersion, mechanically stirring until completely dispersed, to obtain a viscous mixture;

[0059] Step 3, adding plasticizers, colorants, antioxidants and non-toxic stabilizers to the mixed reaction ...

Embodiment 2

[0066] A kind of ultra-high Vicat PVC modified sizing material, comprising the following components in parts by mass:

[0067] PVC 100 parts;

[0068] 105 copies of CPVC;

[0069] 6 parts of magnesium stearate;

[0070] 15 parts of ethylene propylene rubber;

[0071] 120 parts of polyethylene glycol;

[0072] 7 parts of di-n-octyl phthalate;

[0073] 3 parts permanent orange RN;

[0074] 8 parts of 2,6-di-tert-butyl-4-methylphenol.

[0075] Its preparation method is as follows:

[0076] Step 1, weighing the raw materials according to the above components, then adding PVC and CPVC to polyethylene glycol in turn for constant temperature and continuous stirring to obtain a suspension dispersion;

[0077] Step 2, adding ethylene-propylene rubber into the suspension dispersion, mechanically stirring until completely dispersed, to obtain a viscous mixture;

[0078] Step 3, adding plasticizers, colorants, antioxidants and non-toxic stabilizers to the mixed reaction liquid and...

Embodiment 3

[0085] A kind of ultra-high Vicat PVC modified sizing material, comprising the following components in parts by mass:

[0086] PVC 100 parts;

[0087] 98 copies of CPVC;

[0088] 5 parts of calcium stearate;

[0089] 13 parts of ethylene propylene rubber;

[0090] 90 parts of polyethylene glycol;

[0091] 5 parts of dioctyl phthalate;

[0092] 2 parts of sun-fast lake blue lake;

[0093] 5 parts of 2,6-di-tert-butyl-4-methylphenol.

[0094] Its preparation method is as follows:

[0095] Step 1, weighing the raw materials according to the above components, then adding PVC and CPVC to polyethylene glycol in turn for constant temperature and continuous stirring to obtain a suspension dispersion;

[0096] Step 2, adding ethylene-propylene rubber into the suspension dispersion, mechanically stirring until completely dispersed, to obtain a viscous mixture;

[0097] Step 3, adding plasticizers, colorants, antioxidants and non-toxic stabilizers to the mixed reaction liquid and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com