Ultrahigh-Vicat PVC (Polyvinyl Chloride) modified rubber particles

A technology of modified rubber compound and Vicat, applied in the field of plastic granules, can solve the problems of low softening temperature of PVC Vicat, and achieve the effect of preventing rapid softening and deformation, improving the effect of modified connection and improving the connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

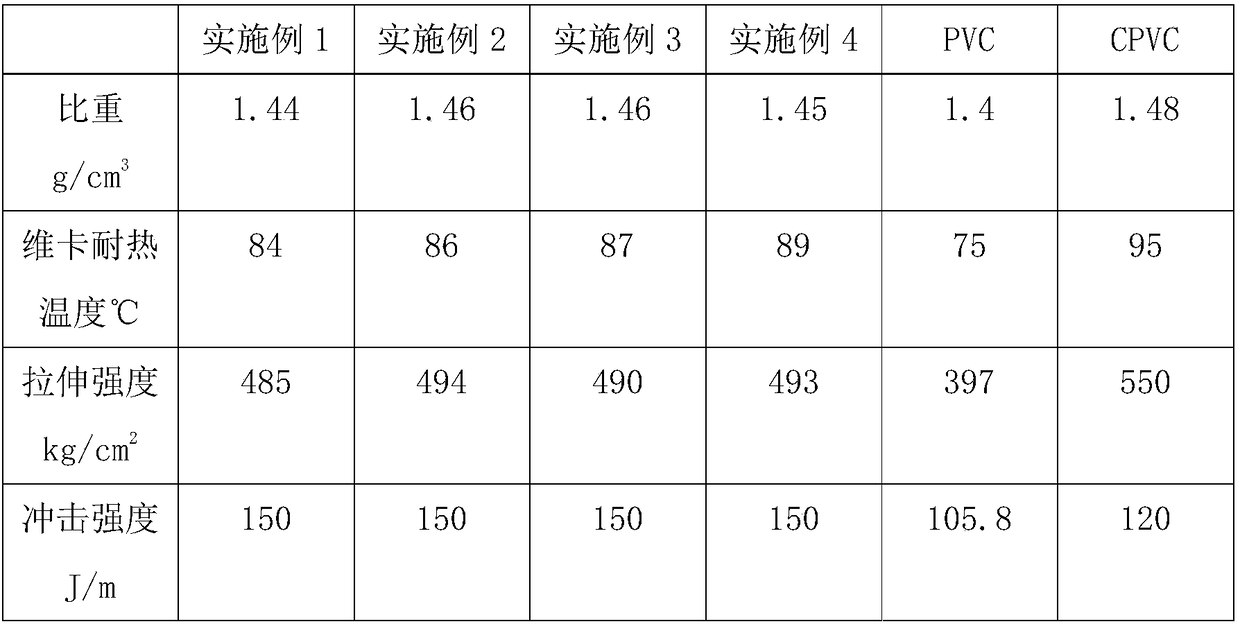

Examples

Embodiment 1

[0047] A kind of ultra-high Vicat PVC modified sizing material, is characterized in that, comprises the following components in parts by mass:

[0048] PVC 100 parts;

[0049] 95 parts of CPVC;

[0051] 10 parts of ethylene propylene rubber;

[0052] 70 parts of polyethylene glycol;

[0053] 3 parts of dioctyl phthalate;

[0054] 1 part of benzidine yellow G;

[0055] 3 parts of 2,6-di-tert-butyl-4-methylphenol.

[0056] Its preparation method is as follows:

[0057] Step 1, weighing the raw materials according to the above components, then adding PVC and CPVC to polyethylene glycol in turn for constant temperature and continuous stirring to obtain a suspension dispersion;

[0058] Step 2, adding ethylene-propylene rubber into the suspension dispersion, mechanically stirring until completely dispersed, to obtain a viscous mixture;

[0059] Step 3, adding plasticizers, colorants, antioxidants and non-toxic stabilizers to the mixed reaction ...

Embodiment 2

[0066] A kind of ultra-high Vicat PVC modified sizing material, comprising the following components in parts by mass:

[0067] PVC 100 parts;

[0068] 105 copies of CPVC;

[0069] 6 parts of magnesium stearate;

[0070] 15 parts of ethylene propylene rubber;

[0071] 120 parts of polyethylene glycol;

[0072] 7 parts of di-n-octyl phthalate;

[0073] 3 parts permanent orange RN;

[0074] 8 parts of 2,6-di-tert-butyl-4-methylphenol.

[0075] Its preparation method is as follows:

[0076] Step 1, weighing the raw materials according to the above components, then adding PVC and CPVC to polyethylene glycol in turn for constant temperature and continuous stirring to obtain a suspension dispersion;

[0077] Step 2, adding ethylene-propylene rubber into the suspension dispersion, mechanically stirring until completely dispersed, to obtain a viscous mixture;

[0078] Step 3, adding plasticizers, colorants, antioxidants and non-toxic stabilizers to the mixed reaction liquid and...

Embodiment 3

[0085] A kind of ultra-high Vicat PVC modified sizing material, comprising the following components in parts by mass:

[0086] PVC 100 parts;

[0087] 98 copies of CPVC;

[0088] 5 parts of calcium stearate;

[0089] 13 parts of ethylene propylene rubber;

[0090] 90 parts of polyethylene glycol;

[0091] 5 parts of dioctyl phthalate;

[0092] 2 parts of sun-fast lake blue lake;

[0093] 5 parts of 2,6-di-tert-butyl-4-methylphenol.

[0094] Its preparation method is as follows:

[0095] Step 1, weighing the raw materials according to the above components, then adding PVC and CPVC to polyethylene glycol in turn for constant temperature and continuous stirring to obtain a suspension dispersion;

[0096] Step 2, adding ethylene-propylene rubber into the suspension dispersion, mechanically stirring until completely dispersed, to obtain a viscous mixture;

[0097] Step 3, adding plasticizers, colorants, antioxidants and non-toxic stabilizers to the mixed reaction liquid and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com