Semitransparent fluorescent powder/glass composite luminescent ceramic wafer and preparation method thereof

A technology for luminescent ceramics and phosphors, applied in the field of ceramic manufacturing technology, can solve problems such as affecting the service life of devices and easy aging, and achieve the effects of reducing equipment investment, improving lighting time and brightness, and reducing process difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

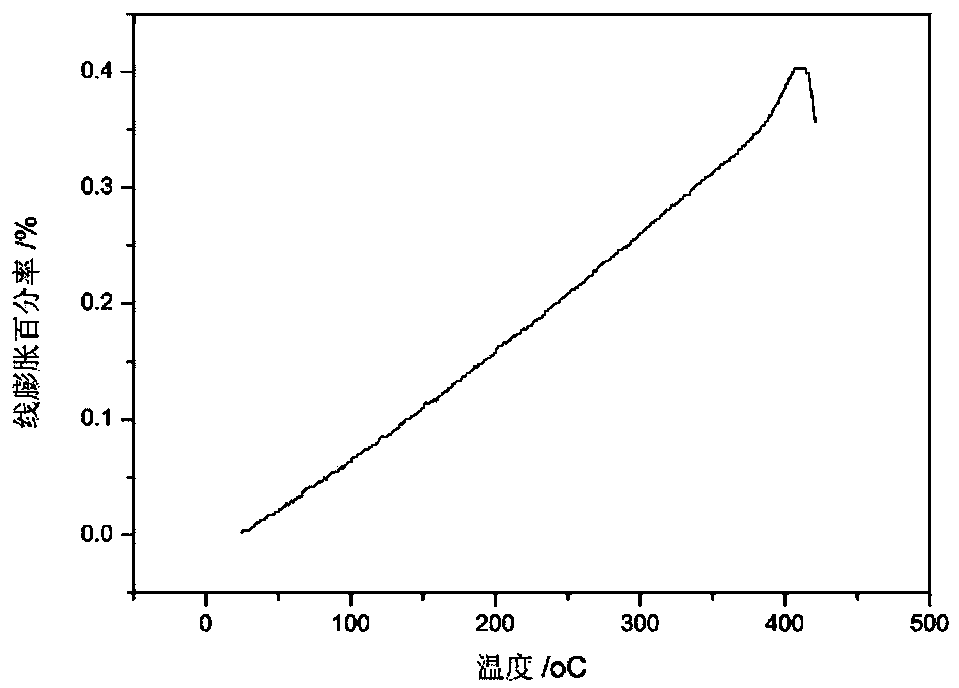

[0070] The low-melting point glass is formulated as shown in Table 1, mixed evenly and melted at a temperature of 1000°C, kept for 120 minutes, and pulverized with a ball mill after melting. The low-melting-point glass powder refractive index 1.8 that is prepared by the formula of table 1 (1), press figure 1 Its softening temperature is 413°C measured from the thermal expansion coefficient percentage and temperature map.

[0071] Table 1 Proportion of low melting point glass (Wt.%)

[0072]

Embodiment 2

[0074] 85wt.% YAG: Ce phosphor (Y 3 al 5 o 12 : Ce, Model PAM YY4425, D 50 =20μm) and 15wt.% low melting point glass powder (D 50 = 10 μm) and mix evenly, add 5wt.% PVB binder to make 80-60 mesh granulated powder, and use a press to make a luminous ceramic sheet green body with a corresponding shape.

[0075] Put the green body of the luminescent ceramic sheet into the sintering furnace, set the debinding area (300-350°C) to run for 3-4h, and the sintering area (400°C) to run for 1.5h to make the luminescent ceramic sheet.

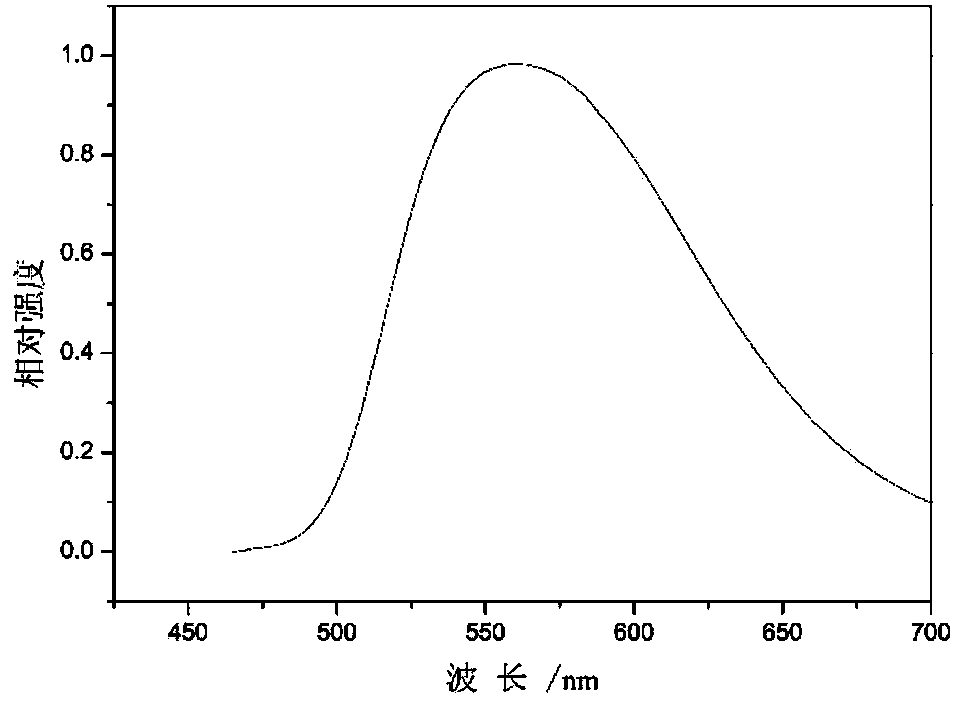

[0076] Under 365nm excitation light, its emission spectrum is as follows figure 2 (The intensity of the luminescent film made of YAG phosphor powder content 85wt.% and epoxy resin is set to 1); the thickness of the luminescent ceramic sheet is 0.6mm, and the transmittance is >20%.

Embodiment 3

[0078] 50wt.% long afterglow phosphor (SrAl 2 o 4 :Eu) and 50wt.% low melting point glass powder (D 50 =10 μm)) After mixing evenly, add 0.5wt.% PVB binder to make 80-100 mesh granulated powder, and use a press to press into a luminous ceramic sheet green body with a corresponding shape.

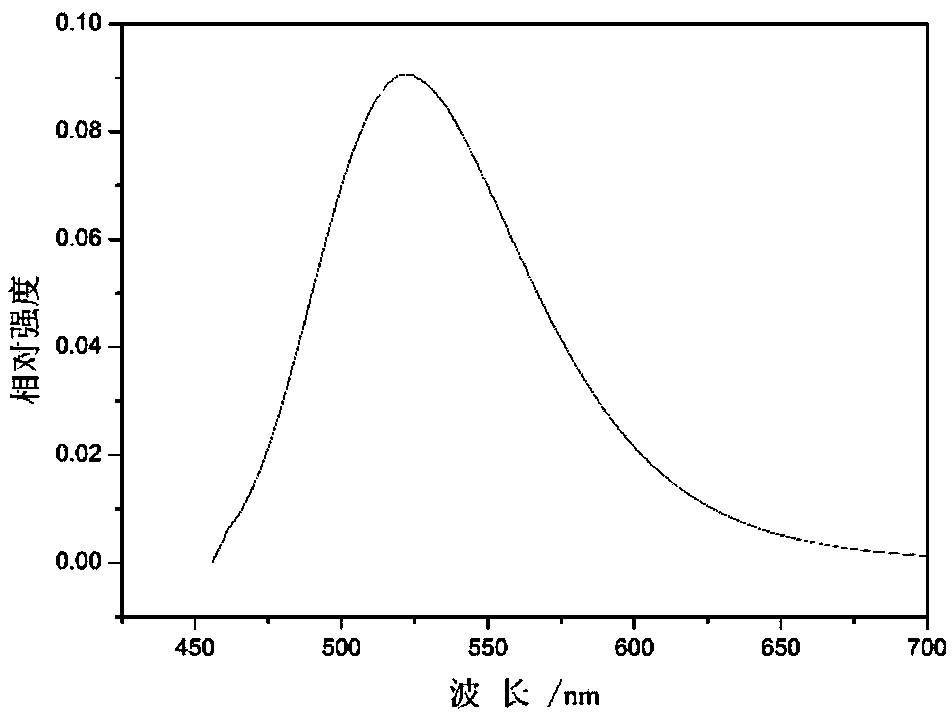

[0079] Put the green body of the luminescent ceramic sheet into the sintering furnace, set the debinding area (350-395°C) to run for 2-3h, and the sintering area (410°C) to run for 1h to make a long afterglow luminescent ceramic sheet. Under the excitation light of 450nm, Its emission spectrum is as image 3 .

[0080] Expose the long-lasting luminescent ceramic sheet to sunlight for 5 minutes, and test its attenuation within 30 minutes to obtain Figure 4 curve shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com