Red fluorophor as well as carbothermal reduction nitridation preparation method and application of red fluorophor

A technology of red fluorescence and phosphor, applied in chemical instruments and methods, luminescent materials, semiconductor devices, etc., can solve the problems of unfavorable industrial production, increase synthesis cost, and high synthesis temperature, and achieve easy mass production, lower color temperature, and synthesis low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] (Preparation method of phosphor)

[0076] The phosphor of the present invention can be prepared by carbothermal reduction nitriding method, which can include batching, mixing, sintering and post-treatment processes.

[0077] 1. Ingredients

[0078] As a Ca source, CaCO can be used 3 and / or CaO and / or CaC 2 o 4 . As Sr, SrCO can be used 3 and / or SrO. As the Si source, Si can be used 3 N 4 and / or SiO 2 . As the Al source, AlN can be used. As the A source, a metal element, an oxide, a nitride, a fluoride, a chloride, a carbonate, or an oxynitride of the A element can be used.

[0079] Weigh the above-mentioned raw materials according to the stoichiometric ratio of the chemical formula of the phosphor, and add reducing agent carbon powder therein. The molar ratio of the amount of carbon powder added to the oxygen element in the raw material (the carbonate decomposed during the heating process is calculated based on the oxides generated after decomposition) can be ...

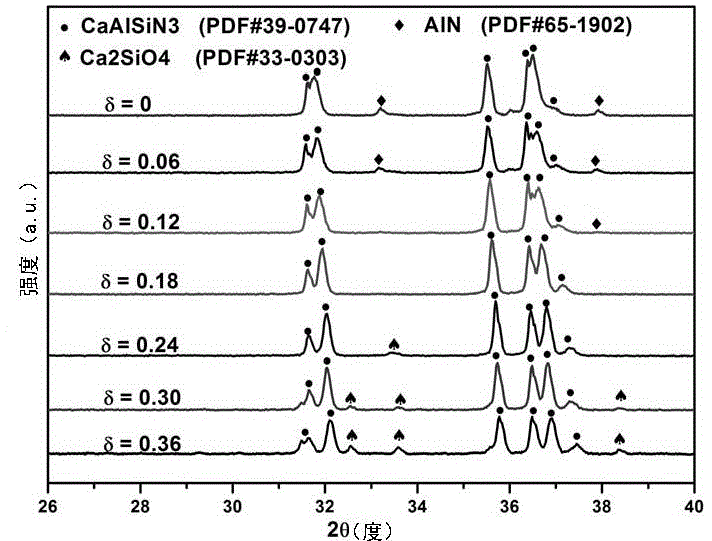

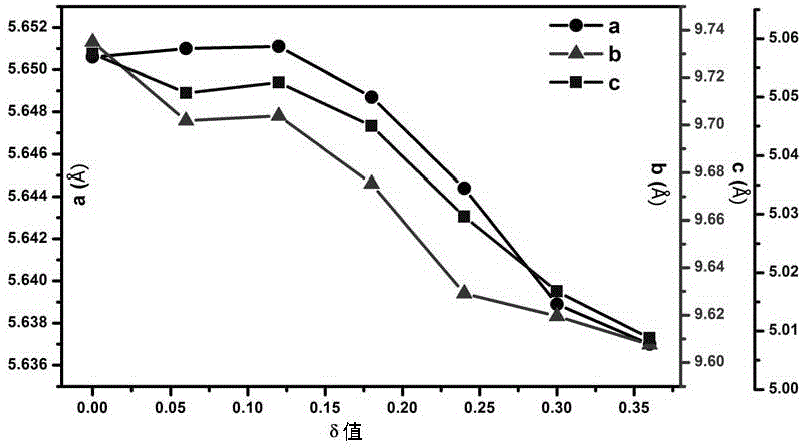

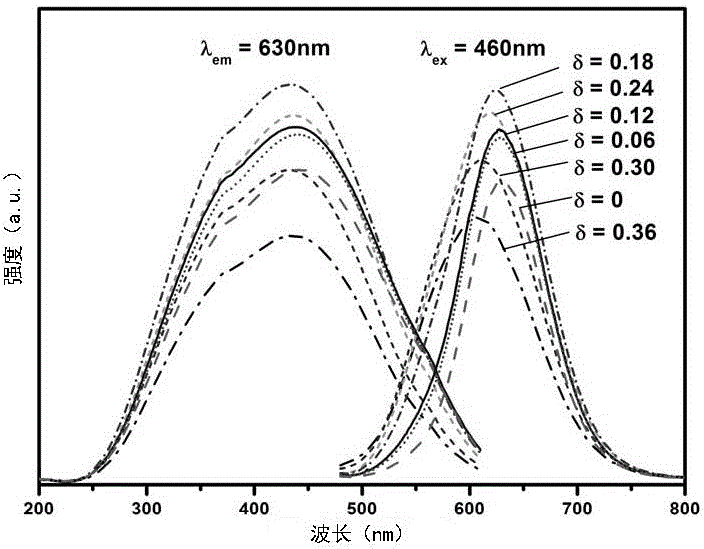

Embodiment 1~7

[0104] Formulation design: according to the chemical formula Ca 0.98 Eu 0.02 Al 1-4δ / 3 Si 1+δ N 3 (Ca 1-x-y Sr y Eu x Al 1-4δ / 3 Si 1+δ N 3-2z / 3 o 3z / 2 , x=0.02, y=0, z=0) designed 7 formulations (δ=0, 0.06, 0.12, 0.18, 0.24, 0.30, 0.36).

Embodiment 8~13

[0106] Formulation design: according to the chemical formula Ca 1-x Eu x Al 0.76 Si 1.18 N 3 (Ca 1-x-y Sr y Eu x Al 1-4δ / 3 Si 1+δ N 3-2z / 3 o 3z / 2 , δ=0.18, y=0, z=0) designed 6 recipes (x=0.01, 0.02, 0.03, 0.05, 0.08, 0.1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com