Patents

Literature

221results about "Combustion ignition/checking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

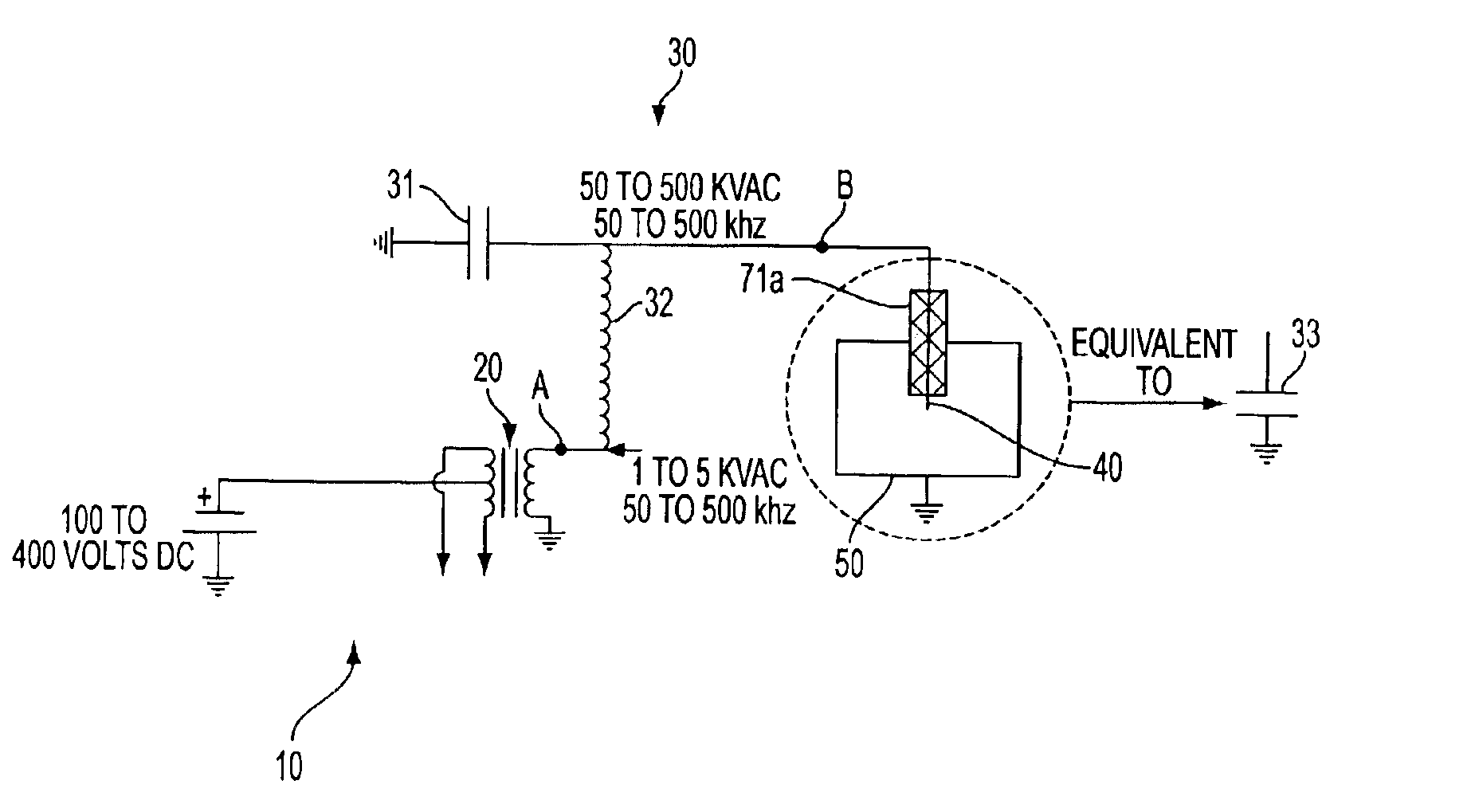

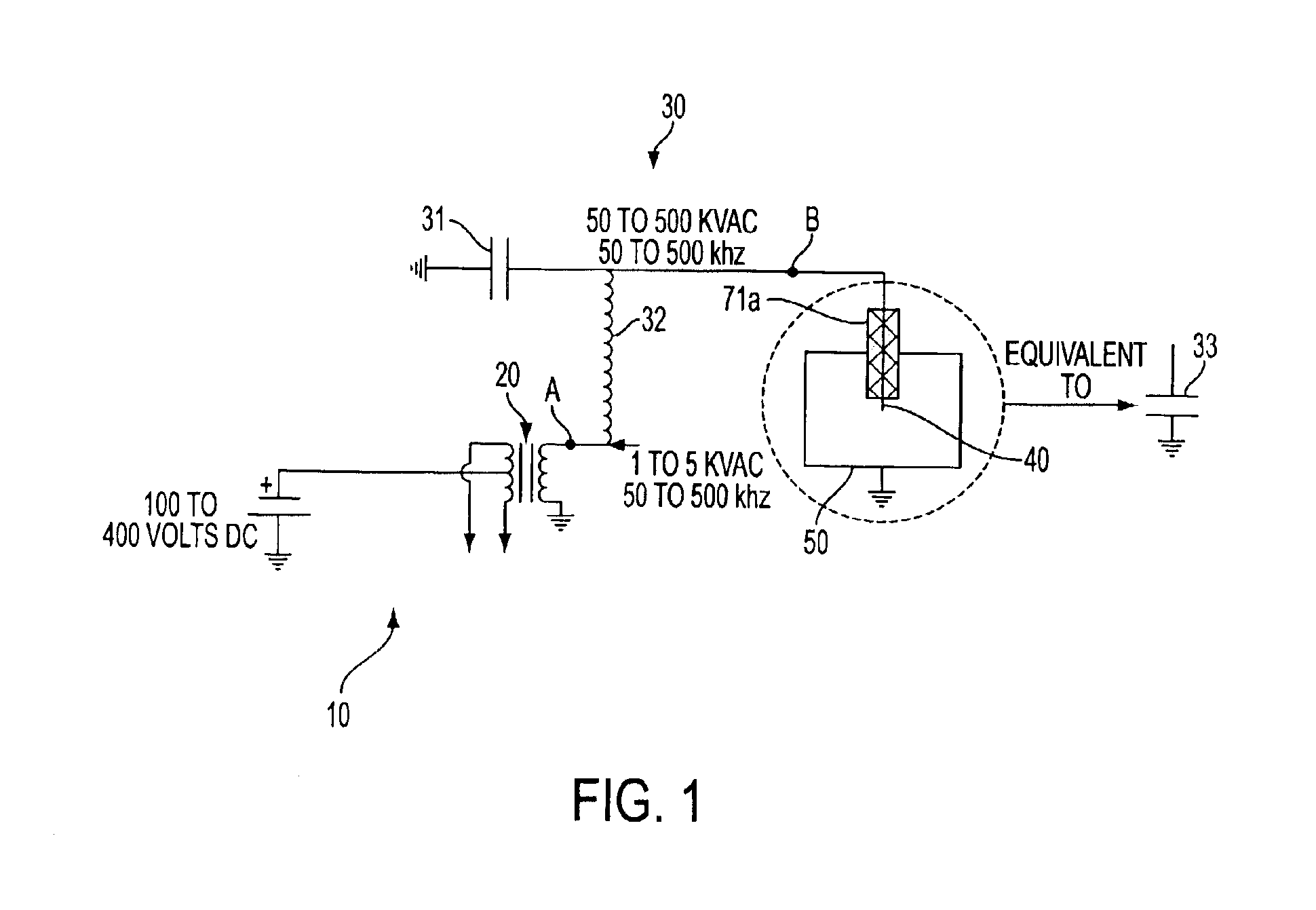

System and method for generating and sustaining a corona electric discharge for igniting a combustible gaseous mixture

InactiveUS6883507B2Sufficient energySparking plugsCombustion enginesCombustion chamberElectric discharge

The invention relates to a system for igniting a fuel-air mixture in a combustion chamber with a corona discharge. The system comprises an electrode inside of the combustion chamber, an electric circuit which provides radio frequency electric power to the electrode, and a ground formed by the combustion chamber walls. A radio frequency voltage differential formed between the electrode and the ground produces a radio frequency electric field therebetween which causes a fuel-air mixture to ionize resulting in combustion of the fuel-air mixture. The system can be utilized in engines such as internal combustion engines or gas turbine engines, for example.

Owner:BORGWARNER INC

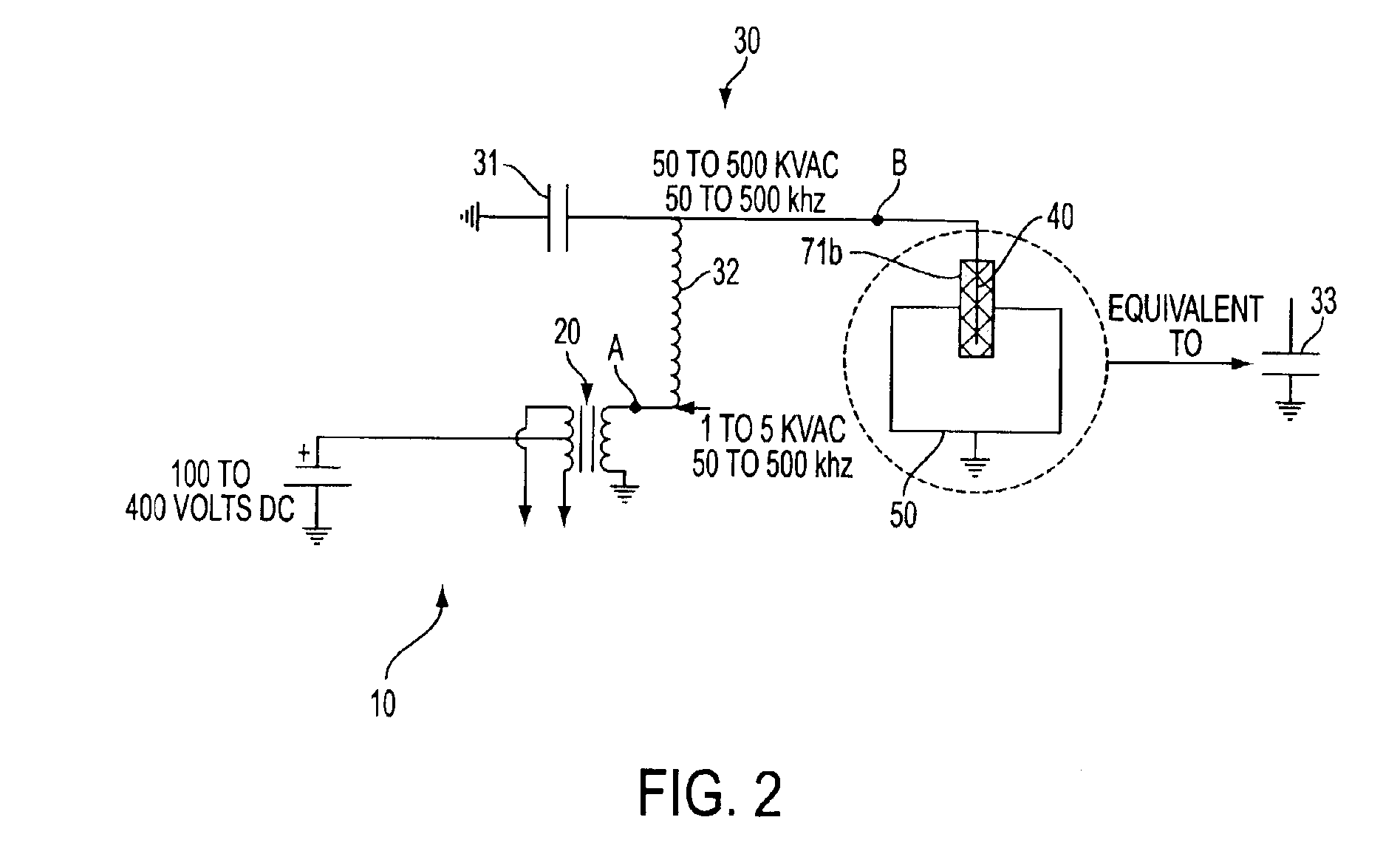

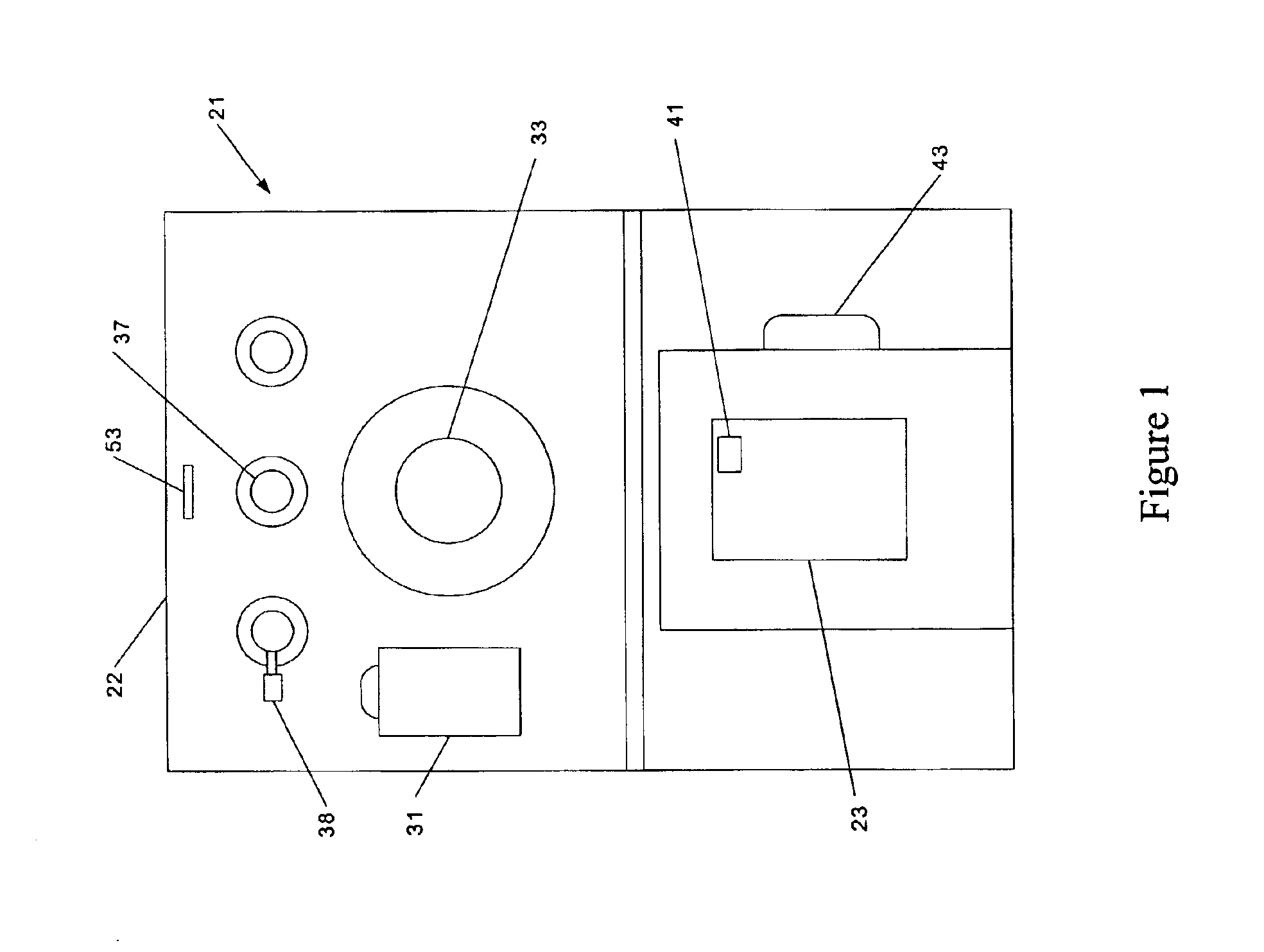

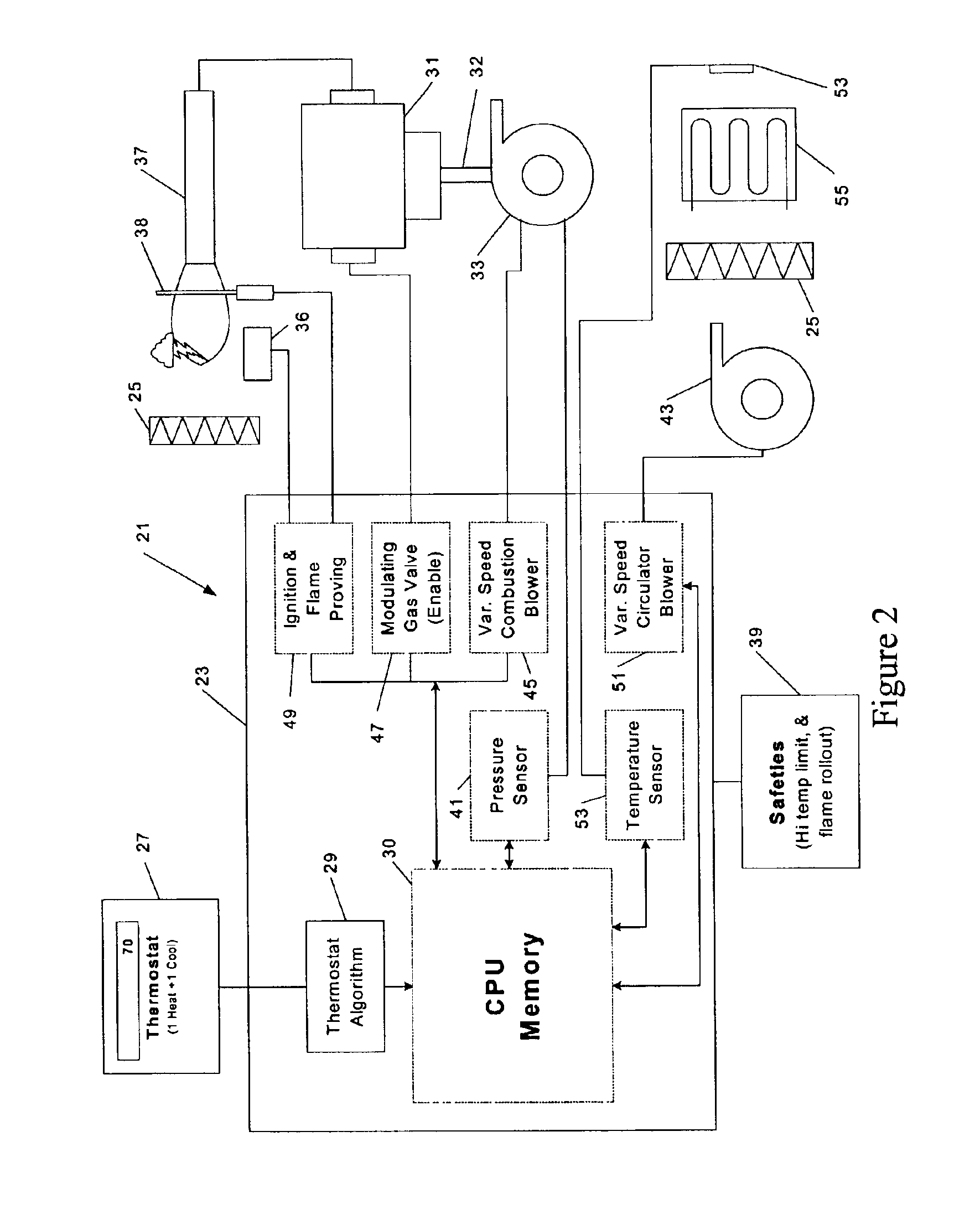

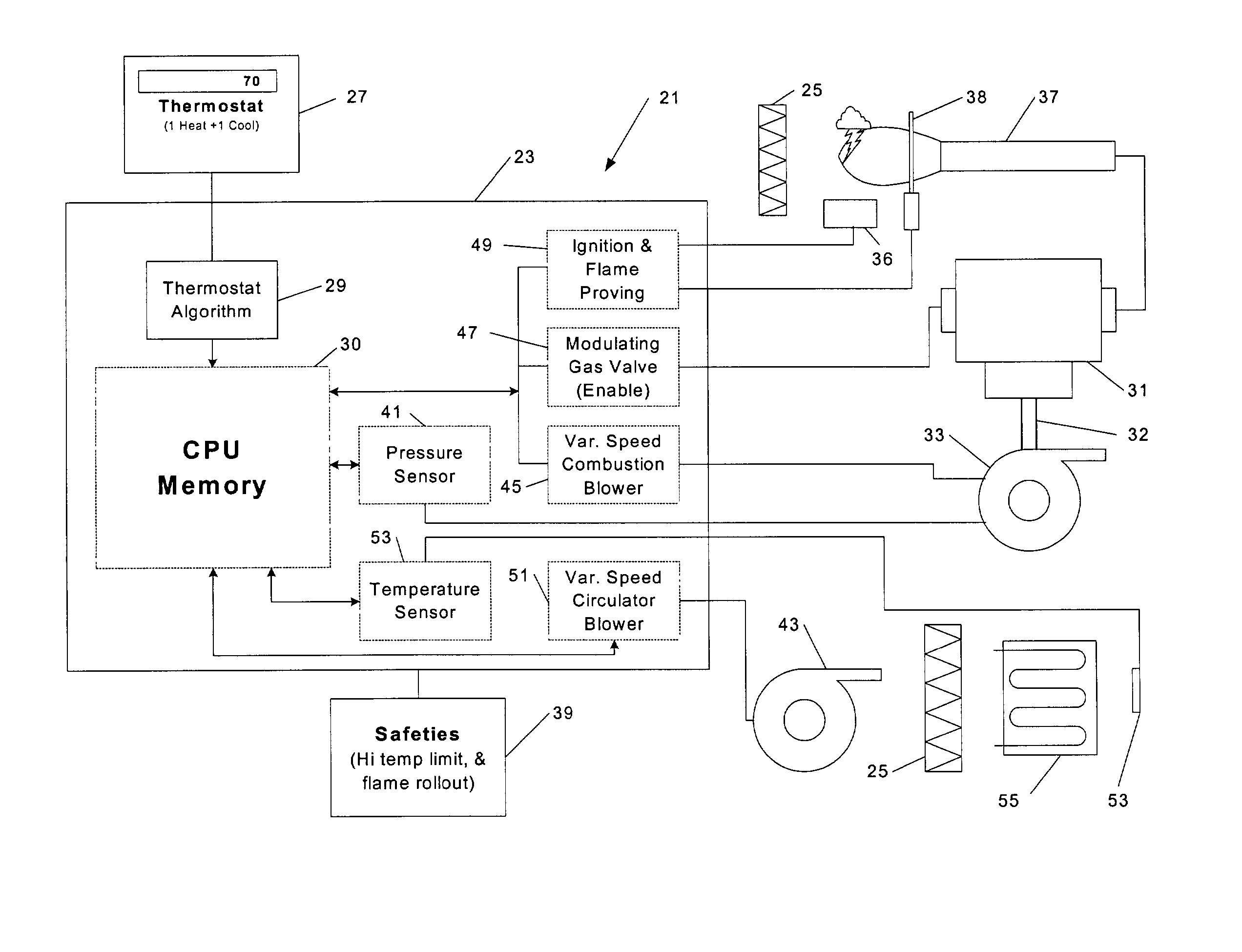

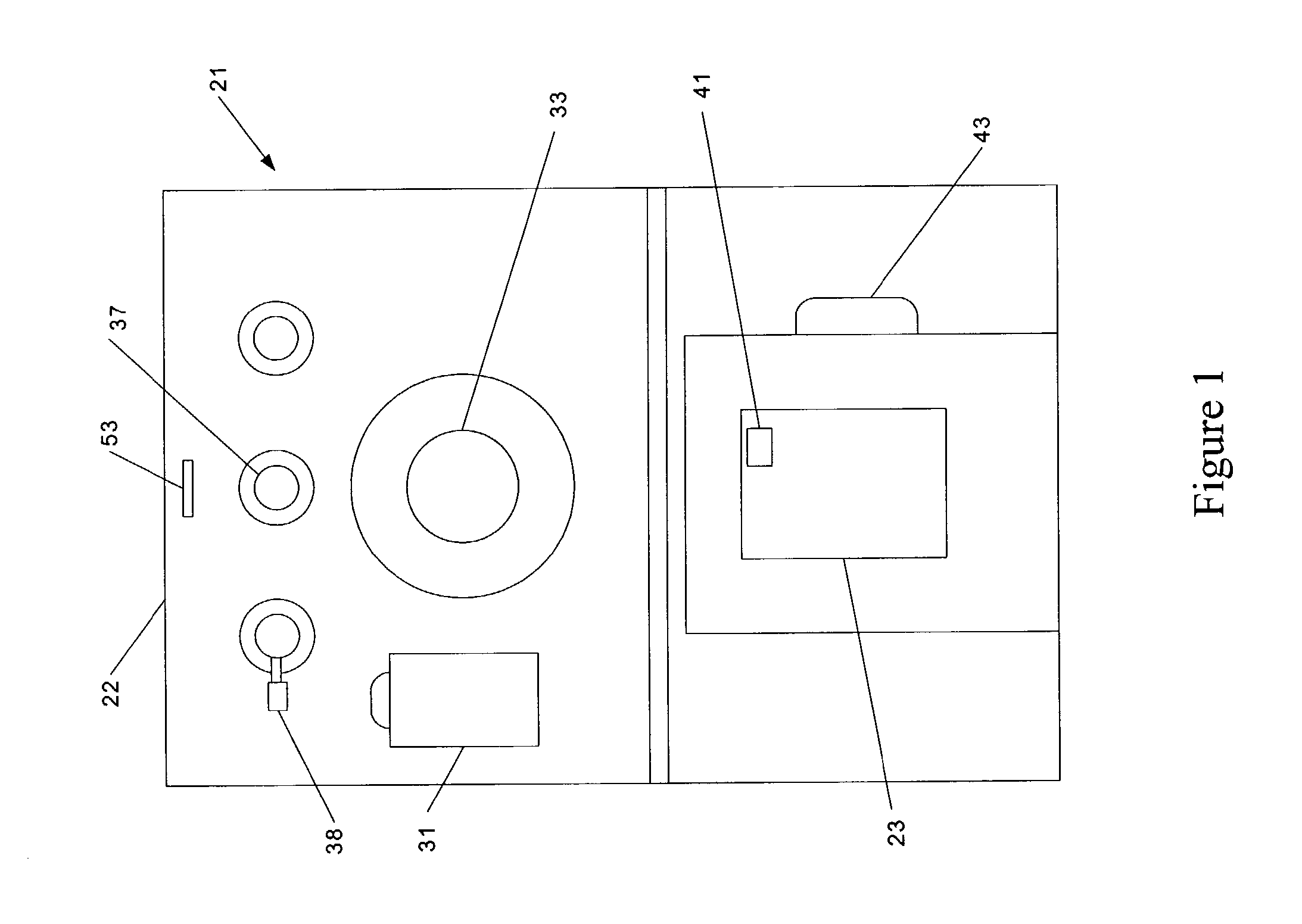

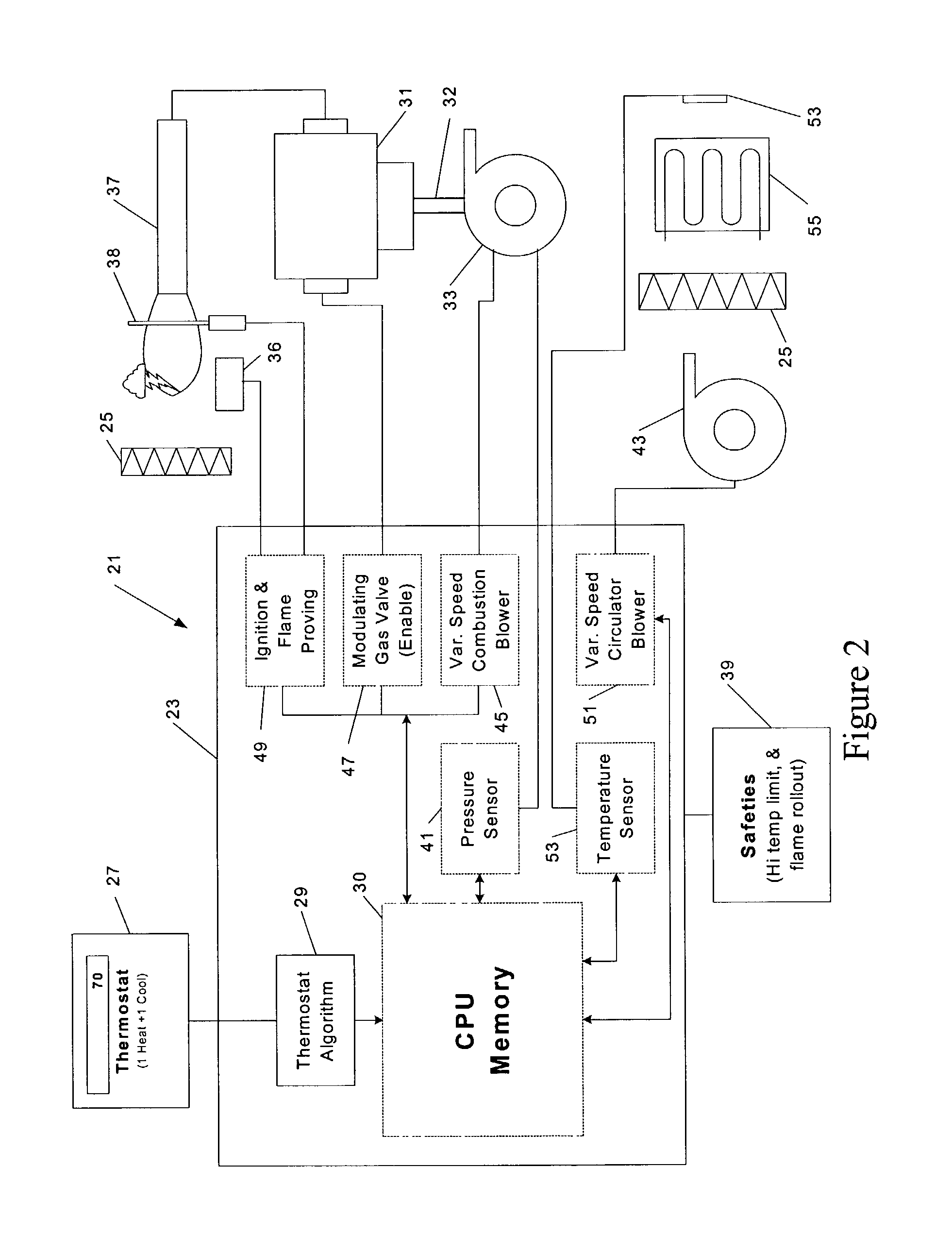

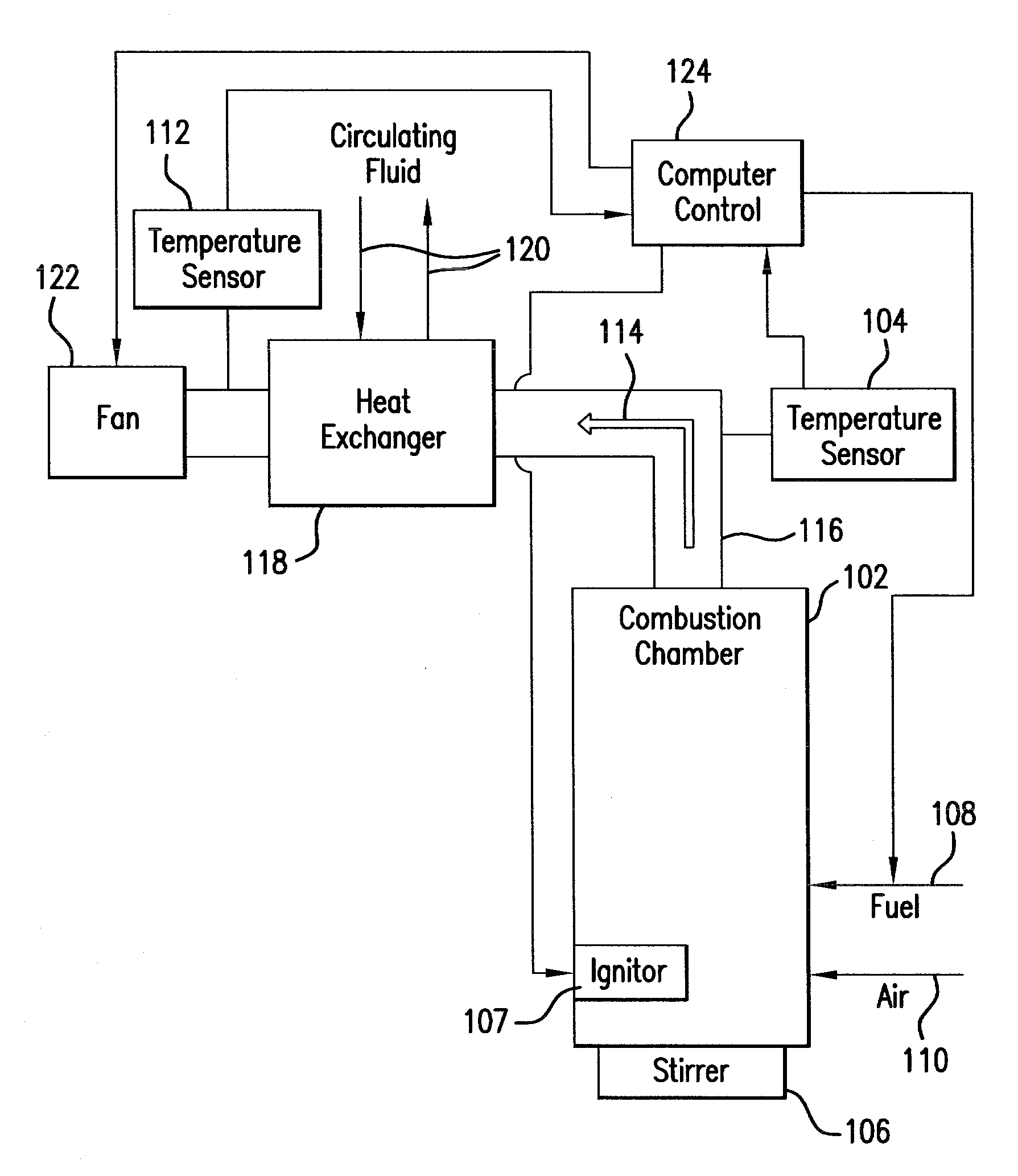

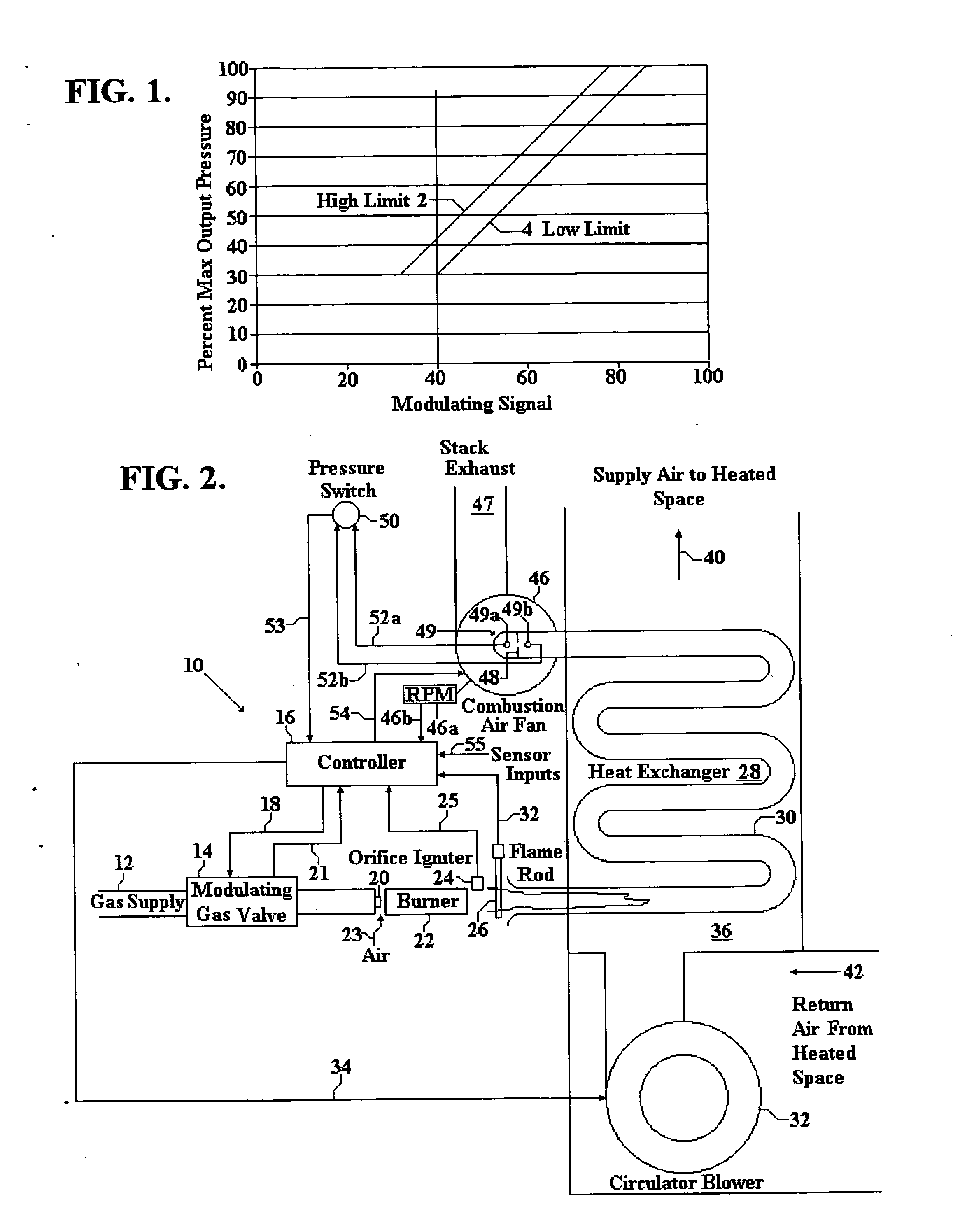

Variable output heating and cooling control

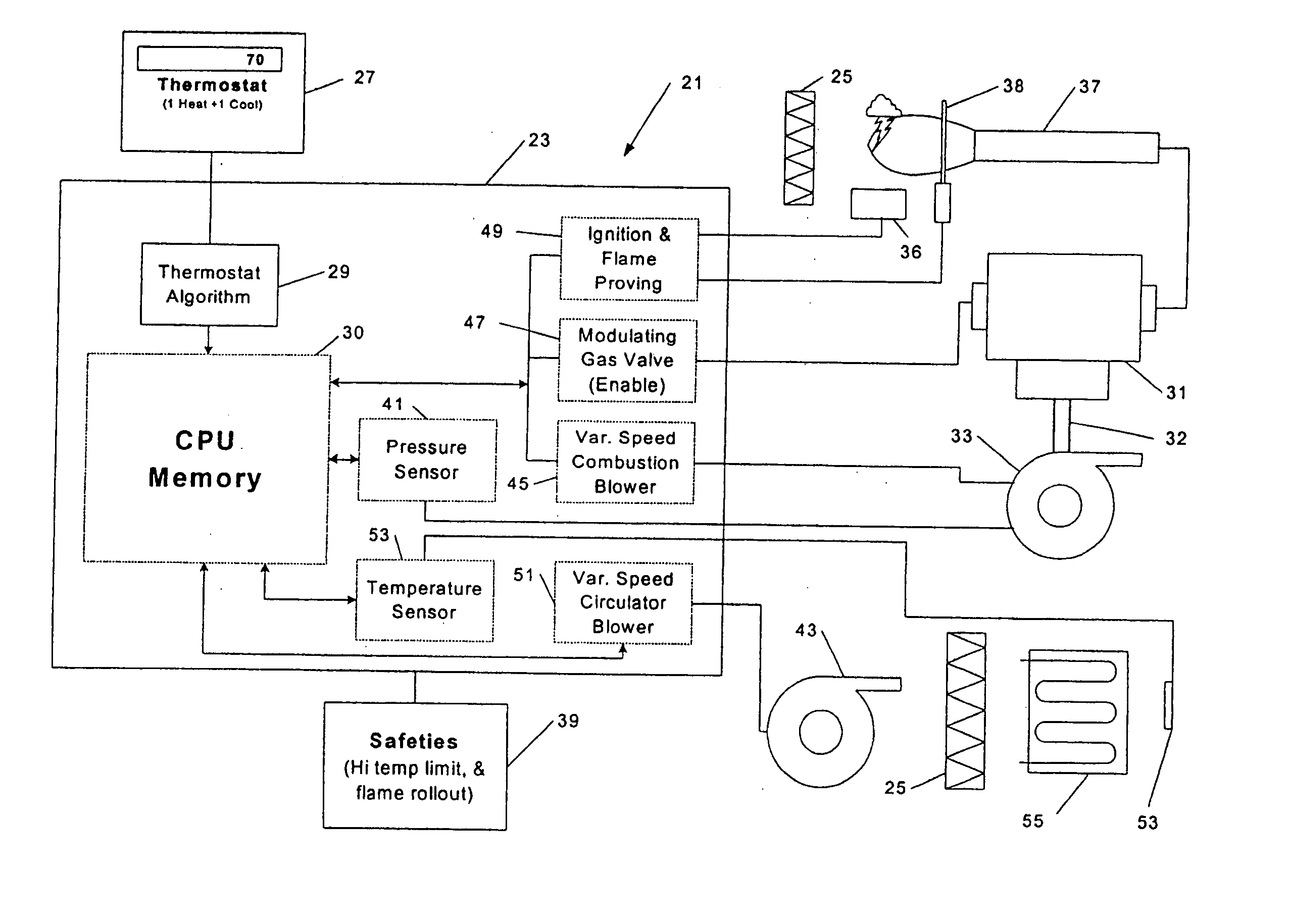

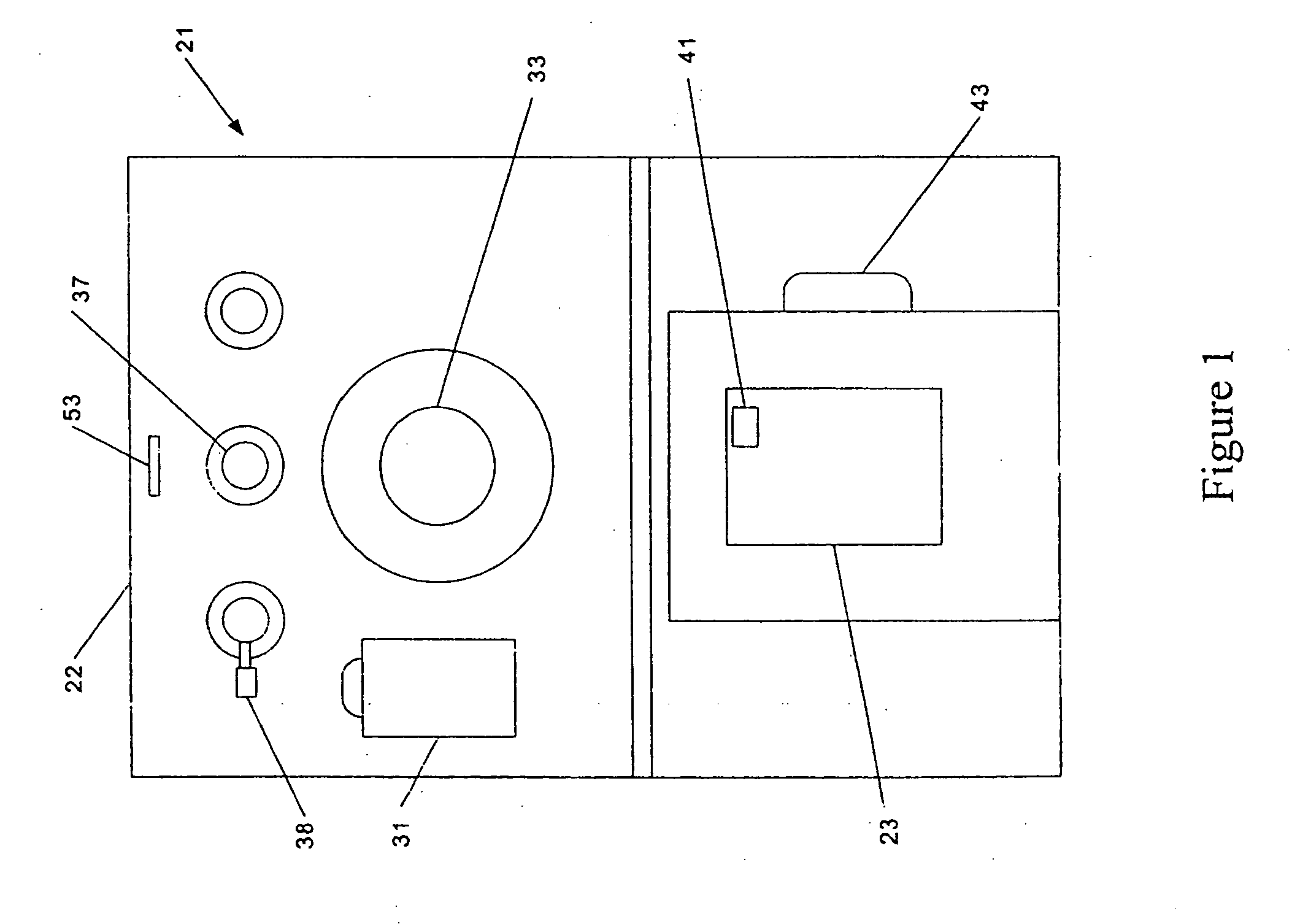

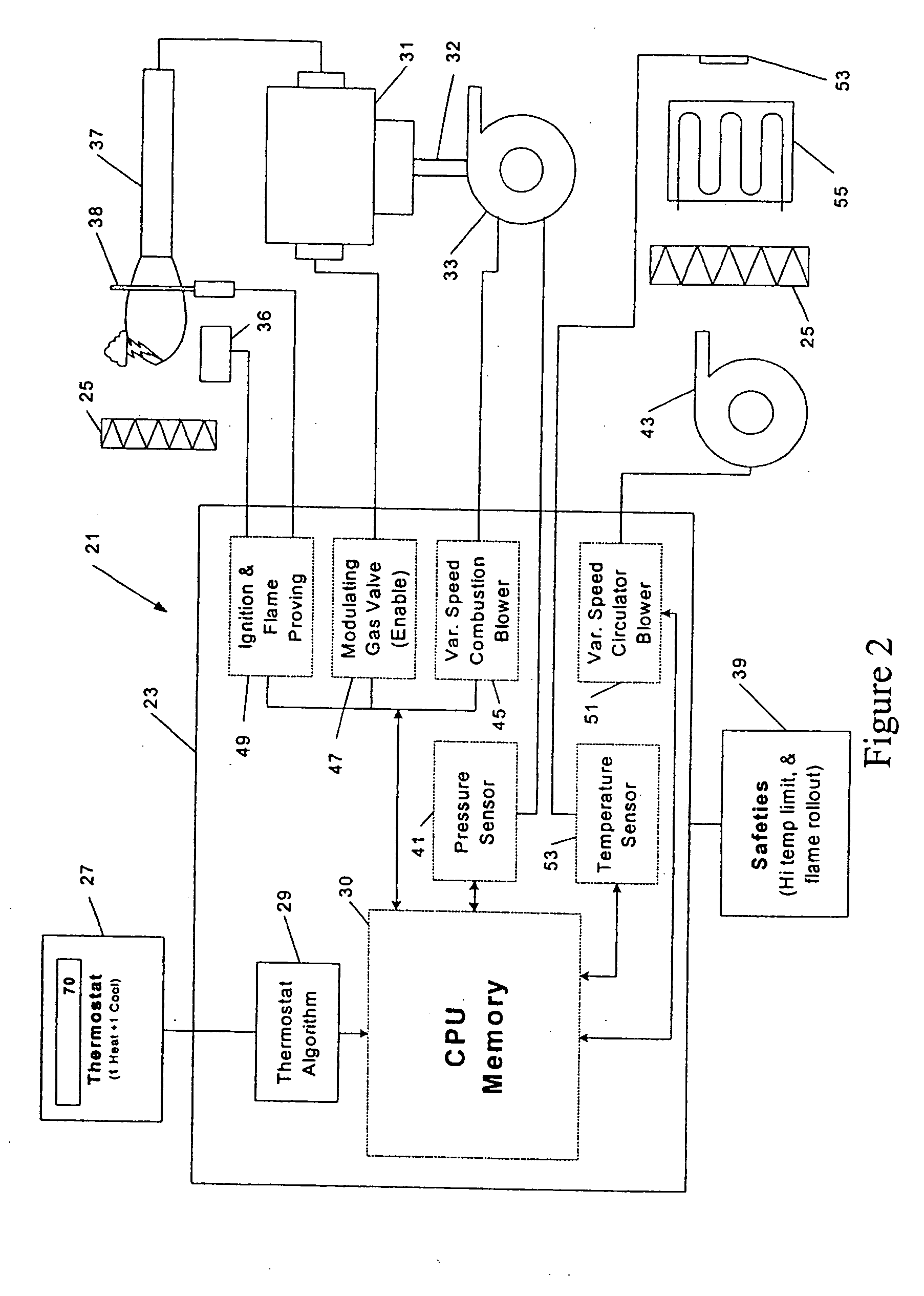

A heating or cooling system, such as an HVAC system, of variable output has a number of control elements and may include a variable speed compressor, a variable speed combustion (induced or forced draft) blower motor; a variable speed circulator blower motor; a variable output gas valve or gas / air premix unit; and a controller specifically developed for variable output applications. The system may utilize a pressure sensor to determine the actual flow of combustion airflow in response to actual space conditions, vary the speed of the inducer blower, and subsequently vary the gas valve output to supply the correct amount of gas to the burner system. A temperature sensor may be located in the discharge air stream of the conditioned air to provide an input signal for the circulator blower.

Owner:HVAC MODULATION TECH

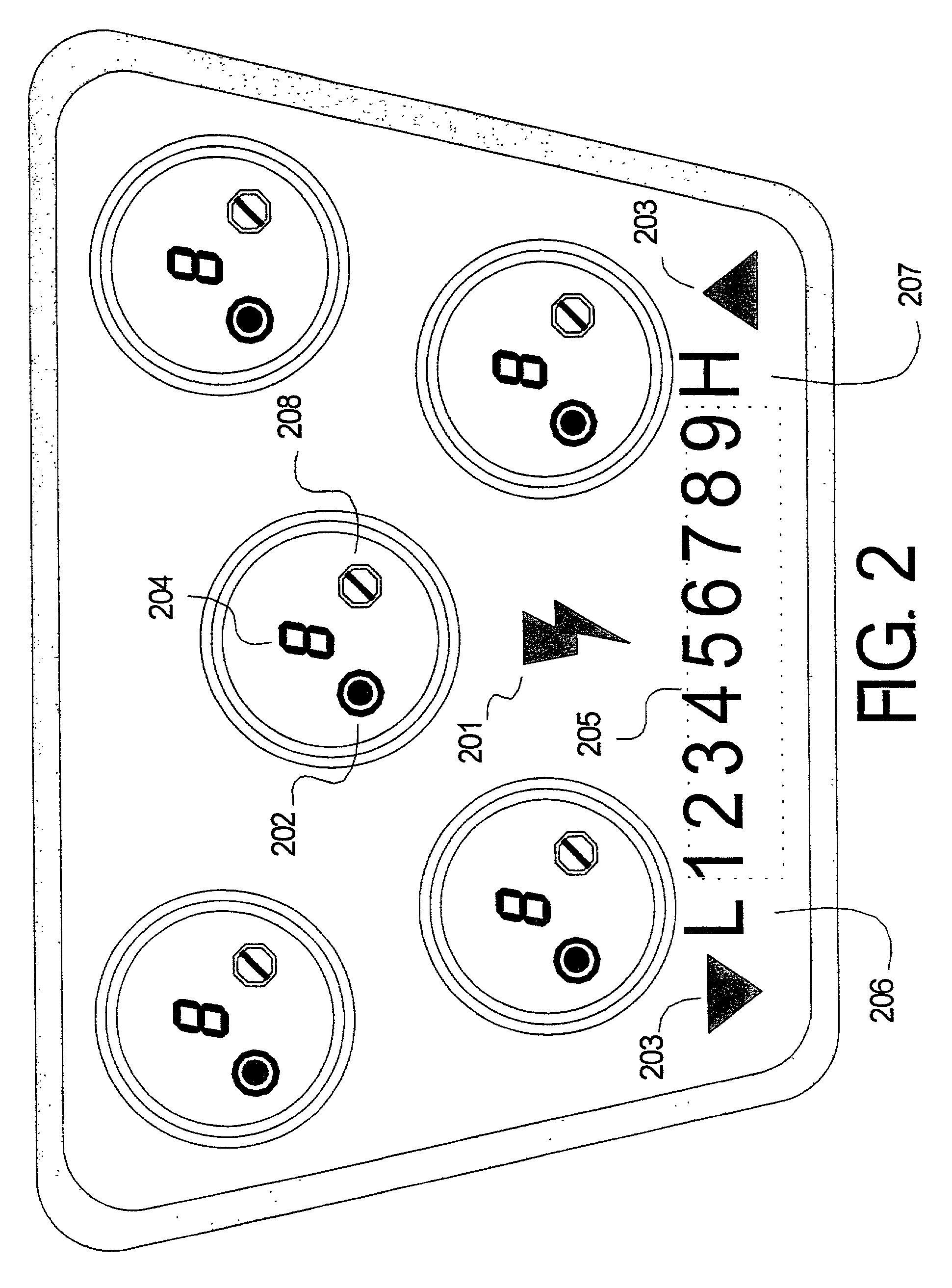

Electronic gas cooktop control with simmer system and method thereof

InactiveUS7255100B2Reduce heating powerHigh outputFuel supply regulationDomestic stoves or rangesControl systemElectromagnetic interference

An electronically activated gas cooktop control system, responsive to a touch-sensitive user interface, and capable of providing a predetermined range of cooking and simmer levels of BTU output, has two complementary heating modes of operation A first heating mode of operation is provided to produce a wide selection of simmer levels of BTU output, by electronically sequencing a solenoid-operated modulating gas valve “on” and “off”, at a predetermined level of flame. A second cooking mode of operation is provided by electronically modulating the level of flame, through use of a pulse-width-modulation (PWM) output signal to produce a wide selection of cooking levels of BTU output. An igniter system capable of insuring proper ignition of gas without generating harmful electromagnetic interference is also provided.

Owner:COMPUVALVE +1

Feedback control for modulating gas burner

Owner:ADEMCO INC +1

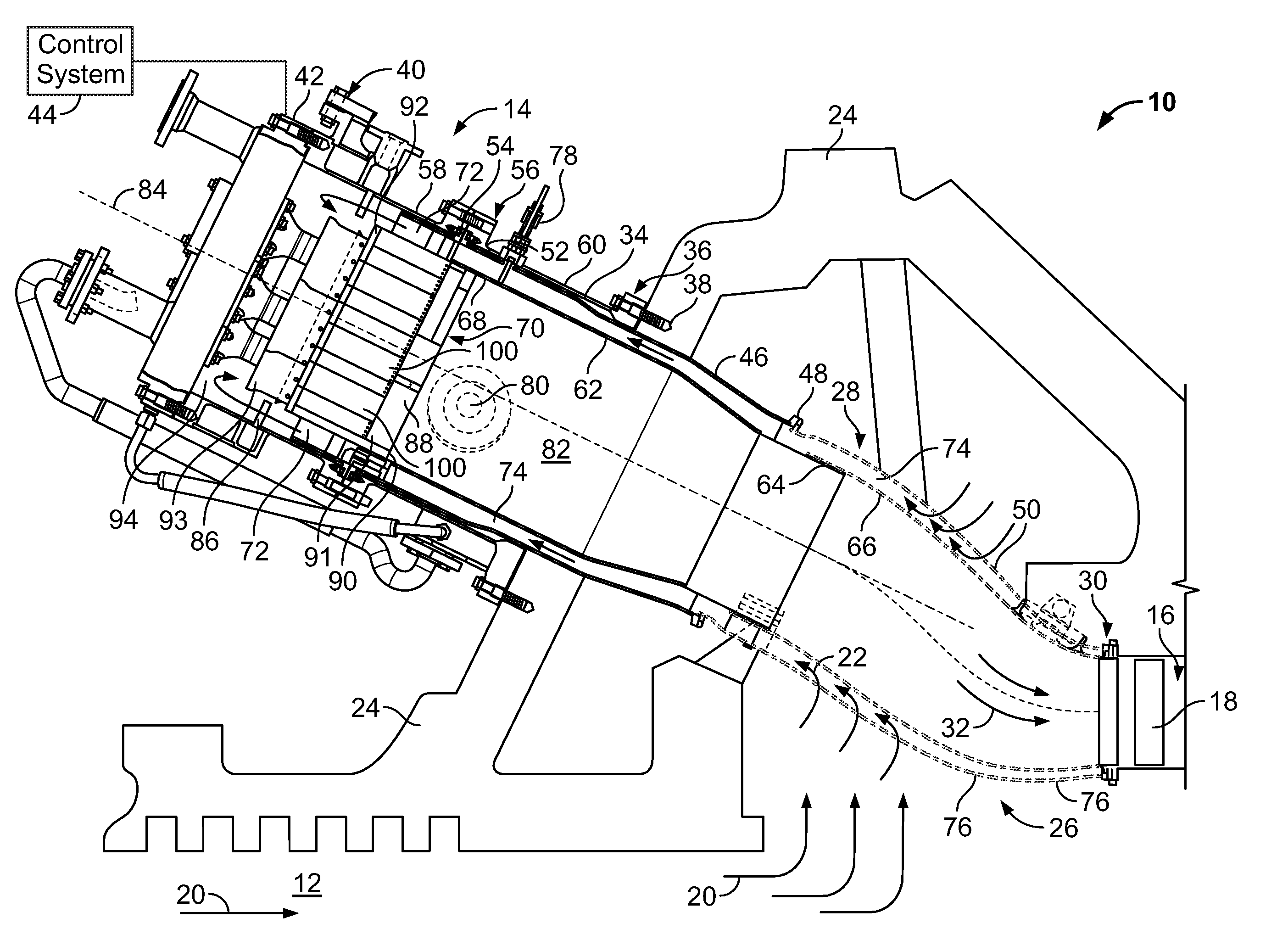

Method and apparatus for combusting fuel within a gas turbine engine

A method for operating a gas turbine engine including a combustor assembly is provided. The method includes channeling a first fluid through a first nozzle into the combustor assembly, igniting the first fluid within the combustor assembly downstream from the first nozzle, channeling a second fluid through a second nozzle into the combustion assembly when the gas turbine engine attains a speed of greater than 85% of rated speed, igniting the second fluid within the combustor assembly downstream from the second nozzle, terminating a flow of the first fluid through the first nozzle, and channeling the second fluid to the first nozzle.

Owner:GENERAL ELECTRIC CO

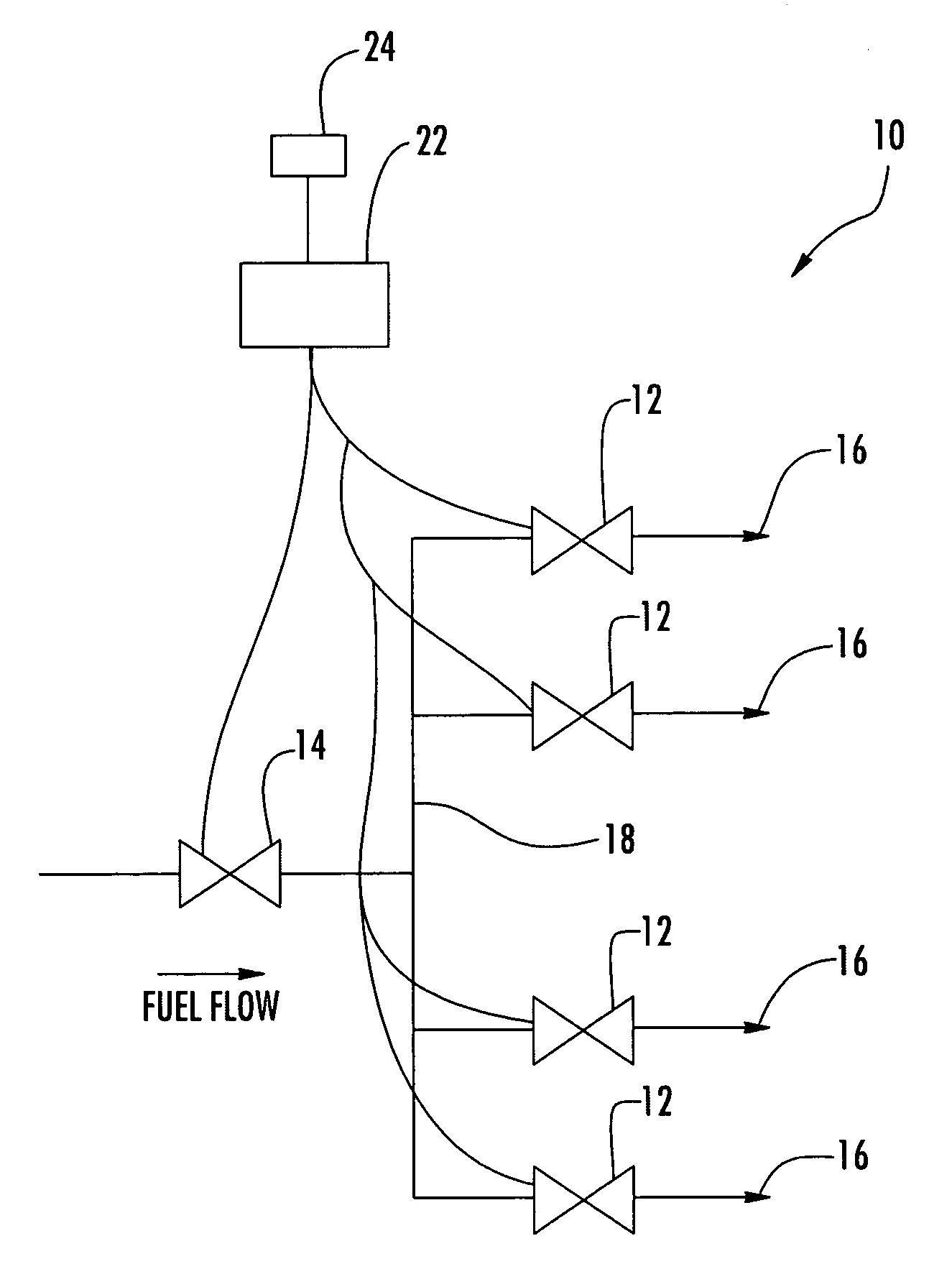

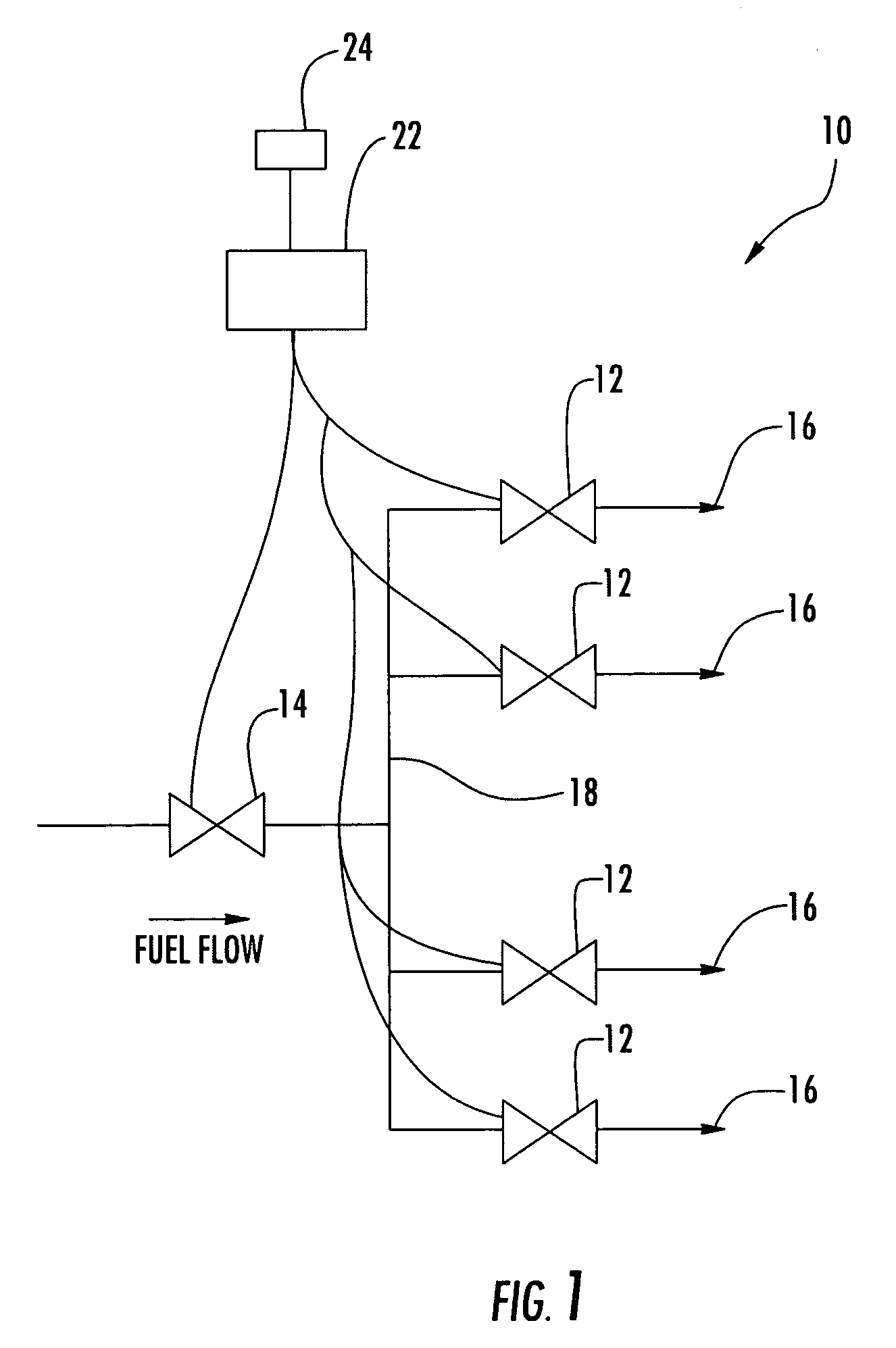

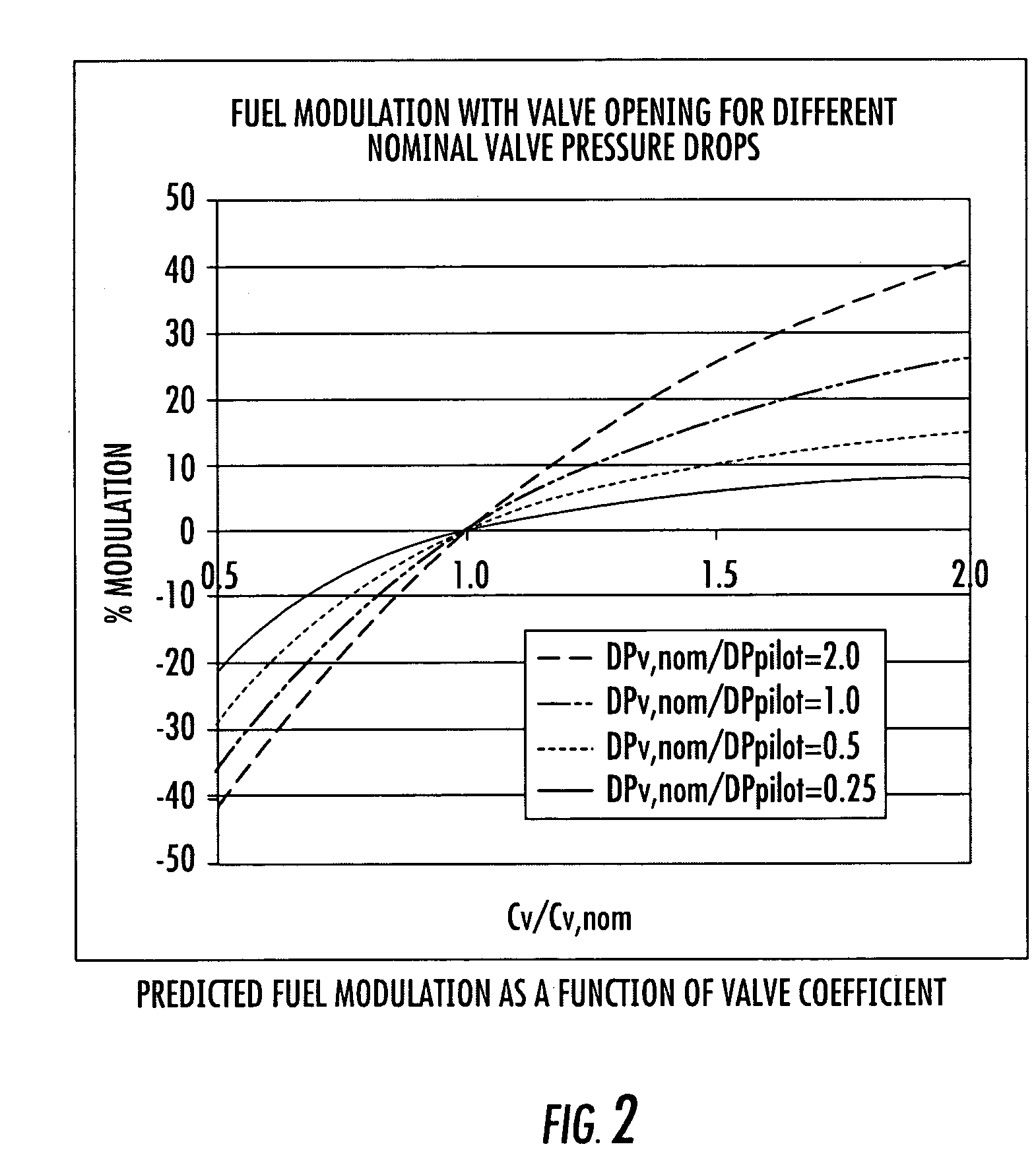

System for modulating fuel supply to individual fuel nozzles in a can-annular gas turbine

ActiveUS20080016875A1Ensure efficient flowReduce the amount of solutionFuel supply regulationContinuous combustion chamberCombustorEngineering

A fuel modulation system usable in can-annular combustor systems of turbine engines for more efficiently managing fuel flow to reduce the amount of NOx while maintaining appropriate combustor flame temperatures. The fuel modulation system controls individual inline modulation valves in cooperation with a overall stage control valve to bring a turbine engine through the startup phase and to maintain operating conditions at a load set point while reducing NOx variability between baskets by using individual combustor dynamic pressure measurements. The fuel modulation system may be managed such that individual inline modulation valves remain within a predetermined range of positions relative to a nominal position to reduce NOx variability.

Owner:SIEMENS ENERGY INC

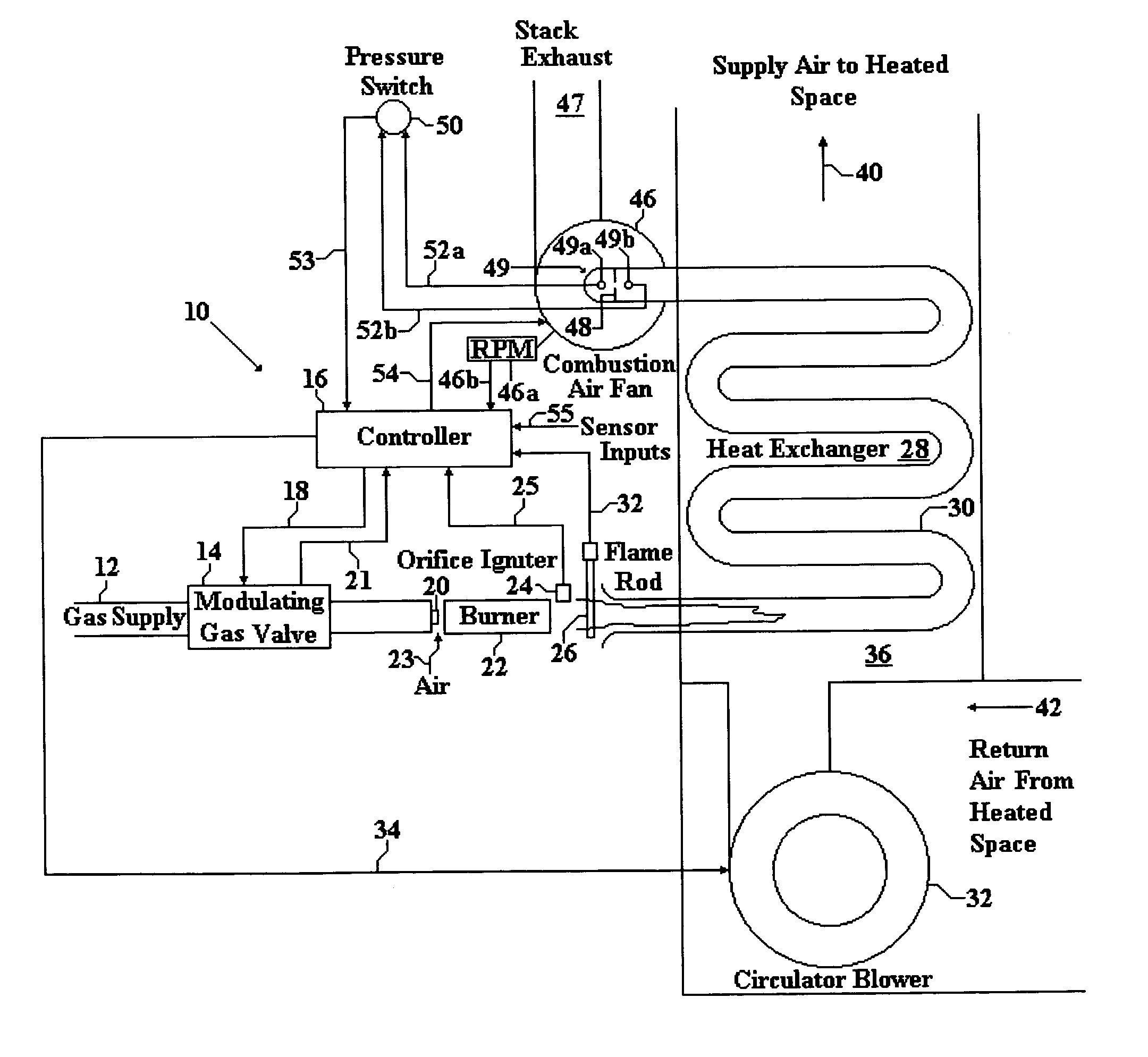

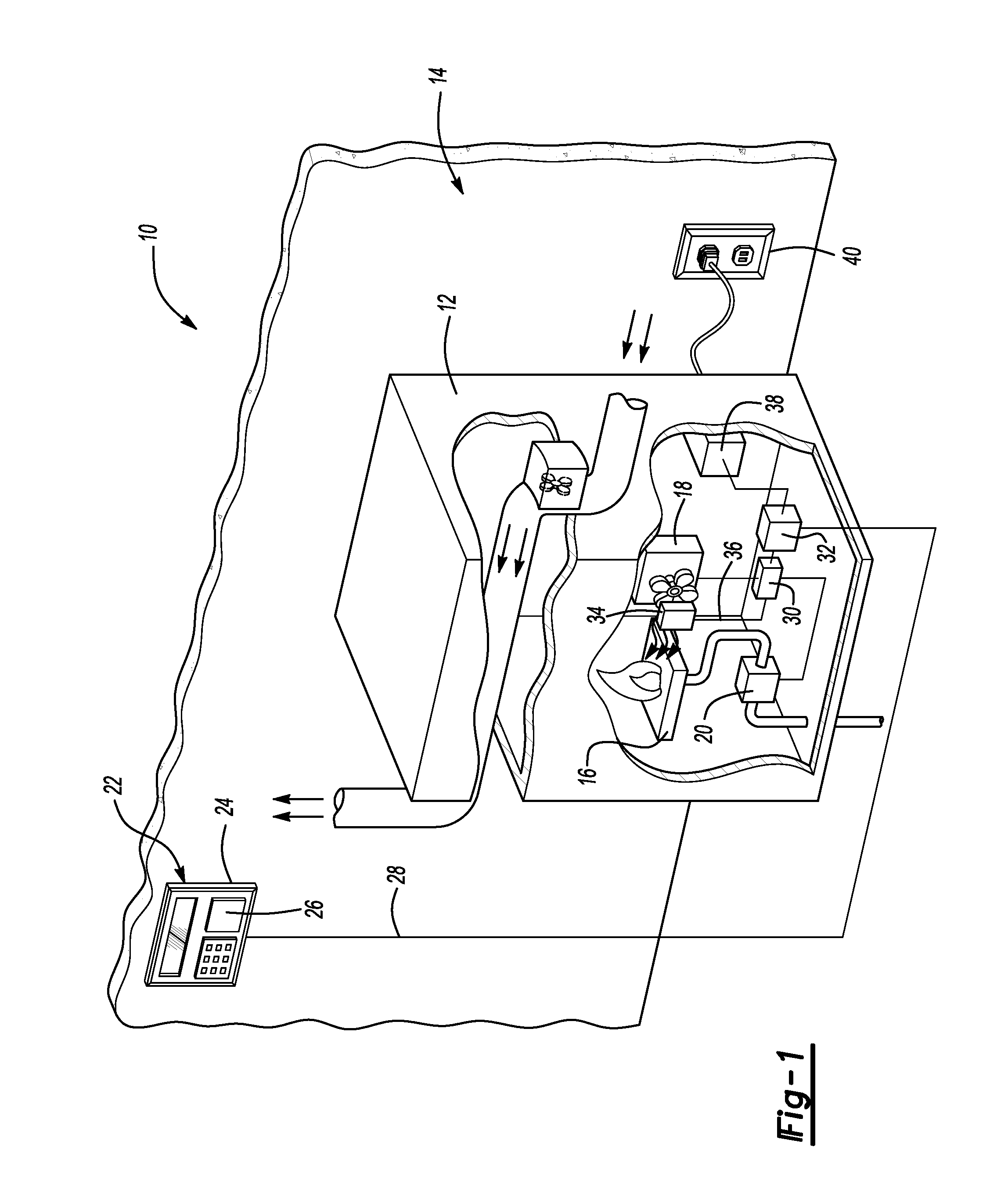

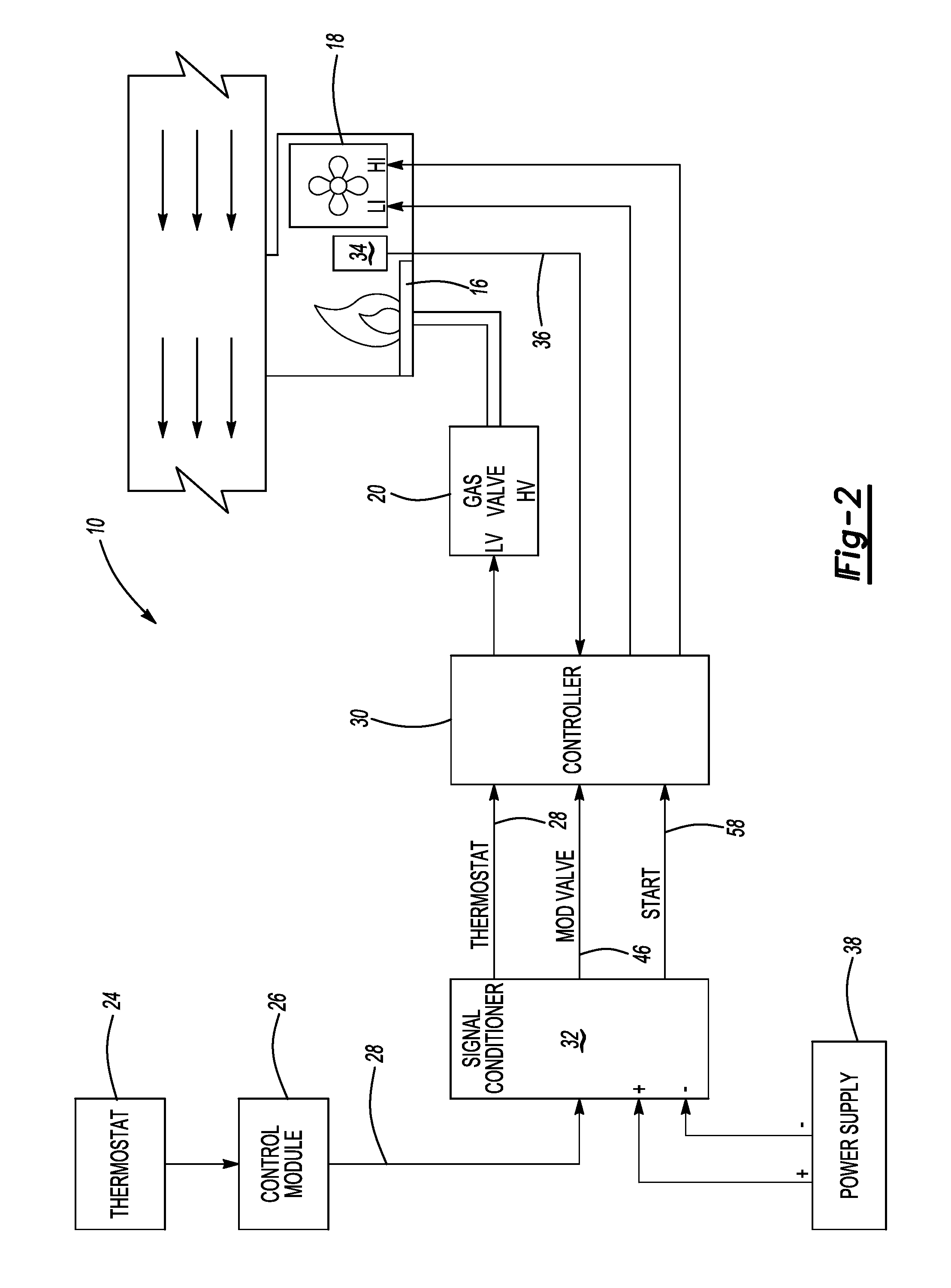

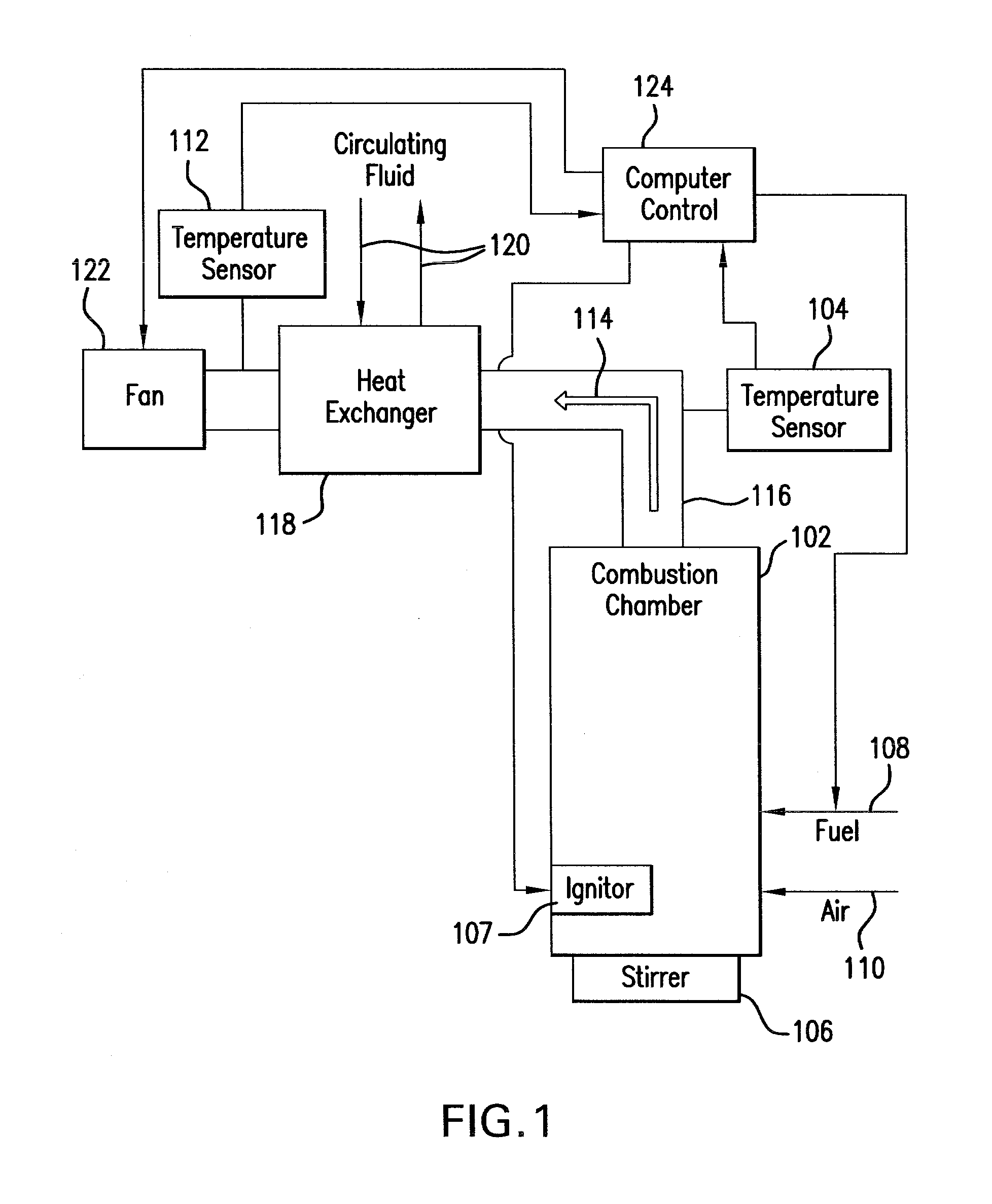

Variable output heating and cooling control

A heating or cooling system, such as an HVAC system, of variable output has a number of control elements and may include a variable speed compressor, a variable speed combustion (induced or forced draft) blower motor; a variable speed circulator blower motor; a variable output gas valve or gas / air premix unit; and a controller specifically developed for variable output applications. The system may utilize a pressure sensor to determine the actual flow of combustion airflow in response to actual space conditions, vary the speed of the inducer blower, and subsequently vary the gas valve output to supply the correct amount of gas to the burner system. A temperature sensor may be located in the discharge air stream of the conditioned air to provide an input signal for the circulator blower.

Owner:HVAC MODULATION TECH

Variable output heating and cooling control

A heating or cooling system, such as an HVAC system, of variable output has a number of control elements and may include a variable speed compressor, a variable speed combustion (induced or forced draft) blower motor; a variable speed circulator blower motor; a variable output gas valve or gas / air premix unit; and a controller specifically developed for variable output applications. The system may utilize a pressure sensor to determine the actual flow of combustion airflow in response to actual space conditions, vary the speed of the inducer blower, and subsequently vary the gas valve output to supply the correct amount of gas to the burner system. A temperature sensor may be located in the discharge air stream of the conditioned air to provide an input signal for the circulator blower.

Owner:HVAC MODULATION TECH

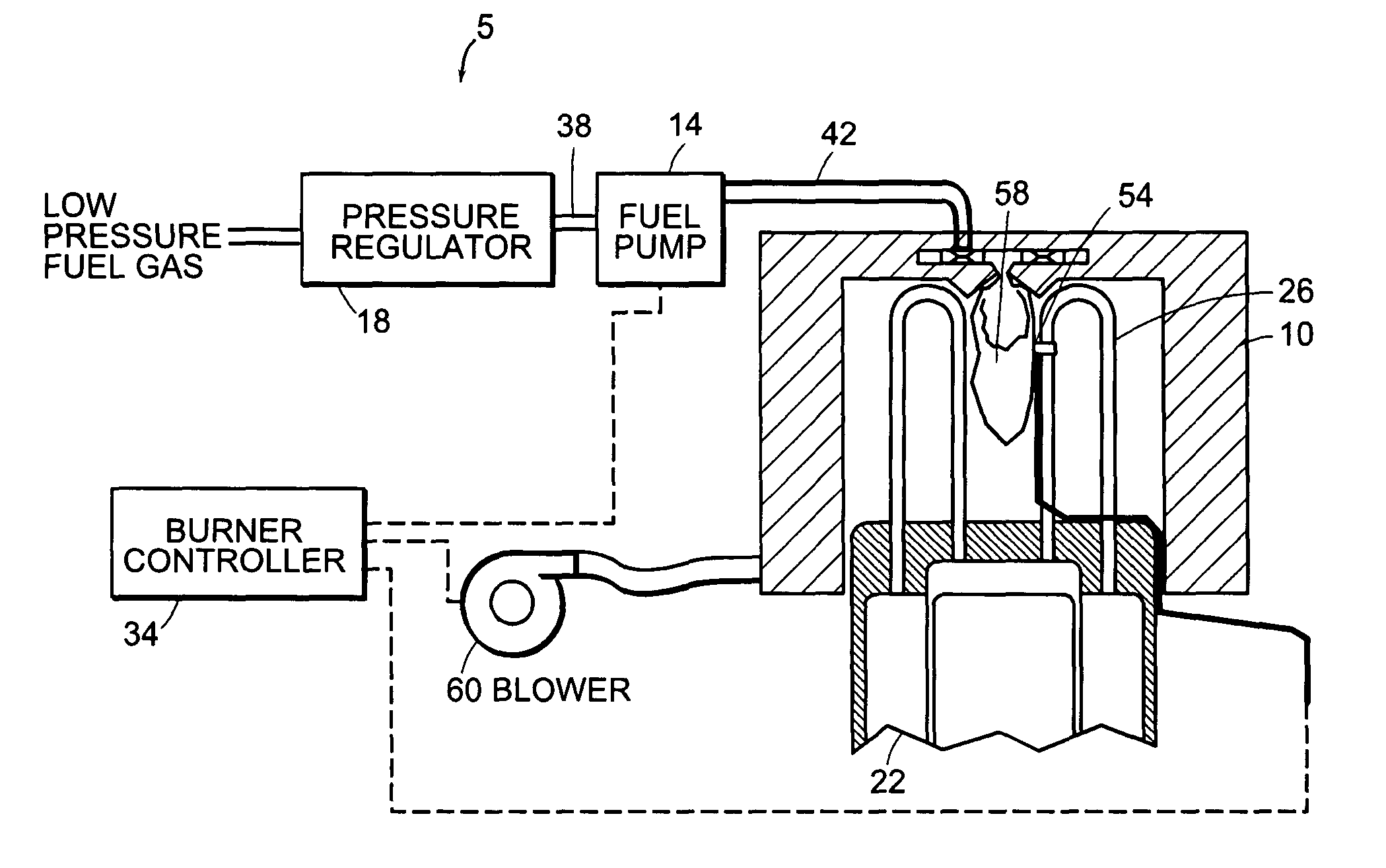

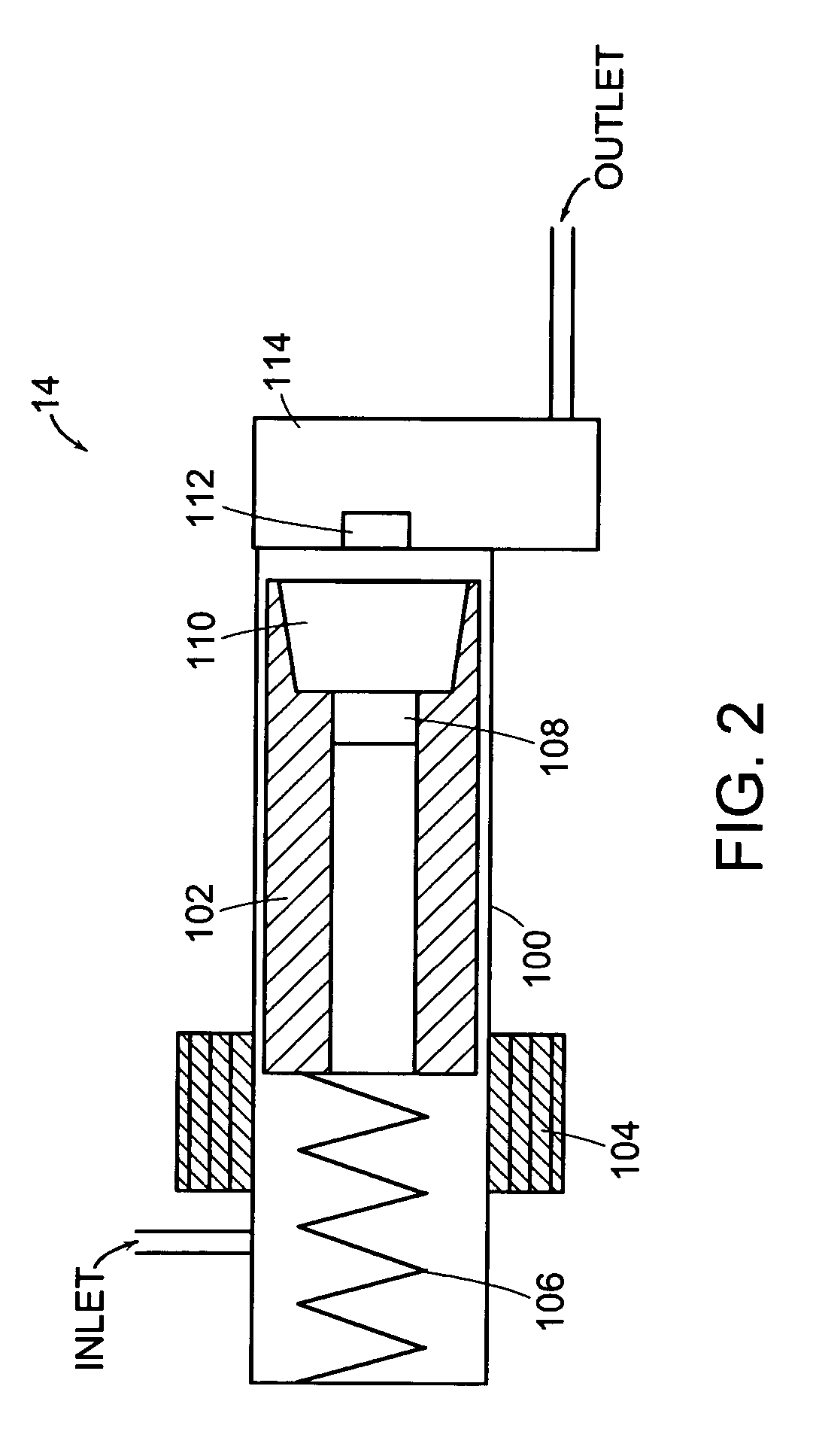

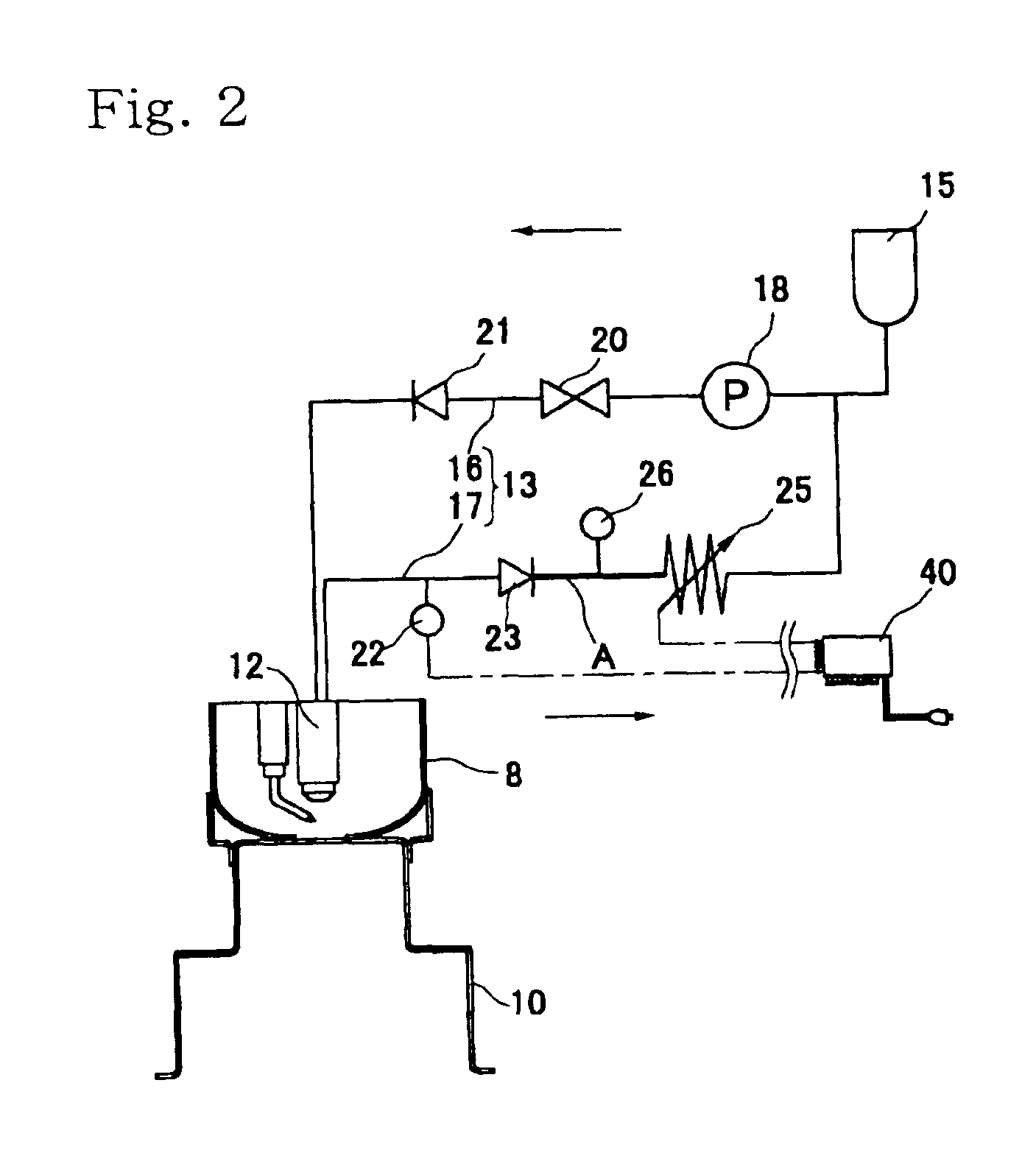

Metering fuel pump

InactiveUS7111460B2Eliminates the throttle plateGaseous fuel feeder/distributionInternal combustion piston enginesDiaphragm pumpCombustion chamber

A device and method for controlling the flow of a gaseous fuel from a fuel supply to a pressurized combustion chamber. A fuel pump is included in the gas train from supply to chamber. The fuel pump increases the pressure of the gas to allow efficient injection into the chamber. The pump is modulated to control the fuel flow. Both alternating current and pulse-width-modulated direct current signals may be used to control the flow. The pump may be a piston pump or a diaphragm pump. Feedback may be provided from sensors that determine operating parameters of the engine and such sensor signals may be used by the controller to maintain a parameter, such as temperature, at a specified value. An acoustic filter can be included in the gas train to significantly reduce gas flow pulsations generated by the pump. This filter improves the uniformity of the combustion process.

Owner:NEW POWER CONCEPTS

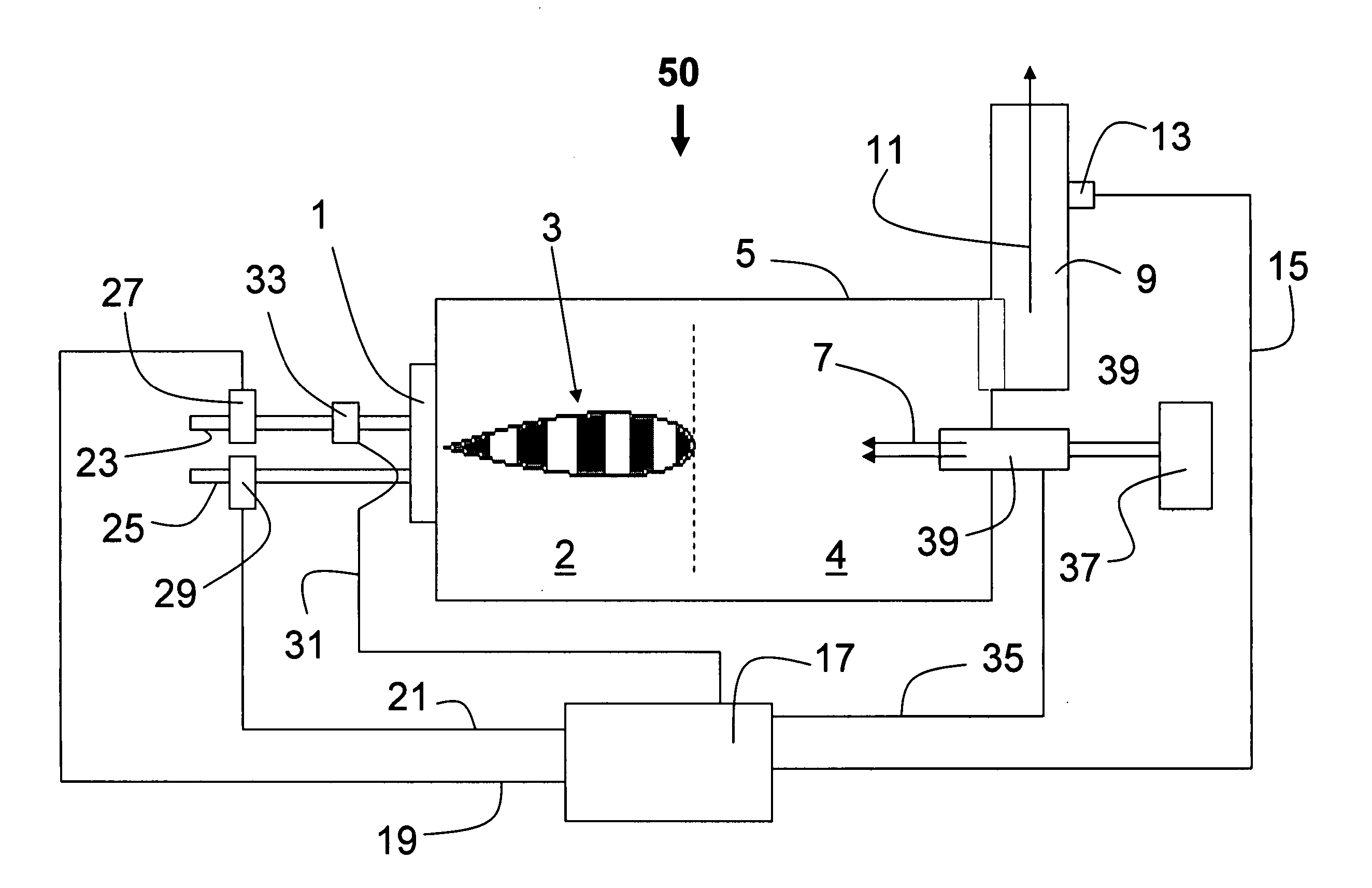

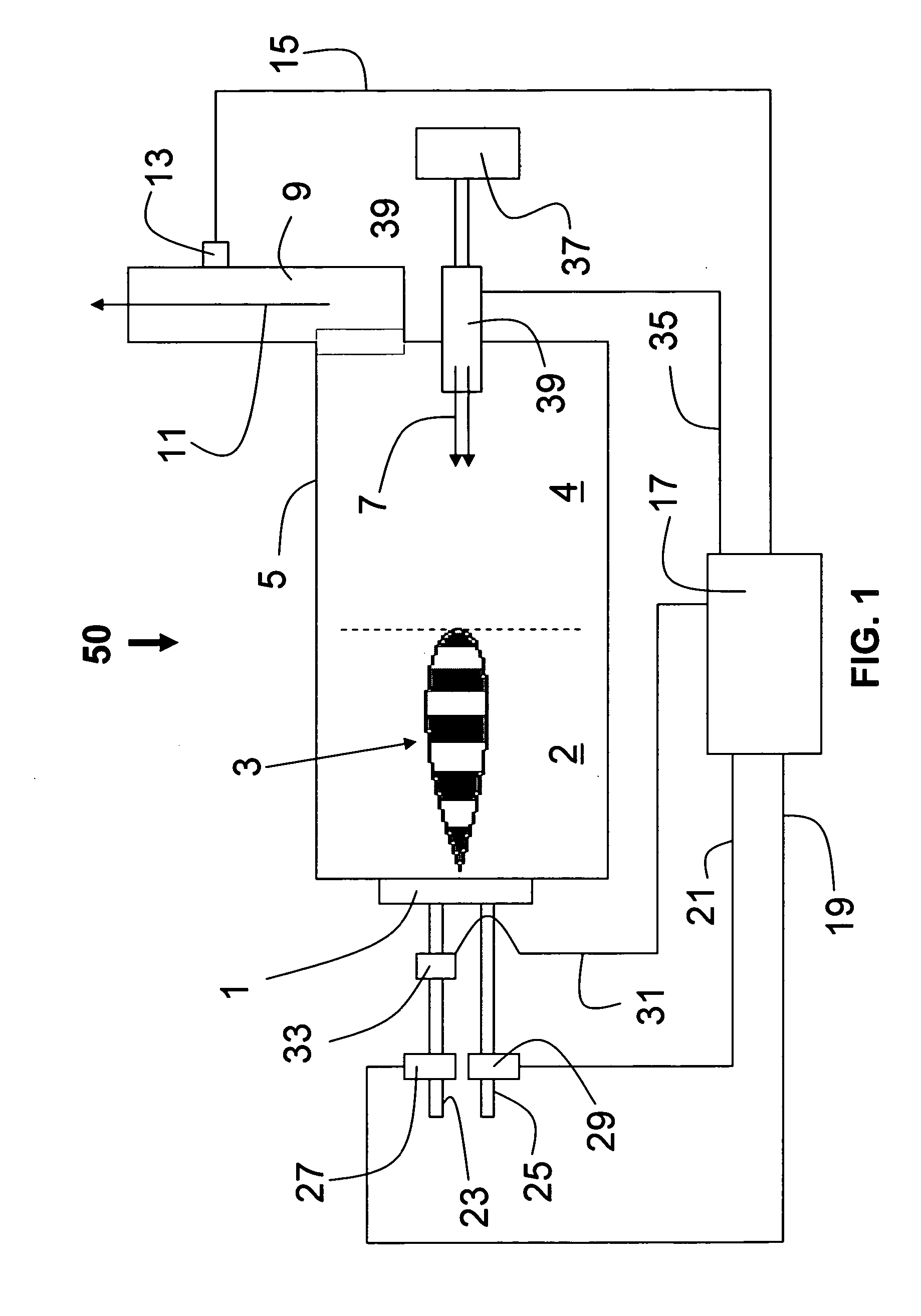

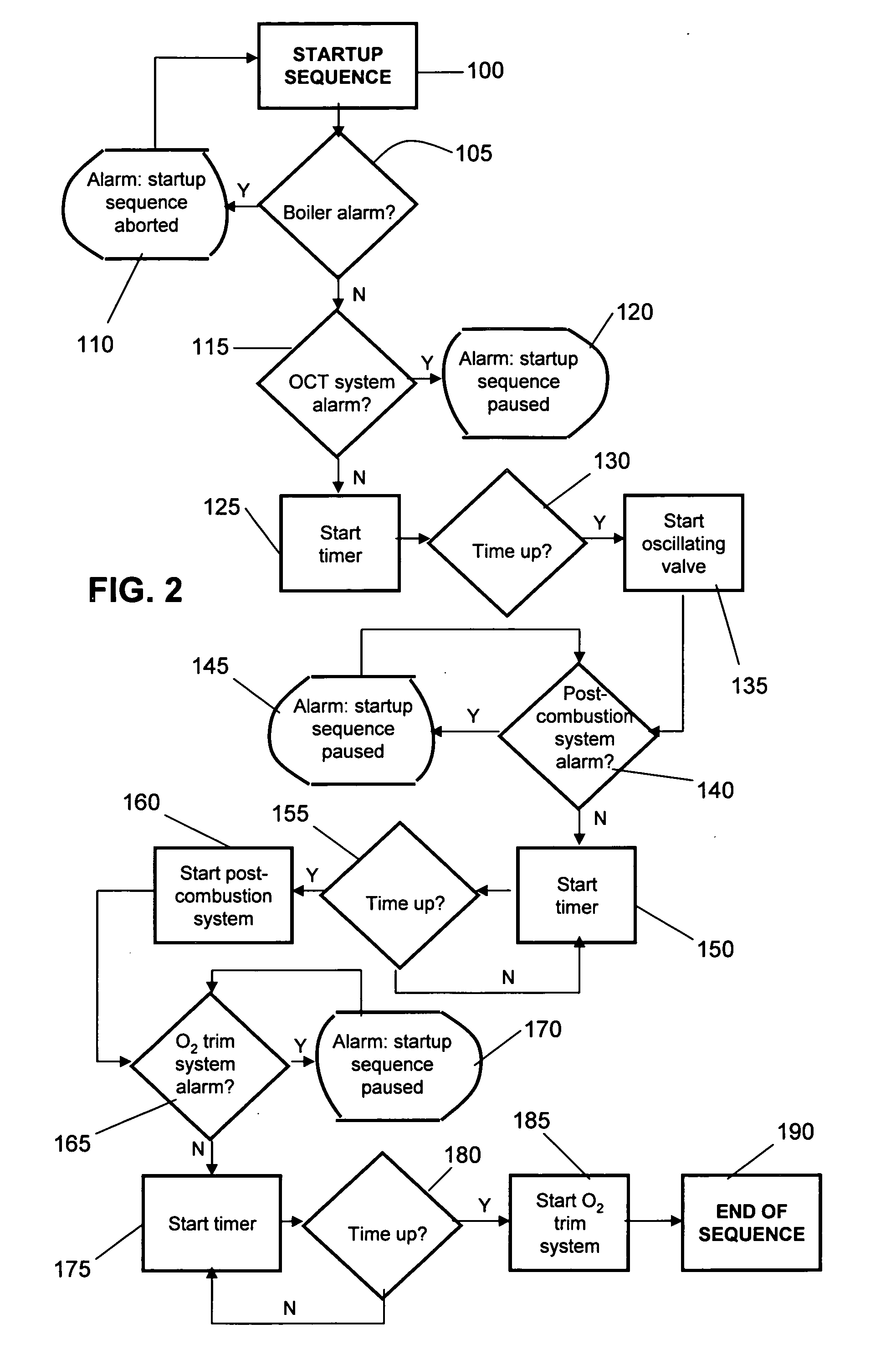

Advanced control system for enhanced operation of oscillating combustion in combustors

InactiveUS20060177785A1Level of optimizationCombustion using gaseous and pulverulent fuelFuel supply regulationCombustion chamberCombustor

Methods for optimizing emission levels from combustion operations, which include a system and process for optimizing levels of NOx and CO during fuel combustion including supplying flows of fuel (which is predetermined) and main oxidant to a burner. Oscillating combustion is generated by oscillating the fuel flow with an oscillating valve and combusting the oscillating fuel with the main oxidant adjacent the burner to produce combustion products. A post-combustion oxidant is injected into the combustion products where it is combusted with the combustion products. A controller is operatively associated with control units for controlling the main oxidant and post-combustion oxidant flow rates and the oscillating valve.

Owner:VARAGANI RAJANI K +2

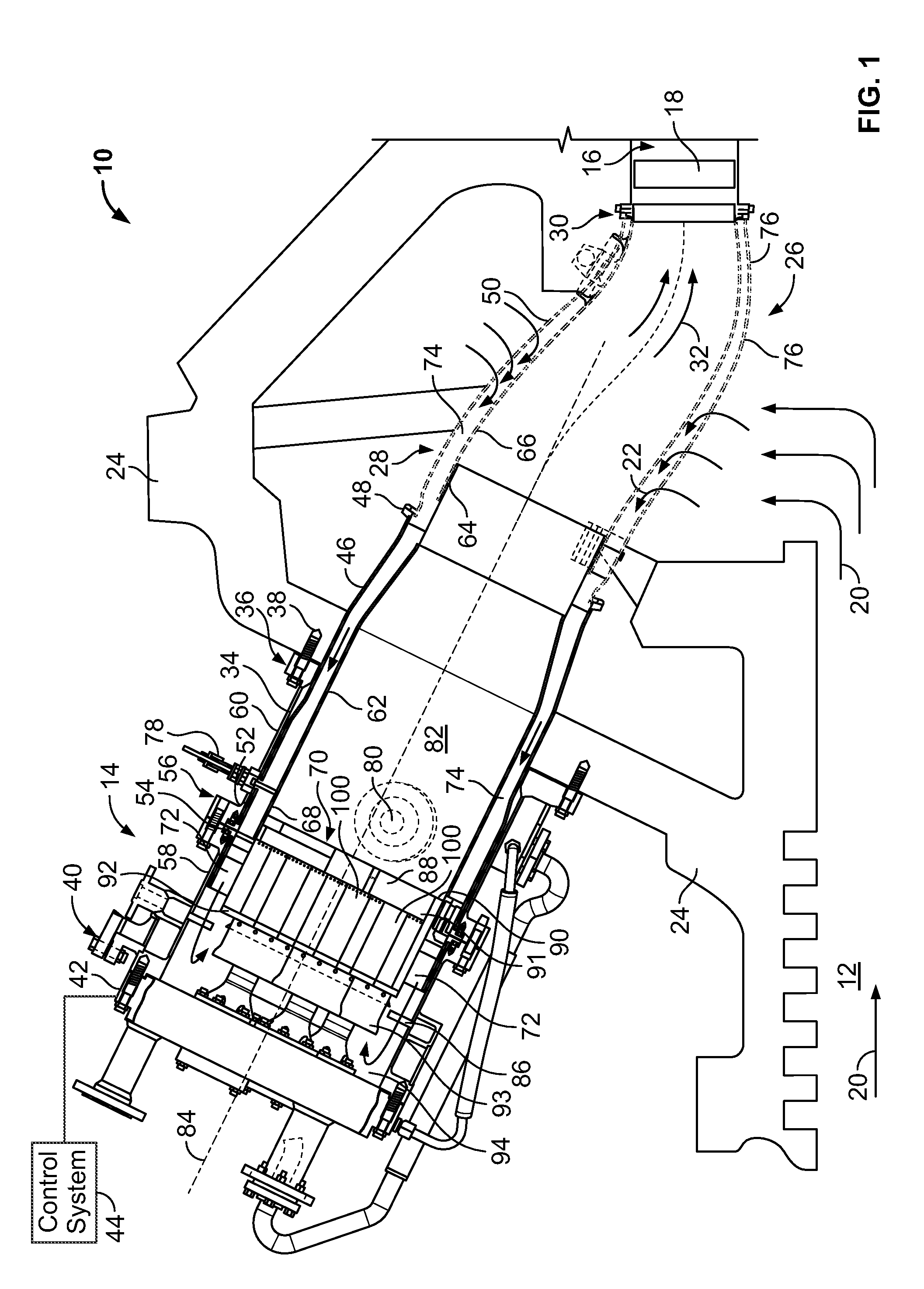

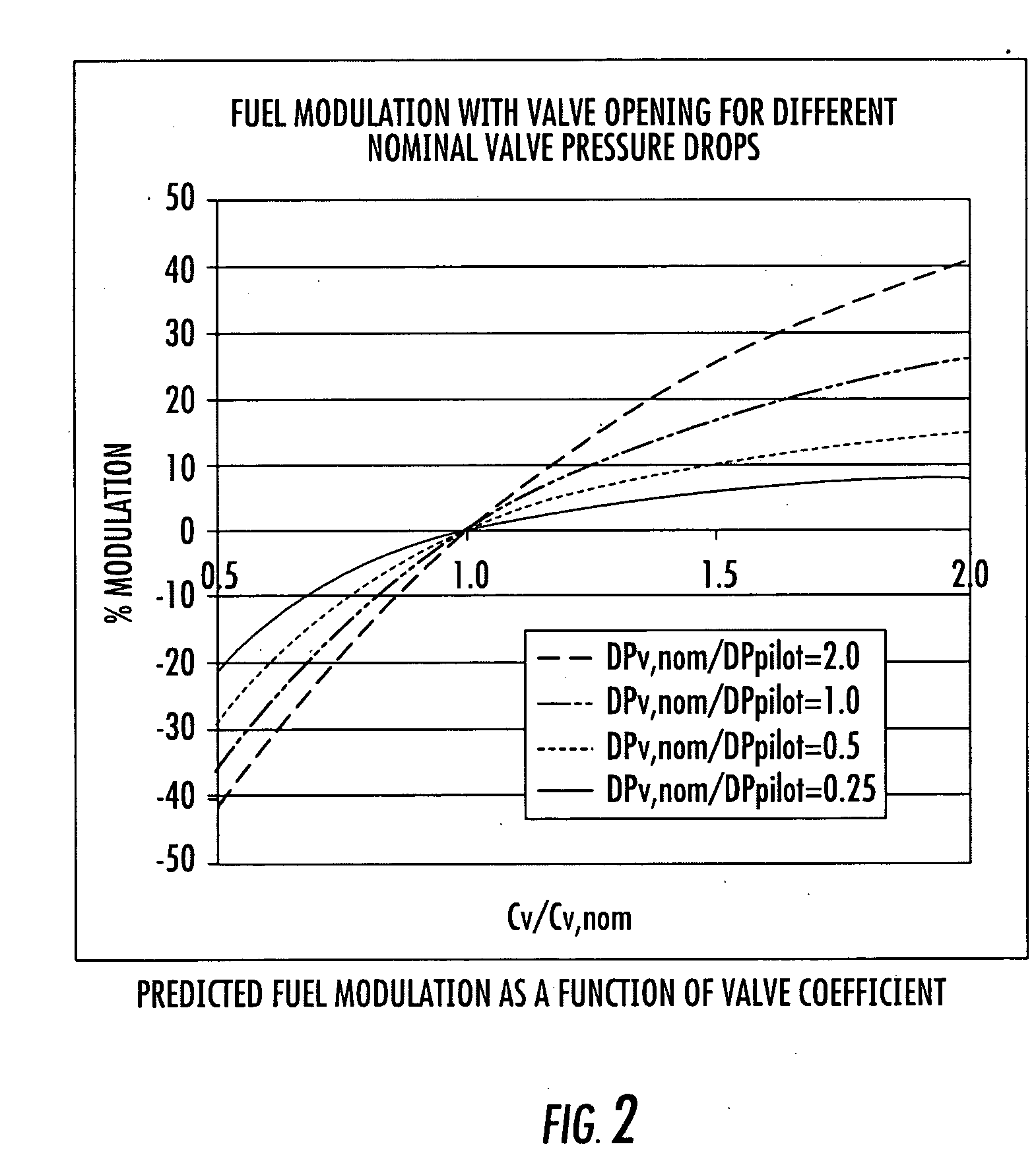

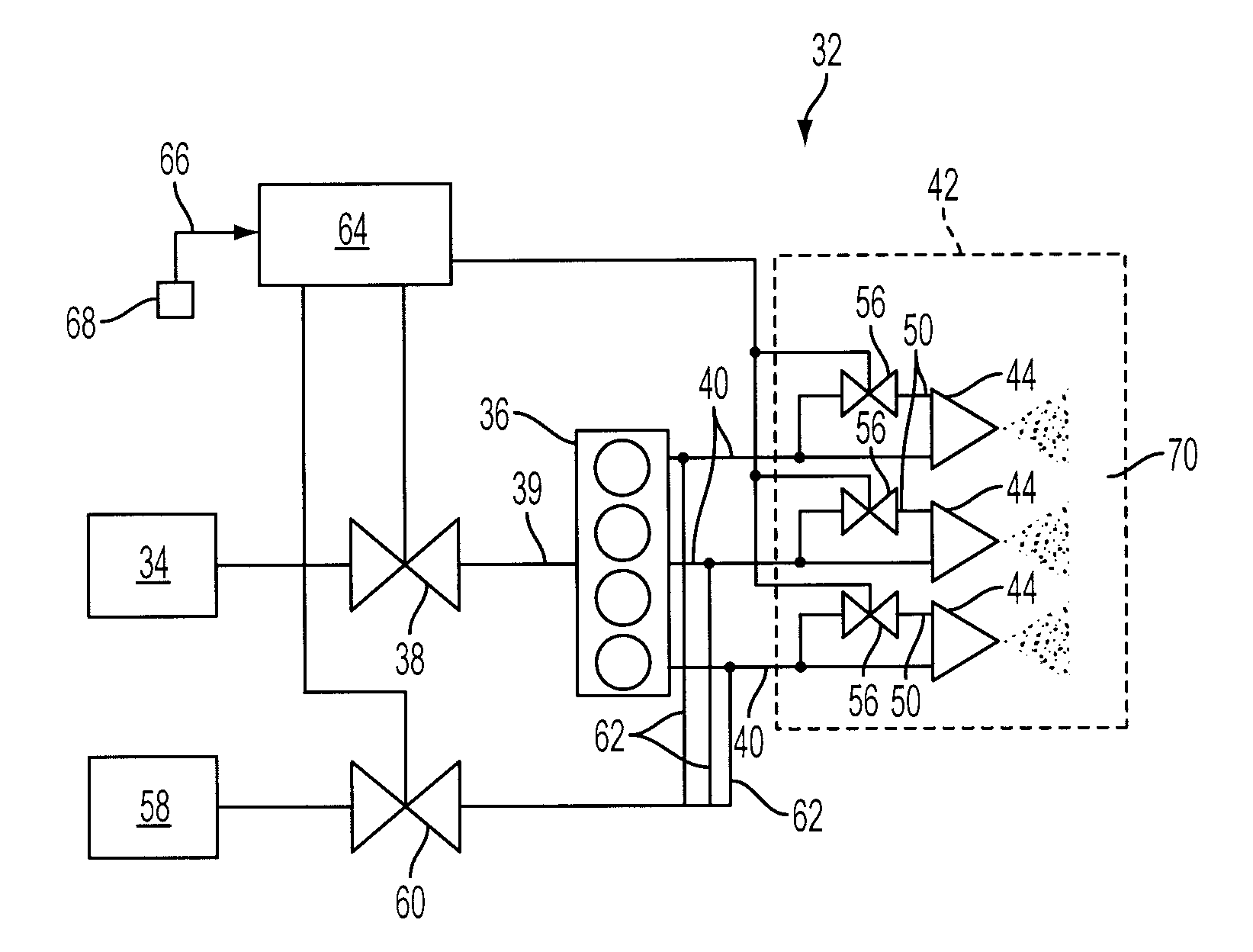

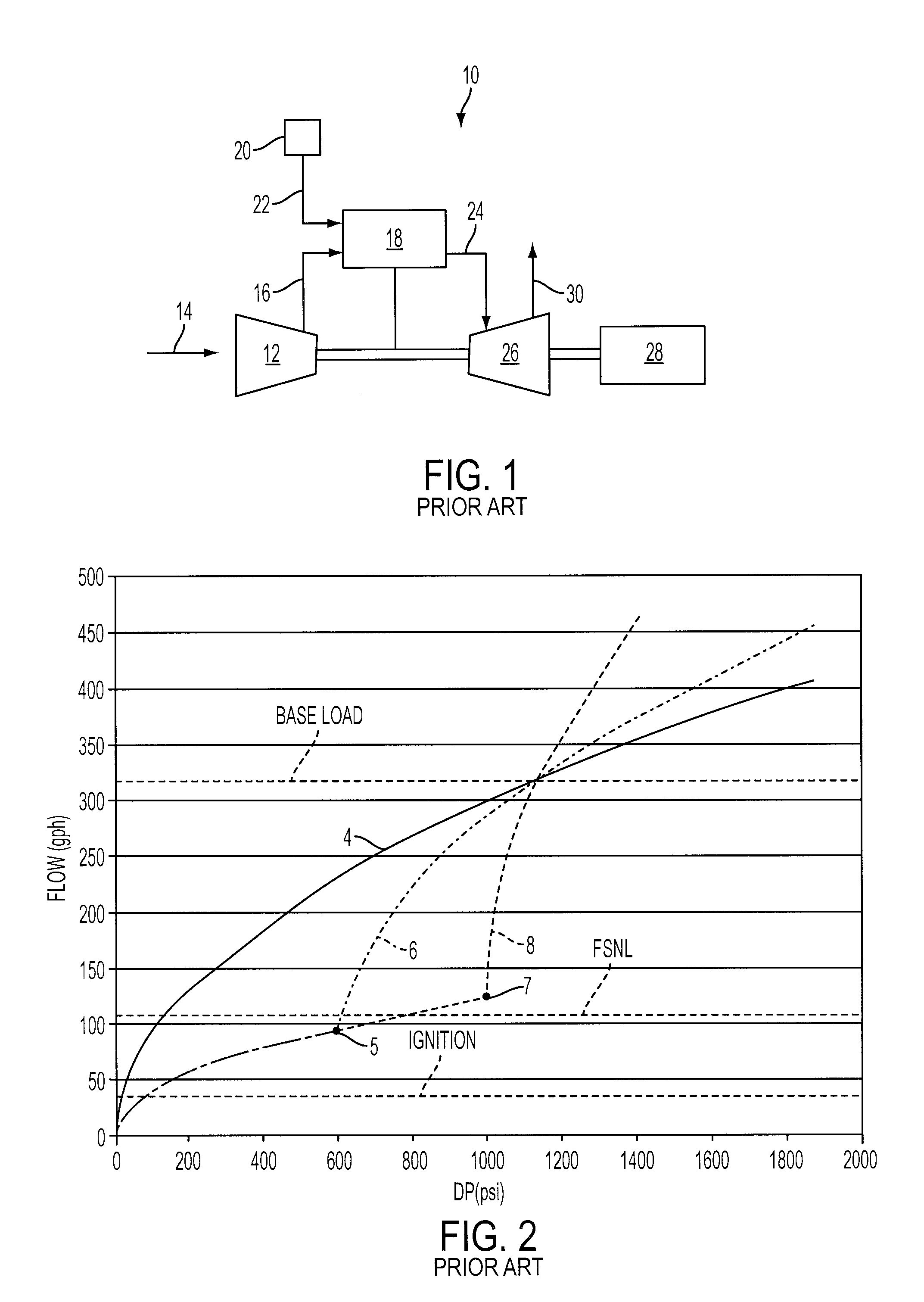

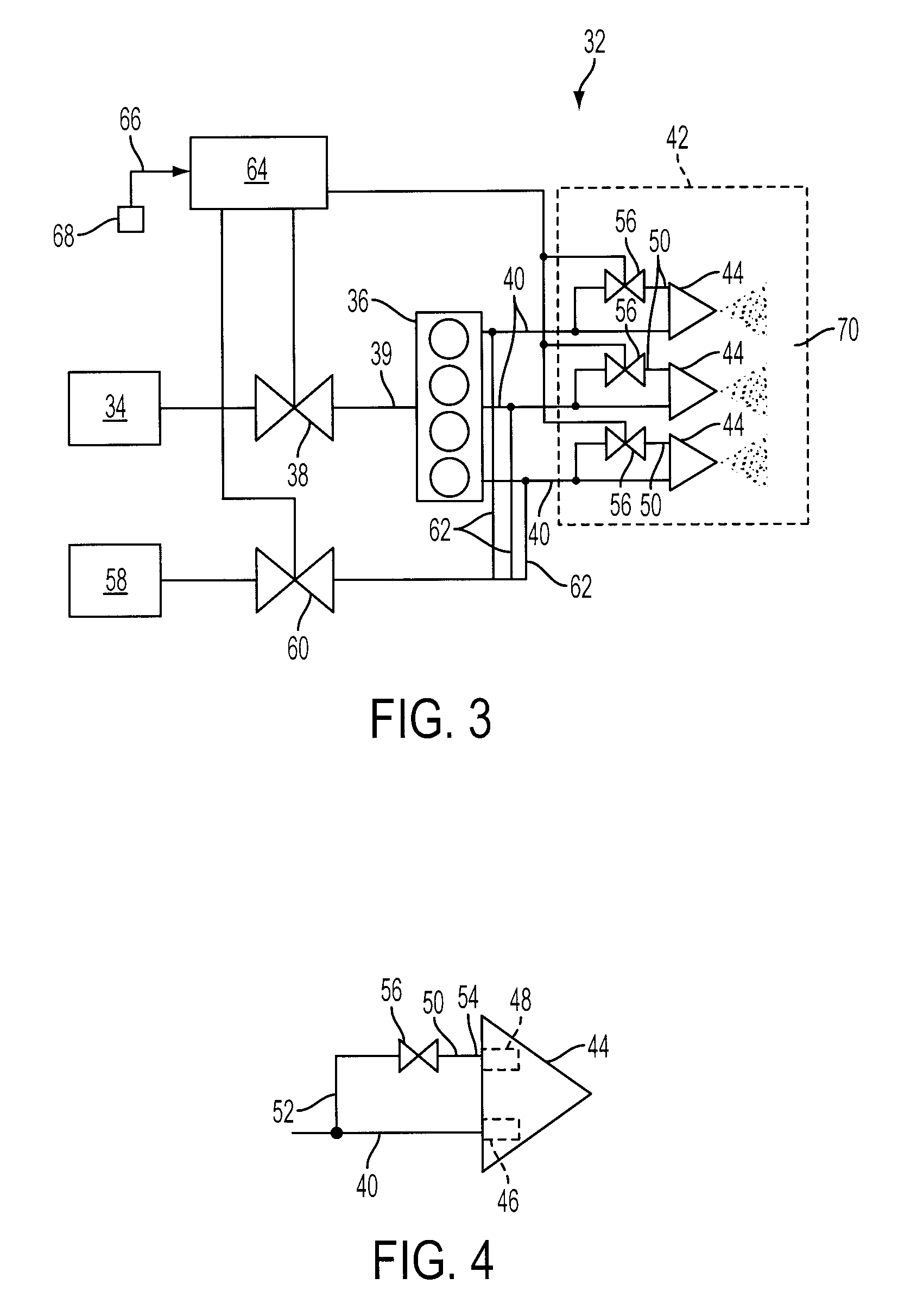

System for modulating fuel supply to individual fuel nozzles in a can-annular gas turbine

ActiveUS7654092B2Ensure efficient flowReduce the amount of solutionFuel supply regulationContinuous combustion chamberCombustorEngineering

A fuel modulation system usable in can-annular combustor systems of turbine engines for more efficiently managing fuel flow to reduce the amount of NOx while maintaining appropriate combustor flame temperatures. The fuel modulation system controls individual inline modulation valves in cooperation with a overall stage control valve to bring a turbine engine through the startup phase and to maintain operating conditions at a load set point while reducing NOx variability between baskets by using individual combustor dynamic pressure measurements. The fuel modulation system may be managed such that individual inline modulation valves remain within a predetermined range of positions relative to a nominal position to reduce NOx variability.

Owner:SIEMENS ENERGY INC

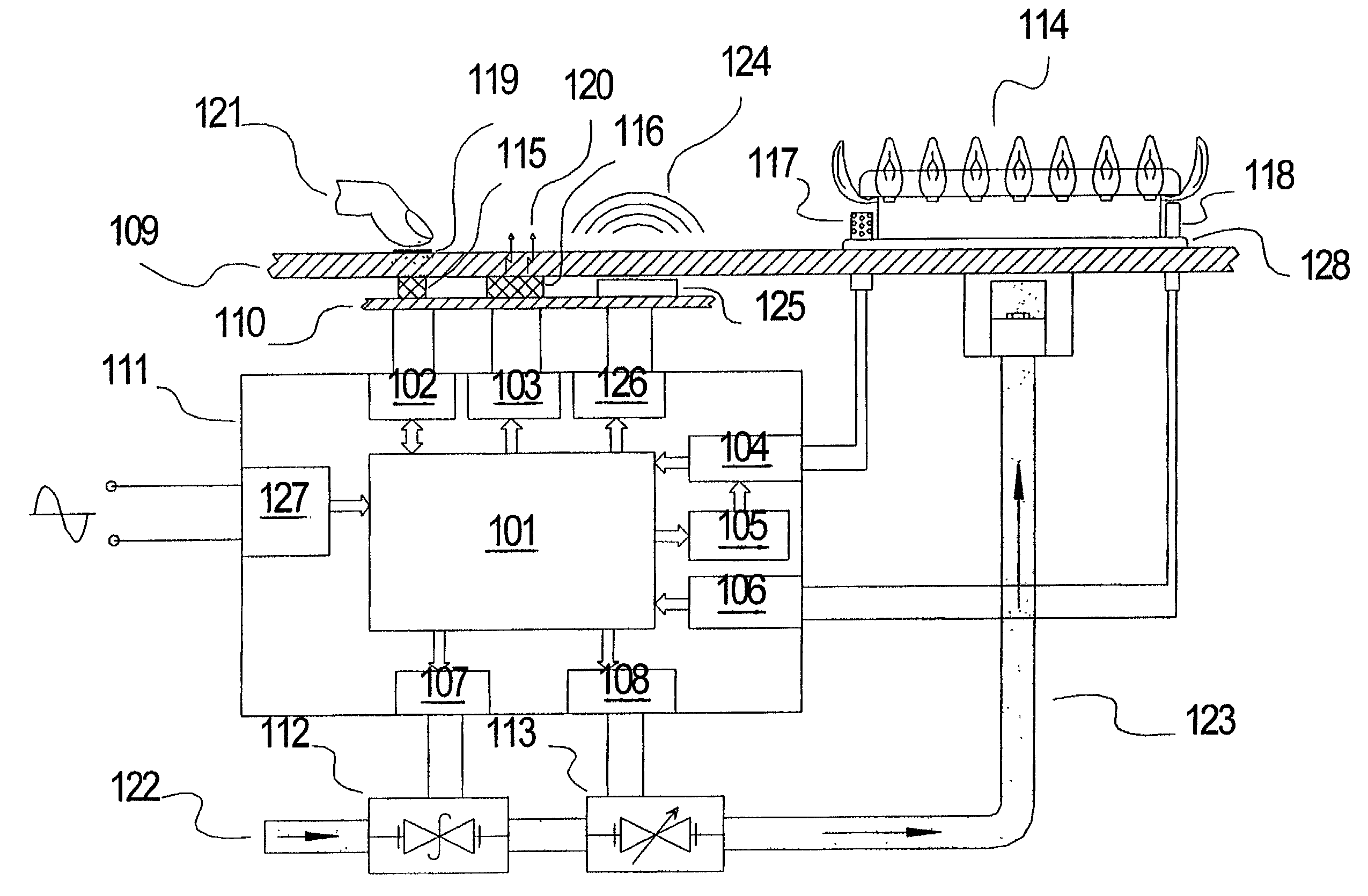

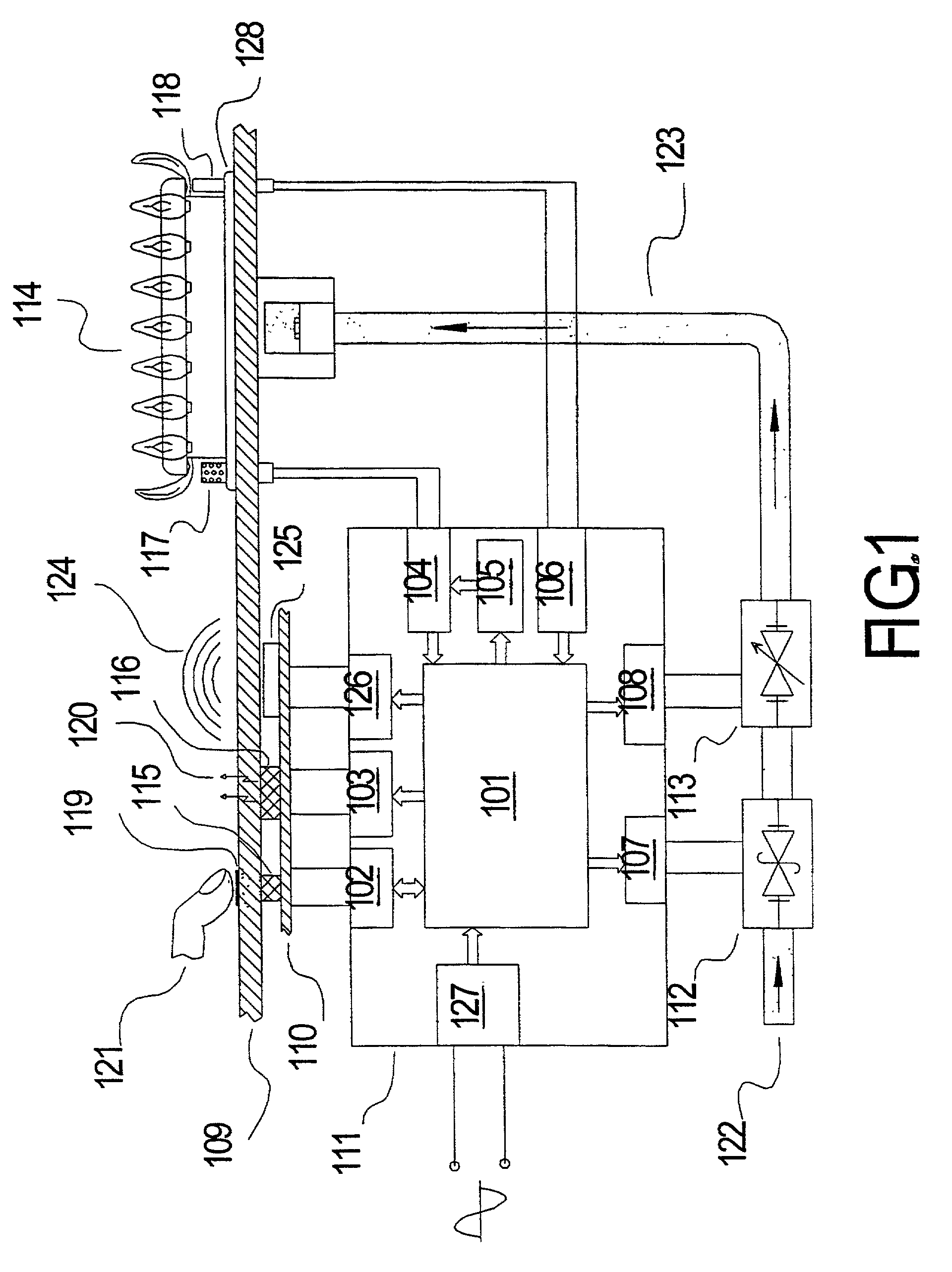

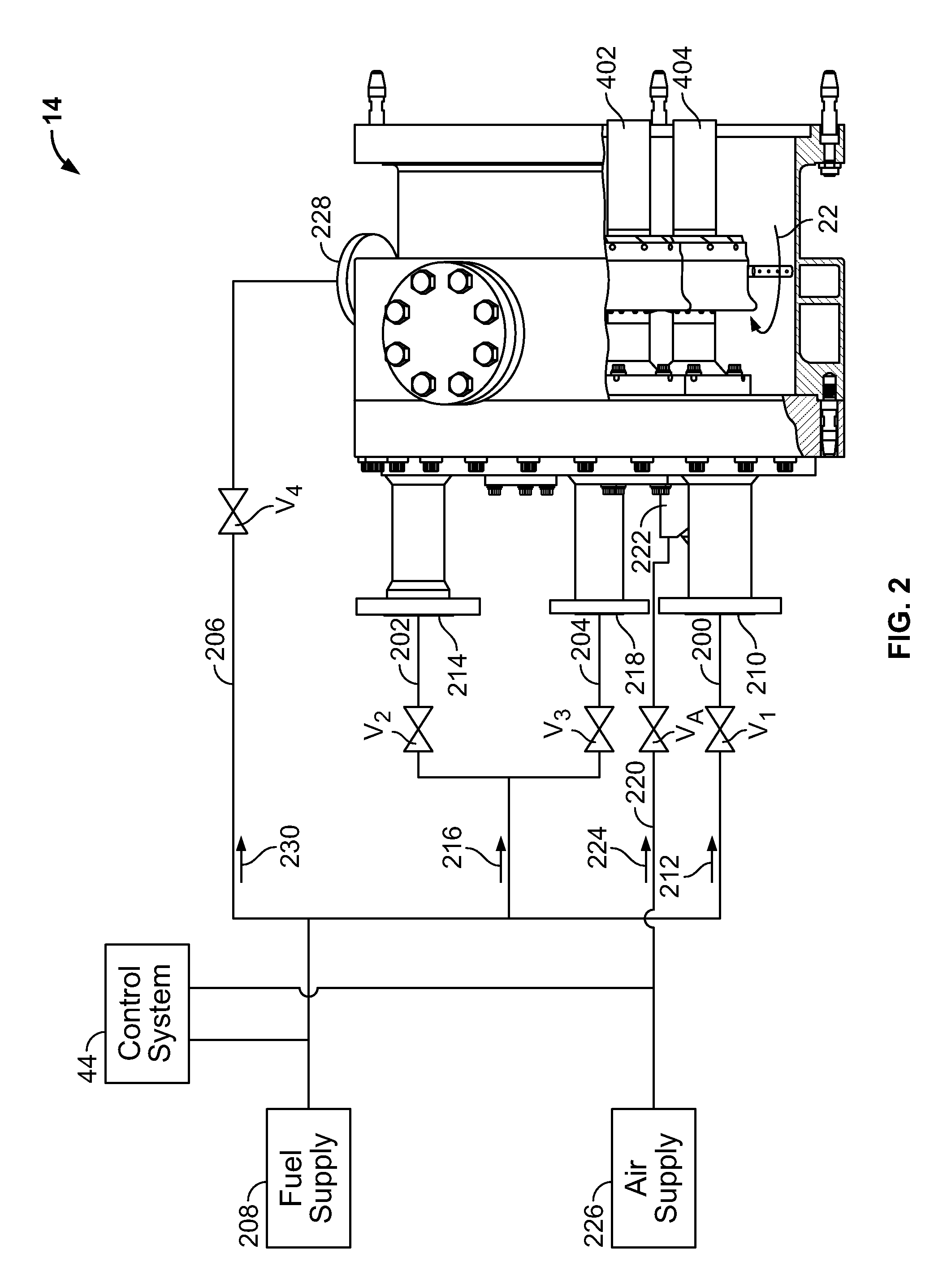

Method and System for Controlling Fuel to a Dual Stage Nozzle

A method and system for controlling delivery of fuel to a dual stage nozzle in the combustor of a gas turbine. A liquid fuel is conveyed from a single stage fuel supply through a plurality of primary fuel supply lines to a first nozzle stage including a plurality of primary nozzles. A predetermined operating condition of the gas turbine is identified and a signal is produced in response to the identified operating condition. The signal effects actuation of valves located on secondary fuel supply lines extending from each of the primary fuel supply lines to supply fuel to respective secondary nozzles.

Owner:SIEMENS ENERGY INC

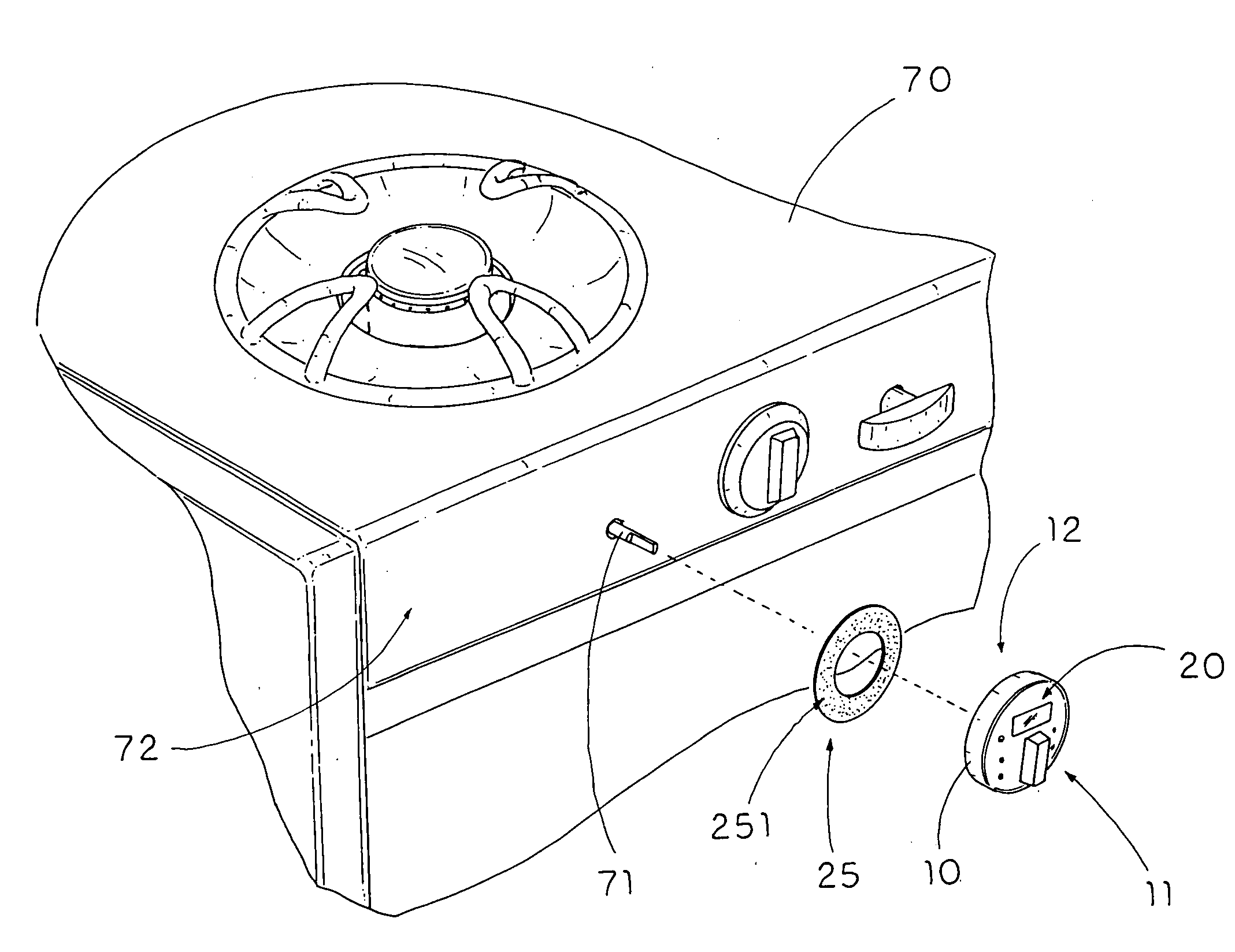

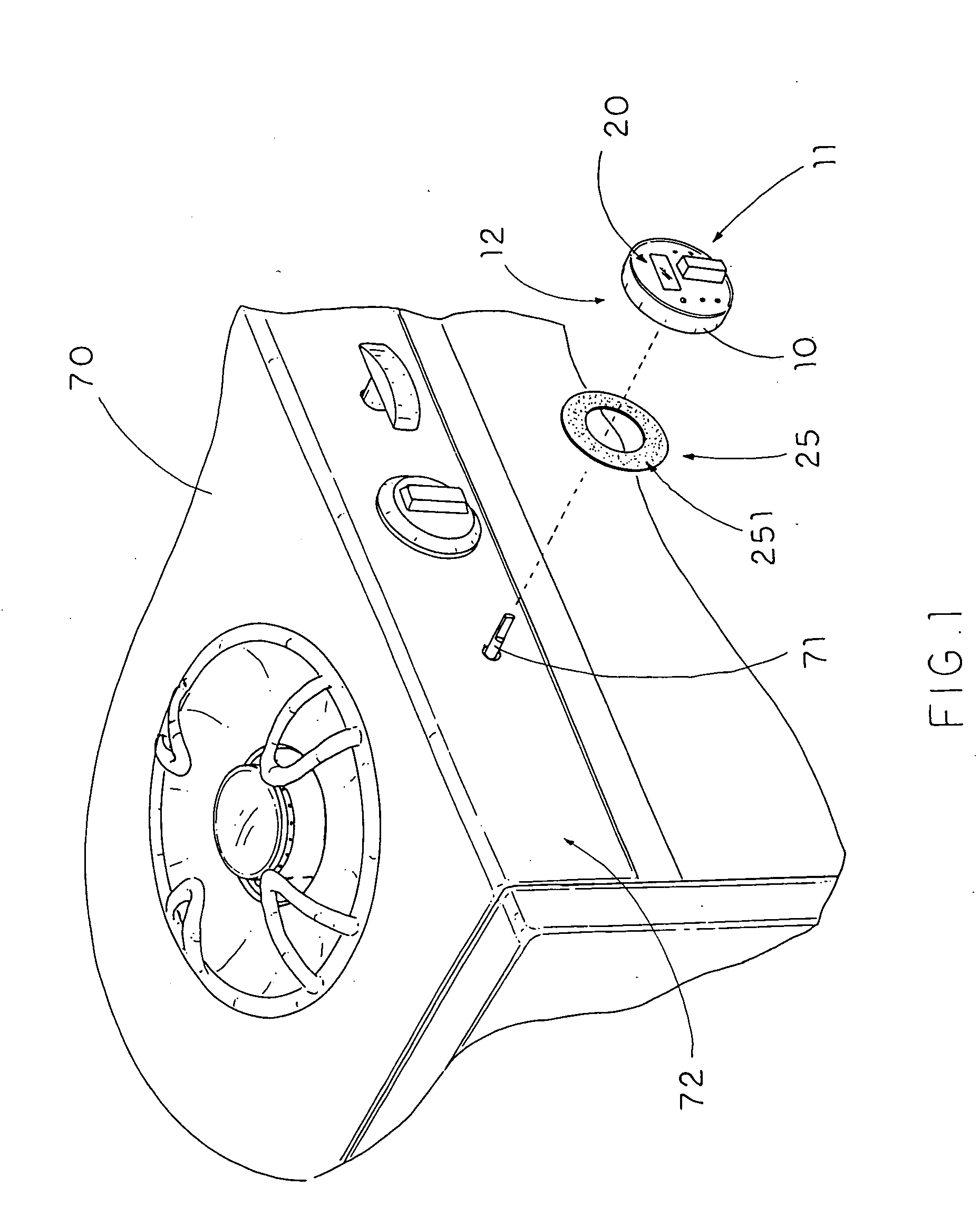

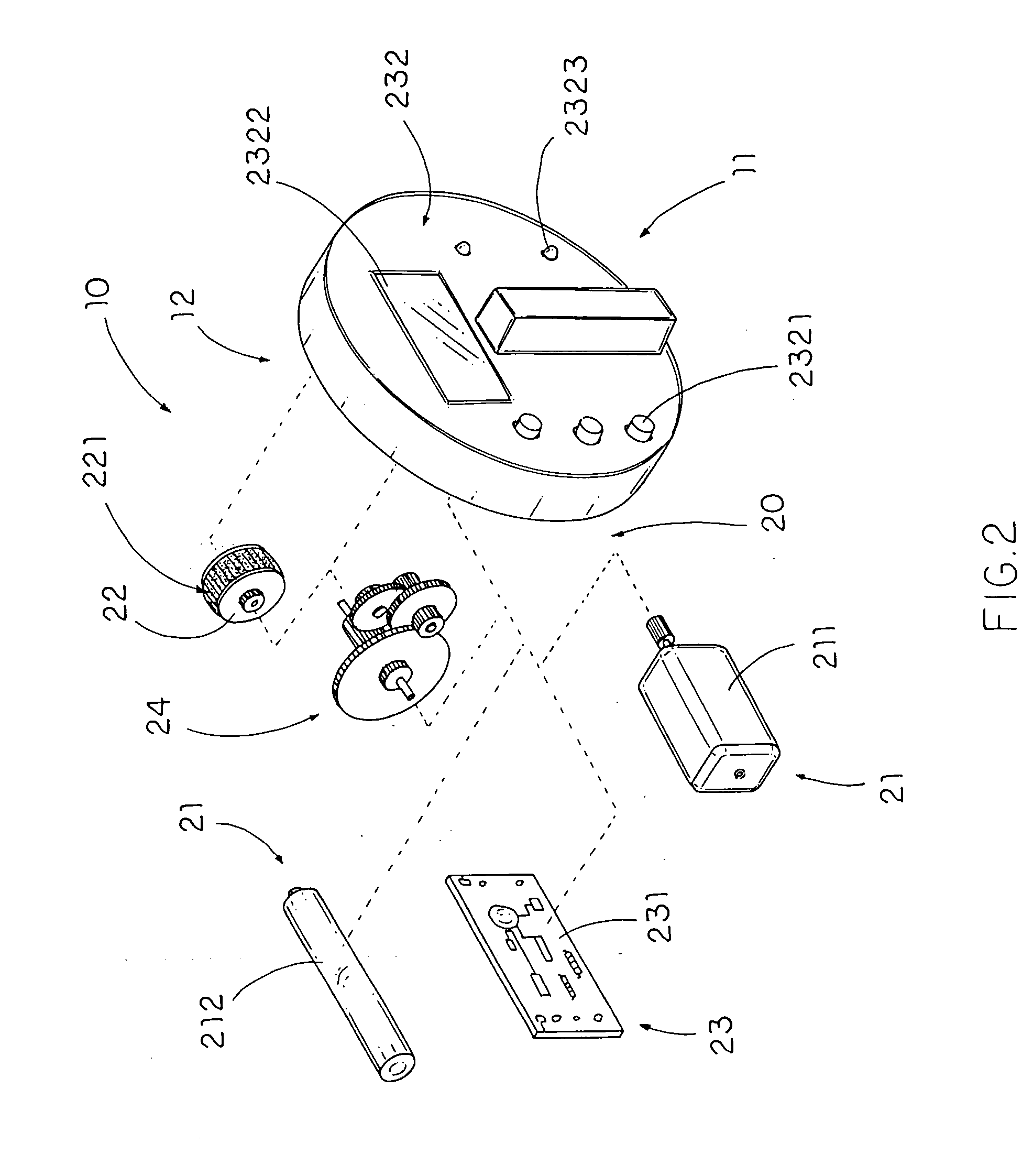

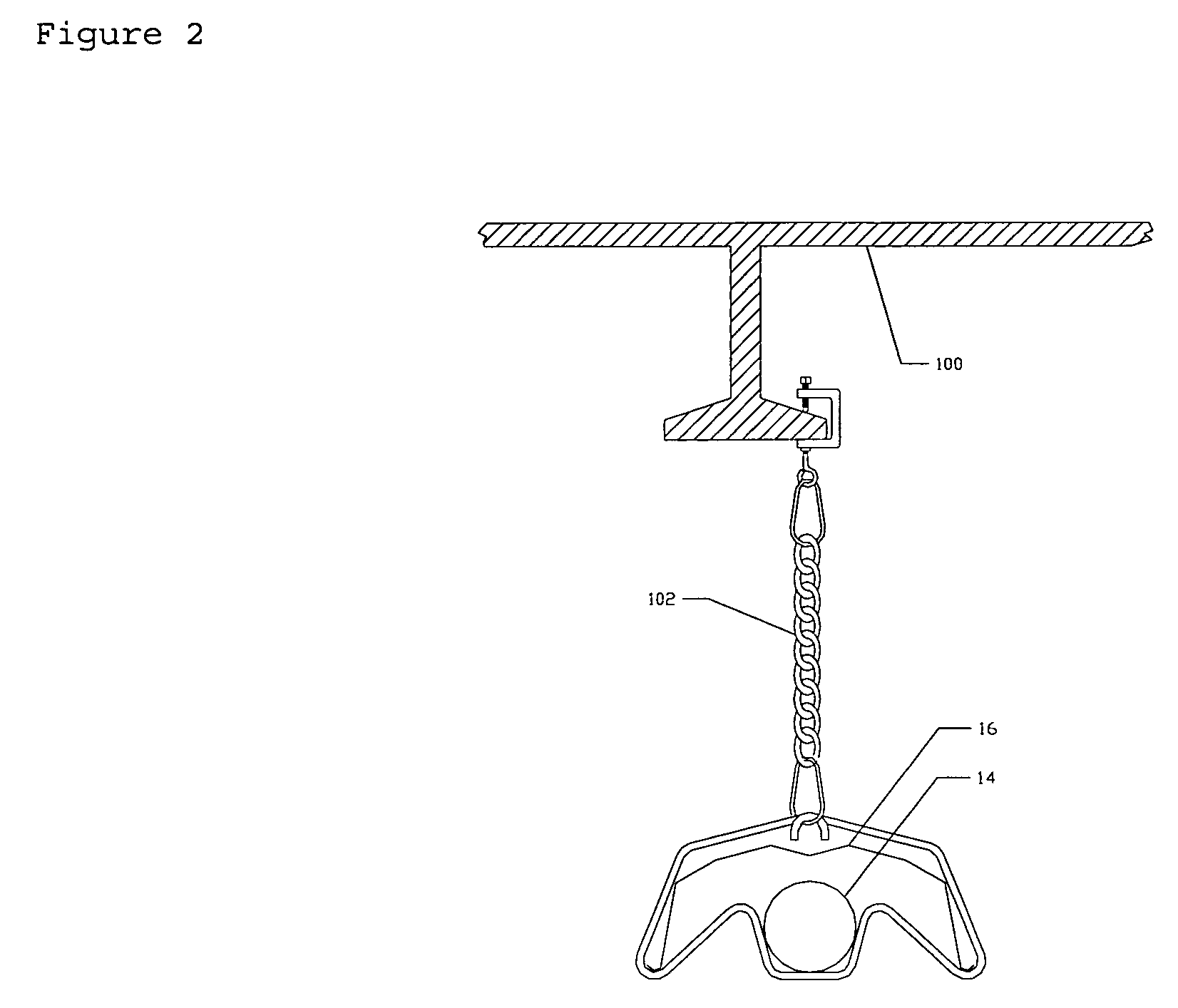

Time knob for gas and electric heater

InactiveUS20060234177A1Low costDomestic stoves or rangesCombustion ignition/checkingTime controlTimer

A timer knob arrangement for a heater includes an ignition button and a timer control. The ignition button is rotatably switched between a switched off position and an operation position with respect to an operation pin of the heater. The timer control includes a power unit, a runner wheel driven by the power unit and is rotatably supported by the ignition button at a position tangentially with respect to the operation pin, and a time control unit. When the time control unit is activated to actuate the power unit, the runner wheel is driven to rotate and to run on the operation surface, so as to drive the ignition button turning back to the switched off position for ensuring a flow of gas being shut off from the heater.

Owner:YU SHIH SZU +1

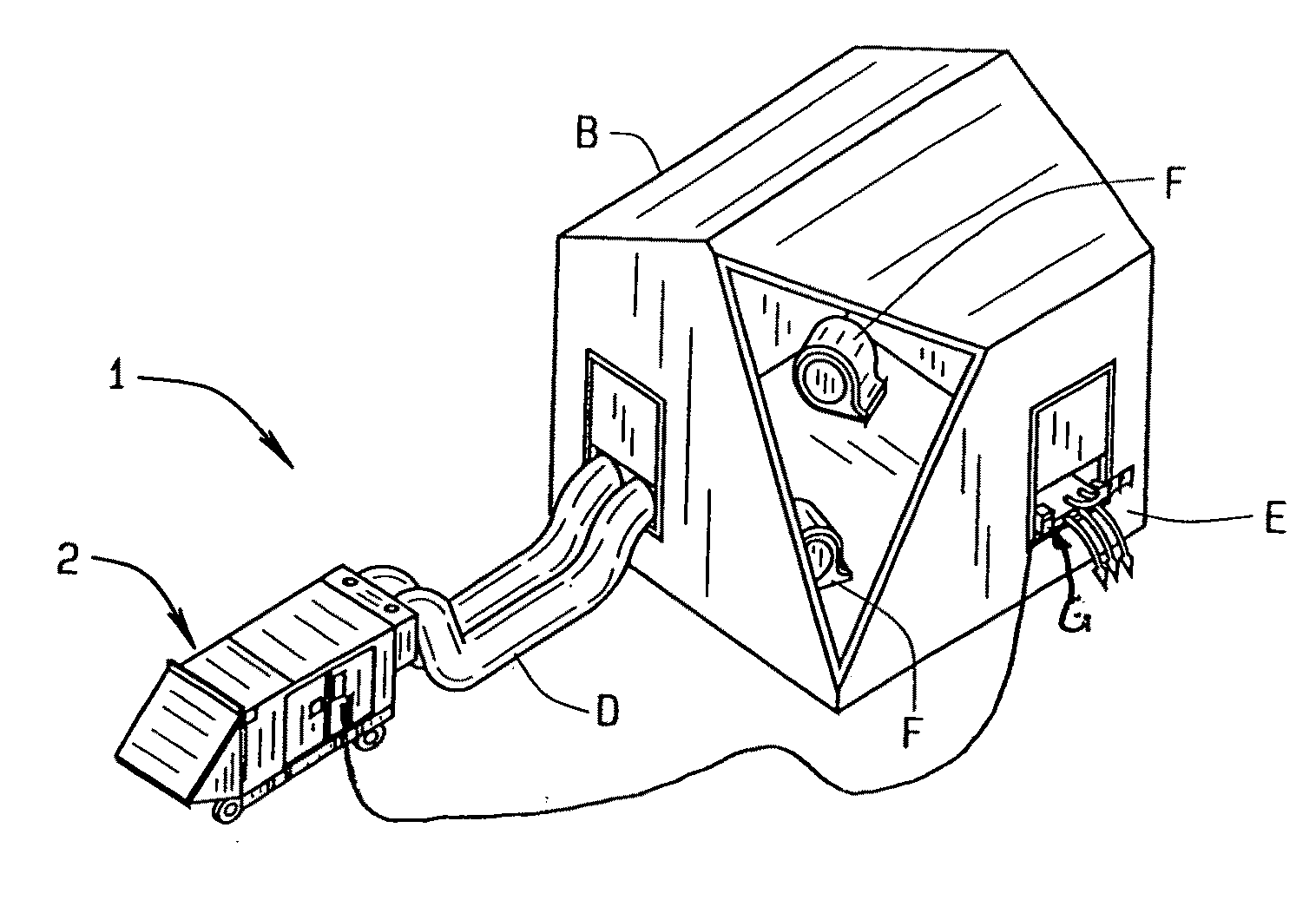

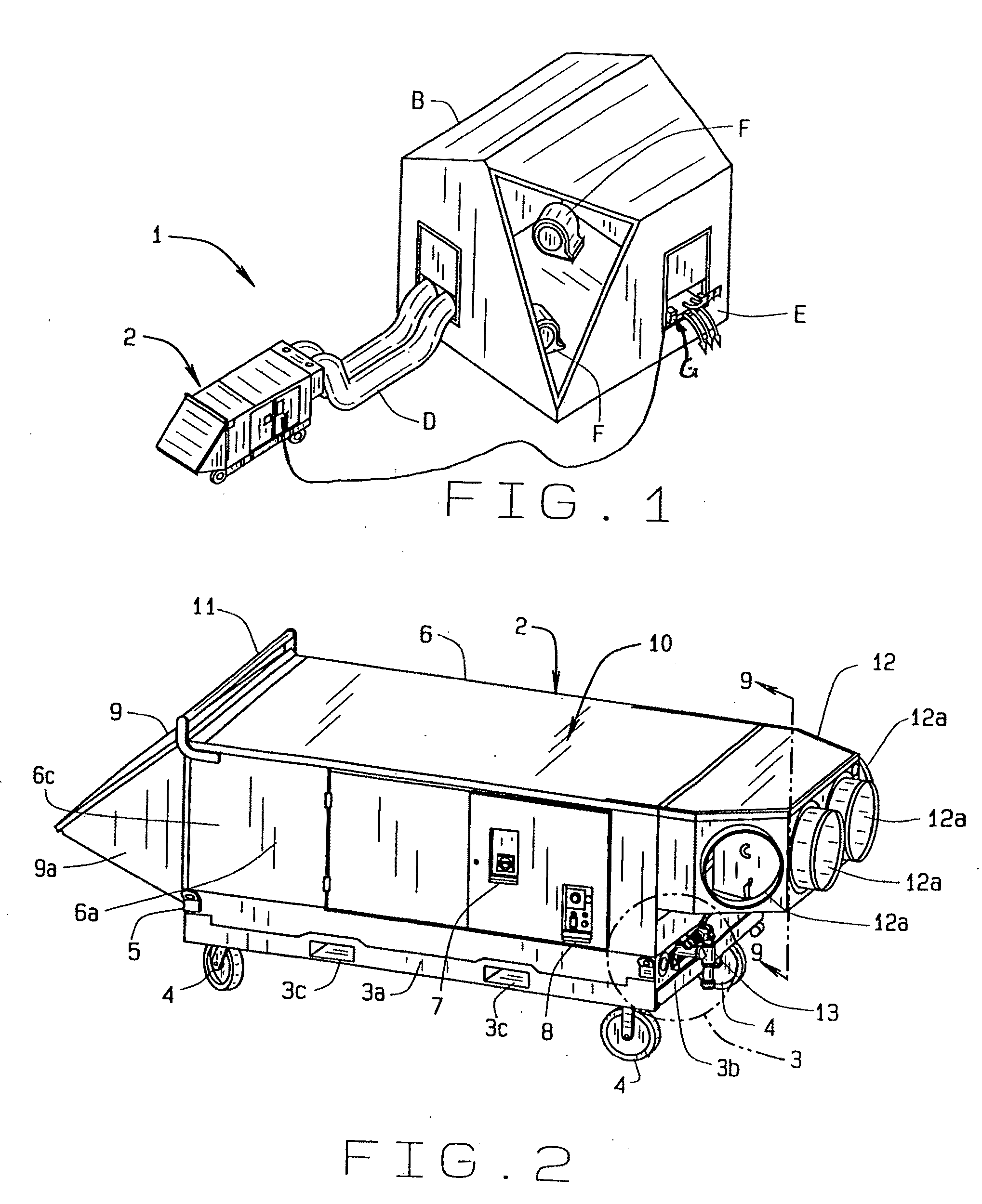

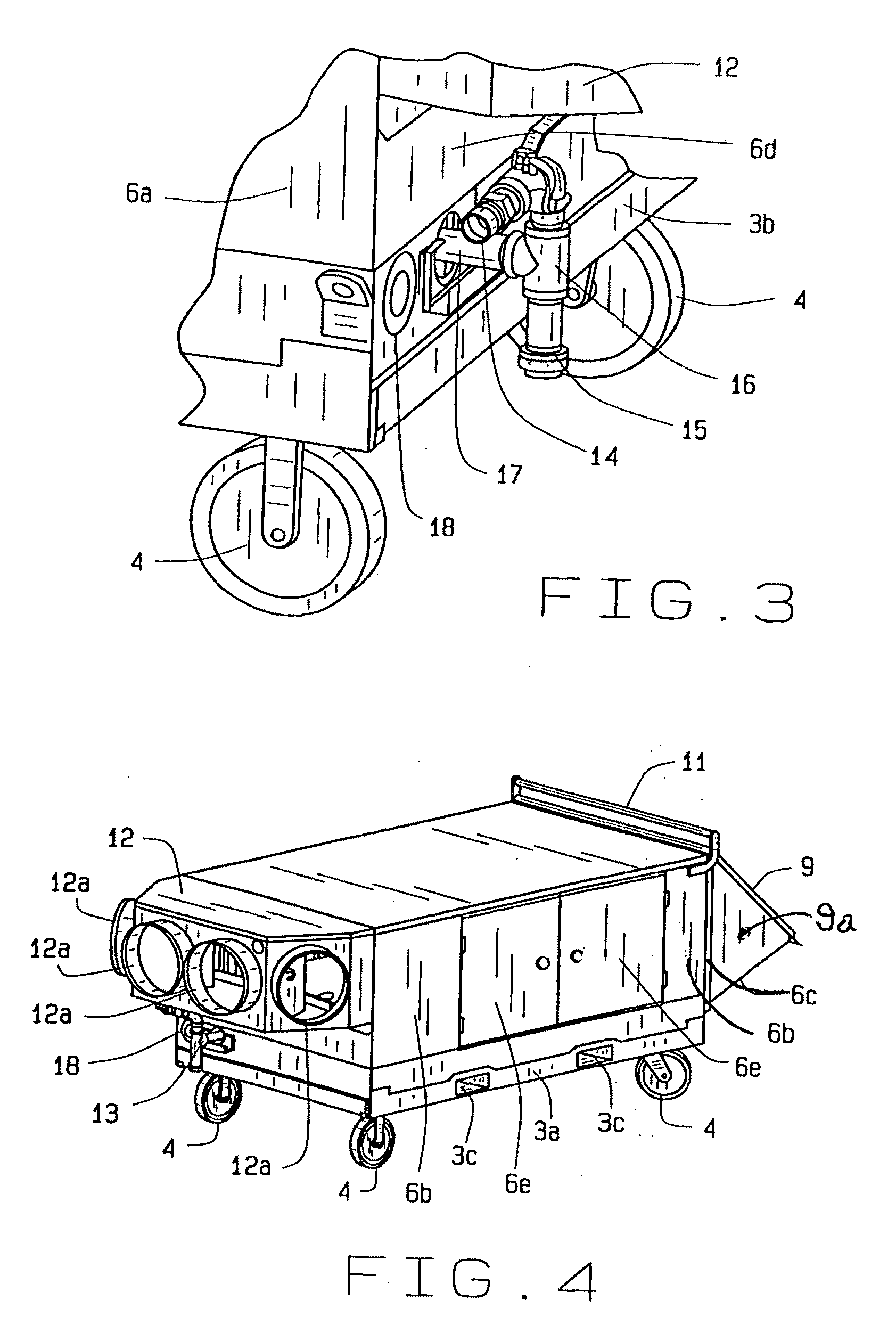

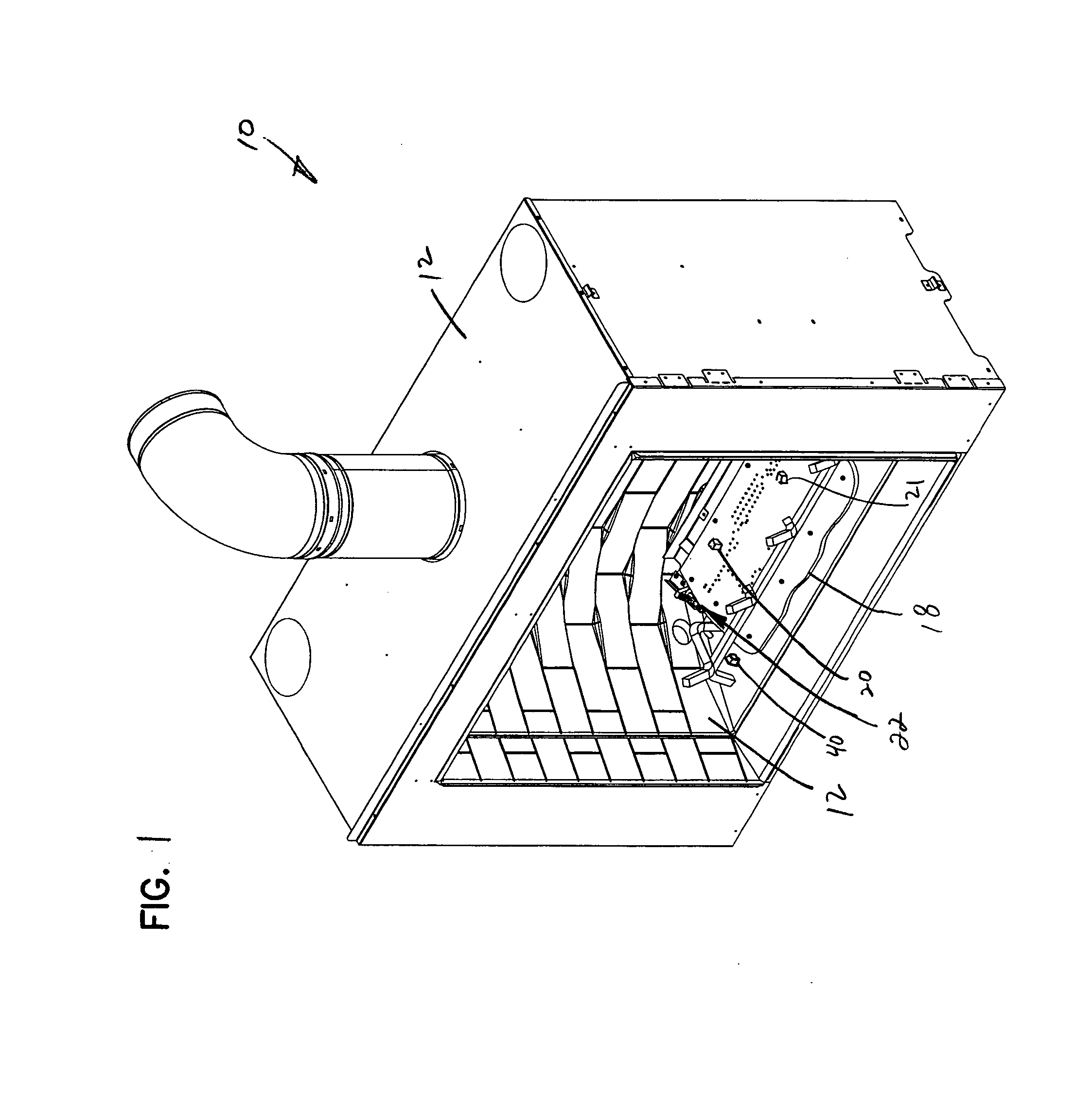

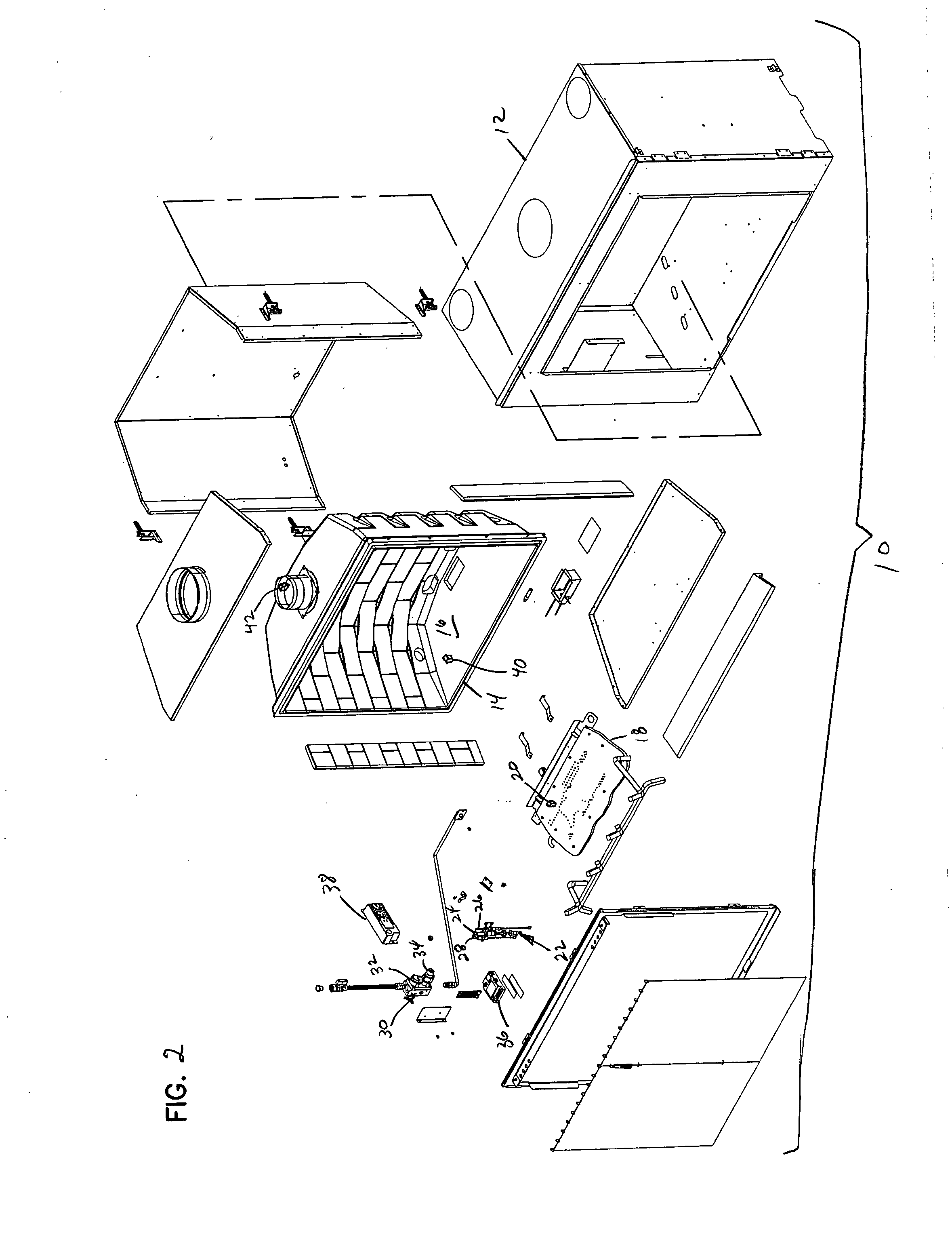

Heater and controls for extraction of moisture and biological organisms from structures

InactiveUS20100024244A1Tremendous ability to absorb water vaporFuel supply regulationDrying solid materials with heatGas heaterAtmospheric air

A gas heater with specialized controls allows an operator to deploy a single device to heat and to dry when extracting moisture from a structure. The heater has a fan in a blow thru arrangement ahead of a burner. The burner uses either natural gas or liquefied petroleum gas. The heater has air flow, fan motor, temperature, and ignition controls and sensors. The heater delivers high temperature air to the structure that hastens evaporation as the heated air absorbs great concentrations of water vapor. Then the moisture laden heated air exits the building as the heater draws in fresh air, ducts it into a structure, and pressurizes the structure. This moisture laden air then leaks from the building through select windows using the energy imparted from the fan and then exhausts the moisture to the atmosphere, drying the structure.

Owner:POTTER GARY J

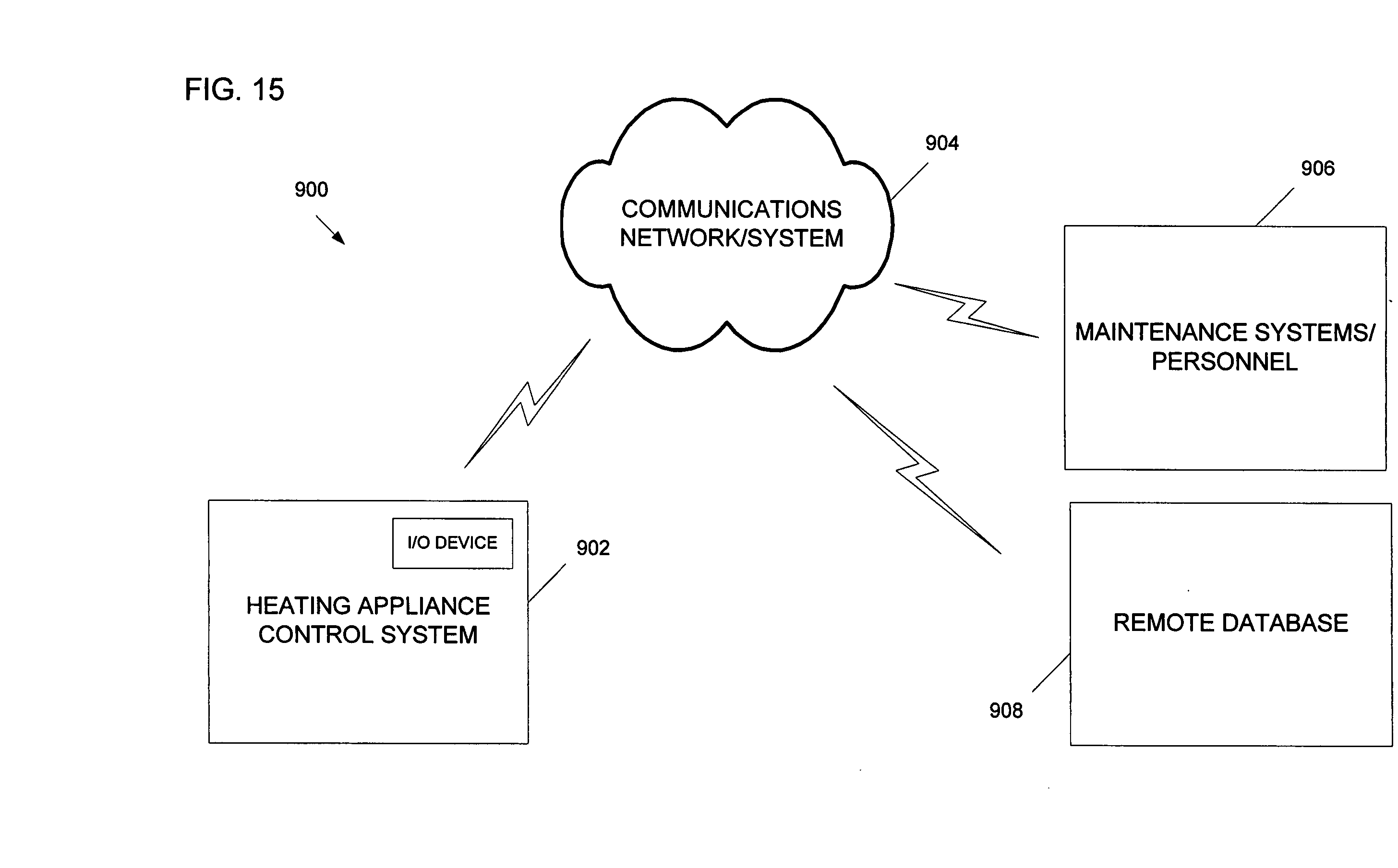

Fireplace control system

InactiveUS20070292810A1Guaranteed smooth progressFuel supply regulationDomestic stoves or rangesCombustorControl system

A heating appliance control system that includes a pilot flame assembly, a main burner assembly, a gas valve, and a controller. The pilot flame assembly includes a pilot flame burner and at least one pilot flame sensor. The main burner assembly includes a main burner. The gas valve is coupled to the pilot flame and main flame burners. The controller is configured to control the variable gas valve in response to signals received from the pilot and main burner sensors. The controller is also configured to monitor a pilot flame at the pilot flame burner with the pilot flame sensor to confirm the presence of the pilot flame before activating the variable gas valve to supply gas to the main burner.

Owner:HNI TECH INC

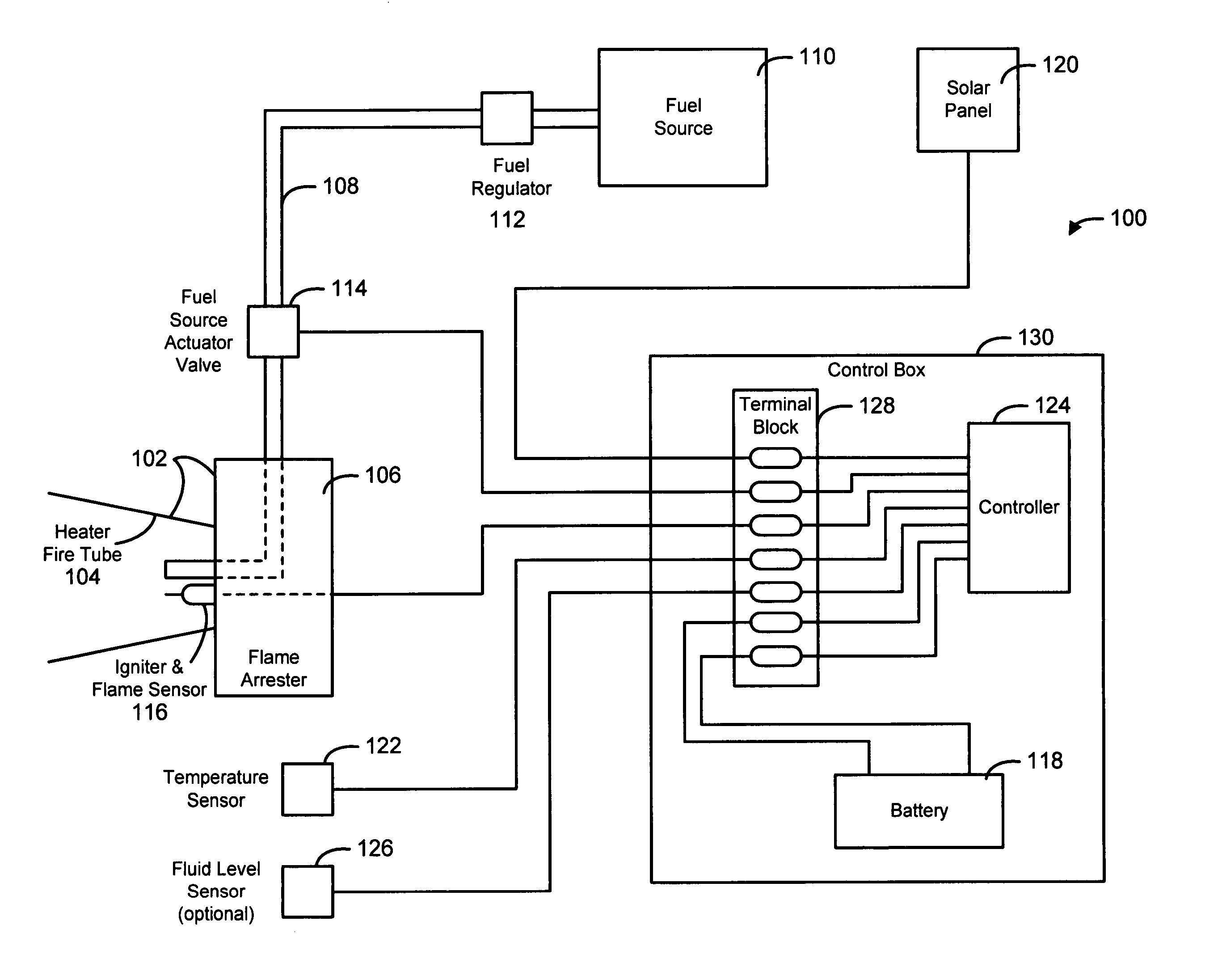

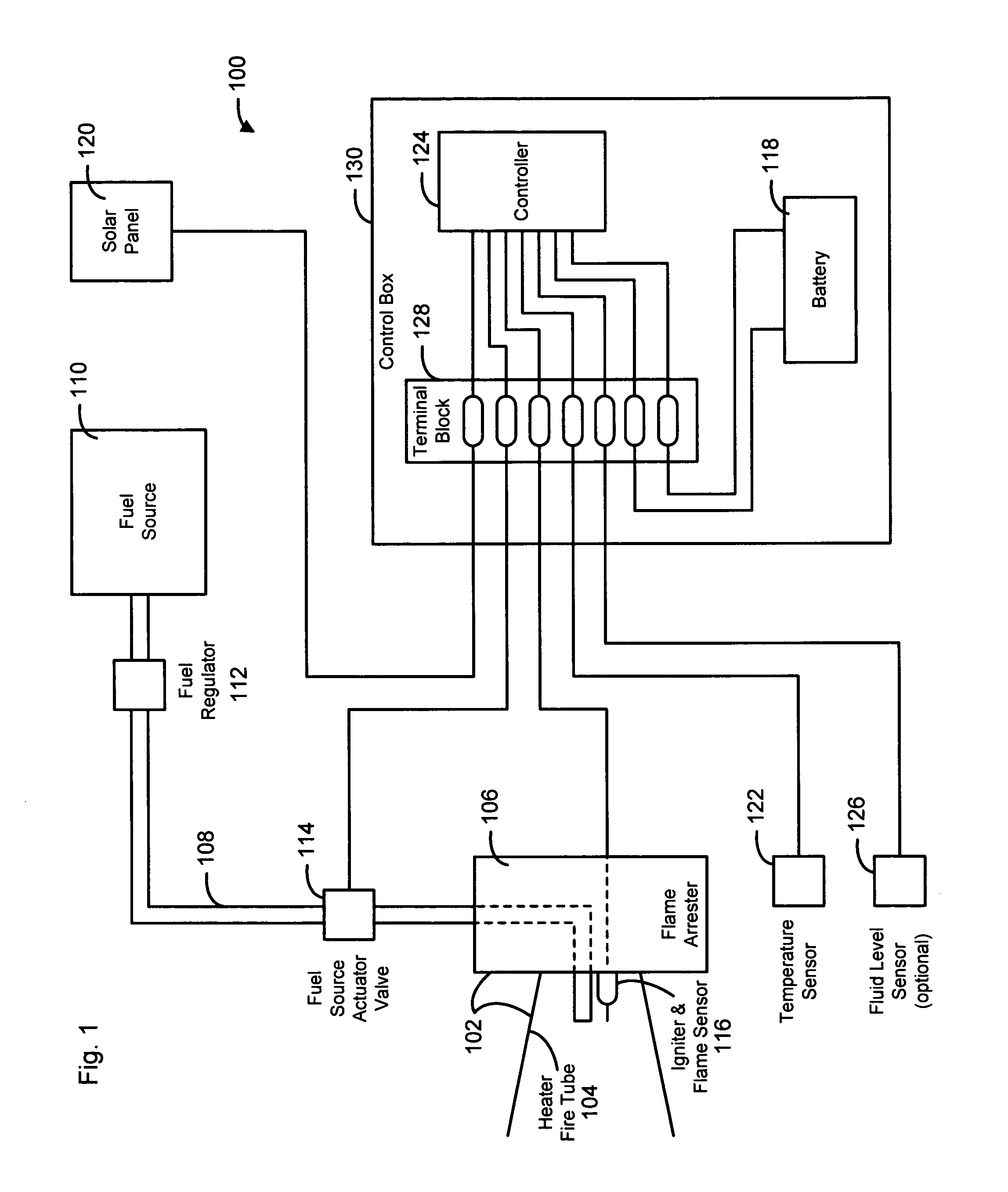

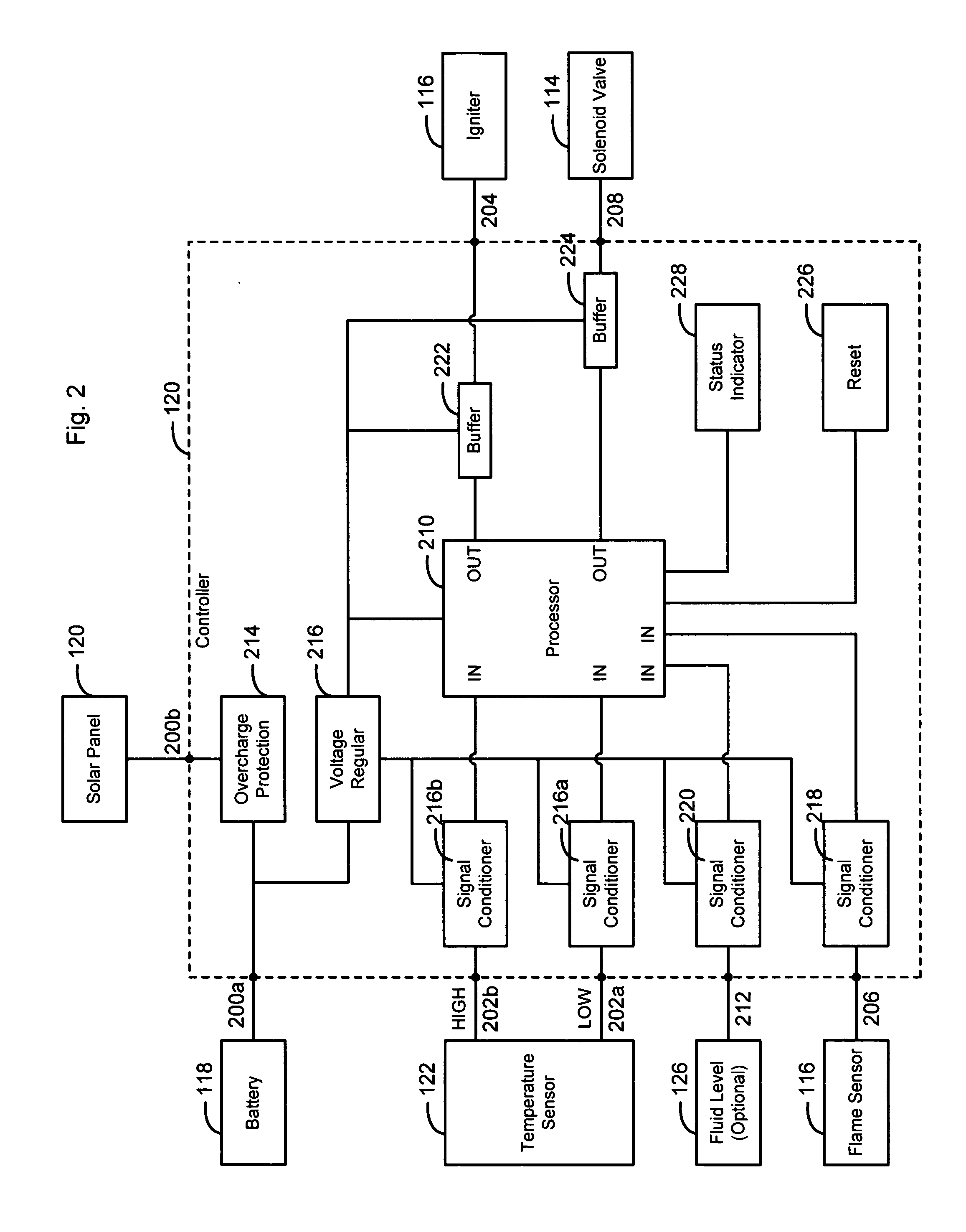

Method, apparatus and system for controlling a gas-fired heater

InactiveUS20060172238A1Eliminate needReduce the introductionCombustion signal processingCombustion measurementsElectricityEngineering

The present invention provides a system, method and apparatus for controlling a gas-fired heater connected to a fuel source via a fuel source valve that includes one or more power sources, a temperature sensor, a pilotless igniter disposed within the gas-fired heater, a flame sensor disposed within the gas-fired heater and a controller electrically connected to the one or more power sources, the temperature sensor, the pilotless igniter, the flame sensor and the fuel source valve. The controller turns the pilotless igniter on for a first time period and opens the fuel source valve whenever the temperature sensor indicates that a temperature is less than or equal to a low temperature setting. The controller also closes the fuel source valve whenever the temperature sensor indicates that the temperature is greater than or equal to a high temperature setting or the flame sensor indicates that a flame has gone out.

Owner:SURE FIRE PILOTLESS BURNER SYST

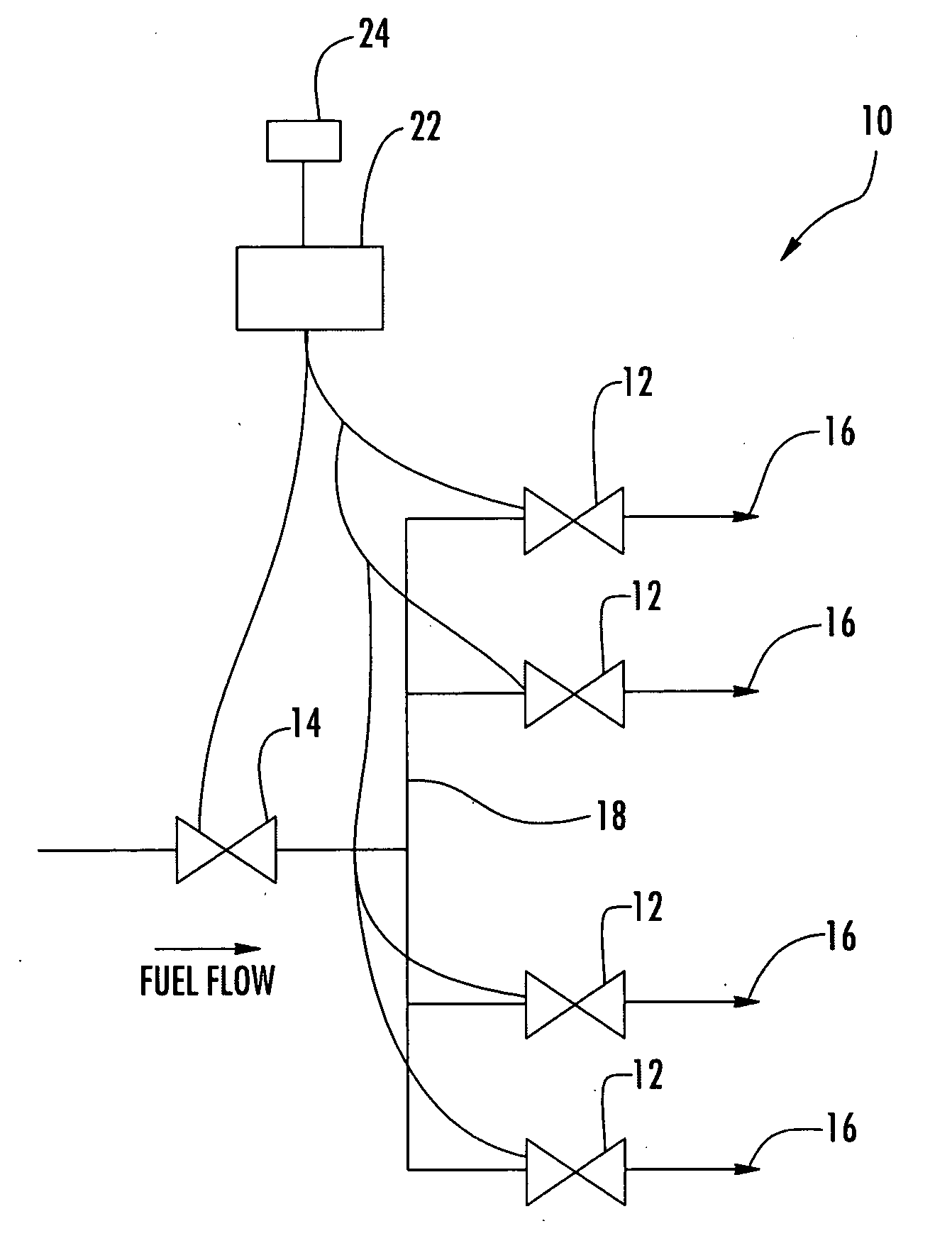

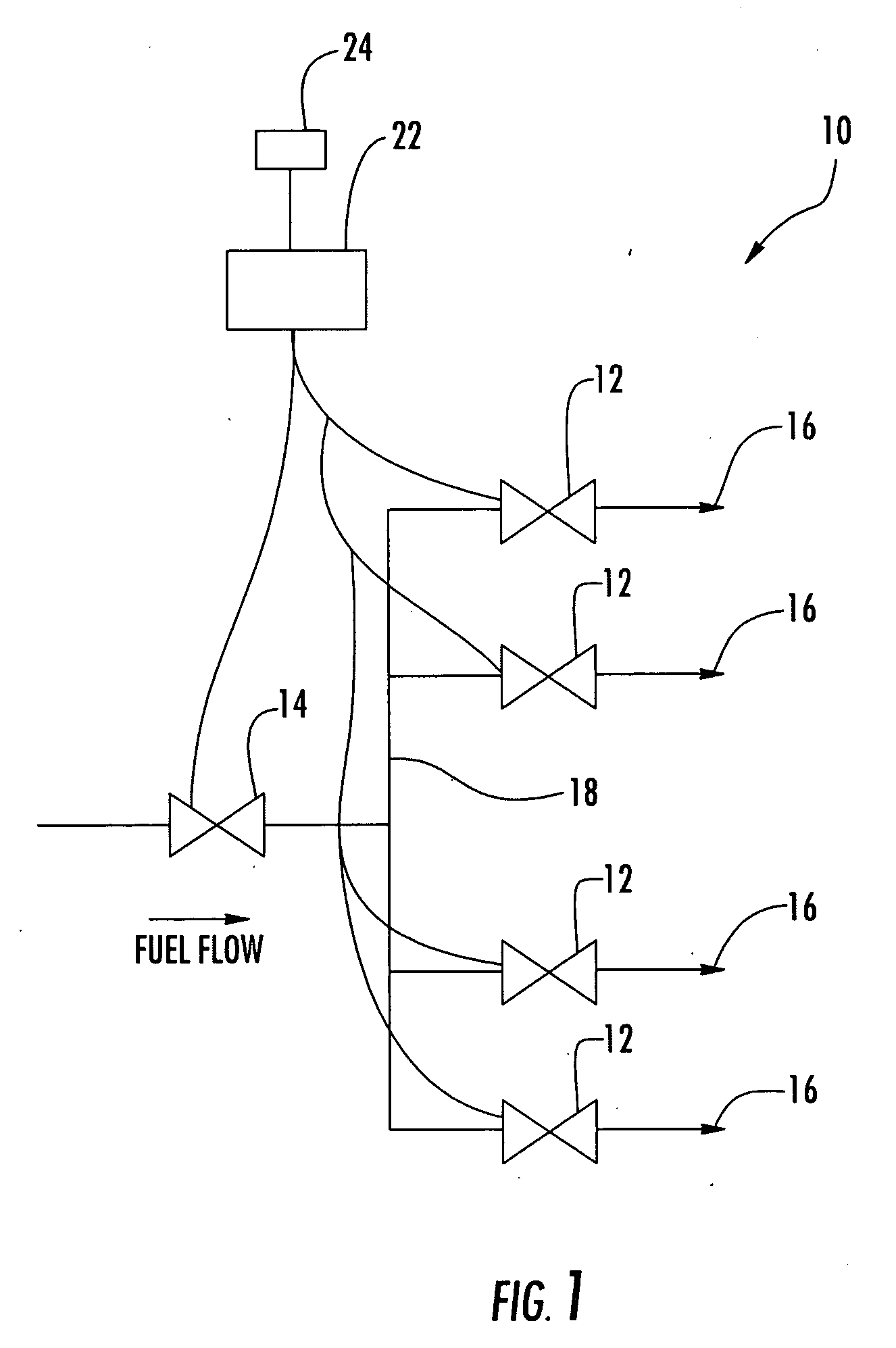

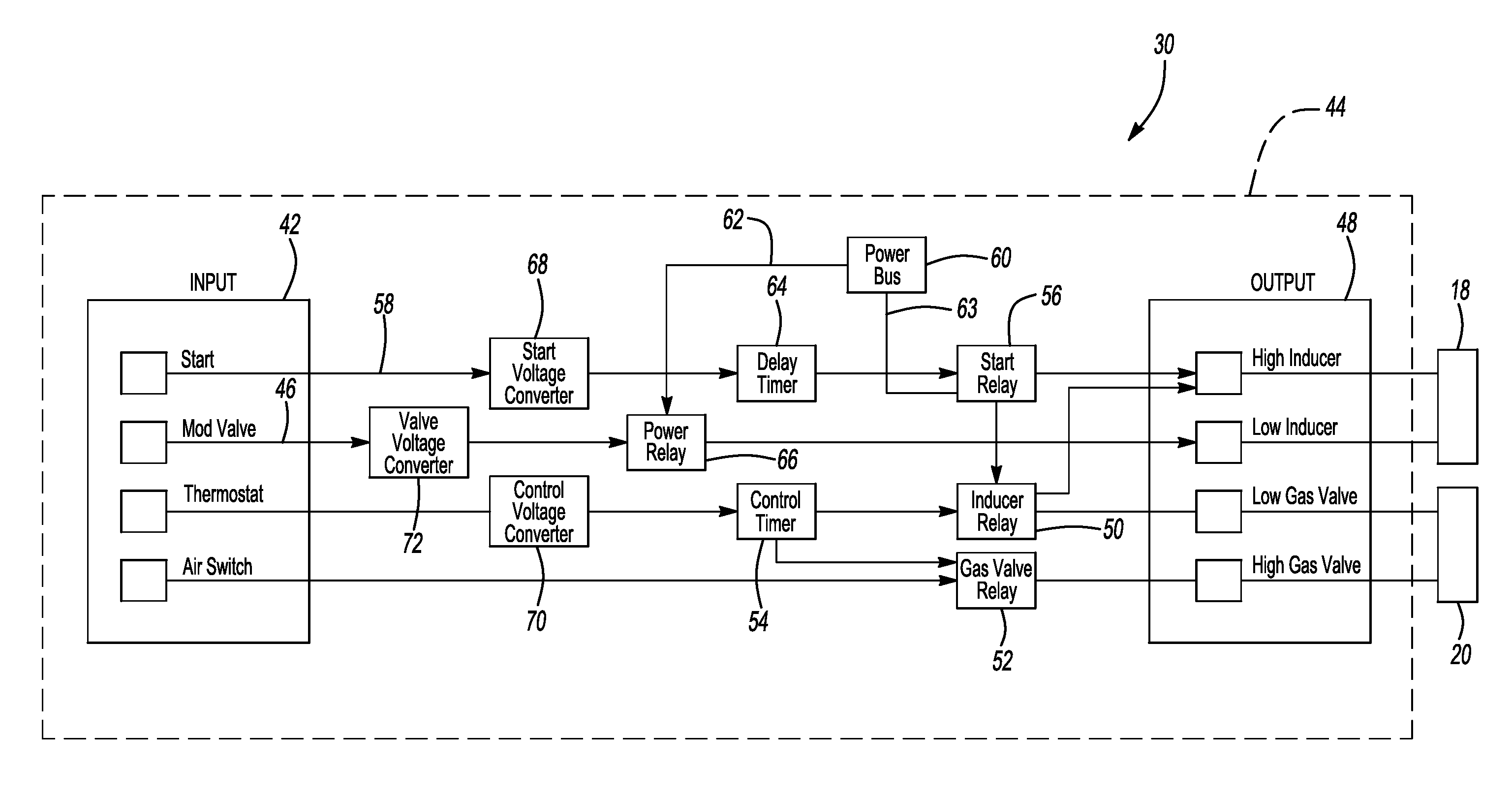

Timer relay control board

A heater (12) includes a burner (16), a valve (20), and an inducer (18). A thermostat (24) is electrically coupled to the heater (12) and a control board (44) is disposed in the heater (12) and electrically connected to the thermostat (24). The control board (44) includes an inducer relay (50), a valve relay (52), and a control timer (54) for switching the valve (20) between a high flow stage and a low flow stage and the inducer (18) between a high speed stage and a low speed stage, respectively, wherein the inducer relay (50), the valve relay (52), and the control timer (54) are mounted to the control board (44) to define a singular and compact controller (30).

Owner:MAXITROL

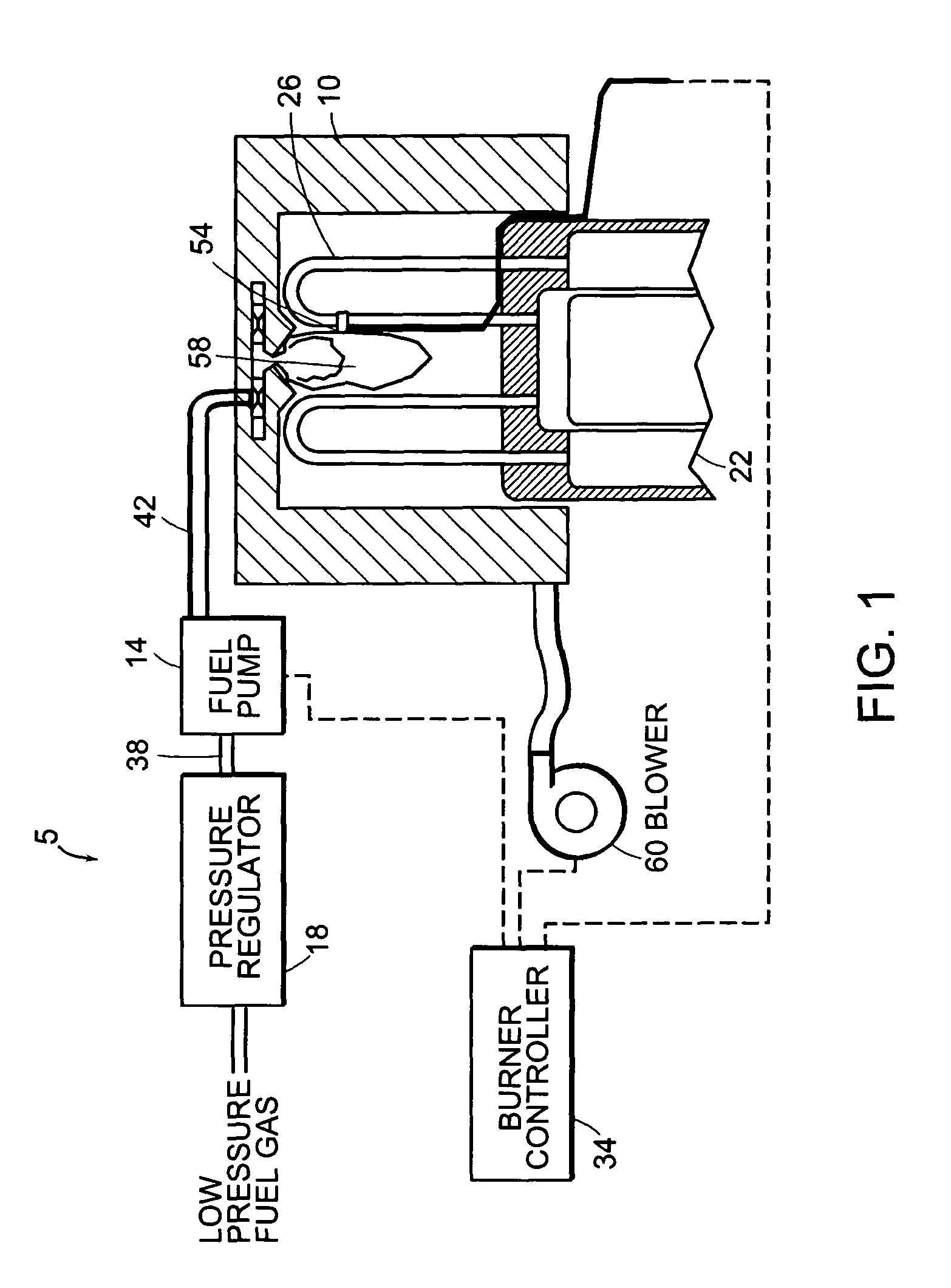

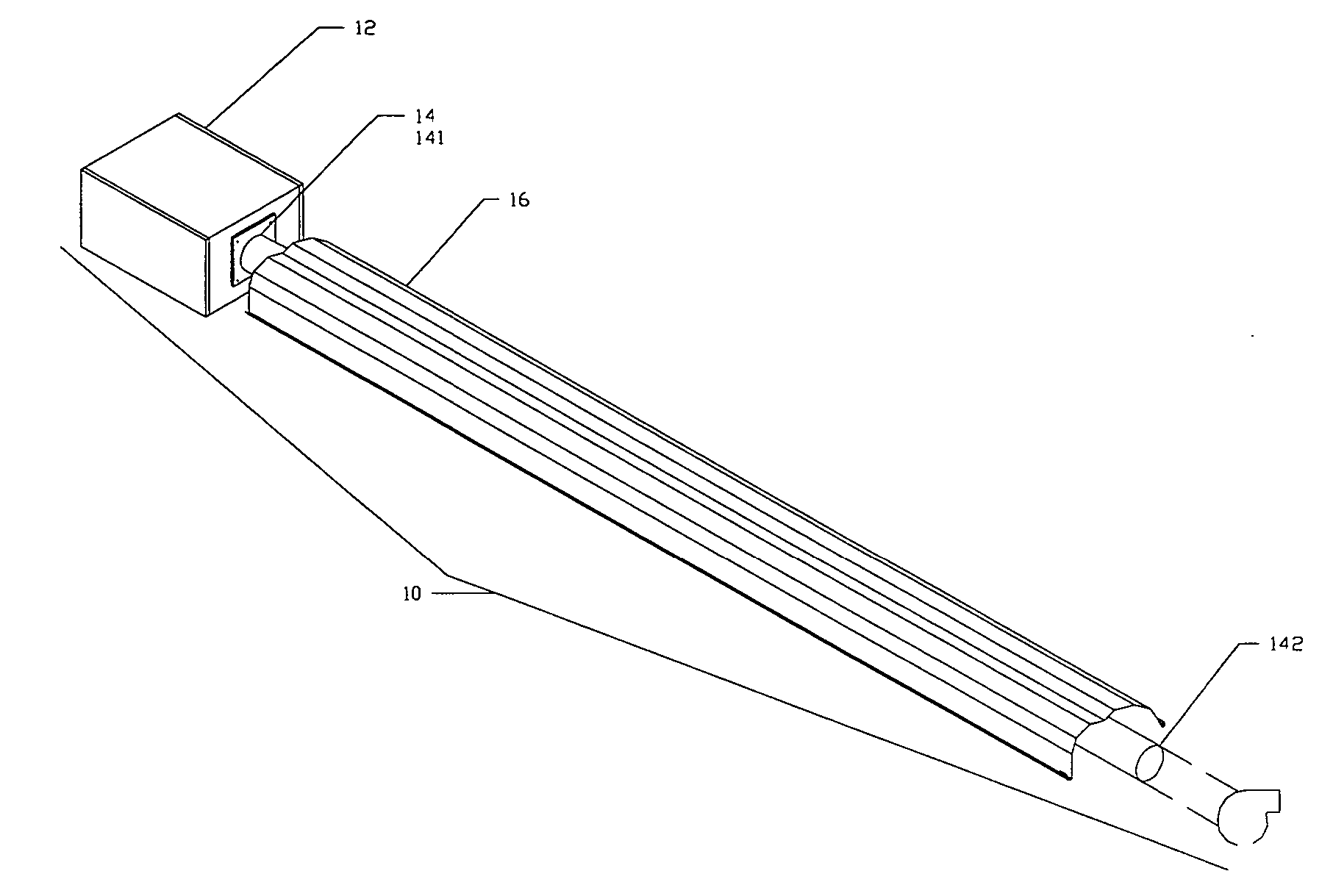

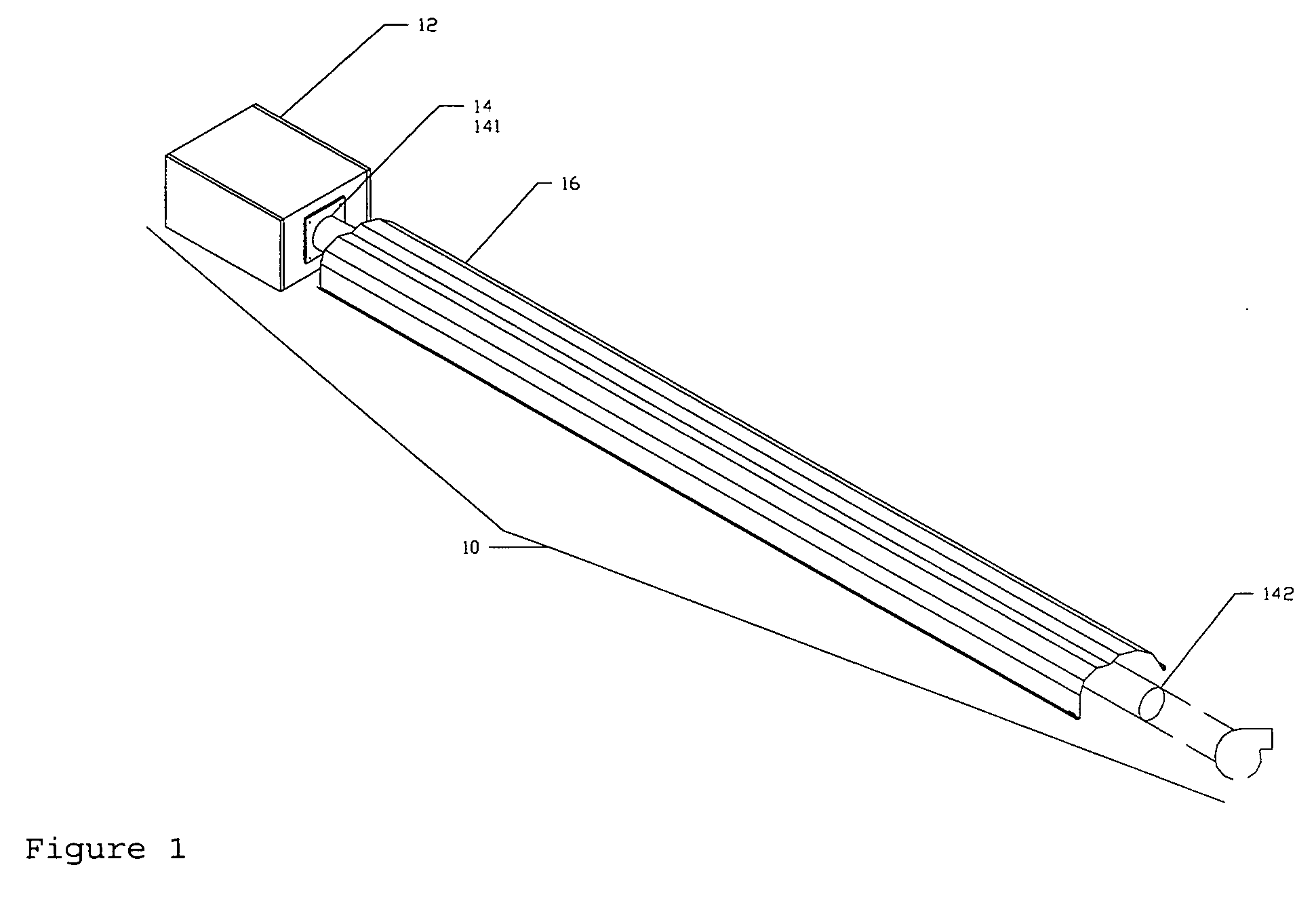

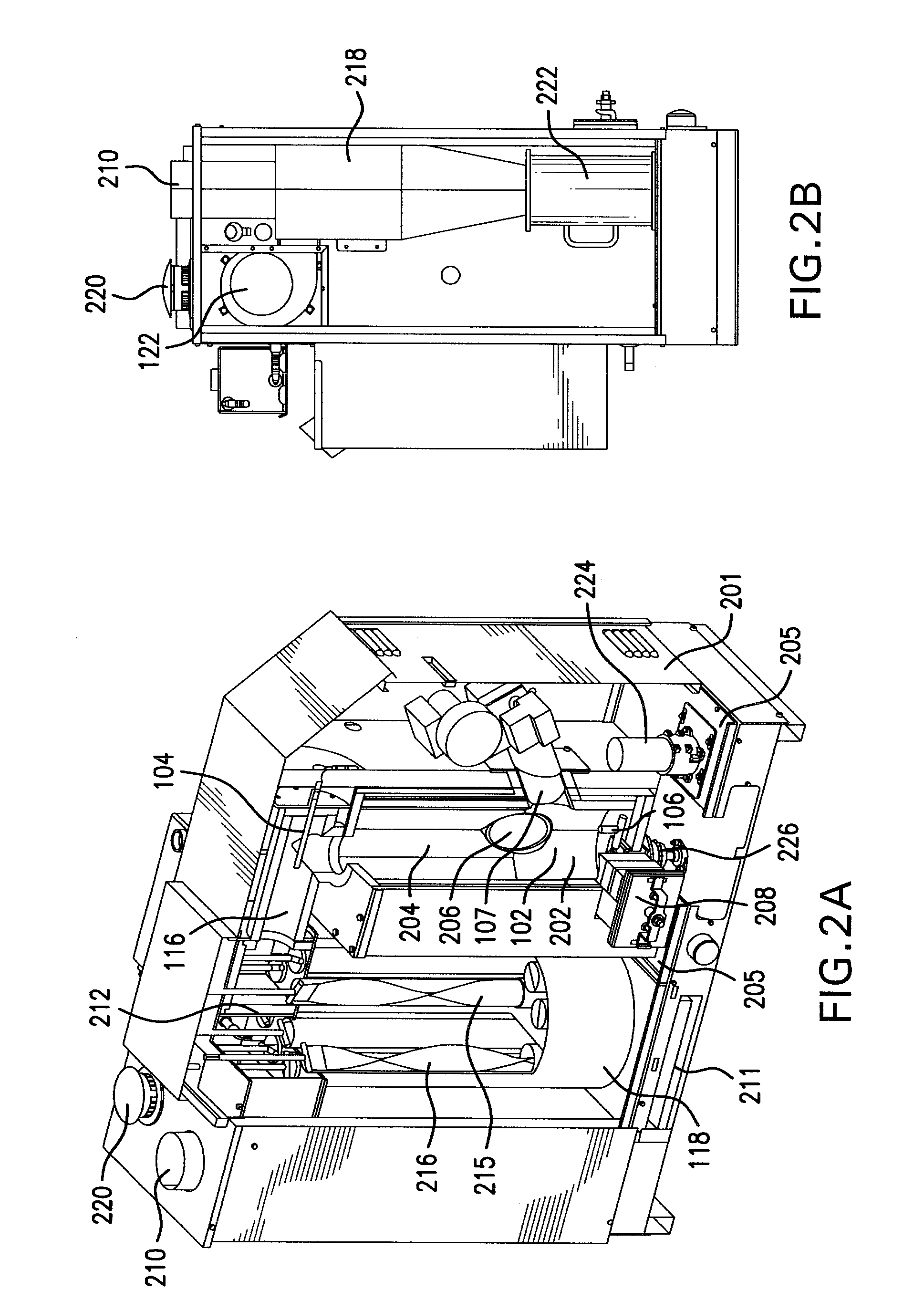

Variable input radiant heater

A variable demand radiant heating system applies variable burner control technology to singular or mulit-burner radiant heating systems. A radiant heater consists of a burner connected to an elongated heat exchanger tube. The combustion air is supplied to the burner via blower or draft inducer. Fuel is supplied to the burner via fuel regulator. Fuel and air are mixed in burner and communicated to the inlet end of the heat exchanger tube. Spent products of combustion are expelled from the heat exchanger at the outlet end. The burner controls continuously vary gas supply pressure (volume), via a modulating gas regulator, and combustion air pressure (volume), via a variable speed blower, communicated to the burner mixing chamber, which in turn, varies the burner input on a continuous curve (not stepped or staged) within a pre-determined input range as heat demand varies.

Owner:ROBERTS GORDON INC

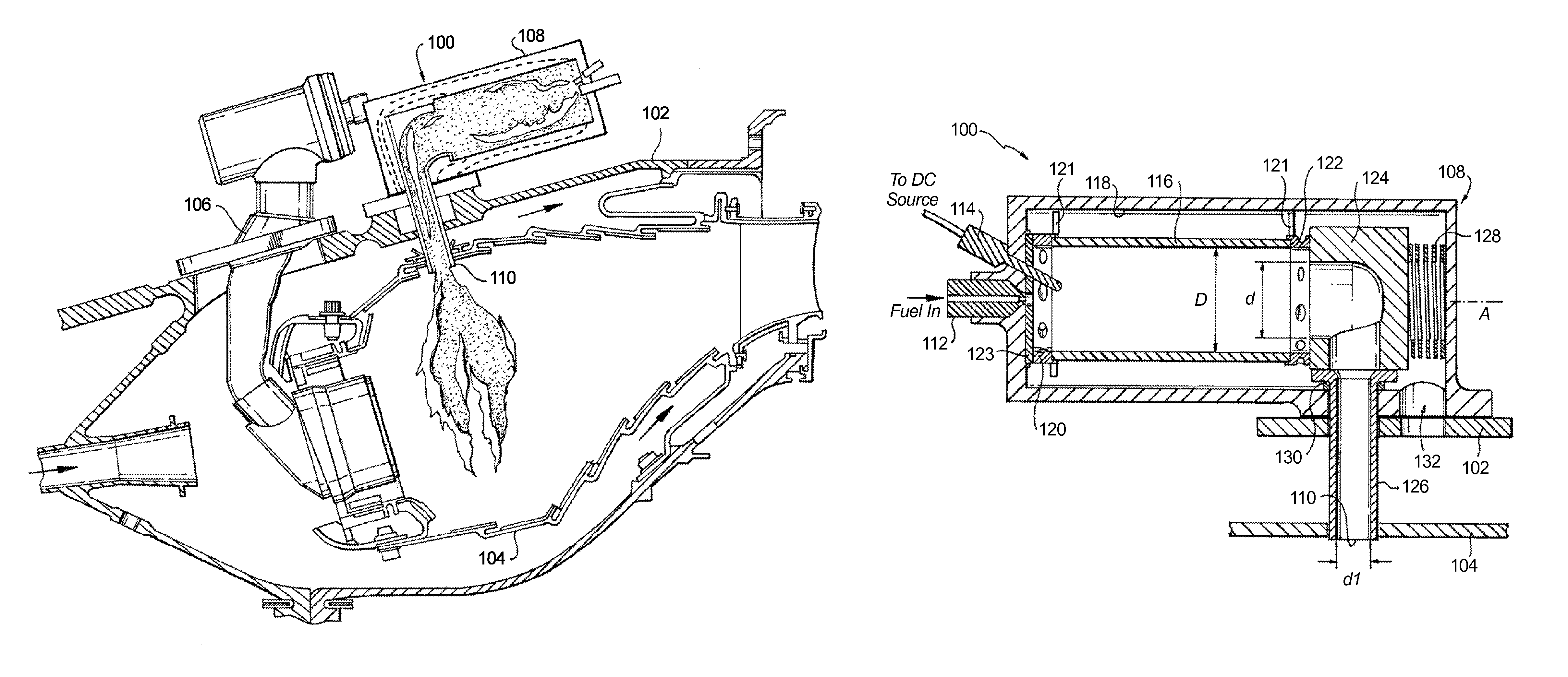

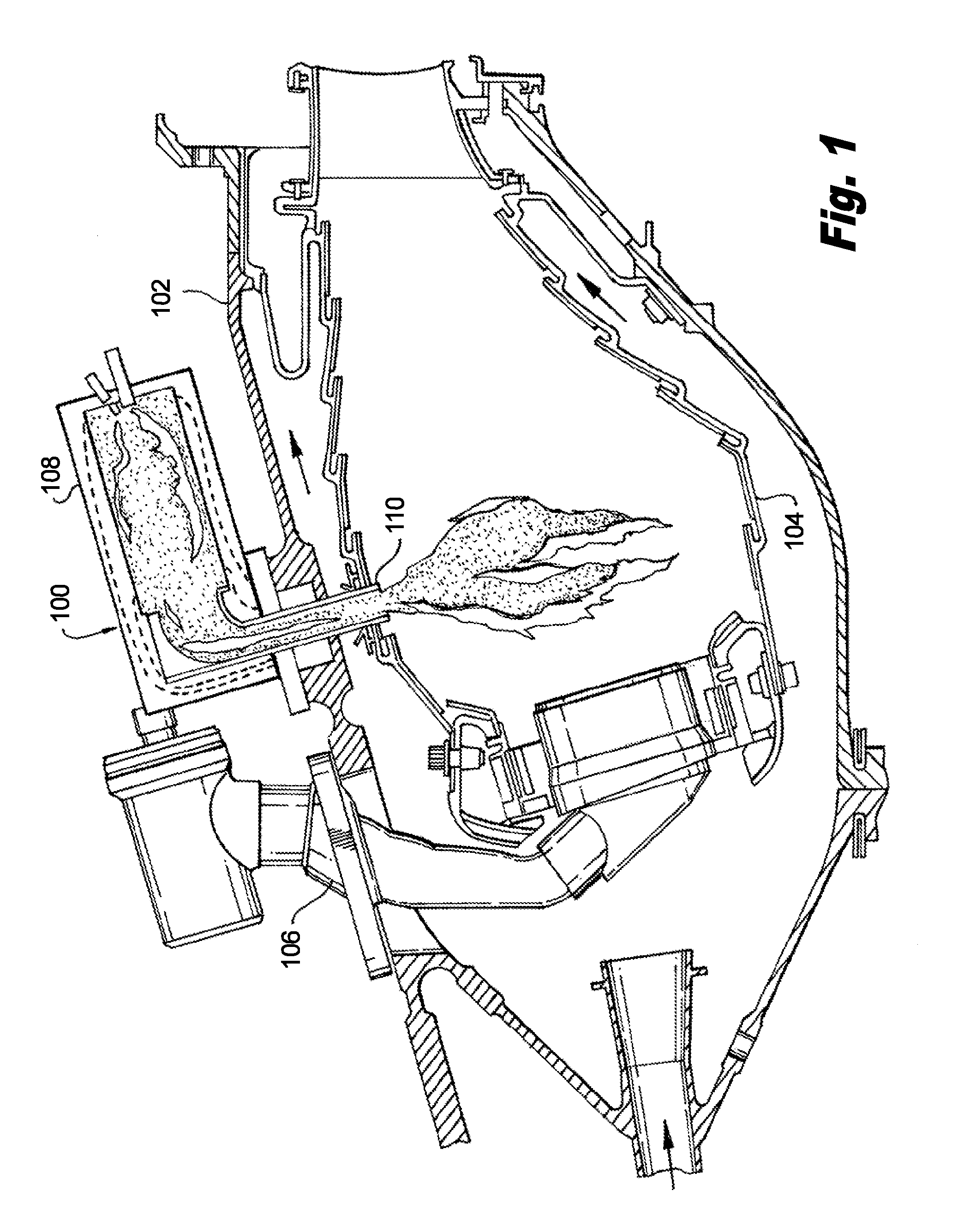

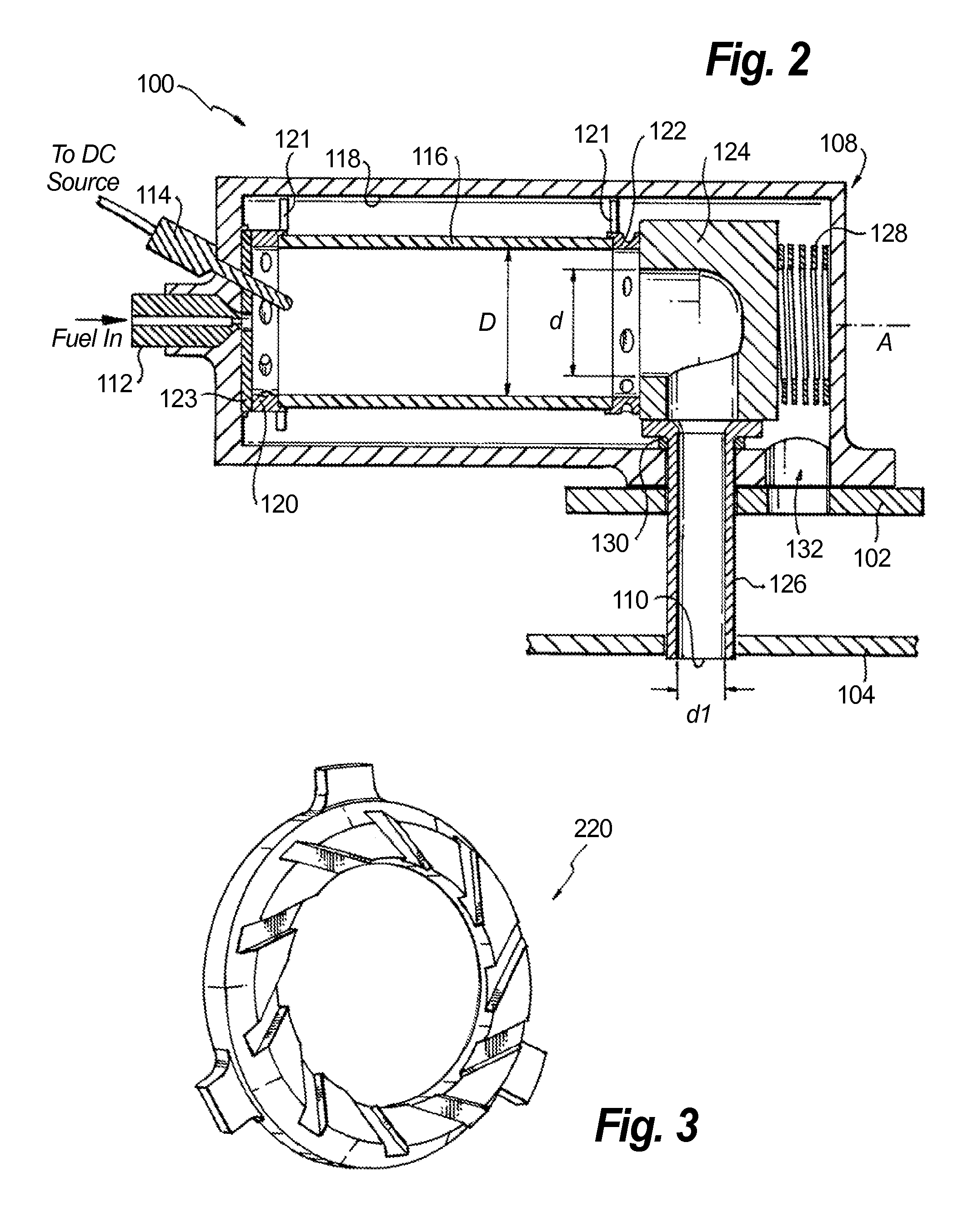

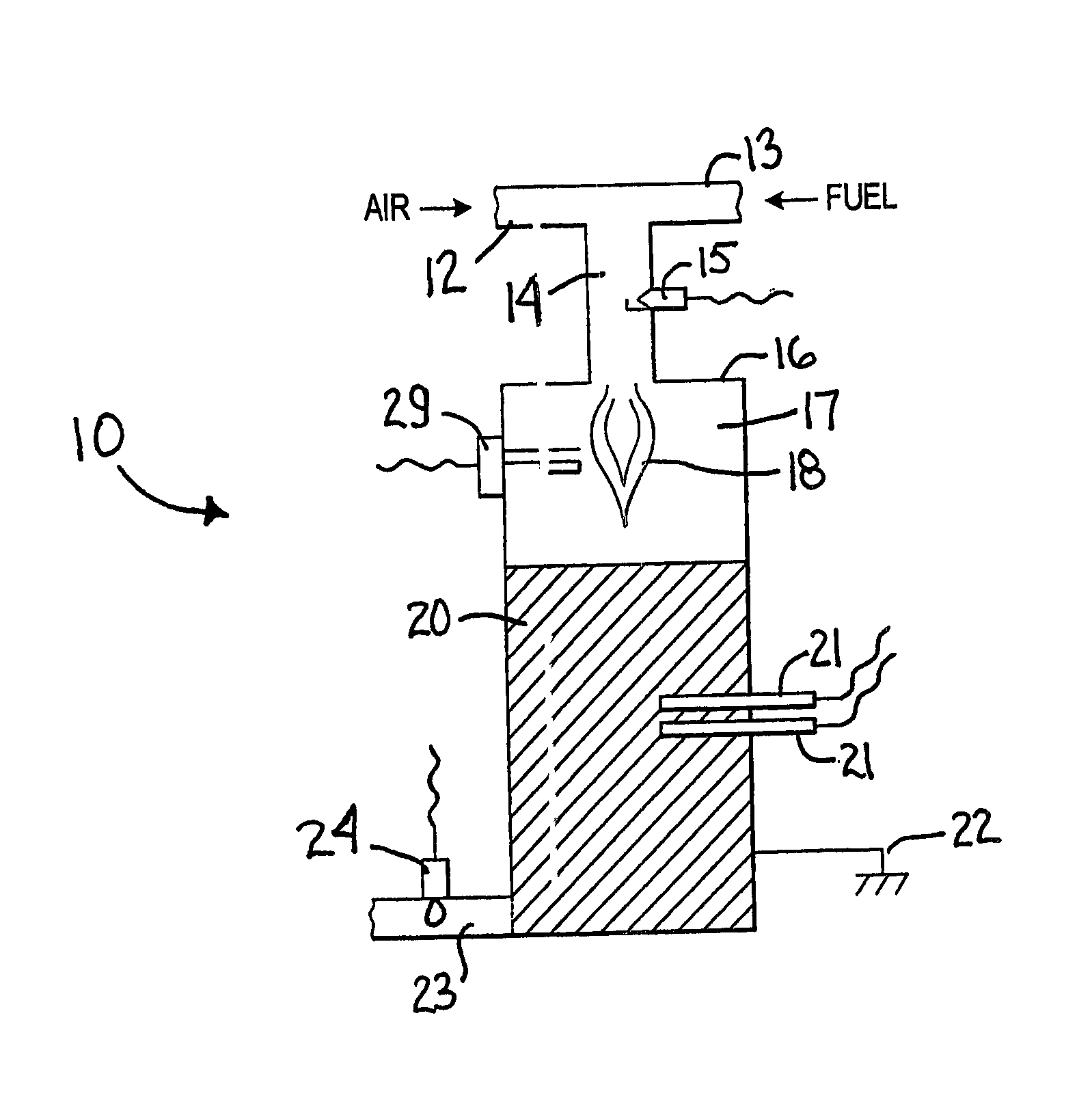

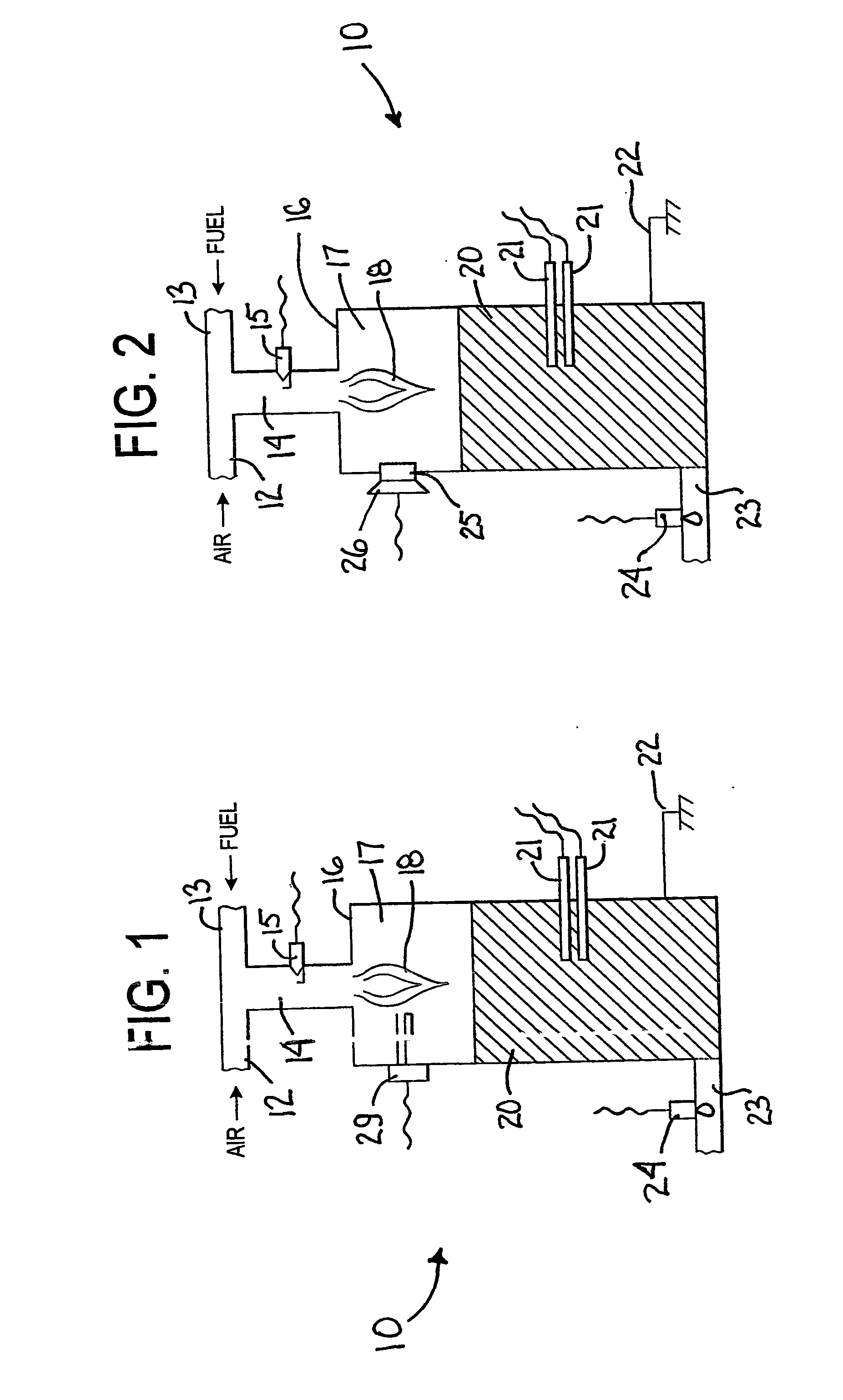

Continuous ignition

ActiveUS9080772B2High flame intensityReduced strengthBurnersContinuous combustion chamberCombustorIgnition point

An ignition system includes a housing defining an interior and an exhaust outlet. The housing is configured and adapted to be mounted to a combustor to issue flame from the exhaust outlet into the combustor for ignition and flame stabilization within the combustor. A fuel injector is mounted to the housing with an outlet of the fuel injector directed to issue a spray of fuel into the interior of the housing. An igniter is mounted to the housing with an ignition point of the igniter proximate the outlet of the fuel injector for ignition within the interior of the housing.

Owner:COLLINS ENGINE NOZZLES INC

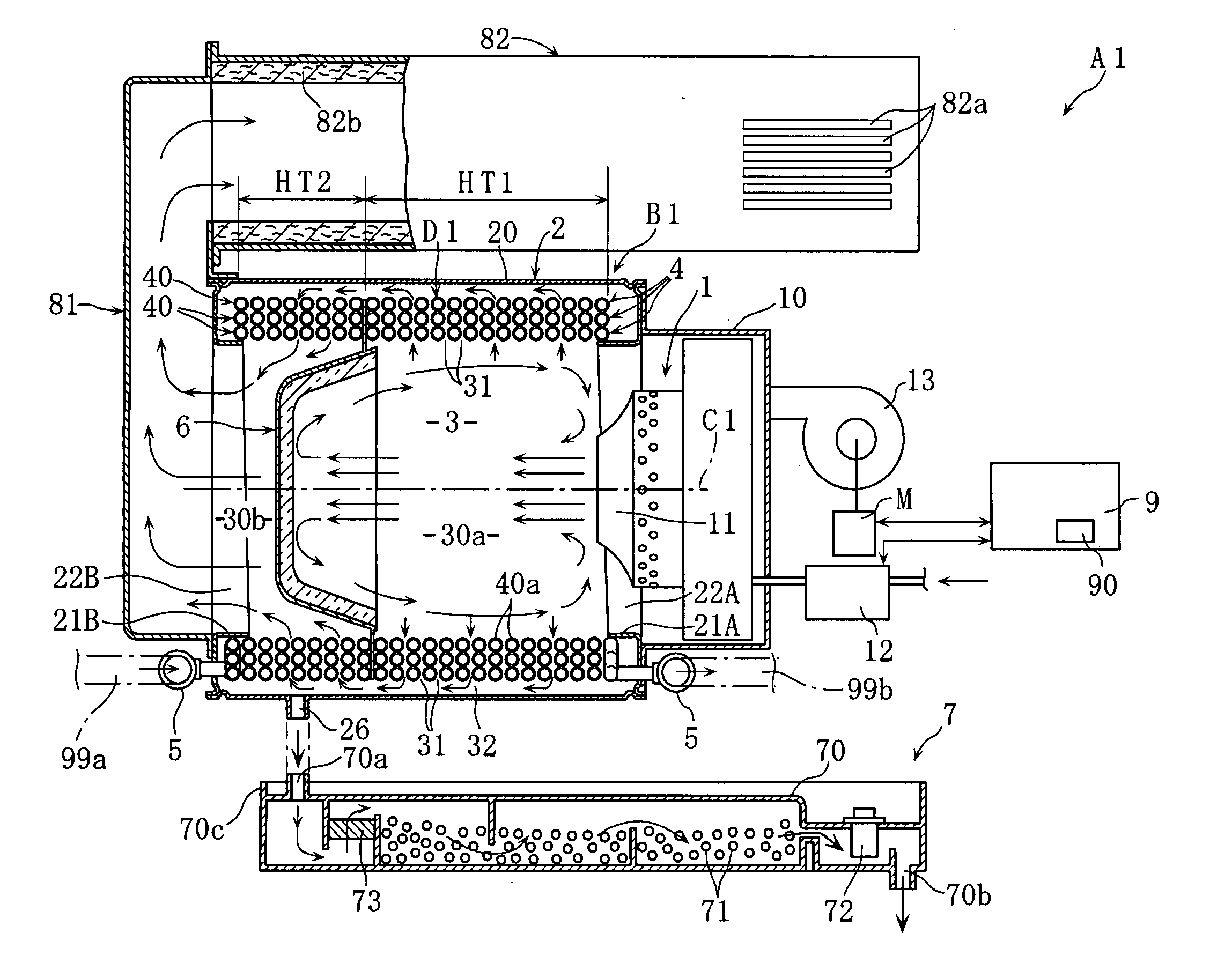

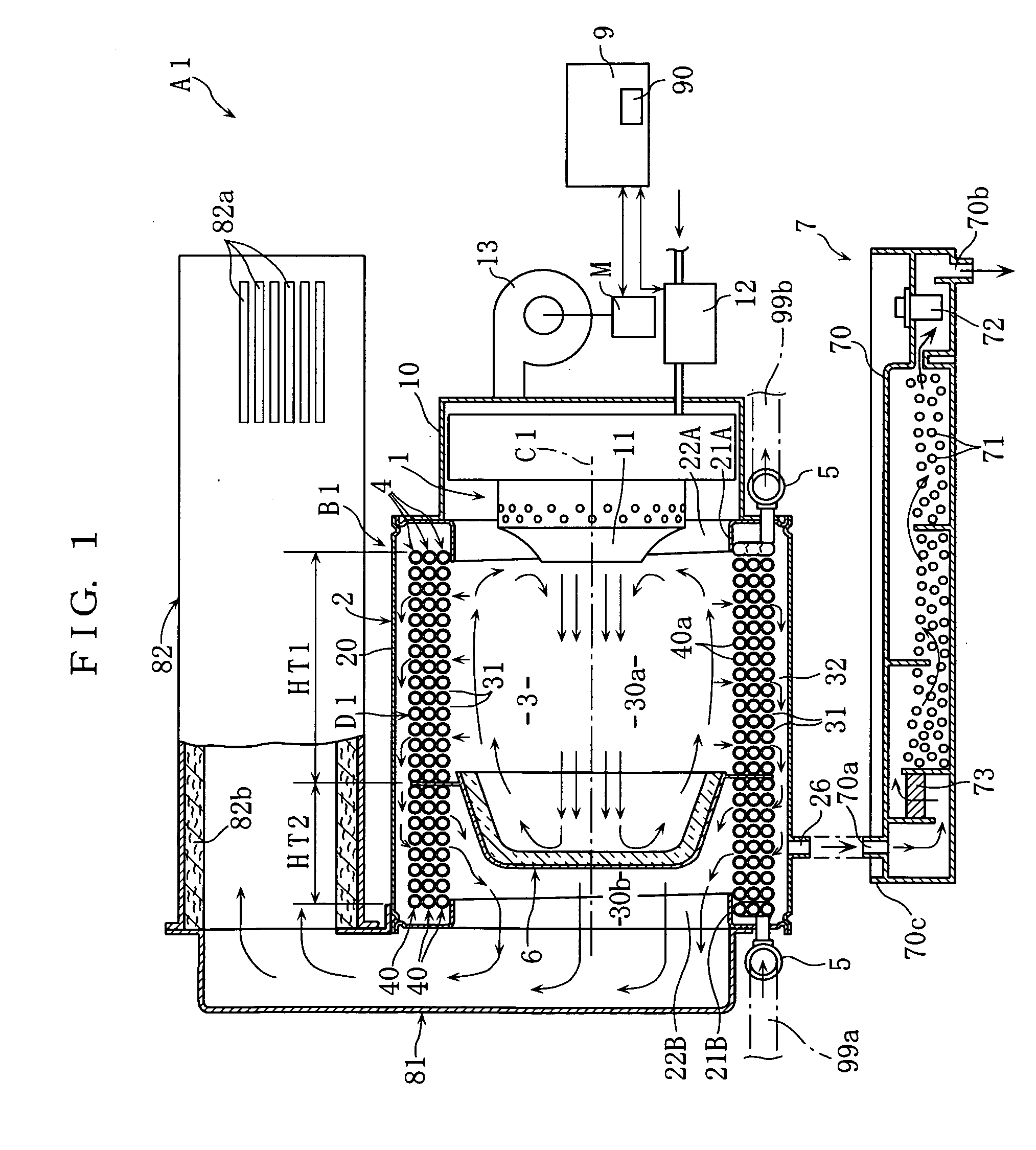

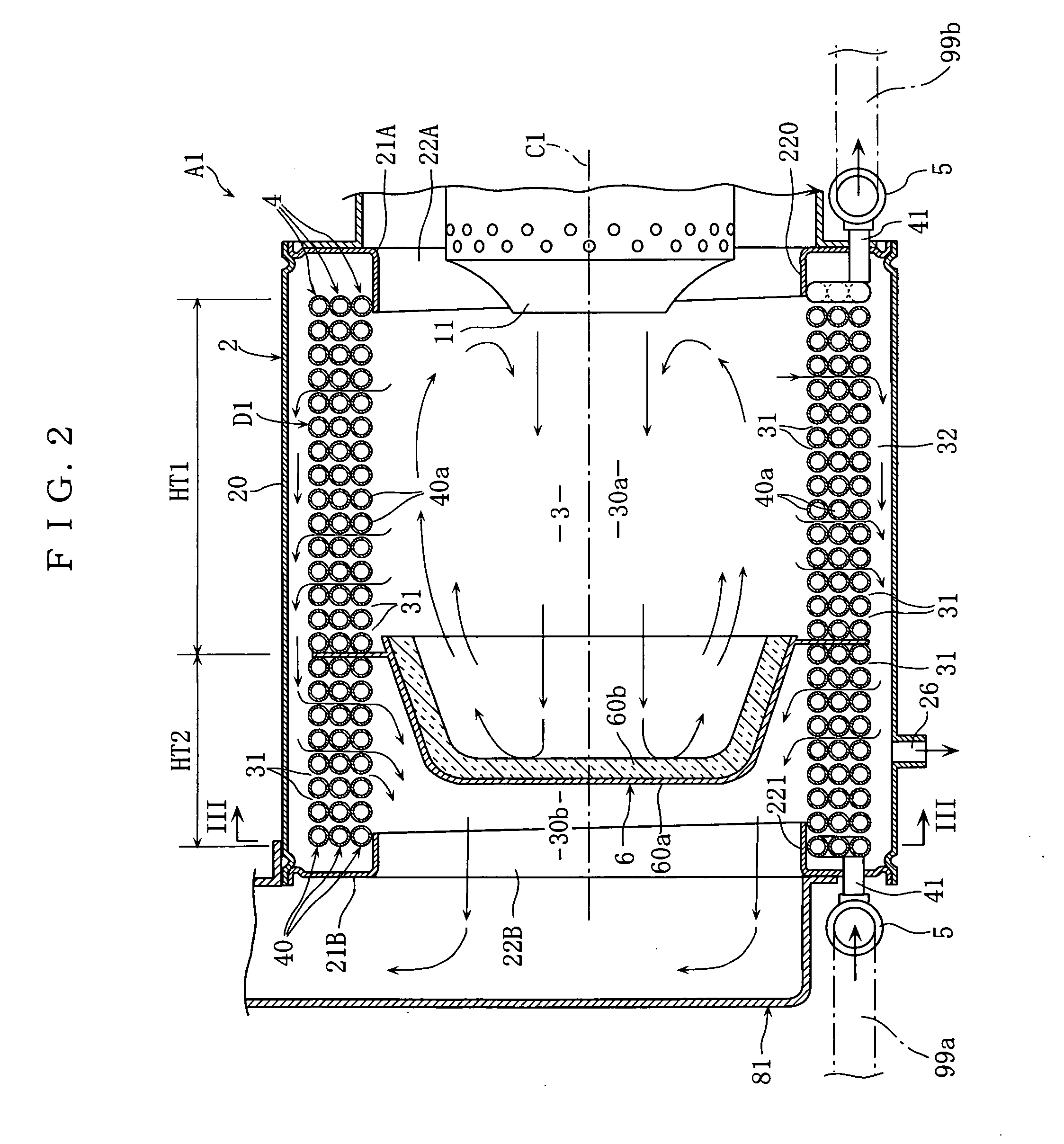

Water heater

A first period during which drain is not substantially generated on a surface of a water tube (4) of a heat exchanger (B1), and a second period as a transition during which an amount of drain on the surface of the water tube (4) is increased are provided. There are a plurality of kinds of fan-controlling data in which operation control contents of the fan (13) in the first and second periods in correspondence with change of conditions of entering water temperature or combustion level of the burner (1). The fan-controlling data are stored in a data table (90) of a controller (9). The controller (9) controls the fan (13) in accordance with the data, and an initial air-fuel ratio of combustion driving of the burner (1) is stabilized.

Owner:NORITZ CORP

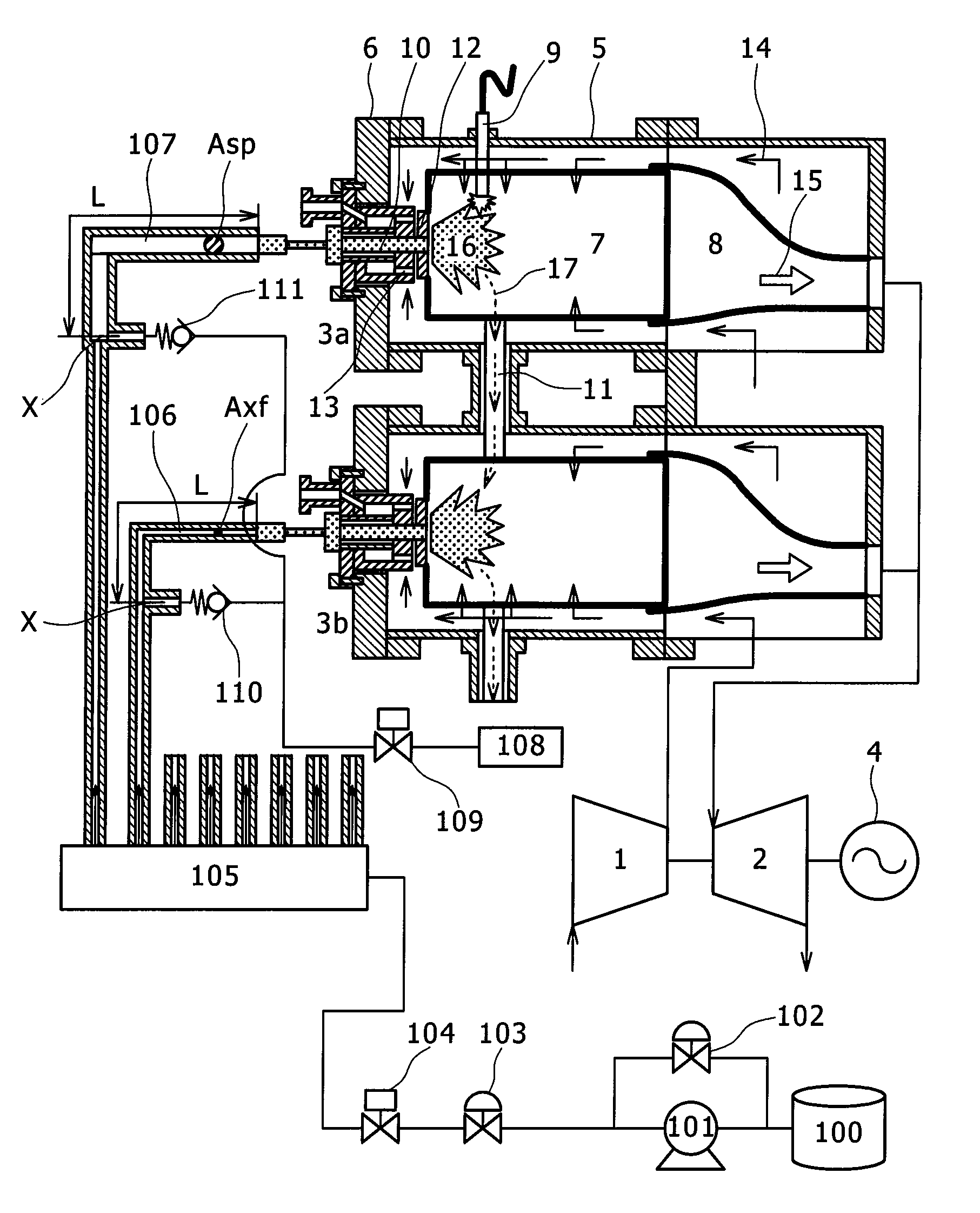

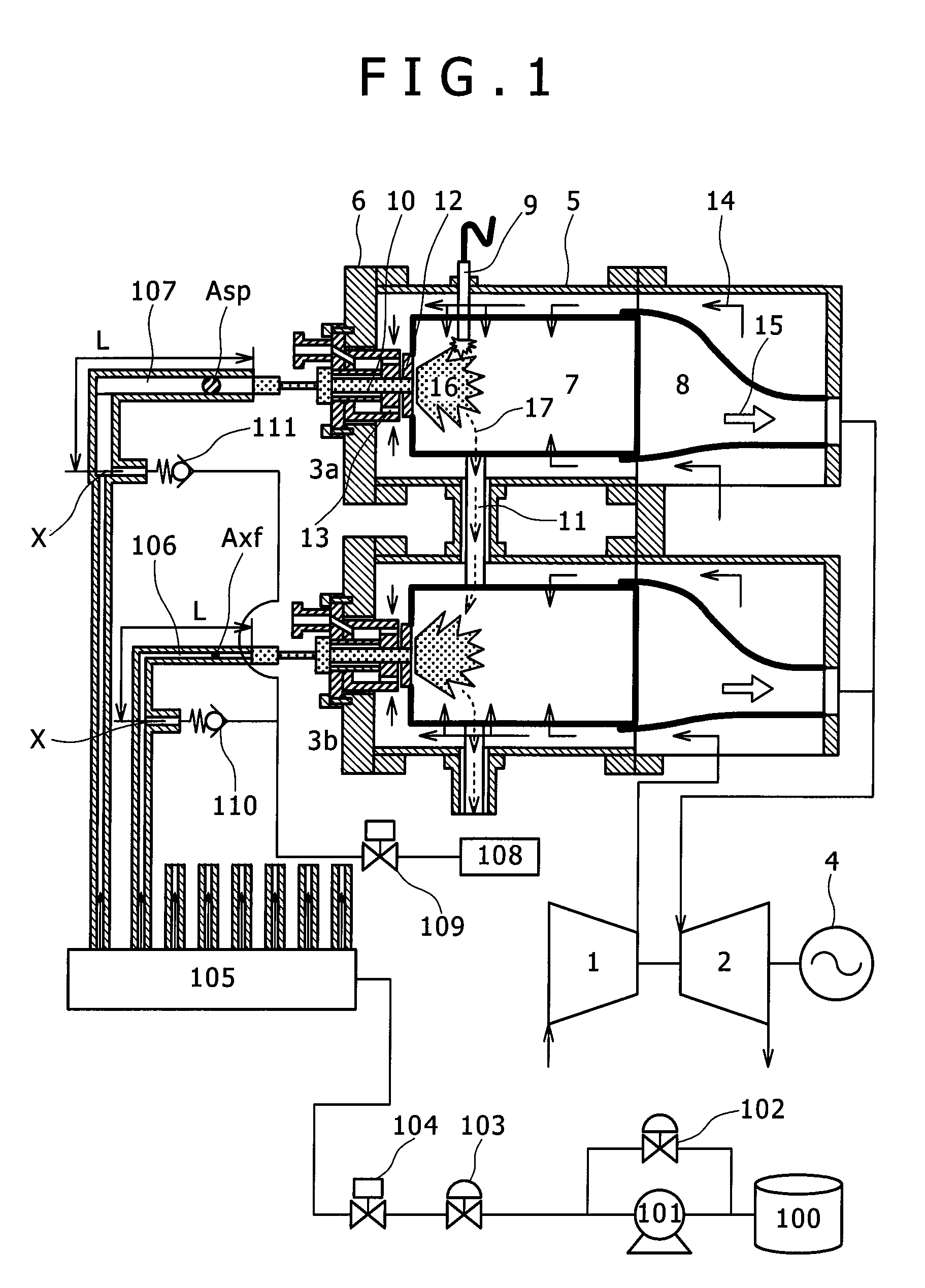

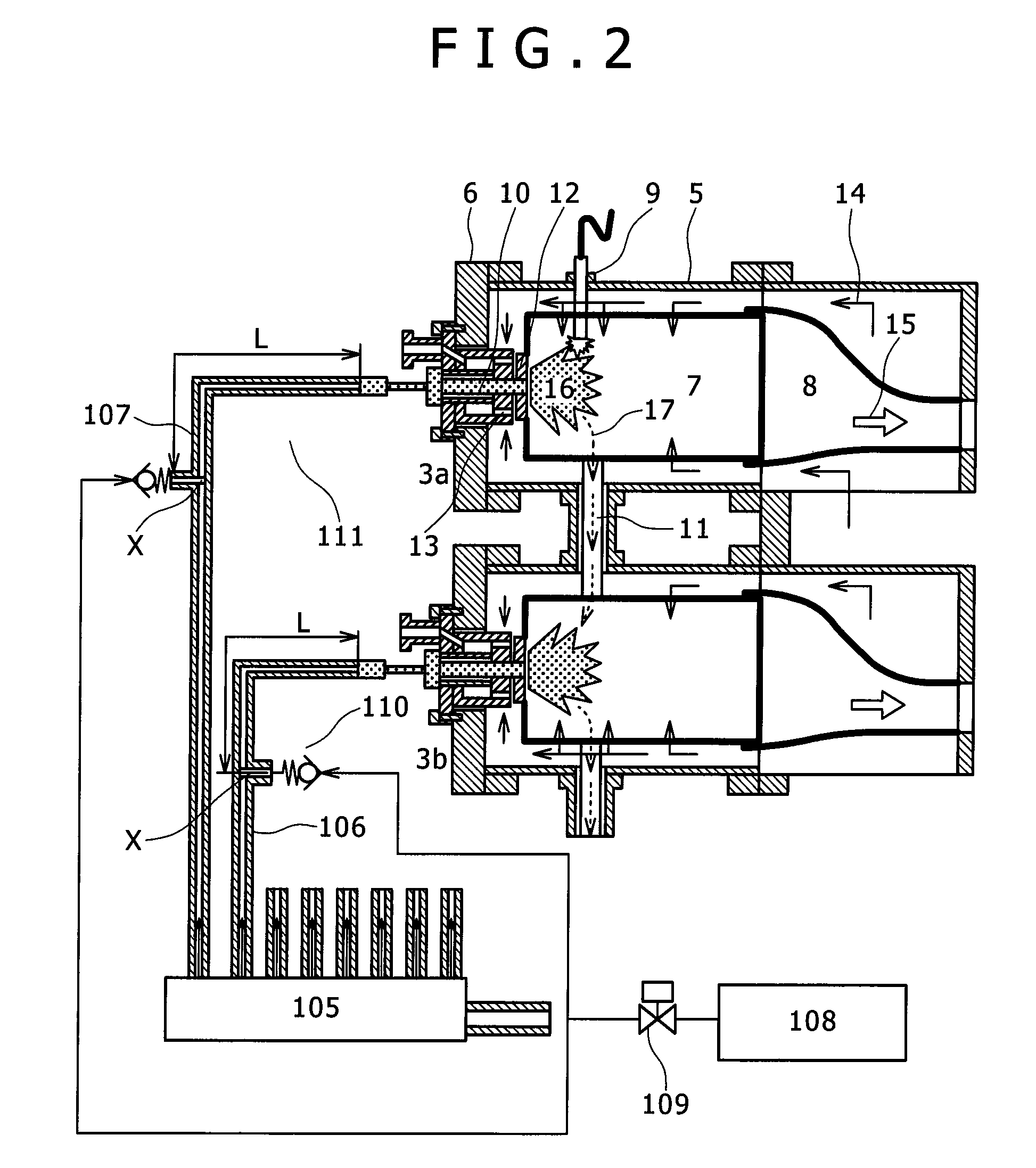

Combusting system, remodeling method for combusting system, and fuel injection method for combusting system

ActiveUS8082724B2Improve performanceImprove reliabilityBurner safety arrangementsBurnersCombustion systemStart time

The present invention improves the reliability of a combusting system including multiple combustors and improves an environmental performance thereof. The invention includes a device that delays the start time of fuel injection from a fuel nozzle of a combustor including a ignitor from the start time of fuel injection from a fuel nozzle of the combustor not including the ignitor.

Owner:MITSUBISHI POWER LTD

Burner Control Sensor Configuration

In domestic installations of any type of furnace or equivalent, proof of lean combustion is necessary to satisfy requirements of certification agencies. Exhibiting proof of lean combustion during the operation of an integrated fuel reformer and fuel cell system can be problematic because the point of combustion and its nature may shift during operation. In addition, the preferred ratio of fuel to air in these fuel-reforming systems is often near a stoichiometry of one. In the present invention, the combination of a flame-detecting device, a temperature sensing device and an oxygen or hydrocarbon sensor is used to verify the occurrence of combustion, and show proof of lean combustion.

Owner:NUVERA FUEL CELLS

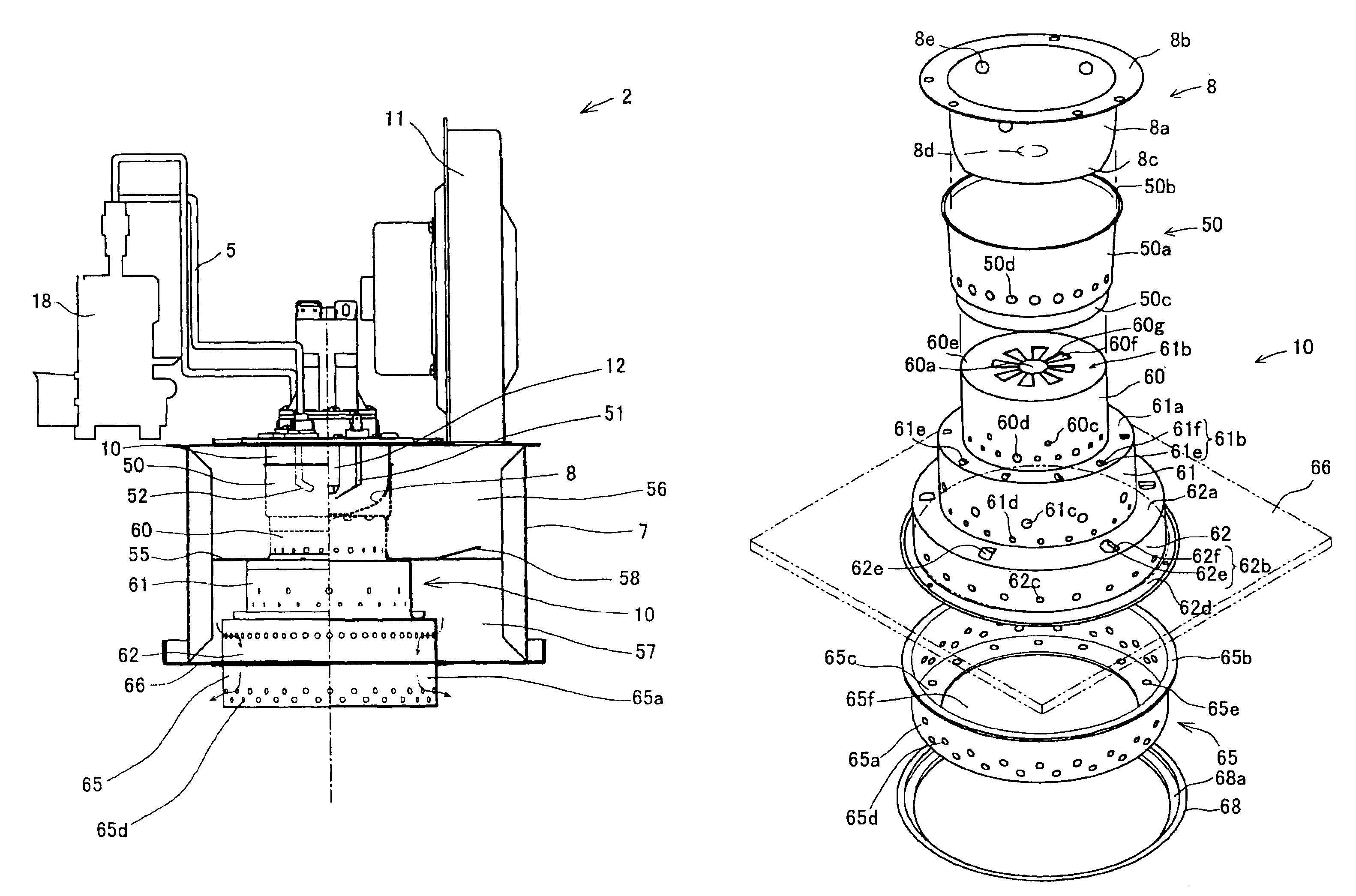

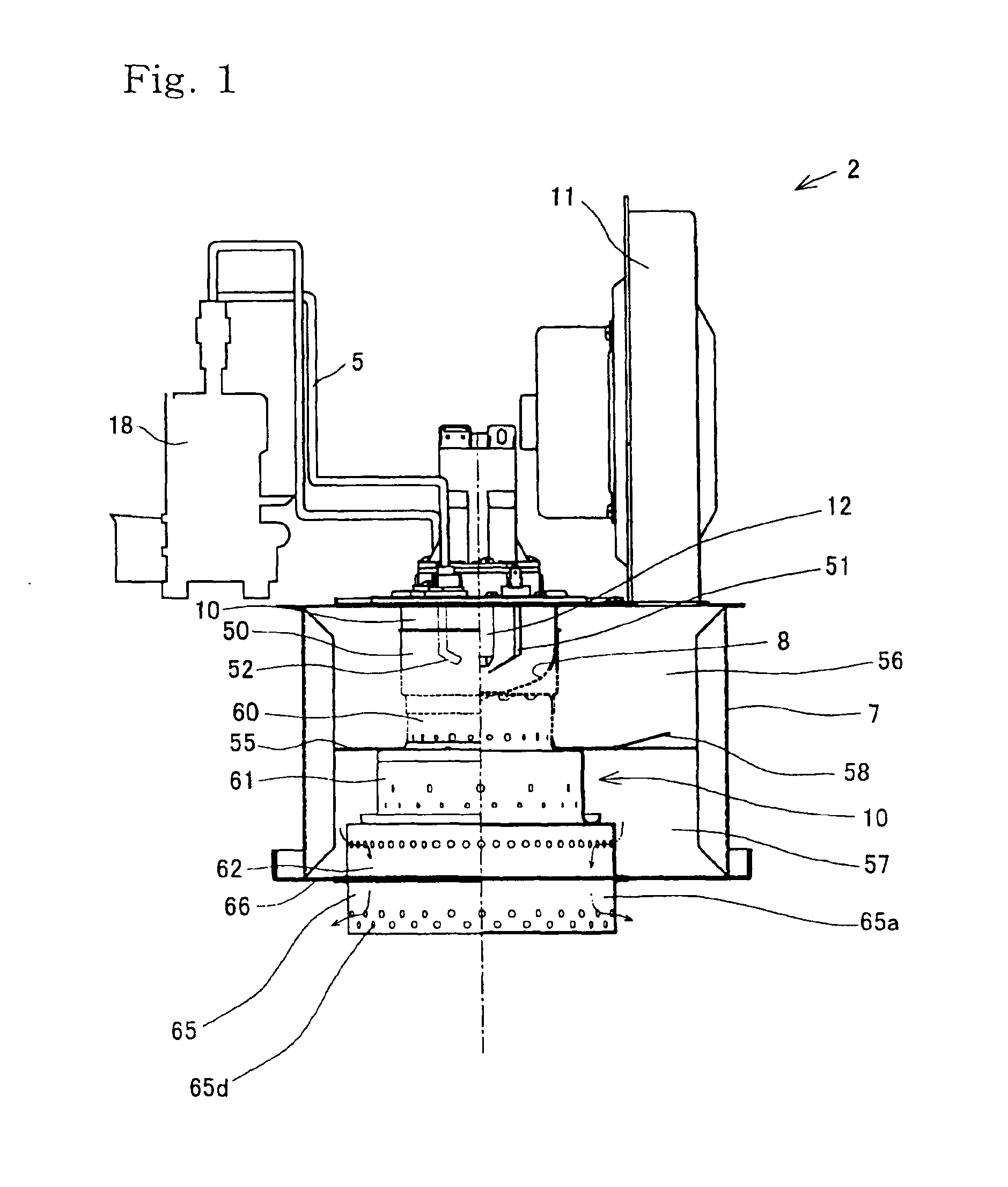

Combustion apparatus

InactiveUS6918757B2Simple structureAccurate supervisionFuel supply regulationCombustion ventilatorsCombustion chamberEngineering

A combustion apparatus 2 has an anti-spreading member 65 disposed below a combustion chamber 10. This anti-spreading member 65 is composed of a generally cylindrical main body 65a, an outer flange 65b and an inner flange 65c, these flanges being formed at and integral with the opposite ends of the main body 65a, respectively. A controller 40 for regulating the operation of this apparatus 2 is designed to preheat the anti-spreading member 65 at a heat generation rate ‘q’ lower than the required heat generation rate ‘Q’, before the apparatus starts its normal operation to burn a fuel.

Owner:NORITZ CORP

Non-catalytic biomass fuel burner and method

The present invention relates to a non-catalytic biomass burner that may be used to burn a variety of fuel types at high efficiencies. The burner may include a cylindrical combustion chamber with an auxiliary igniter to heat the fuel in the combustion chamber until desirable combustion temperatures are reached. Fuel may be added to the chamber via a fuel feed assembly, and the rate of fuel addition to the chamber by the fuel feed assembly may be controlled by a computer. A fan located on the distal side of a flue pipe from the chamber may also be provided that pulls air into the chamber through one or more air inlets that are designed to encourage cyclonic air and exhaust flow in the chamber. Methods are further provided for controlling the manner of operation of the burner by a computer that may be instructed by a computer program code.

Owner:LASKOWSKI SCOTT +3

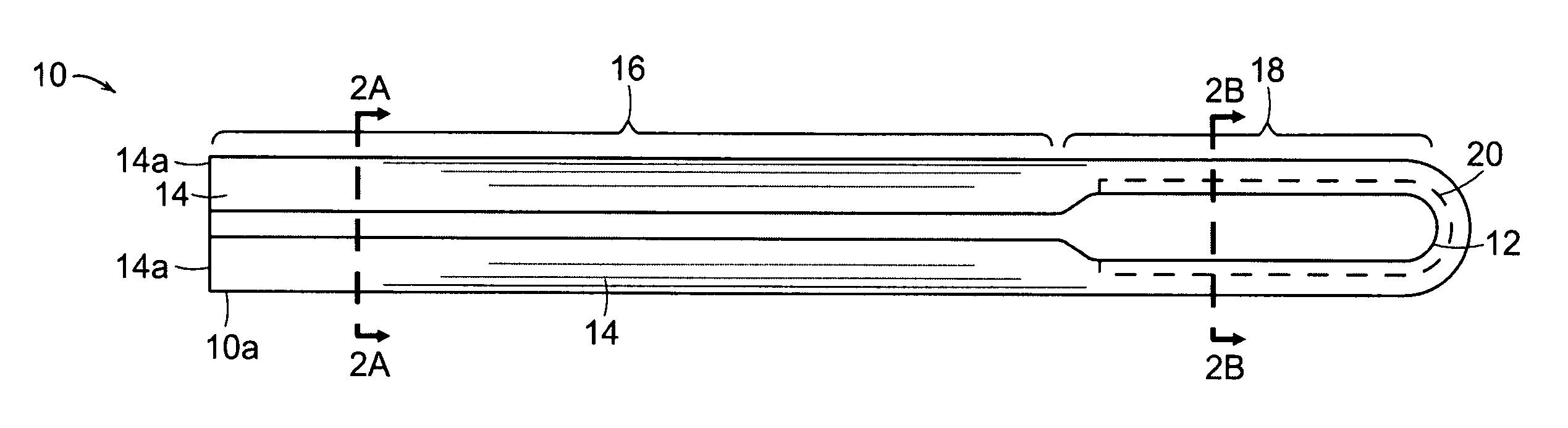

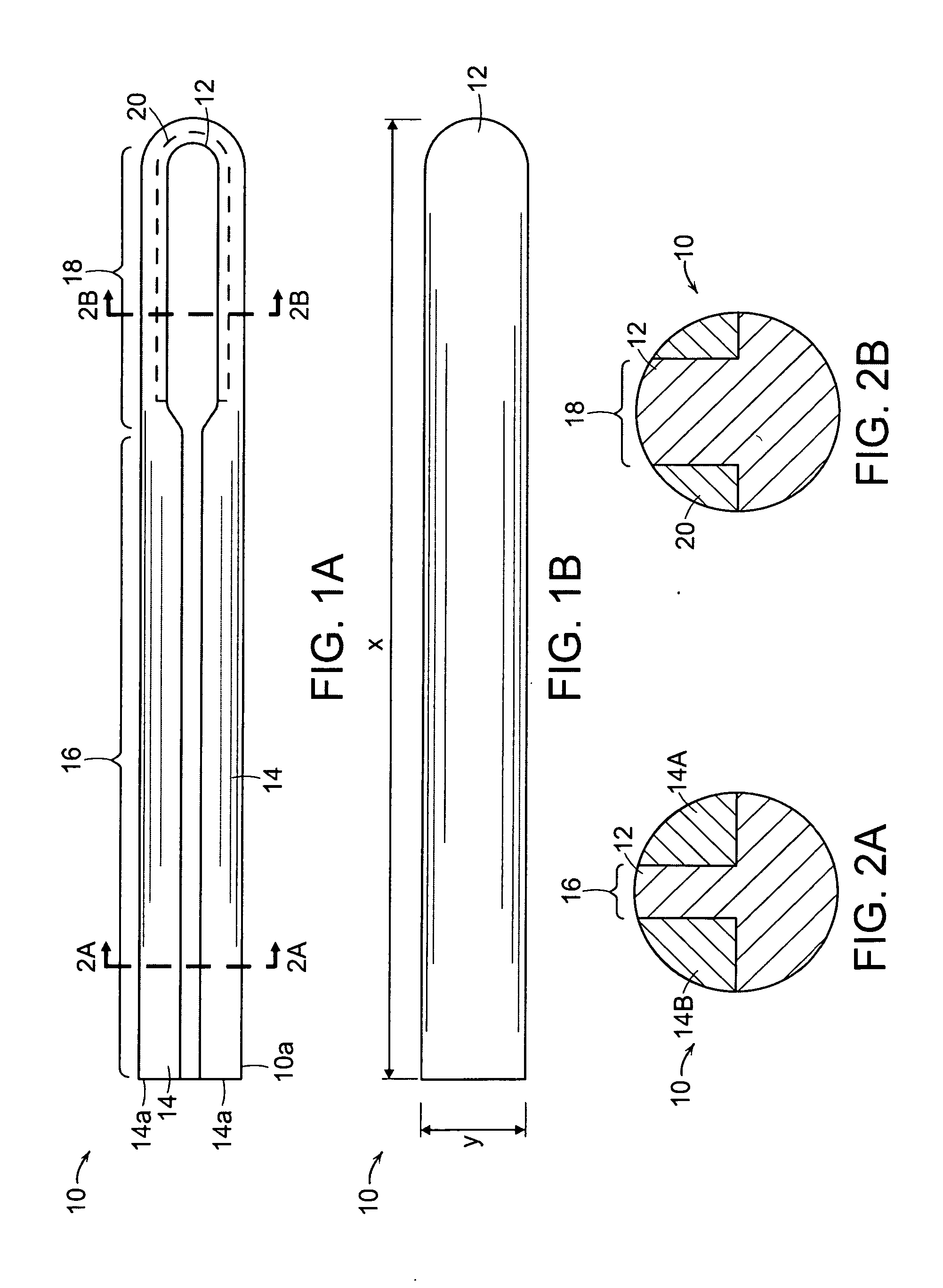

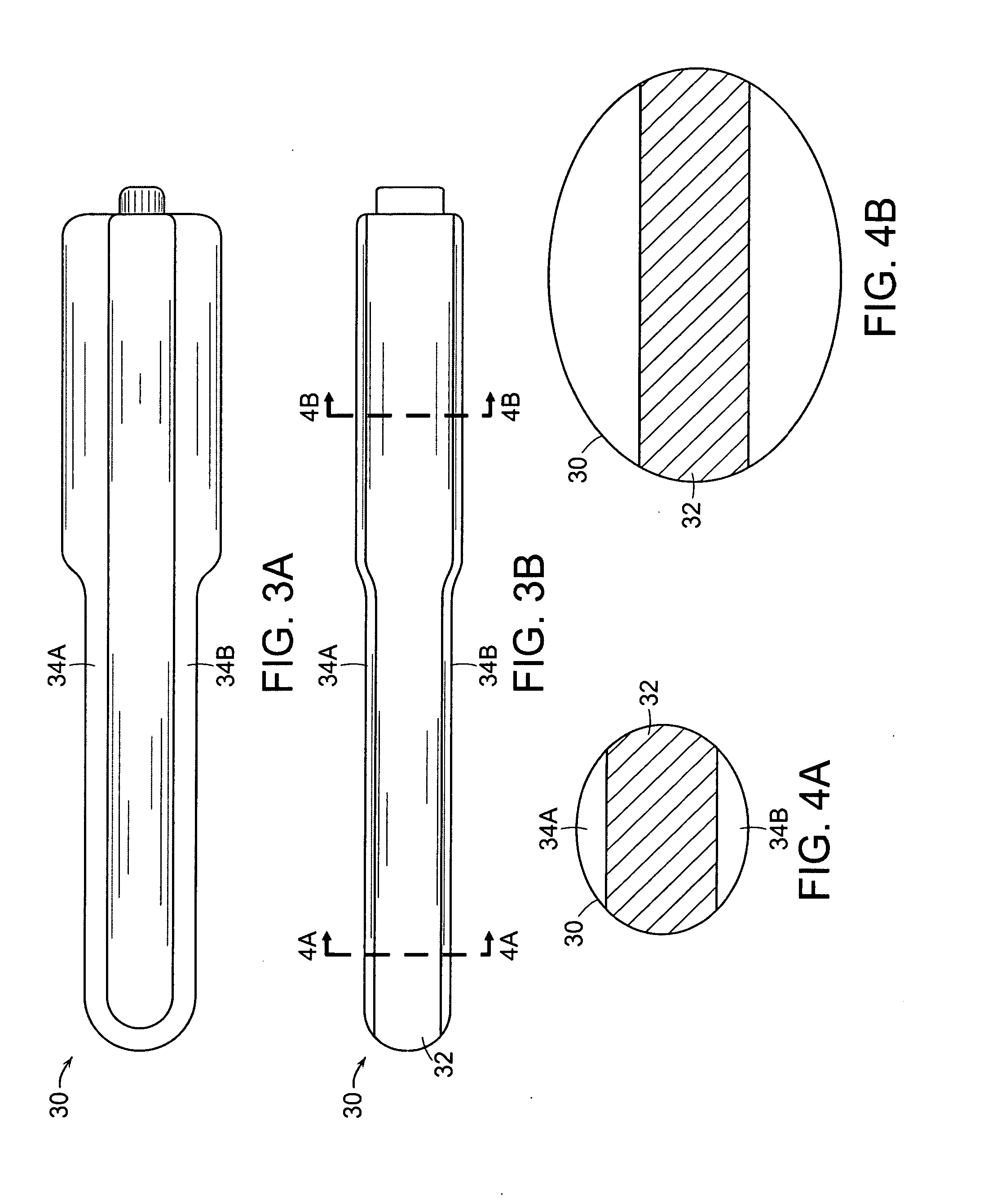

Ceramic igniters

InactiveUS20060213897A1High outputImprove cost efficiencyIncandescent ignitionCeramic shaping apparatusElectrical resistance and conductanceMetallurgy

Owner:COORSTEK INC

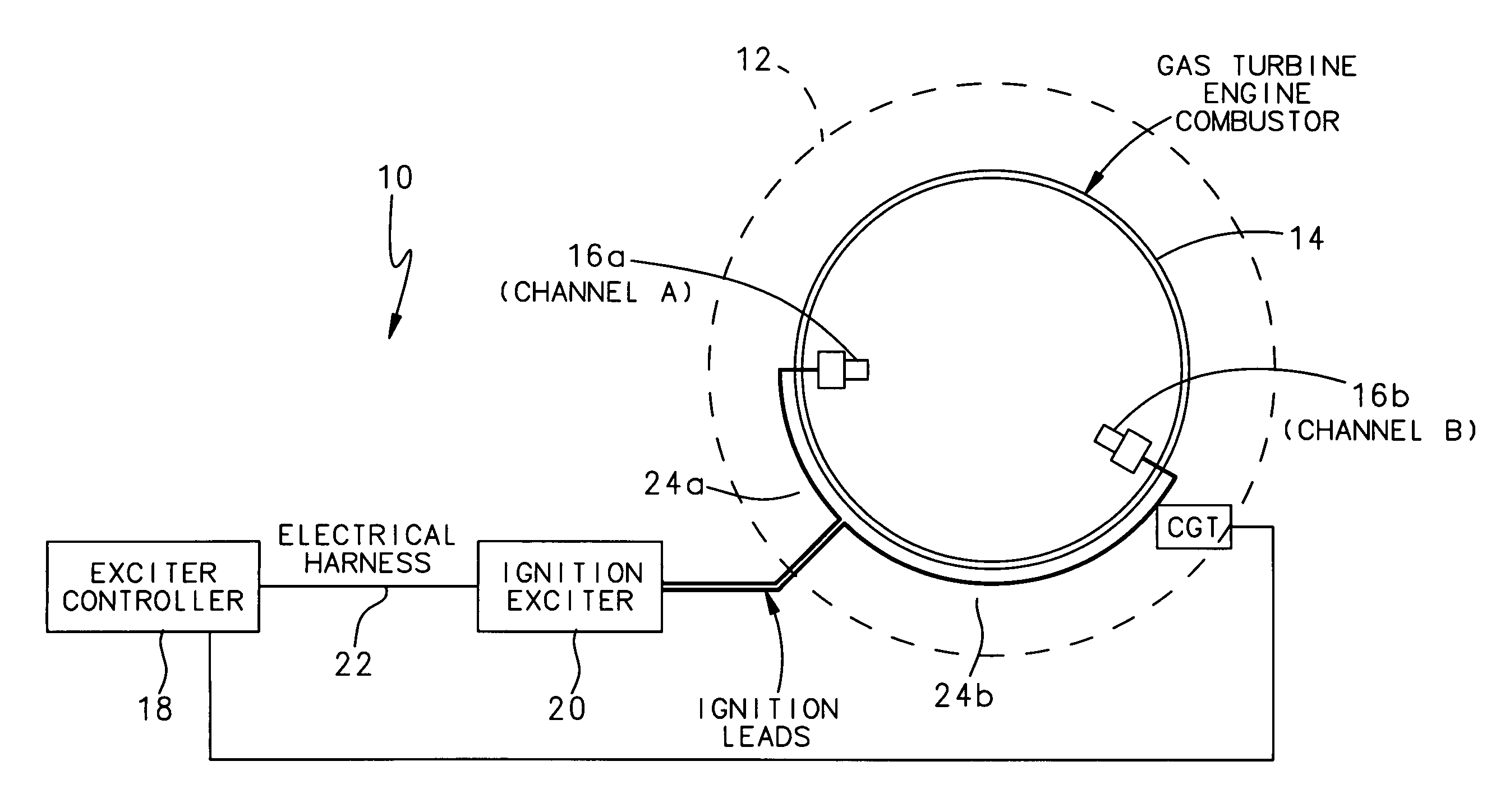

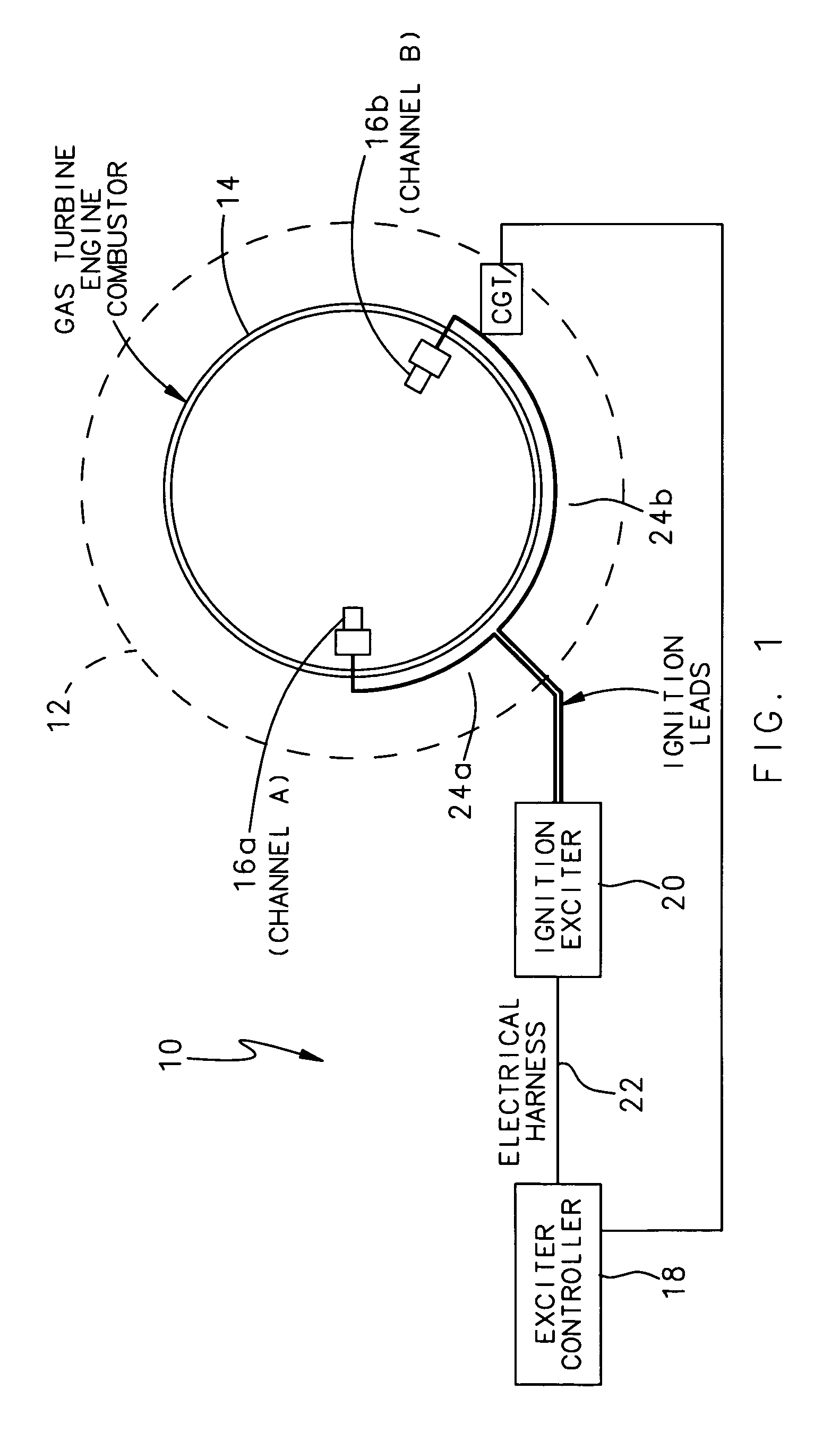

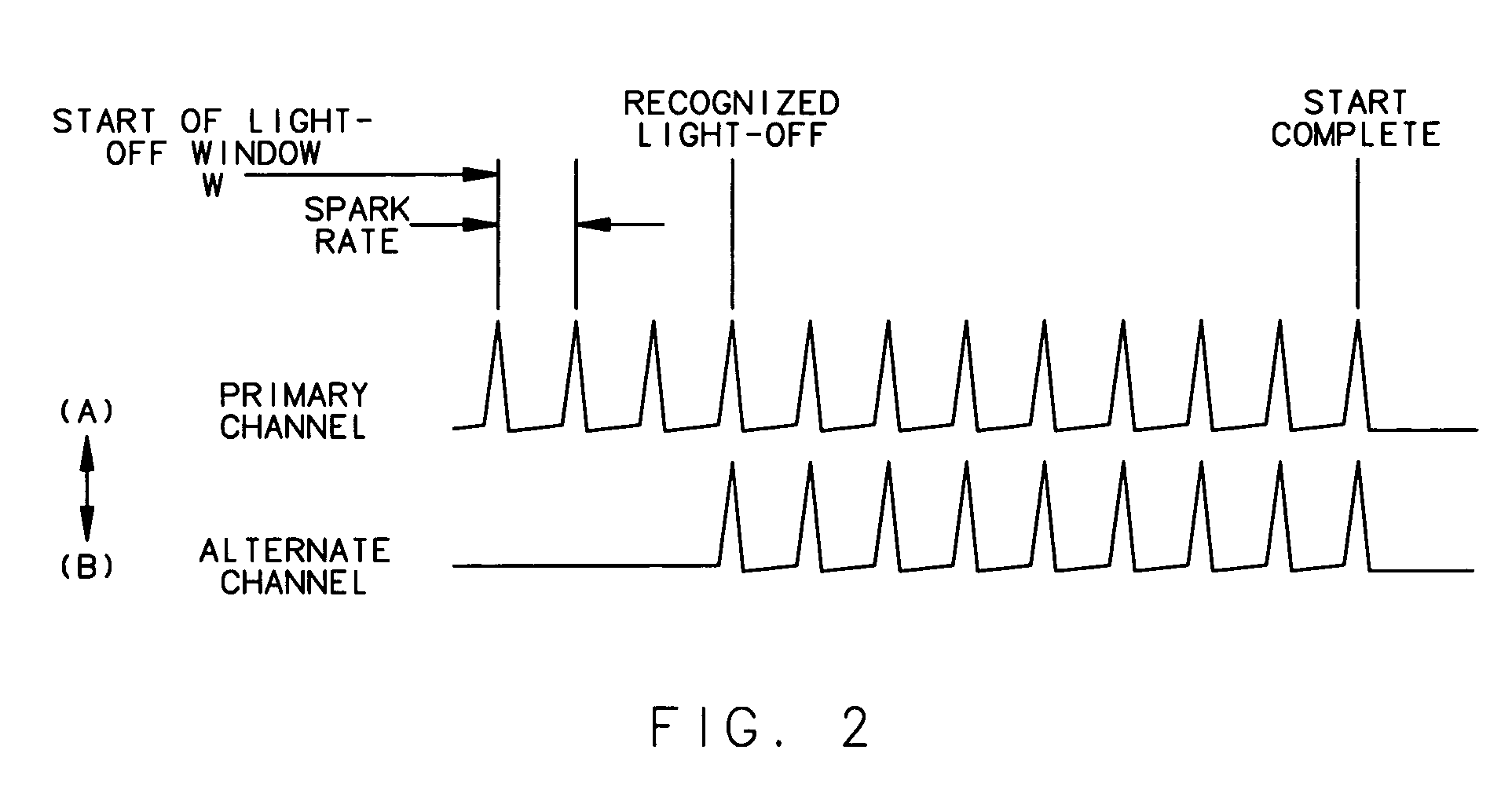

Dual ignition system for a gas turbine engine

InactiveUS7509812B2Improve abilitiesInexpensive and uncomplicatedTurbine/propulsion fuel supply systemsElectric ignition installationEngineeringDependability

A dual channel ignition circuit (Channel A and a Channel B). In a start sequence in which a successful ignition event occurs, an exciter controller first energizes only a primary ignition channel (Channel A). Once the exciter controller recognizes a success light-off, the alternate channel (Channel B) will also then be excited as the gas turbine engine is accelerated to a self-sustaining speed. The exciter controller will then switch the primary alternative designation of the channels for the next start attempt. In a start sequence in which an unsuccessful ignition event occurs, the exciter controller sets a fail-to-start on the primary ignition channel on a failure to start A / B counter such that a failed ignition channel is diagnosed without dedicated electronic diagnostic circuits while still attempting to excite both circuits to enhance the dependability of a successful engine light-off.

Owner:HAMILTON SUNDSTRAND CORP

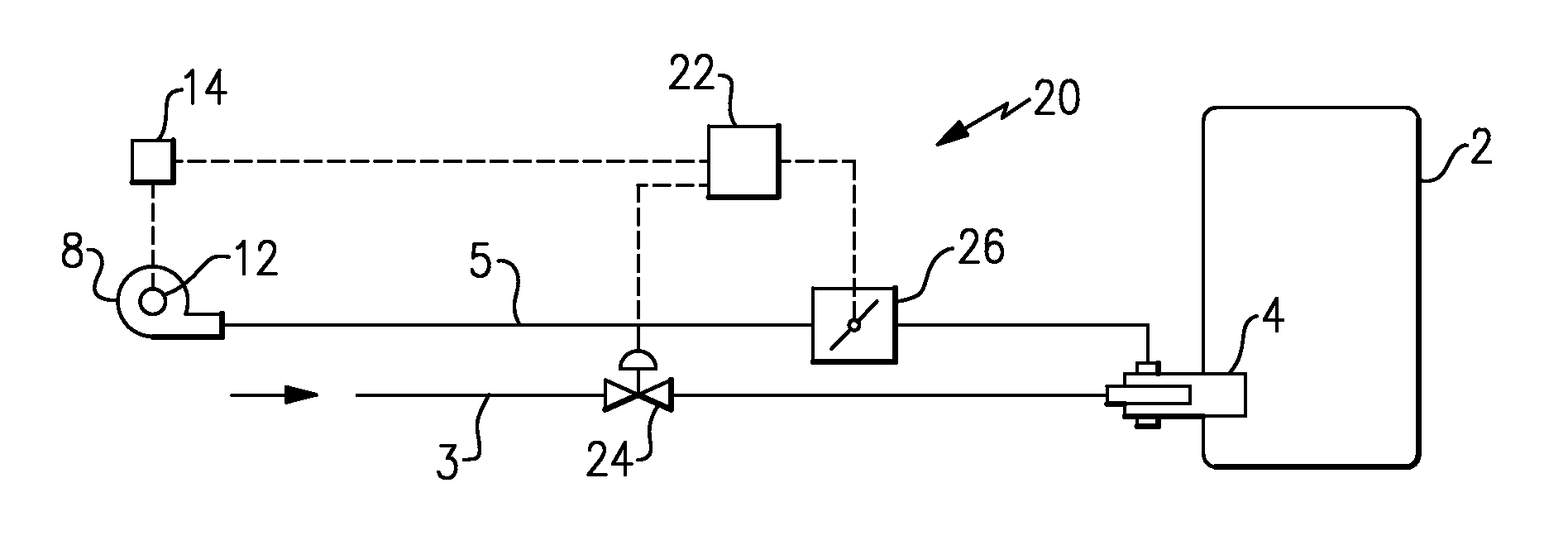

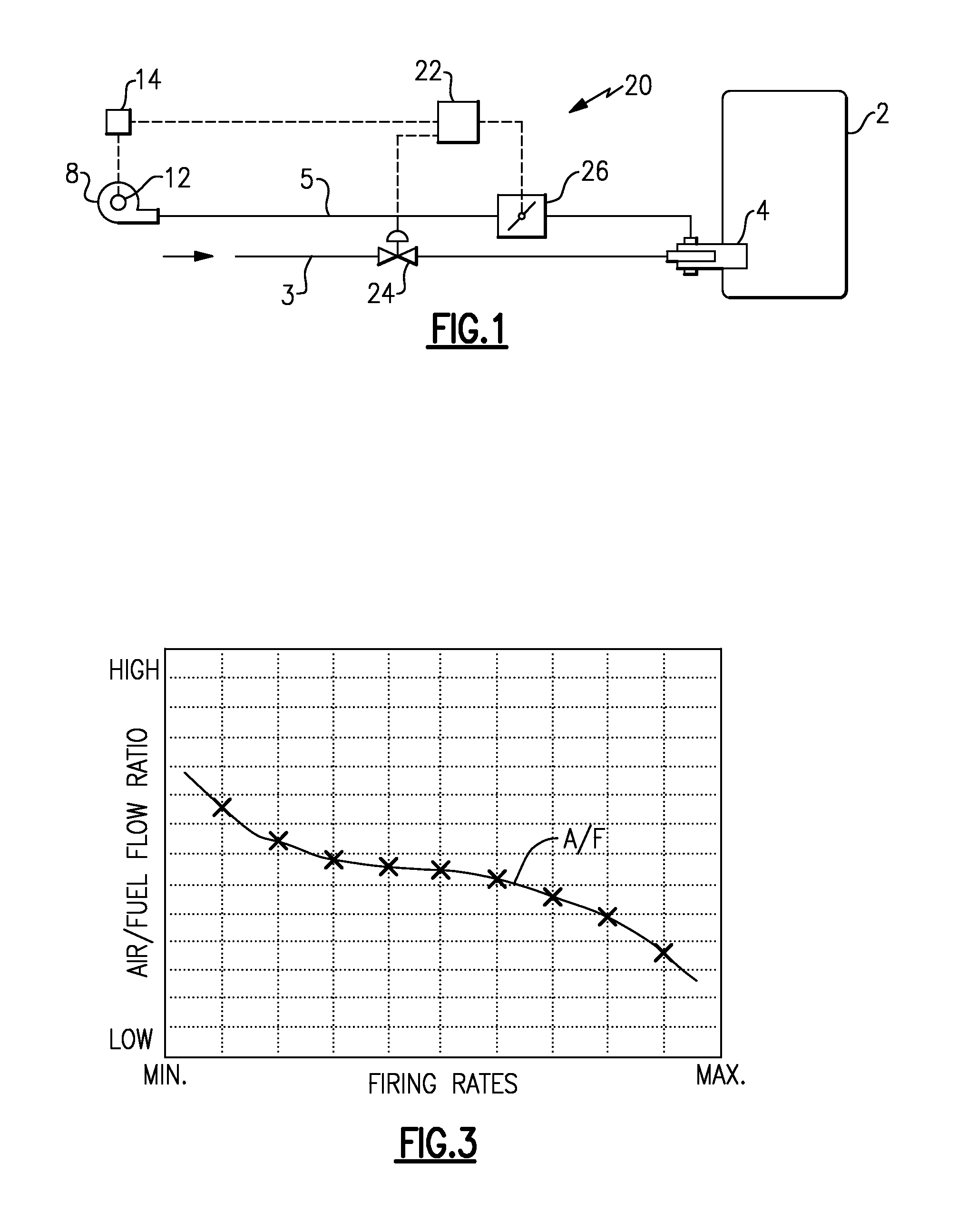

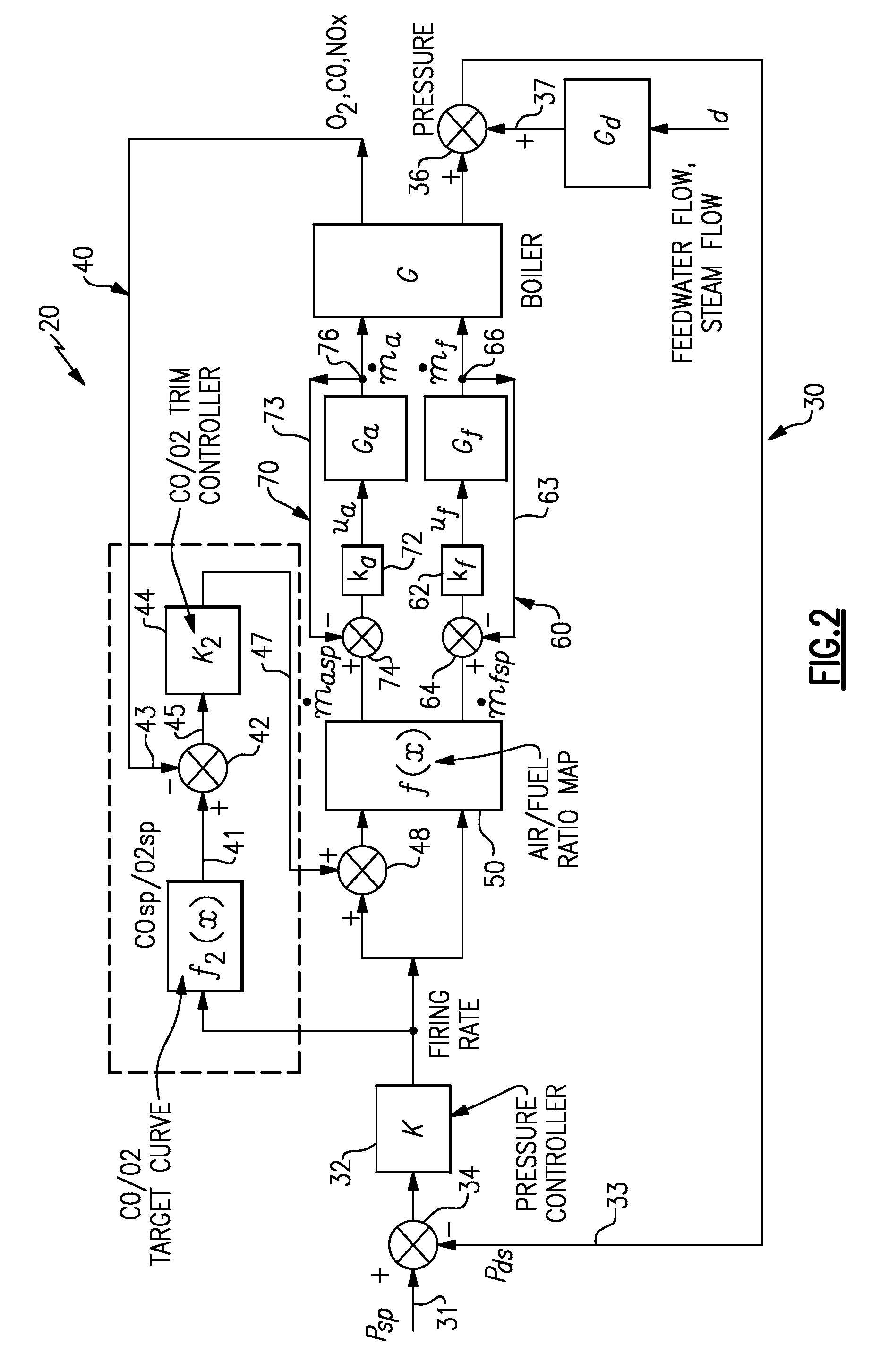

Automated setup process for metered combustion control systems

A method is provided for the automated setup of a metered combustion control system for controlling operation of a boiler combustion system. The automated setup process includes both commissioning and controller tuning, rather than tuning the carbon monoxide and / or oxygen trim controller after the commissioning process has been completed. The oxygen trim controller or the carbon monoxide trim controller is used to identify the air / fuel ratio.

Owner:UTC FIRE & SECURITY AMERICAS CORPORATION INC

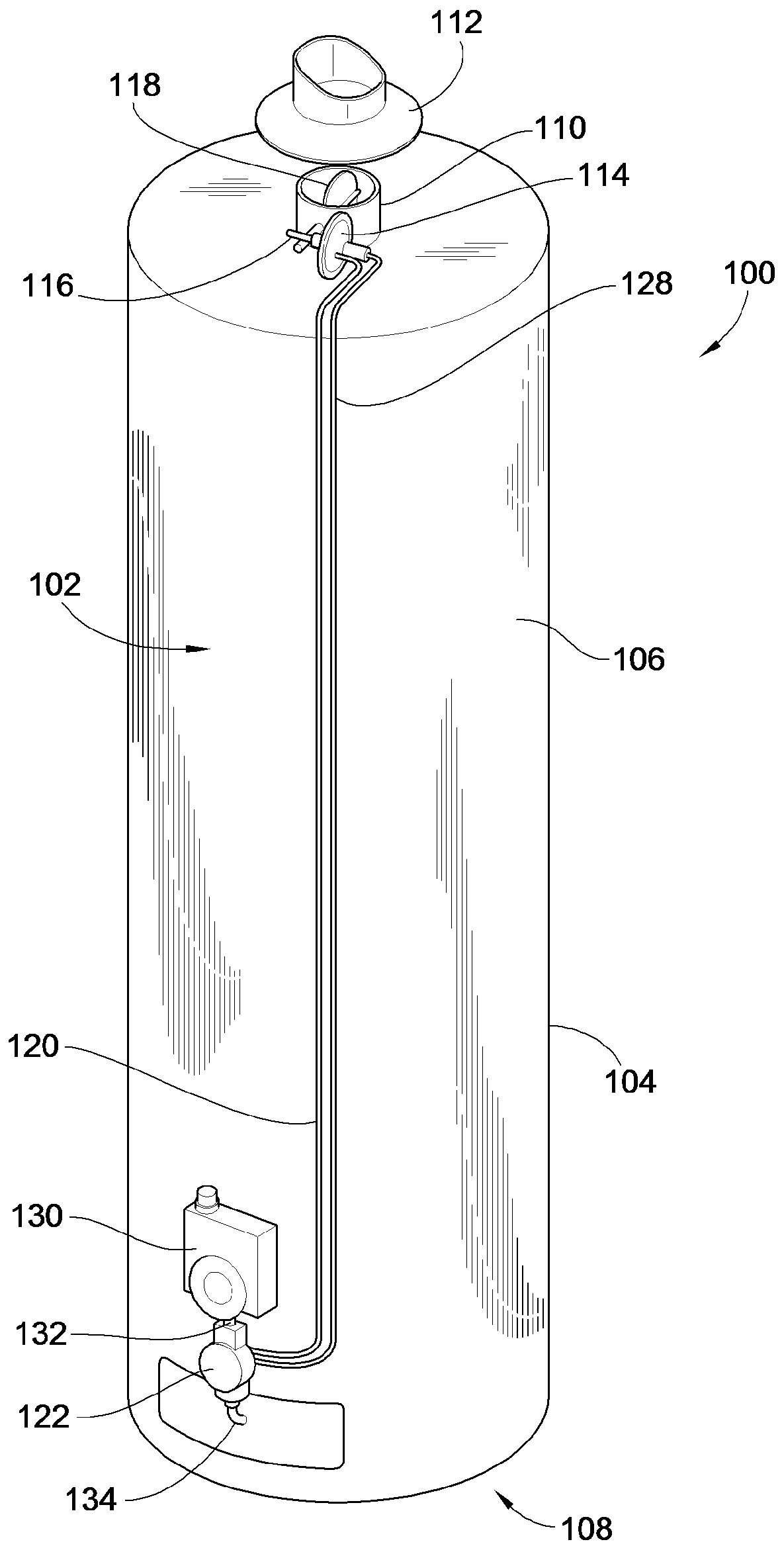

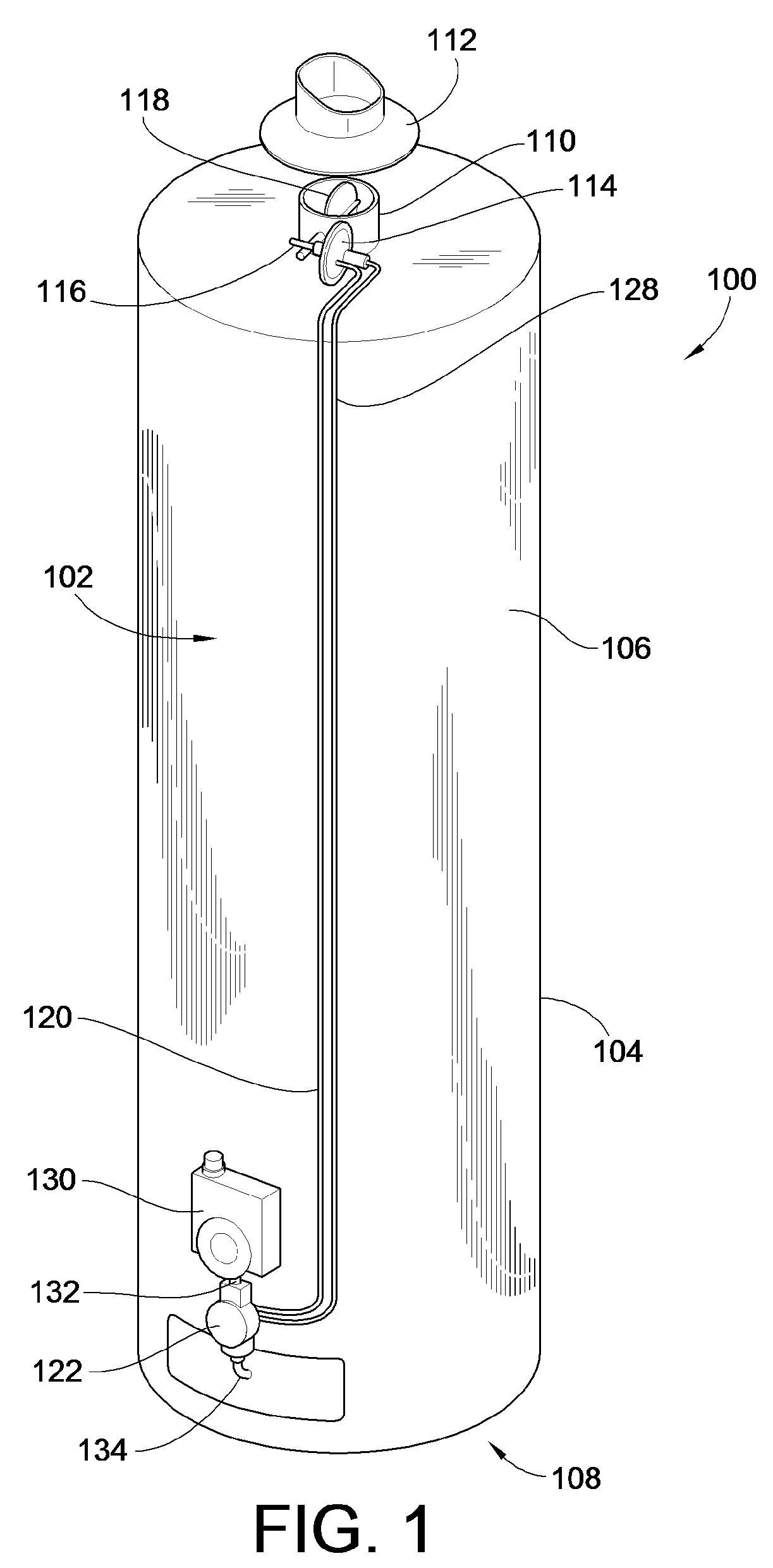

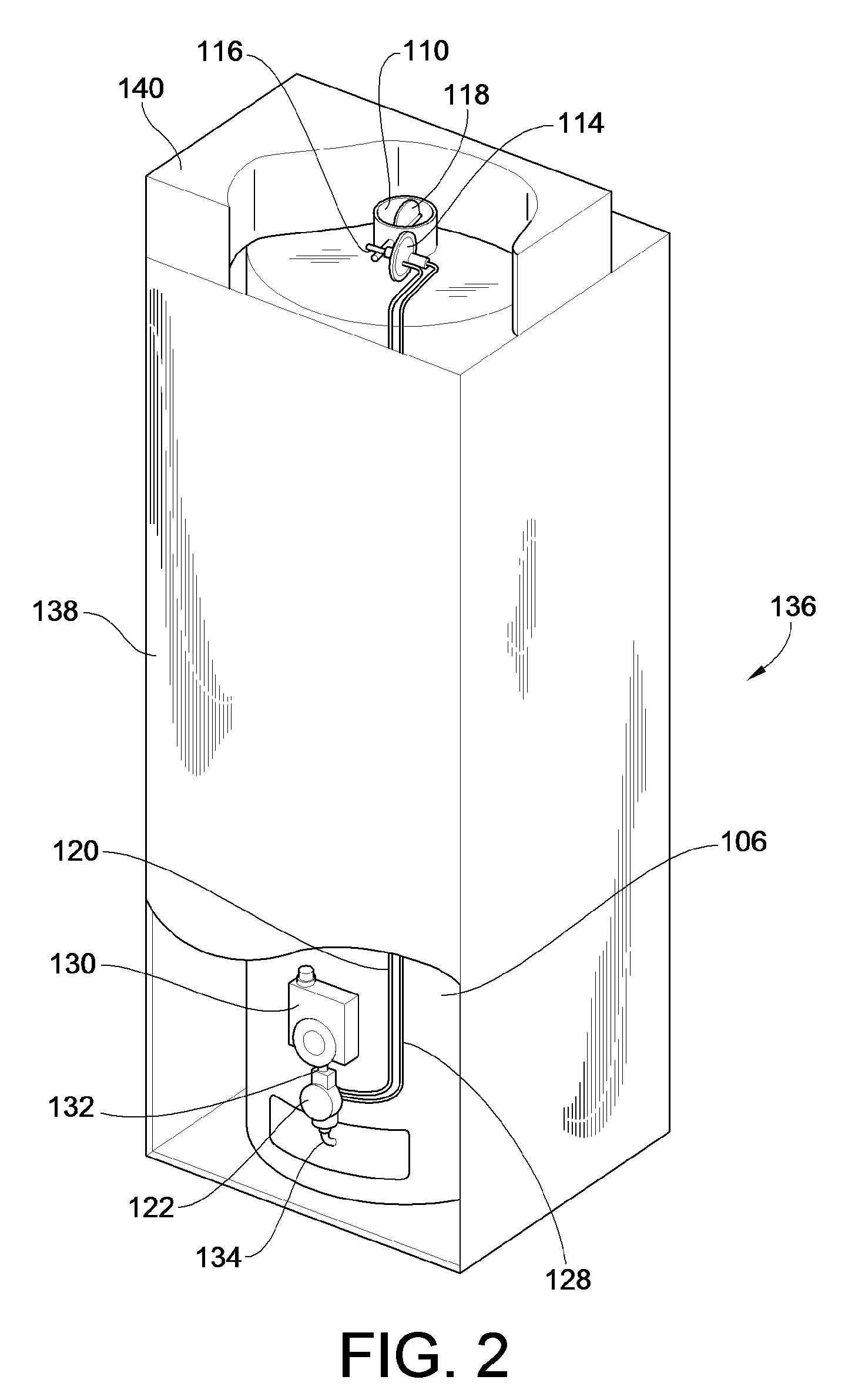

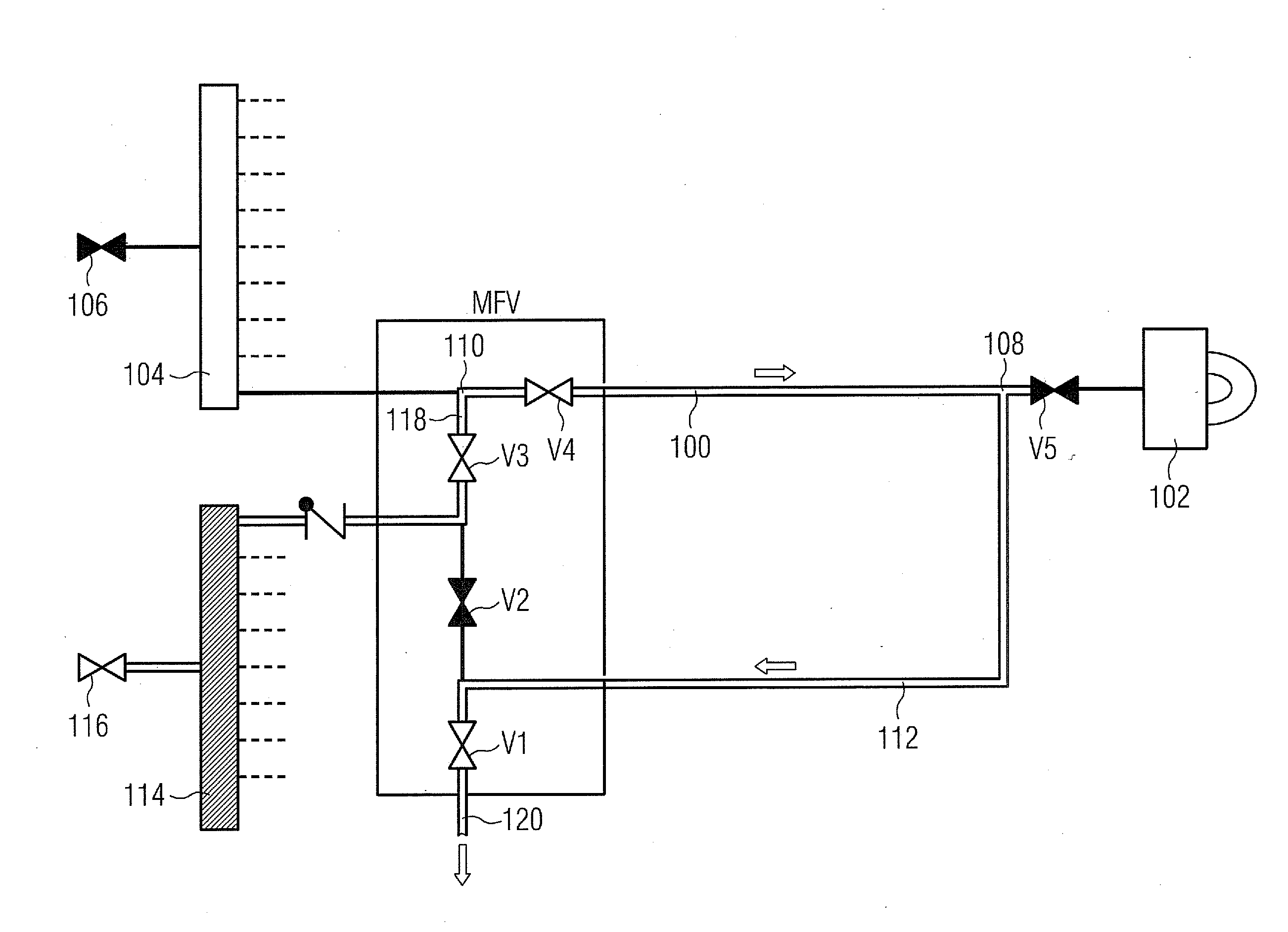

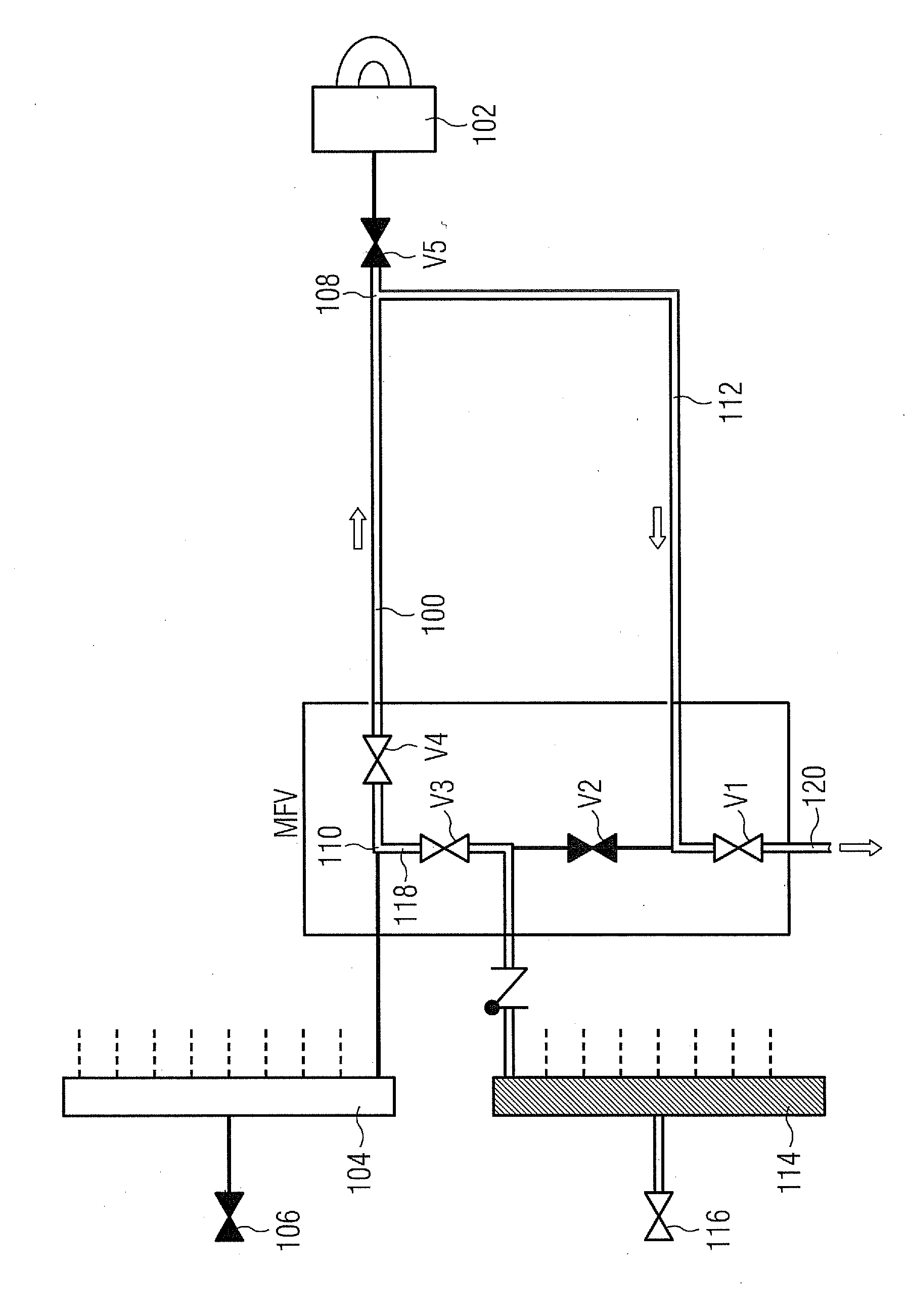

Micro-Pilot For Gas Appliance

InactiveUS20100015559A1Save energyReducing greenhouse gas emissionMechanical apparatusIncandescent ignitionCombustorFuel gas

A micro pilot for a gas hot water heater is provided. The micro pilot provides a flame that is substantially smaller than a typical pilot in a hot water heater during standby operation of the burner. Just prior to allowing gas to flow to the burner upon a call for heat, a pilot flame of sufficient size to ensure ignition of the burner is provided. In one embodiment this larger pilot flame is produced by providing an additional amount of bleed gas to the pilot to increase flame size. In another embodiment, bleed gas is provided to a separate booster pilot, which is ignited by the micro pilot. The flame from the booster pilot is then used to ignite the main burner. This design allows for the micro pilot to be positioned closer to the flame trap of a flammable vapor resistant hot water heater to ensure smooth ignition of any such vapor.

Owner:INVENSYS CONTROLS AUSTRALIA

Method for rinsing a fuel system of a gas turbine and associated fuel system

ActiveUS20110146807A1Simple and inexpensive mannerOvercome disadvantagesLiquid fuel feeder/distributionTurbine/propulsion fuel flow conduitsCombustorEngineering

A method for flushing a section of a fuel system of a burner of a gas turbine is provided. The method includes the steps of providing a feed line for feeding fuel from a fuel source to the burner, providing a first feed point close to the burner and a second feed point remote from the burner in the feed line in each case for feeding a medium into the feed line, feeding the medium via the first feed point, and discharging, via the burner, the fuel which is in the feed line between the first feed point and the burner, and also feeding the medium via the second feed point, and discharging, via the first feed point, the fuel which is in the feed line between the second feed point and the first feed point.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

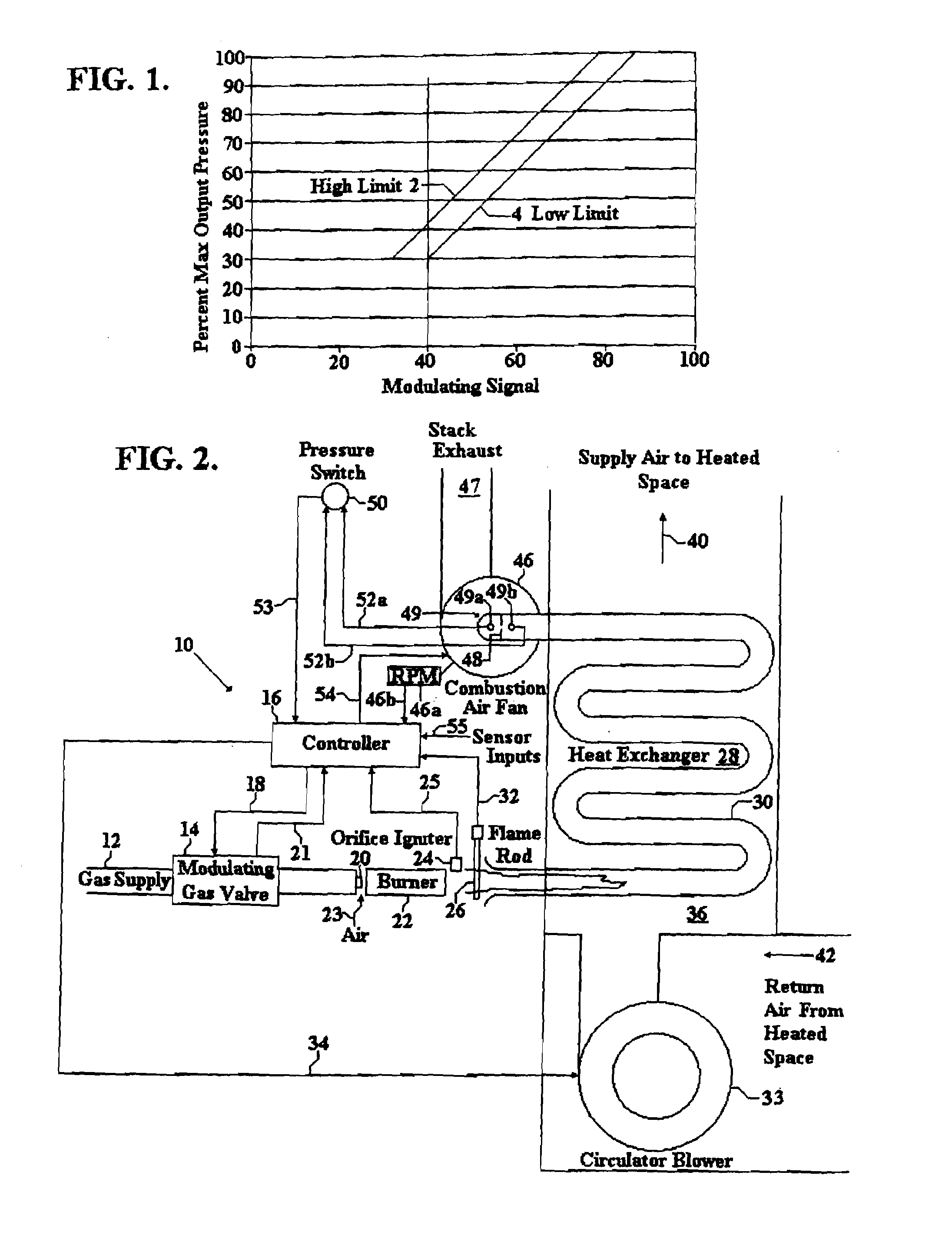

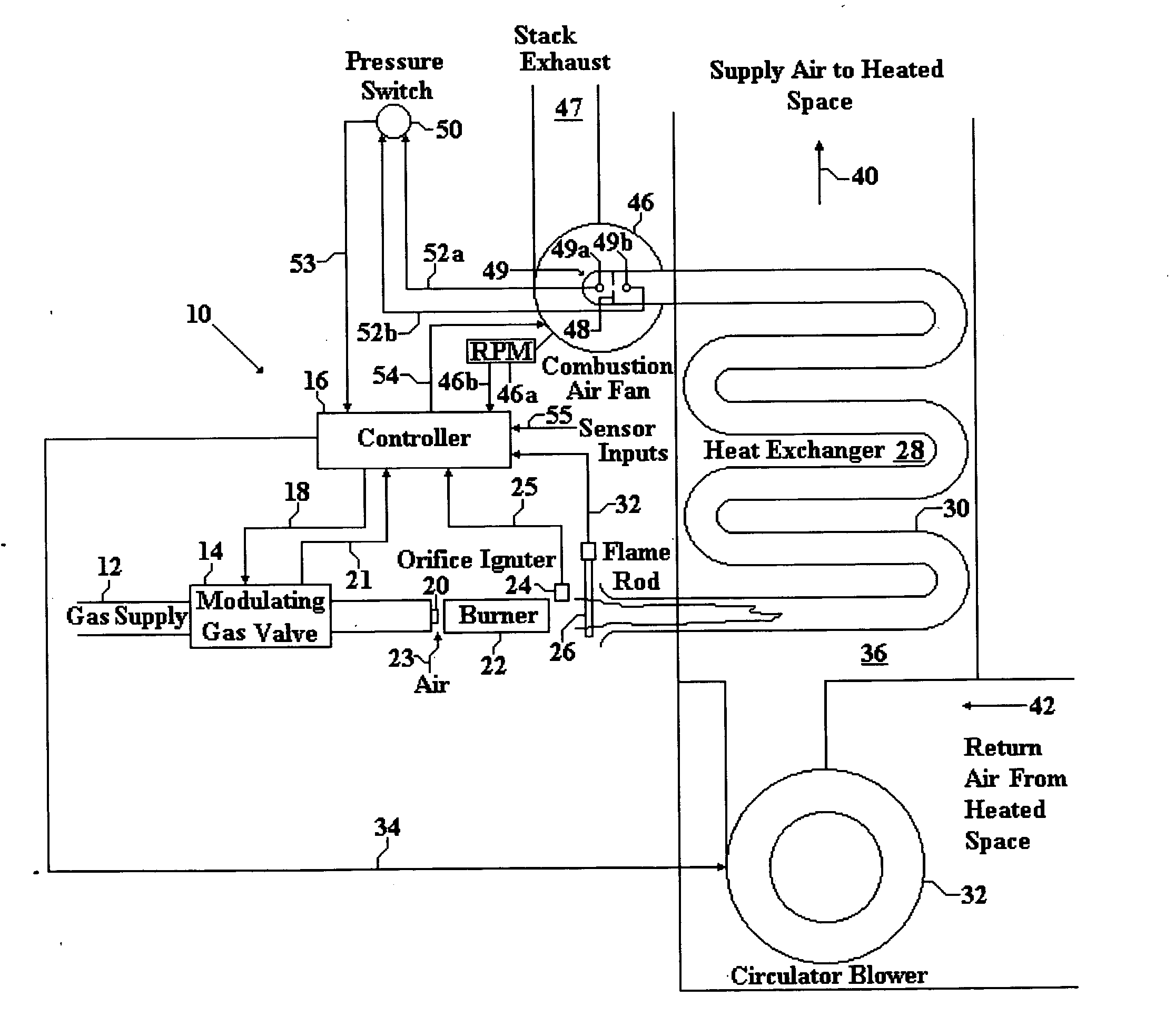

Feedback control for modulating gas burner

ActiveUS20060105279A1Maintain accuracyLarge signalFuel supply regulationCombustion ventilatorsClosed loop feedbackControl system

A modulating gas burner control system using closed loop feedback from a flame rod which provides a signal that varies with gas pressure and which provides combustion air fan control to accurately control the heat from the system without use of expensive control valves.

Owner:ADEMCO INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com