Burner Control Sensor Configuration

a sensor configuration and burner technology, applied in combustion control, combustion regulation, fuel supply regulation, etc., can solve problems such as system errors registered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

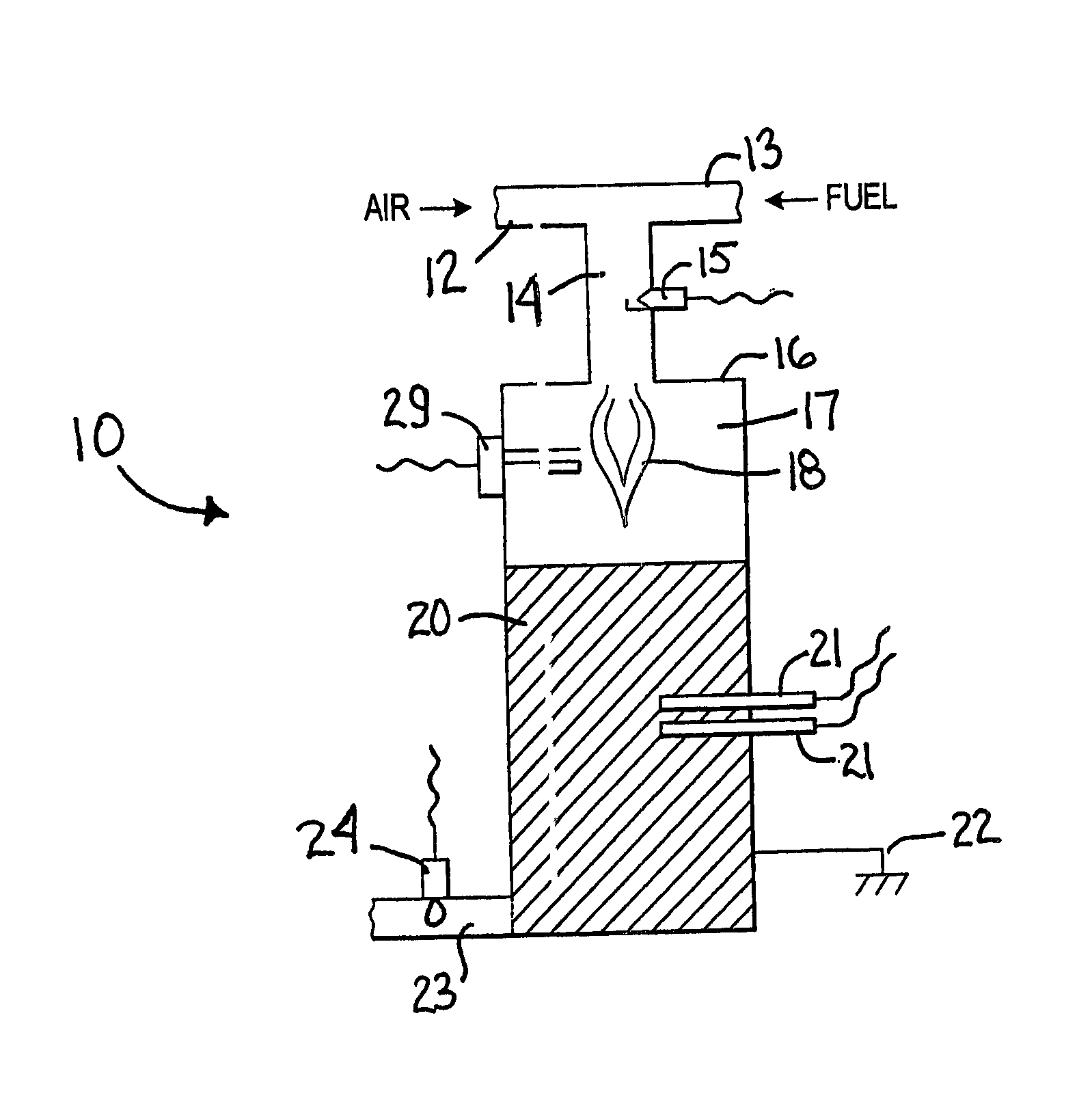

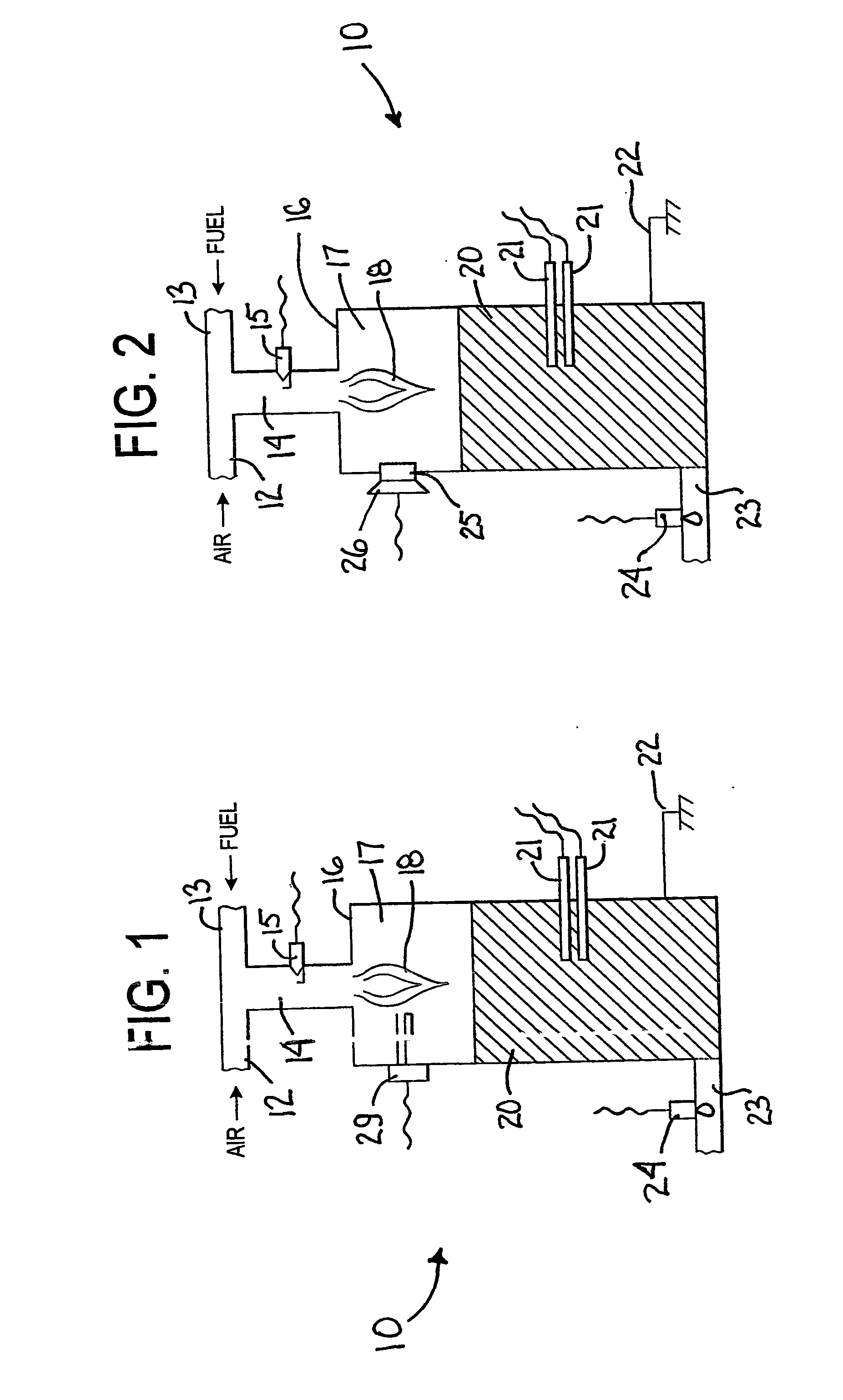

[0025]In this application, the term “burner” and the phrase “tail gas combustor” are used interchangeably to describe a vessel where the combustion of fuel and air takes place to generate heat. The term “fuel” includes any hydrocarbon, alcohol, reformate stream, unreacted hydrogen from a fuel cell stack, and reformate from a fuel cell stack. “Air” includes any oxygen containing gas suitable for use in a burner. Likewise, “hydrogen” includes any hydrogen containing gas suitable for use in a burner, and in particular pure hydrogen and reformate. “Reformer” includes any catalytic vessel responsible for the production of hydrogen by a steam reforming reaction.

[0026]The present invention describes methods and apparatus for demonstrating proof of combustion within a burner or tail gas combustor of a fuel processing system in a fuel cell power plant. This process may be generally referred to in the following description as verifying (-ication), validating, demonstrating, proving, and evide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com